Ke Eng hlobo Teko Ka shoa lahla

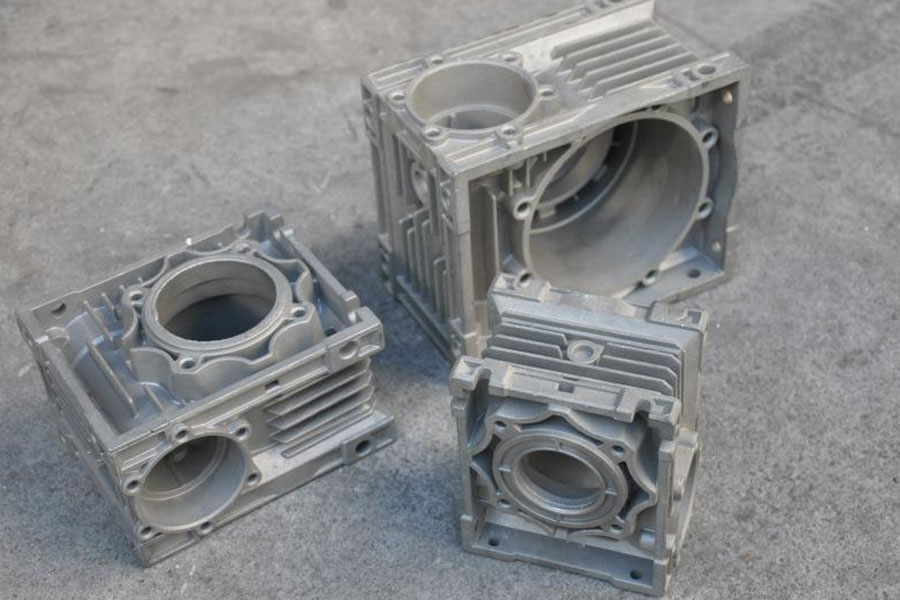

Teko ea ho lahla hlobo ke ts'ebetso ea netefatso ea tlhahiso ea 'nete le moralo oa hlobo, hape ke ts'ebetso ea bohlokoa ea hlobo e lahlang thepa, lisebelisoa, ts'ebetso ea ts'ebetso le phetoho ho tlhahiso ea bongata. Sengoloa sena se hlahisa tšebetso ea moetso oa hlobo ho netefatsa netefatso ea liteko le ntlafatso e latelang le phetoho.

Boemong ba ntlafatso ea sehlahisoa se secha le liteko tse ncha tsa hlobo, ho tla ba le mathata a mangata kapa a fokolang a lebisang ho hloleheng ha nyeoe. Hape ho na le lintlha tse ngata tse amang ho hloleha ha tlhahlobo ea mohlala. Lintlha tse amehang ke li fe?

Pele ho tsohle, ho lekola le ho sekaseka sebopeho sa ho betsa le moralo oa sistimi ea ho qhekella mohatong oa nts'etsopele. Tabeng ya bobedi, entsprechen thulaganyou e ea shoa-lahla tlhahiso e kang mocheso oa tšepe e qhibilihisitsoeng, shoa-lahla khatello, lebelo le ho itima lijo ho switjha ntlha le kahlolo e molemo. Joalo joalo, lintlha tse ling ke senotlolo sa ho ama ka kotloloho boleng ba kahare le kantle ba castings ea lefu.

Empa maemong a mangata, moralo oa hlobo le tlhahiso li amana haufi-ufi. Lintho tse amang hlobo, ho kenyelletsa palo ea likheo, moralo oa sistimi ea heke, mofuta oa heke (boemo, sebaka, tataiso), jj. pholileng le tsona lia sebelisoa. Ho fihlela sepheo sa ho leka-lekanya mocheso oa hlobo. Ke feela ka moralo o motle oa hlobo o ka fumanoang ka mekhahlelo e mengata ea tšebetso, e loketseng boleng ba kahare le kantle ba ho betsa. Bakeng sa tlhahlobo le tlhahlobo e ikhethileng, re tlameha ho sebelisa software e thusang. Mohlala: software ea tlhahlobo ea hlobo ea phallo, software ea ts'ebetso ea tlhahlobo ea parameter PQ 2 joalo-joalo.

Tlhahlobo ea Boitsebiso ba Khopolo

1) Hlahloba moralo oa pele oa sebaka sa heke, sebaka le tataiso, sebaka sa mokotla oa slag, joalo-joalo ka software ea phallo ea hlobo. Utloisisa sekhahla, kabo ea mocheso, tsela ea phallo le lebelo la tšepe e qhibilihisitsoeng e phallang kahare, hammoho le pokello ea slag le mokhathala oa mokotla oa slag, 'me u fumane mathata ho fana ka motheo oa tlhahlobo le phetoho e latelang. mabapi le ho fumana Sisteme ea gating e betere.

2) Re sebelisa setšoantšo sa PQ 2 ho kenya hlobo, lisebelisoa le tlhahlobo e 'ngoe ea lipehelo, qalong re ka beha mekhahlelo ea ts'ebetso le ho utloahala ha khetho ea tonne ea boralitaba, fumana mathata ho li-parameter tsa ts'ebetso le ho li lokisa ka nako; hape re ka fumana mohopolo.

Teko ea Die Casting hlobo le Ts'ebetso ea Paramente ea ntlafatso

Morero oa mantlha oa teko ea hlobo ke ho fumana lits'ebetso tse ntlafalitsoeng tsa ts'ebetso le moralo oa phetoho ea hlobo. Ho hlokahala hore le ha lisebelisoa, maemo a mochini kapa maemo a tikoloho a fetohile, e ntse e ka netefatsa hore hlobo e ka hlahisa lihlahisoa tse tšoanelehang ntle le tšitiso ea letho. Ntlafatsa "ho feto-fetoha" ha hlobo ho isa tekanyong, eseng feela ho fumana lisampole tse 'maloa tse ntle tsa hlobo ea teko.

Mosebetsi oa ho itokisa pele ho tlhahlobo ea hlobo. Ho latela meralo ea hlobo, etsa tlhahlobo e qaqileng ea litekanyo tse amehang (haholoholo boholo ba sehokelo sa sprue bushing); fumana tatellano ea likarolo tsa karolo e ngoe le e ngoe e tsamaeang ea hlobo (ho hula le ho thella); netefatsa se lokelang ho amoheloa Mochini oa mochini o lahlang mochini, boemo ba ente, sebopeho sa tubing, bophara ba kamore ea khatello le boholo ba li-interface li lumellana le litlhoko tsa 'nete tsa hlobo. Tlhokomelo e khethehileng e tlameha ho lefuoa mochini o lahlang o sebelisoang mohloeng oa teko o lokela ho tšoana le mofuta oa mochini o lahlang o sebelisoang tlhahiso ea bongata ba hlobo, ho seng joalo hlobo e ka se sebelisoe.

Ho latela lipalo tsa ts'ebetso ea mohopolo tse fumanoeng chate ea PQ2, tlhahiso ea liteko e etsoa ho fumana phapang lipakeng tsa mekhahlelo ea 'nete le ea thuto. Mme o tsoelepele ho feto-fetoha le ho fetoloa, ho fihlela ho fumanoa mochini o entsoeng hantle o nang le boleng bo botle ba kahare. Har'a bona, ts'ebetso ea boralitaba e kanna ea se tsitse, e leng se re thatafalletsang ho ahlola bothata. Ka nako ena, "lisebelisoa tsa ente" li ka sebelisoa ho lekola lebelo, khatello, ho fallisoa le maemo a mang ts'ebetsong ea ente, le ho ahlola ka ho fetoha ha mothinya. Re thuse ho fumana bothata ka nepo, tataisa ka nepo tokiso ea mekhahlelo ea ts'ebetso le ho utloisisa ts'ebetso ea lisebelisoa. Qetellong, ho tla fumaneha likarolo tse nepahetseng tsa ts'ebetso tse loketseng sesebelisoa sena.

Mefuta e hlahisoang ke feme ea hlobo hangata e bakoa ke maikutlo a fosahetseng a moralo kapa ts'ebetso e sa lokang molemong oa tlhahiso. Hangata ho na le mathata a mang, a joalo ka mamello e fetelletseng, liphetoho tse sa tsitsang tsa lehae, sebopeho se fosahetseng, le peakanyo ea metsi a pholileng a sa utloahaleng. Phapang e kholo ea mocheso, jj. Ka lebaka la phapang lipakeng tsa sephetho sa nnete le khopolo, teko ea hlobo ke tsela e bonolo ka ho fetisisa, e otlolohileng le e sebetsang ea ho fumana mathata a hlobo. U ka tseba le kabo ea mocheso oa hlobo le hore na sebaka sa metsi a pholileng sea utloahala ka setshwantsho se chesang sa motlakase, se thusang haholo ho lelefatsa bophelo ba hlobo. E boetse e na le bohlokoa bo tataisang bakeng sa phetoho ea spray.

Ts'ebetsong ea hlobo ea liteko, likarolo tsa hlobo tsa teko tse hlahisitsoeng kamora hore lits'ebetso tsa ts'ebetso li tsitsisoe li hloka tlhahlobo ea sebaka sa marang-rang ke baenjiniere ba lihlahisoa, litsebi tsa ts'ebetso le lienjineri tsa boleng ho latela litlhoko tsa moreki. Litaba tse ka sehloohong tsa tlhahlobo ke:

- Tekanyo ea litekanyo tsa bohlokoa le litekanyo tsa machining ea margin;

- Hore na sebōpeho sa ponahalo ea tšebetso ea ho betsa se ntse se le joalo, ebang mohala oa karohano o fosahetse, ebang ho na le khatello, ho taboha, ho fokotseha, jj .;

- Tlhatlhobo ea anatomy le X-ray ho lekola porosity le shrinkage kahare ho lahla. Utloisisa boemo ba boleng ba li-castings le mathata a hlobo ka tlhahlobo ea pele, 'me u fane ka motheo le tataiso bakeng sa tokiso ea morao.

Teko ea ho lahla hlobo ha se feela ts'ebetso ea khopolo-taba le e sebetsang le netefatso, empa hape le ts'ebetso ea khalemelo le phoso e tsoelang pele. Ho feta moo, ho lahla sejoale-joale ho na le software e thusang le lisebelisoa tse phahameng ho re thusa ho lekola hlobo ka mahlale. Etsa tlhahlobo e hlophisehileng ea sebopeho sa ho betsa, sebopeho sa hlobo, ts'ebetso ea ho lahla le ts'ebetso ea lisebelisoa tsa ho lahla thepa ho fumana phapang le mathata. Kamora hore bothata bo rarolloe, sebopeho sa hlobo le likarolo tsa ts'ebetso li ntlafalitsoe. Etsa hlobo ea rona e loketseng lihlahisoa tse tsitsitseng le tlhokomelo ea boleng. Sena se tletse ka botlalo bohlokoa ba teko e bolaeang hlobo.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Ke Eng hlobo Teko Ka shoa lahla

Khamphani ea Minghe Casting e nehetsoe ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo (likarolo tsa tšepe tsa die die li kenyelletsa haholo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off