Slag kenyelletsoa ha lintho ka Lahlehileng bubble lahla

Lost foam ho lahla hajoale ke e 'ngoe ea lits'ebetso tse tsoetseng pele ka ho fetesisa lefatšeng. E thoholetsoa e le phetohelo nalaneng ea ho betsa. Ke "tsela e ka sehloohong ea ho betsa ka botala bo botala" lekholong la bo21 la lilemo, 'me e bapala karolo ea bohlokoa ho hlahiseng tlhahiso. Lahla foam e lahlehileng e na le mefuta e fapaneng ea ho ikamahanya le maemo, empa ha se likarolo tsohle tse loketseng ho lahla foam.

Li-castings tse ling li ka etsoa hanyane, empa ts'ebetso ea sekhahla sa lihlahisoa e tlase kapa sekhahla sa ho hana se holimo. E boetse e na le meeli ea mahlale. Mohlala, mokhoa oa foam o bonolo ho holofala ka likhoka; Ha e bapisoa le mokhoa oa setso oa ho betsa, e boetse e na le bothata ba pyrolysis le gasification ea hlobo ea foam.

Liphoso tsa ho lahla foam li lahlehetsoe hape li hloka ho utloisisoa ka botlalo le ho felisoa. Liphoso tse tloaelehileng tsa ho lahla foam li lahlehile li kenyelletsa makhapetla, kh'abone e ntšo, deformation, lehlabathe le khomarelang, ho putlama, li-pores, li-slag inclusions, likarolo tse batang, le marang-rang a litšepe tsa tšepe. Carbon, jj., Ha re bue ka boiphihlelo le kutlwisiso ea liphoso tsa ho kenyelletsa slag

Slag kenyelletsoa ha liphoso tsa ho lahla foam

Liphoso tse kenyelletsoang ke slag li bua ka liphoso tse entsoeng ke lehlabathe le ommeng, pente le lintho tse ling tse kenang ha tšepe e qhibilihisitsoeng e kenella nakong eo e tšolloang. Holim'a litšepe tse entsoeng ka machined u ka bona mabala a li-inclusions tse tšoeu kapa tse ntšo tse ajoang ka bonngoe kapa ka likotoana. Bosoeu ke likaroloana tsa lehlabathe la quartz, 'me bosootho bo botšo ke slag, pente, masalla a mofuta oa foam le li-inclusions tse ling kamora pyrolysis. . Mofuta ona oa sekoli o tsejoa e le "sand ingress" kapa "slag inclusion", mme ke phoso e atileng haholo tlhahisong ea ho lahla foam. Hoo e ka bang lifeme tsohle tse sebelisang ho lahla foam li atile, mme ho thata ho li felisa ka botlalo. Ke ka ho nka mehato e fapaneng le ts'ebetso e hlokolosi ts'ebetsong e ngoe le e ngoe moo "ho kenyelletsoa ha slag" ho ka fokotsoang boemong bo tlase haholo mme litholoana tse khotsofatsang li ka fihlelleha. Kamora hore litšepe tse lahlehileng tsa foam li pholile ebe li behiloe ka mabokoseng pele li hloekisoa, ho latela maemo a bokaholimo ba castings le sisteme e tšeloang, ho ka ahloloa hore na ho na le mefokolo ea lehlabathe le slag. Haeba senoelo sa sprue, sefapano, sefapano se sefapano, sefahleho le heke holimo kapa khokahano, 'me bokaholimo ba samente bo lehlabathe le matla kapa bo na le lehlabathe le petsohileng, ho hlile ho na le bonnete ba hore ho betloa ho na le litšitiso tsa slag le lehlabathe. Smash the sprue rod kapa sprue sefaha, o ka bona matheba a masoeu ho robeha, 'me maemong a boima, ho robeha ho tla etsa selikalikoe sa mabala a masoeu. Litšoantšo tse joalo, haholo-holo tse bopehileng joaloka poleiti le tse chitja, li tla ba le liphoso tse bosoeu le botšo bo bosoeu holim'a sebaka se sebetsoang kamora machining. Haeba lits'ebetso tsa ts'ebetso li sa laoloe ka thata, likhetho tse hlahisitsoeng li tla ama boleng ba li-castings le tsoelo-pele ea ho phetheloa ha odara.

Lisosa tsa ho kenyelletsoa ha slag le liphoso tsa lehlabathe

Ka ho lemoha ha rona nako e telele ts'ebetsong ea tlhahiso, ho netefalitsoe hore ho tloha senoelong sa sprue, sprue, semathi se sefapano, semathi se ka hare ho isa ho lahla, likarolo tsohle li ka baka lehlabathe le kenang, haholoholo karolo e kopaneng ea sistimi le ho betsa. Ketsahalong eohle ea tlhahiso, pente e ebola le ho petsoha ka holim'a hlobo e tšoeu ea sistimi, pente e ebola le ho petsoha karolong e tlamang ea hlobo e tšoeu, pente ea ho penta le ho petsoha ka holim'a hlobo e tšoeu ea foam , sprue ha e koaloe ka thata 'me mabaka a mang a bakoa ke ho kenyelletsoa ha slag le ingress ea lehlabathe. Sesosa sa bohlokoahali. Taba ea bobeli, khetho ea mekhahlelo ea ts'ebetso, joalo ka boholo ba hlooho ea letlooa la sistimi e tšollang, mocheso o tšollang, boemo ba khatello e mpe, boholo ba phatsa ea lehlabathe le omileng, jj. le ts'ebetso ea ho paka, tsohle li na le tšusumetso ho kenyellelitsoeng ha slag le mefokolo ea lehlabathe ea ho kenella. Tšusumetso e kholo. Ke feela ka ho nka mehato e hlophisehileng le ts'ebetso e hlokolosi ho lihokela tsena moo liphoso tsa kenyelletso ea slag li ka fokotsoang mme tsa felisoa, mme ho ka fumanoa li-castings tsa boleng bo holimo. Ho hlola likoli tsa kenyelletso ea slag ke projeke e hlophisehileng.

Mekhoa le mehato ea ho fokotsa le ho hlola likoli tse kenyelletsang slag

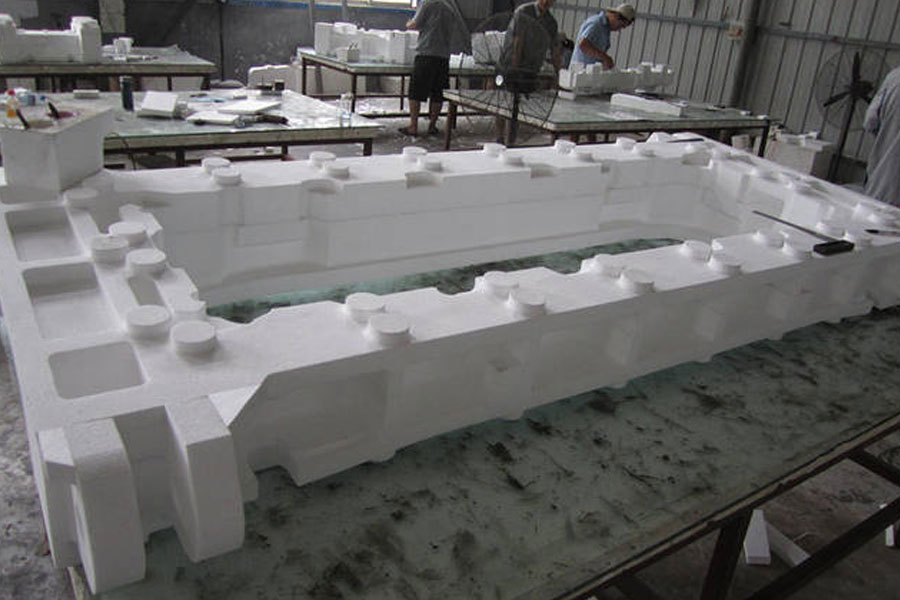

Liphoso tsa lehlabathe le ho kenella ha slag ke bothata bo boholo ho tlhahiso e lahlehileng ea foam. Hajoale, ho na le mefuta e meraro ea lihlahisoa tse hlahisitsoeng ka katleho ke ho lahla foam, e leng, likarolo tse sa roaleng, liphaephe le li-castings tsa mabokose, tseo kaofela ha tsona li sa sebetsoang hangata kapa li sa sebetsoang. Bakeng sa li-castings tse nang le libaka tse ngata tsa ts'ebetso le litlhoko tse phahameng, bothata ba ho kenyelletsa slag ke bothata ba mantlha bo hlokang ho rarolloa. Boiphihlelo ba rona ke hore mehato e ka nkuoa ho tsoa lintlheng tse latelang ho fokotsa le ho felisa liphoso tsa kenyelletso ea slag:

1. Pente

Karolo ea sekoaelo se lahlehileng sa foam ke: 1) Ntlafatsa bokaholimo ba ho betsa, fokotsa bohale ba ho betla ka maemo a 2-3, le ho ntlafatsa boleng ba bokaholimo le ts'ebetso ea ho betsa. 2) Fokotsa le ho thibela lehlabathe ho khomarela le likoli tsa lehlabathe. 3) E loketse ho tlosoa ha lehlabathe le lehlabathe le oang. 4), mokelikeli le khase e qhibilihisitsoeng ka lekoeba le lahlehileng nakong ea ho tšela li qhalloa hantle ka lehlabatheng ka lera, 'me tšepe e qhibilihisitsoeng e kenella ka hare ho hlobo ea lehlabathe, e thibela ho lahla ho hlahisa masoba, ho kenella ka tšepe le khabone bokooa. 5) Ntlafatsa matla le ho tiya ha paterone, ho thibela ho fetoha le tšenyo nakong ea lipalangoang, ho tlatsa lehlabathe le ho etsa mohlala oa ho thothomela, ho leng molemo ho ntlafatsa ho nepahala ha tlhakore le sehlahisoa sa castings. Liaparo bakeng sa ho lahla foam li lahlehile li hloka letoto la matla, ho kenella hoa moea, ho qhekella, ho chesa mocheso, ho phatloha le ho hanyetsa, ho pholisa ka potlako le ho futhumatsa mocheso kapele, ho monya mongobo, ho hloekisa, ho roala, ho emisa, ho sa phalleleng, jj. thibela slag kenyelletso likoli, pele hloka hore barbotage ho ba le matla a phahameng le ho hanyetsa mollo. Ho hlokahala hore lera le koahelang holim 'a hlobo e tšoeu le se ke la petsoha kapa ho petsoha nakong ea ho omisa le ho tsamaisa, ke hore, ho roala ho lokela ho ba le matla a lekaneng a mocheso oa kamore; 'me nakong ea ts'ebetso ea ho tšela, lera la ho roala le lona le tla angoa ke ho hohloa hoa tšepe ea nako e telele. Haeba e sa oe kapa e petsoha, e na le matla a phahameng a mocheso. Ha tšepe e mokelikeli e kenella ka hlobo, heke e otlolohileng e koetsoe ka thata, 'me lera le koahelang bokaholimo ha samente le sistimi ha e oele, mapetso le mapetso ke maemo a mantlha a ho thibela likoli tsa kenyelletso ea slag. Haeba semathi se sa tiisoa ka thata, lera la sona le tla oa. Mapetso le mapetso, lehlabathe le leholo, pente le lintho tse kenyellelitsoeng li tla kena tšepe ho theha litšitiso tsa ho kenyelletsa slag. Matla le ho kenella hoa moea ke litšobotsi tse peli tsa bohlokoa tsa ho roala. Ka linako tse ling liphahlo tse sebelisitsoeng ts'ebetsong ea ho tšela li hlokahala hore li be le ts'ireletso e phahameng ea mollo ho feta tse koahelang ho hanela khoholeho ea nako e telele ea tšepe e nang le mocheso o phahameng ntle le ho oela le ho petsoha. Motsamaisi o tlameha ho netefatsa ho tšoana ha pente nakong ea ts'ebetso ea ho penta.

2. Ts'ebetso ea ho paka

Nakong ea ho paka, lera le koahelang bokaholimo ba sehlopha sa mohlala (model + gating system) ha lea lumelloa ho ba le tšollo, mapetso kapa mapetso, haholo-holo mateanong a sprue le semathi, mateanong a semathi le kahare semathi, le bokantle Hafeela ho ntse ho e-na le ho hlepha, mapetso, kapa khokahano e fokolang lipakeng tsa heke le hlobo, lehlabathe le ka kena. Sena se hloka matla a kopaneng a kopaneng, pente e tenya, ho tenyetseha ho lekaneng bakeng sa sistimi ea ho phunya, le lithupa kapa marikhoe a matlafatso ha ho hlokahala. Sehlopha sa mohlala se lokela ho tsitsa ha se beoa lehlabatheng le ka tlase la lebokose la lehlabathe. Ha e lumelloe ho qala ho roka lehlabathe le mohlala oa ho thothomela ha e beoa moeeng ho qoba ho petsoha ho tšosang ha lera le koahelang. Se ke oa eketsa lehlabathe ka kotloloho ponahalong, sebelisa lethompo ho eketsa lehlabathe pele, ebe u sebelisa sesebelisoa sa ho hlapa pula ho fafatsa lehlabathe pele u thothomela le ho thothomela. Ha o qala ho sisinya sebopeho, thothomelo e lokela ho ba nyane mme bophahamo bo lokela ho ba bonyane, ebe o thothomela haholo kamora hore lehlabathe le ommeng le patoe. Ha ho etsoa li-vibration, sistimi e tšolleloang, haholo-holo sprue, ha e lumelloe ho robeha kapa ho kobeha, e le ho thibela lera la ho roala hore le se ke la taboha, 'me leqhubu le tlameha ho koaloa ka thata ho thibela lehlabathe ho kena. Mesebetsi eohle ea ho paka, ho roka lehlabathe, ho sisinyeha le ho etsa mohlala e tlameha ho ba hlokolosi le ho ba hlokolosi, 'me e tlameha ho netefatsoa hore lera le koahelang sehlopha sa paterone ha le oe, ho petsoha kapa ho petsoha pele le tšoloha. Pele o tšela, senoelo sa sprue se lokela ho hloekisoa hape ho netefatsa hore ha ho na lehlabathe le phaphametseng, lerōle le maloanlahla.

3. Ho tšela hlooho, mocheso le nako

Ha hlooho ea khatello e phahama nakong ea ho tšela, khoholeho ea sistimi le hlobo e kholo, mme monyetla o moholo oa ho kenella lehlabatheng o bakoa ke ho otloa hoa seaparo. Hlooho ea khatello e fapane bakeng sa castings ea boholo bo fapaneng. Ho khetha lere le nang le bokhoni bo loketseng, lere le lokela ho ba tlase ka hohle kamoo ho ka khonehang bophahamo ba ho tšela, mme molomo oa ladle o lokela ho ba haufi ka hohle kamoo ho ka khonehang ho senoelo se tšolleloang, mme ladle e kholo e lokela ho qojoa bakeng sa ho tšela mesebetsi e menyenyane. Ha mocheso o tšoloha o phahama, litšoaneleho tsa ts'ebetso ea seaparo li phahama, mme ho ba bonolo ho hlahisa litšitiso tse joalo ka lehlabathe le khomarelang. Mocheso o tšollang o nepahetseng o lokela ho khethoa. Bakeng sa castings ea tšepe e putsoa, mocheso oa ho tlanya o ka ba haufi le 1480 ° C, 'me mocheso o tšollang o lokela ho ba 1380-1420 ° C; mocheso o tlamang oa cast iron ductile o lokela ho ba kaholimo ho 1500 ° C, 'me mocheso o tšollang o lokela ho ba 1420-1450 ° C; mocheso o tšollang oa castings ea tšepe o lokela ho ba 1480-1560 ° C. Nako e tšolotsoeng ea lebokose la litšepe tse hlokang 300-500 kg ea tšepe e qhibilihisitsoeng e ka laoloa nakong ea metsotsoana e 10-20.

4. Khatello e mpe

Ts'ebetso ea ho tšela foam e lahlehileng hangata e etsoa tlasa maemo a lephaka. Karolo ea khatello e mpe ke ho kopanya lehlabathe le ommeng, ho potlakisa ho qeta, le ho ntlafatsa bokhoni ba ho tlatsa. Ho tšela ka tlas'a maemo a ho tiisa moea ho ntlafatsa tikoloho e sebetsang. Tekanyo ea khatello e mpe e na le tšusumetso e kholo boleng ba li-castings. Khatello e fetelletseng e mpe e eketsa monyetla oa ho hema lehlabathe le ommeng le lits'oants'o ha tšepe e qhibilihisitsoeng e phalla mapetsong le mapetsong, hape e eketsa litšitiso tsa lehlabathe tse khomarelang. Lebelo la ho tlatsa ka potlako le eketsa bokhoni ba tšepe ho semathi le hlobo, mme ho bonolo ho etsa hore pente e oe ebe e kenella tšepe, hape ho bonolo ho hlatsoa lera la pente le ho etsa hore lehlabathe le kene . Bakeng sa li-castings tsa tšepe, khatello e nepahetseng e fosahetseng hangata ke 0.025-0.04MPa. ,

5. Theha lithibelo tsa slag, slag skimming le slag bokella risers

Ho beha poloko ea slag le ho sesa ha slag tsamaisong ea gating le ho beha li-slag tse bokellang li-slag ho li-castings le ho nka mehato ea ho boloka slag le slag skimming ho ka thusa ho ntlafatsa mefokolo ea lehlabathe le ea slag.

6. Ho betla lehlabathe

The phatsa boholo ba lehlabathe bōpa ke mahoashe haholo kapa o motle haholo ho ama ketsahalo ea slag kenyelletsoa ha lintlha le lehlabathe sekoli khomarelang. Haholo mahoashe phatsa boholo tla eketsa lehlabathe khomarelang le slag kenyelletso likoli. Lisebelisoa tsa tšepe hangata li sebelisa lehlabathe le ommeng la quartz (lehlabathe le hlatsoitsoeng) le boholo ba lijo-thollo tse 30/50.

7. Ts'ebeliso ea theknoloji ea ho hloekisa tšepe

Ts'ebetso eohle ea ho betla ea foam e lahlehileng e tlameha ho nahana ka bothata ba tlhoekiso ea tšepe, e leng e 'ngoe ea mahlale a morao-rao a lahlehileng a foam. Ts'ebetso eohle e kenyelletsa ho qhibilihisoa ha tšepe e qhibilihisitsoeng, ho chesa haholo, le ho tšela ka hlobo ho tlameha ho nahana ka bothata ba tlhoekiso, 'me mahlale a karaoke ke e' ngoe ea tsona.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Slag kenyelletsoa ha lintho ka Lost bubble lahla

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off