Lahleloa thaethaniamo

Litšebeletso tsa ho lahla tsa Titanium - Tloaelo ea Tloaelo ea Tloaelo ea Titanium ea China ea China

IATF 16949 E NETEFITSOA HO ETSA LITLHAKISO TSA BOTSOALI

Ho lahla thaethaniamo ke eng? Lahla motsoako thaethaniamo e bua ka ts'ebetso ea ho qhibilihisa le ho tšela lisebelisoa tsa thaethaniamo ka har'a li-castings tlasa lephaka kapa maemo a sireletsang khase. Boholo ba lits'epe tsa tšepe tsa titanium tse holofetseng li na le thepa e ntle ea ho betsa. E 'ngoe ea tse sebelisoang ka ho fetisisa ke motsoako oa Ti-6A1-4V. E na le ts'ebetso e ntle ea ts'ebetso ea ho betsa le sebopeho se tsitsitseng, 'me e na le matla a matle (5σbσ890MPa) le ho thatafala ha fracture ka tlase ho 350 ° C.

Li-castings tsa titanium li sebelisoa haholo indastering ea lifofane. Likarolo tsa bohlokoa tse sebelisitsoeng ke: enjene ea konteraka, sekontiri se mahareng, likhakanyo tse se nang letho, lesale la kahare, mokelikeli oa turbocharger, o nang le matlo le ts'ehetso, bracket ea sefofane, sekhele sa sekhele, mekotla, molamu o mokhutšoane, lilakane tsa mapheo a mapheo, likhetla tse robehileng; Likamore tsa taolo ea metsu, mapheo a mohatla, lihlooho tse ka morao tsa rokete, libotlolo tsa sechaba, jj .; li-satellite tsa maiketsetso, liforeimi tsa li-scanner, libarele tsa lense, jj. E sebelisoa haholo indastering ea lehae ho etsa lipompo tse sa keneleng ts'enyeho, li-valve, li-impellers; lisebelisoa tsa likepe bakeng sa likepe; likhetla, masakaneng le lisilindara tsa mechini e nepahetseng; manonyeletso a maiketsetso le likarolo tsa maiketsetso bakeng sa ts'ebeliso ea bongaka; lihlooho tsa papali ea kolofo bakeng sa lisebelisoa tsa lipapali, lisebelisoa tsa lipere, likarolo tsa baesekele, jj.

Minghe ke k'hamphani ea China e lahlang thaethaniamo ea China e ikhethang e hlahisang likarolo tsa likarolo tsa titanium ka lilemo tse fetang 35, e nang le lisebelisoa tse tsoetseng pele tsa ntlo le lisebelisoa tsa lisebelisoa, bo-rakhoebo ba nang le boiphihlelo le boiphihlelo bo ruileng, re ka fana ka lits'ebeletso tsa boima ba thaethaniamo le ho etsa likarolo tsa boleng bo phahameng tsa titanium ka lintlha tse qaqileng, litheko tsa tekanyetso le ho pepa ka nako ho ipapisitse le litlhoko tsa hau. Lebenkeleng la rona la ho lahla thaethaniamo, Die Casting, Sand Casting, Investment Casting, Lost Foam Casting le lits'ebetso tse ling lia fumaneha, hammoho le qetello e ntlehali ea bokaholimo. Lenaneo la rona la likaroloana tsa thaethaniamo le thaethaniamo le ka sebelisoa mefuteng e mengata ea liindasteri le lits'ebetso, tse kenyelletsang likarolo tsa sefofane le li-fasteners, lienjiniere tsa turbine tsa khase, li-compressor blades, li-casings, li-enjini le likhalase tsa mocheso. Re ikemiselitse ho theha tšebelisano 'moho le botsoalle le bareki ba lefats'e ka bophara.

Ikopanye le moenjineri oa rona oa karolo ea "casting" kajeno ho buisana ka lintlha tsa merero ea hau e rarahaneng.

Nalane ea Aluminium Alloy e lahleloang.

Titanium e sebetsa haholo maemong a qhibilihisitsoeng. Nako e telele ho ne ho sa khonehe ho fumana mokhoa o loketseng oa ho betsa le thepa ea mohlala. Ka lebaka leo, lahlela thaethaniamo ea lags ka mora motsoako o senyehileng oa titanium ka lilemo tse fetang 20. Ho tloha ka 1956 ho isa ho 1962, American Bell (Beal) le ba bang ba ile ba nts'etsapele theknoloji e qhekellang ea arc e khelosang khetla, e entseng hore titanium e kenngoe semmuso tlhahiso ea indasteri. Ka li-1970, e ile ea qala ho sebelisoa lebaleng la Aerospace. Ho tloha lilemong tsa bo-1970, thekenoloji ea thaethaniamo e kholo e tšesaane e leboteng e thehiloe mme e sebelisoa. Tlas'a khopolo ea hore ts'ebetso ea eona ea thepa e haufi kapa e lekana le lipallo tsa titanium tsa lifofane, litheko li fokotsoe ka 50%, ka hona theknoloji ea ho betla ea thaethaniamo e tsoetse pele ka potlako. Ho lebelletsoe hore haufinyane, e tla fihlela boemo ba bohlokoa bo ts'oanang le alloy ea titanium e sebelisitsoeng.

Mokhoa oa ho lahla oa Titanium

Li-castings tsa thaethaniamo li sebelisoa haholo seboping se koahelang lephaka le ho lahla graphite. Ha li bapisoa le lits'epe tse kopantsoeng tse holofetseng tsa sebopeho se le seng, matla a tsona a lekana, empa polasetiki le mokhathala li ka tlase ho 40% -50%, 'me ho thatafala ha fracture ho betere hanyane. Boholo ba li-castings tsa titanium li phekoloa ka annealing e tsitsitseng. Phekolo ea tharollo le kalafo ea hydrogenation e ntseng e ithuta e ka ntlafatsa sebopeho sa motsoako oa motsoako mme ea eketsa matla a mokhathala ho isa boemong ba tšoarelo.

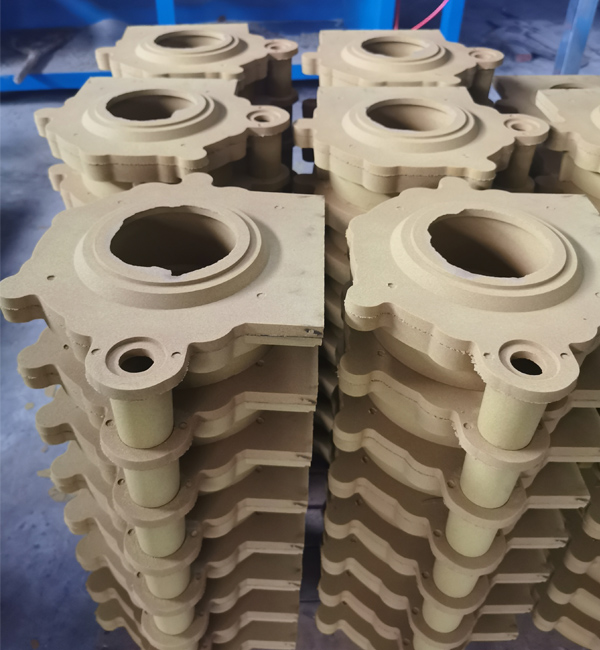

1.The Graphite lahla Of thaethaniamo

Graphite ke ts'ebetso e ka sehloohong ea ho etsa tlhahiso ea li-castings tsa sechaba tsa titanium. E arotsoe ka ho e lokisa mofuta graphite le graphite tamping mofuta. The sebetswa graphite hlobo e entsoe ke pukwanana kapa phetha molao e lokisa ea boleng bo phahameng dibopeho tsa maiketsetso graphite. Ho ea ka ho rarahana ha hlobo, ho ka sebelisoa likarolo tse ngata tse ka tsamaisoang. Hlobo ena e ka sebelisoa makhetlo a mangata. Mofuta oa tamping oa graphite o thehiloe ka ho sila le ho kopanya lehlabathe la maiketsetso le carbonaceous organic binder hore e be motsoako, o bōpiloeng ka letsoho kapa ka mechini ea meetso ka hlobo ea lepolanka kapa lebokose la lehlabathe la tšepe. Sebopeho sa lehlabathe la graphite se feliloeng se koahetsoe, se omisitsoe ebe se tiisoa ka mocheso o tlase, ebe se thunngoa ka mocheso o phahameng tlasa sekoaelo sa phofo ea graphite e ommeng kapa ka tlasa ts'ireletso ea sepakapaka se se nang oxidizing. Kamora hore motsoako oa hlobo o etsoe, o ka kenngoa seboping bakeng sa ho betloa. Bakeng sa tlhahiso ea li-castings tsa Aerospace tse nang le litlhoko tse thata tsa boleng, mefuta ea ho e lokisa le ho e hatakela e hloka ho qhekelloa pele ho lahla

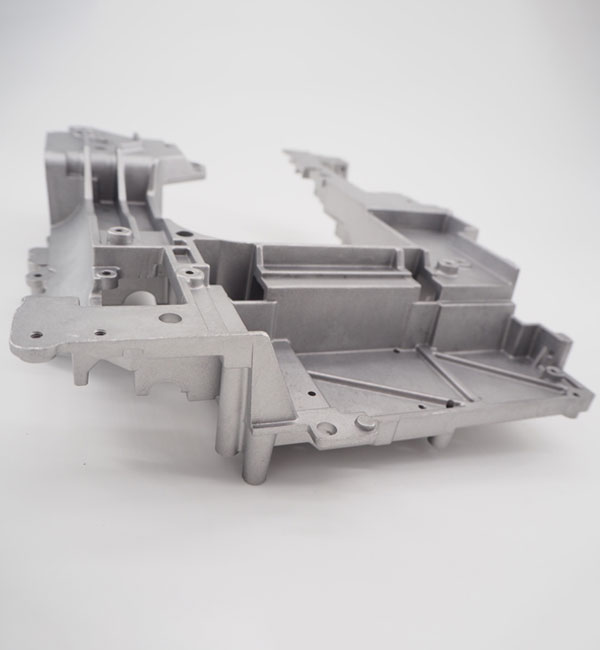

2.The Investment lahla Of thaethaniamo

Ts'ebetso ea matsete ke ts'ebetso e ka sehloohong ea ho hlahisa likarolo tsa titanium tsa alloy bakeng sa lifofane tse nang le ts'ebetso e phahameng, sebopeho se rarahaneng, bokaholimo bo boreleli le bokahare bo teteaneng. Mokhoa oa ho lahla letsete oa titanium ha e le hantle o ts'oana le ts'ebetso ea tšepe e entsoeng ka tšepe, ntle le lisebelisoa tsa likhetla le lits'ebetso tse itseng Ho na le lits'ebetso tse tharo tse sebelisoang ho hlahisa li-castings tse nepahetseng tsa titanium kajeno:

- - Tshebetso ea likhetla tsa graphite.

- - Ceramic shell technology e nang le lera la tšepe.

- - Mokhoa oa likhetla tsa khalase ea oxide. Mofuta oa pele o theko e tlase ebile o ka sebelisoa bakeng sa tlhahiso ea li-castings tse nyane le tse mahareng, 'me tse peli tsa morao-rao li ka sebelisoa bakeng sa tlhahiso ea li-castings tse kholo tsa lebota le tšesaane.

Ho lahla motsoako oa titanium le boleng ba ho lahla Li-alloys tse ngata tse holofetseng tsa titanium li ka sebelisoa bakeng sa ho betsa, e sebelisoang ka ho fetesisa ke motsoako oa Ti-6A1-4V. E na le thepa e ntle ea ho lahla le thepa e tsitsitseng ea mokhatlo. Ha ho bapisoa le motsoako oa deformation oa sebopeho se ts'oanang, matla a alloy titanium alloy ha e le hantle a lekana, empa polasetiki ea eona le mokhathala o ka tlase ho 40% -50%, 'me ho thatafala ha fracture ho betere hanyane.

Li-castings tsa titanium hangata li alafshoa ka annealing e tsitsitseng. Phekolo ea tharollo le kalafo ea hydrogenation e ntseng e ithuta e ka ntlafatsa lithollo, ea ntlafatsa sebopeho le ho ntlafatsa ts'ebetso ea mokhathala oa alloy ho isa boemong ba tšoarelo. Ho hatella ka isostatic ke mokhoa o tloaelehileng oa kalafo bakeng sa li-castings tsa boleng bo holimo tsa titanium. Kamora mocheso o phahameng le kalafo e phahameng, boholo ba ho betsa ha bo fetohe, empa sebopeho sa kahare se ba boima haholo, 'me botsitso ba thepa ea mochini bo tla ntlafatsoa haholo. Boleng ba li-castings bo lokela ho hlahlojoa ho latela maemo a naha a GB6614, maemo a sesole a naha GJB2896 kapa maemo a lifofane HB5448. Litšobotsi tsa mahlale a titanium alloy castings li thathamisitsoe tafoleng

Litaba tsa Minghe tsa ho lahleloa ha titanium

Lits'ebeletso tsa masela tsa Minghe li fumaneha bakeng sa boqapi ba 'nete ebile li tlase ho hlahisa lihlahisoa tse phahameng tsa likarolo tsa hau tsa aluminium, likarolo tsa zinki, likarolo tsa magnesium, likarolo tsa tšepe tsa titanium, likarolo tsa tšepe tse sa hloekeng, likarolo tsa koporo tsa tšepe, likarolo tsa tšepe likarolo le tse ling.

Eya ho Bona Litaba Tse Eketsehileng tsa Likarolo tsa Likarolo >>>

Khetha Mofani oa Molemo ka ho Fetisisa oa Lisebelisoa tsa Titanium

Hajoale, likarolo tsa rona tsa ho lahla thaethaniamo li romelloa Amerika, Canada, Australia, United Kingdom, Jeremane, Fora, Afrika Boroa le linaheng tse ling tse ngata lefats'eng lohle. Re ISO9001-2015 e ngolisitsoeng hape e netefalitsoe ke SGS.

Ts'ebeletso ea rona ea ho qapa ea thaethaniamo e fana ka litšepe tse tšoarellang le tse theko e tlase tse fihlelang lintlha tsa hau bakeng sa likoloi, bongaka, sepakapaka, elektroniki, lijo, kaho, ts'ireletso, likepe tsa lewatle le liindasteri tse ling. Potlako ho romella potso ea hau kapa ho kenya litšoantšo tsa hau ho fumana qotsulo ea mahala ka nako e khuts'oane haholo thekiso@hmminghe.com ho bona hore na batho ba rona, lisebelisoa le lisebelisoa li ka tlisa boleng bo holimo joang bakeng sa theko e ntle bakeng sa projeke ea hau ea ho betla thaethaniamo.

Re fana ka litšebeletso tsa ho lahla ho kenyelletsa:

Litšebeletso tsa Minghe Casting li sebetsa ka ho betsa lehlabathe, ho betla tšepe, ho tsetela matsete ho lahlile foam

Ho Cast Cast

Ho Cast Cast ke moetlo oa ho betla o sebelisang lehlabathe e le sesebelisoa sa mantlha sa ho etsa mefuta. Ho betsa matla a khoheli ho sebelisoa ka bongata bakeng sa hlobo ea lehlabathe, le ho lahla ka khatello e tlase, ho lahla centrifugal le lits'ebetso tse ling ho ka sebelisoa ha ho na le litlhoko tse ikhethang. Ho lahla lehlabathe ho na le mefuta e mengata e fapaneng ea ho ikamahanya le maemo, likotoana tse nyane, likotoana tse kholo, likotoana tse bonolo, likotoana tse thata, likotoana tse le 'ngoe le bongata bo boholo li ka sebelisoa.

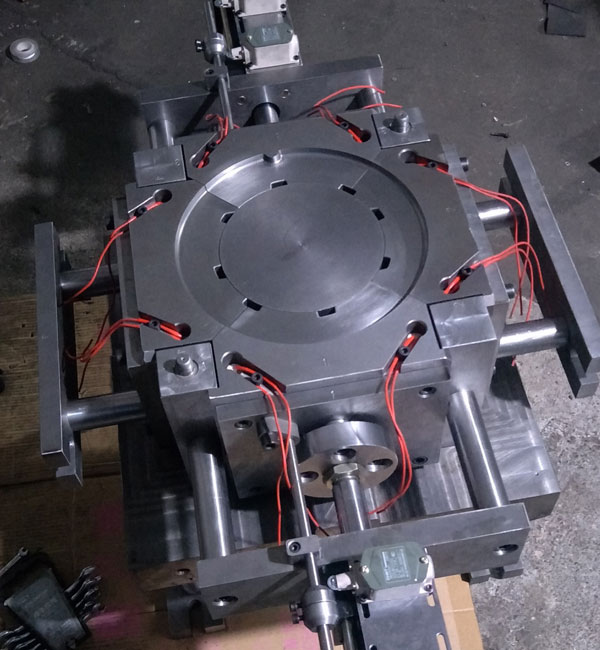

Sa Feleng hlobo lahla

Sa Feleng hlobo lahla ba na le bophelo bo bolelele le ts'ebetso e phahameng ea tlhahiso, ha ba na ho nepahala hantle feela 'me ba boreleli, empa hape ba na le matla a phahameng ho feta ho lahla lehlabathe mme ha ba na monyetla oa ho senyeha ha tšepe e tšoanang e qhibilihisitsoeng. Ka hona, tlhahiso ea bongata ba litšepe tse mahareng le tse nyane tse se nang litšepe, ha feela ntlha ea ho qhibiliha ea thepa e sa phahama haholo, hangata ho lahloa ka tšepe ho khethoa.

Ho etsa chelete

Monyetla o moholo oa ho lahla lichelete ke hobane castings dipeeletso na phahameng tlhakore ho nepahala le holim fihlela qetellong, ba ka fokotsa machining mosebetsi, empa siea e nyenyane machining kabelo ka likarolo le ditlhoko tse phahameng. Ho ka bonoa hore ts'ebeliso ea mokhoa oa ho lahla lichelete e ka boloka lisebelisoa tse ngata tsa mochini le ho sebetsana le lihora tsa motho, mme ea boloka lisebelisoa tse tala tsa tšepe.

Lahlehileng bubble lahla

E lahlehetsoe ke foam ke ho kopanya boka ba parafini kapa mefuta ea foam e ts'oanang le boholo ba sebopeho le sebopeho ho lihlopha tsa mohlala. Kamora ho hlatsoa le ho omisa liphahlo tse haelloang, li patoa lehlabatheng le ommeng la quartz bakeng sa mohlala oa thothomelo, 'me li tšeloa ka khatello e mpe ho felisa mohlala. , Sesebelisoa sa mokelikeli se maemong a mohlala mme se theha mokhoa o mocha oa ho lahla kamora ho tiisa le ho pholisa.

Ho Casting

Die foromeletsoeng ke tšepe tshepe thulaganyou e, e tšoauoa ka ho sebelisa khatello e phahameng ea tšepe entsoeng ka ho qhibilihisoa sebelisa cavity ea hlobo ena. Hlobo hangata e entsoe ka lits'epe tse kopantsoeng ka matla a holimo, 'me tšebetso ena e batla e tšoana le ho bopa ente. Boholo ba batho ba shoang ha ba na tšepe, joalo ka zinc, koporo, aluminium, magnesium, lead, tin le li-alloys tsa lead-tin le lits'epe tsa tsona. Minghe e bile moetapele oa China shoa lahla tšebeletso ho tloha 1995.

Ho ts'oaroa ha Centrifugal

Ho ts'oaroa ha Centrifugal ke mokhoa le mokhoa oa ho kenya tšepe ea mokelikeli ka hlobo e potolohang ka lebelo le leholo, e le hore tšepe ea mokelikeli e sisinyehe ho tlatsa hlobo ebe e etsa tšepe. Ka lebaka la motsamao oa centrifugal, tšepe ea mokelikeli e ka tlatsa hlobo hantle tseleng ea maqhubu mme ea theha sebaka sa mahala sa ho betsa; e ama ts'ebetso ea kristale ea tšepe, ka tsela eo e ntlafatsa likarolo tsa mochini le tsa 'mele tsa ho betsa.

Lahla Khatello e tlase

Lahla Khatello e tlase ho bolela hore hlobo hangata e behiloe kaholimo ho tsoana le sebopi se tiisitsoeng, 'me moea o hatelletsoeng o hlahisoa ka har'a tsoana le' mele ho baka khatello e tlase (0.06 ~ 0.15MPa) holim a tšepe e qhibilihisitsoeng, hore tšepe e qhibilihisitsoeng e nyolohe ho tsoa phala e nyolohelang ho tlatsa hlobo le taolo Mokhoa oa ho betsa o tiileng. Mokhoa ona oa ho betsa o na le phepo e ntle le sebopeho se teteaneng, ho bonolo ho lahla li-castings tse kholo tse nang le marako a tšesaane, ha ho na risers, le sekhahla sa ho hlaphoheloa ha tšepe sa 95%. Ha ho na tšilafalo, ho le bonolo ho elelloa itsamaise.

lephaka lahla

lephaka lahla ke mokhoa oa ho lahla oo tšepe e qhibilihisoang, e tšolleloang le ho khabisoa ka phapusing e lephaka. Lepolanka lahla ka fokotsa dikahare khase ka tšepe le ho thibela tšepe ho kena moea. Mokhoa ona o ka hlahisa casting e khethehileng ea tšepe ea tšepe le likarolo tse bonolo haholo tsa oxidized titanium. Minghe Casting e na le feme e lahlang lephaka, e lekane ho rarolla mathata ohle a amanang le ho betsa lephaka