Litšebeletso tsa ho lahla litšepe tsa inthanete

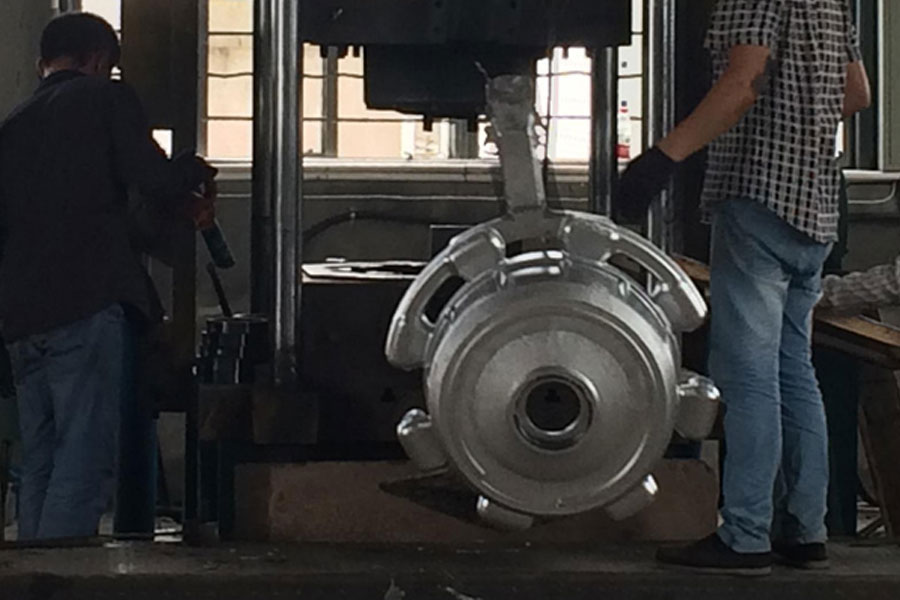

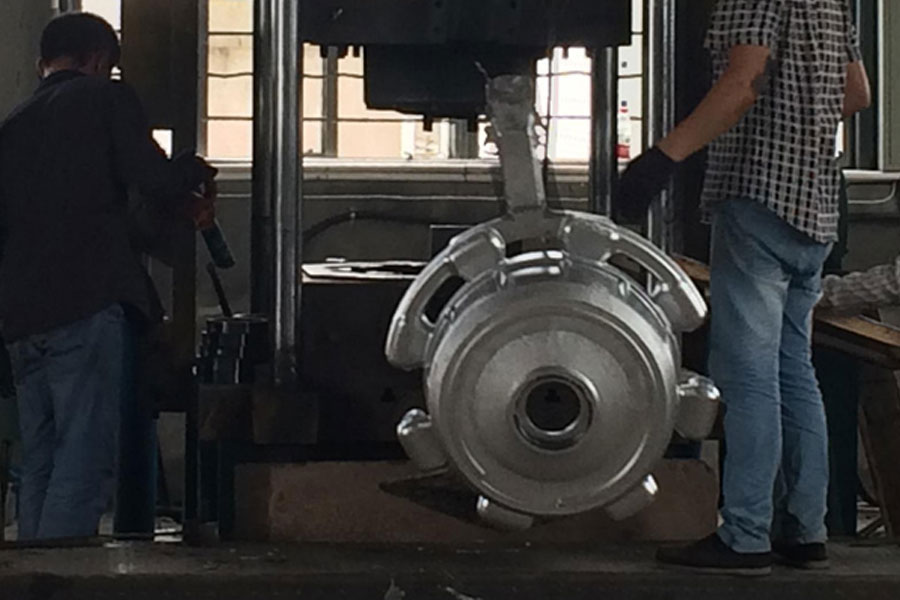

Ho lahla tšepe ke mokhoa oo tšepe e qhibilihisoa ka mokelikeli o fihlelang litlhokahalo tse itseng ebe o tšeloa ka hlobo. Kamora ho futhumatsa, ho tiisa le ho hloekisa, ho lahleloa ka sebopeho se reriloeng esale pele, boholo le ts'ebetso ea sebetsa. Hobane ho lahla letho ho batla ho thehiloe, ho ka fihlela sepheo sa ho qoba ho sebetsa kapa ho sebetsa hanyane, ho fokotsa litšenyehelo le ho fokotsa nako ho isa bohōleng bo itseng. Lahla ke e 'ngoe ea lits'ebetso tsa mantlha tsa indasteri ea tlhahiso ea mechini ea sejoale-joale.

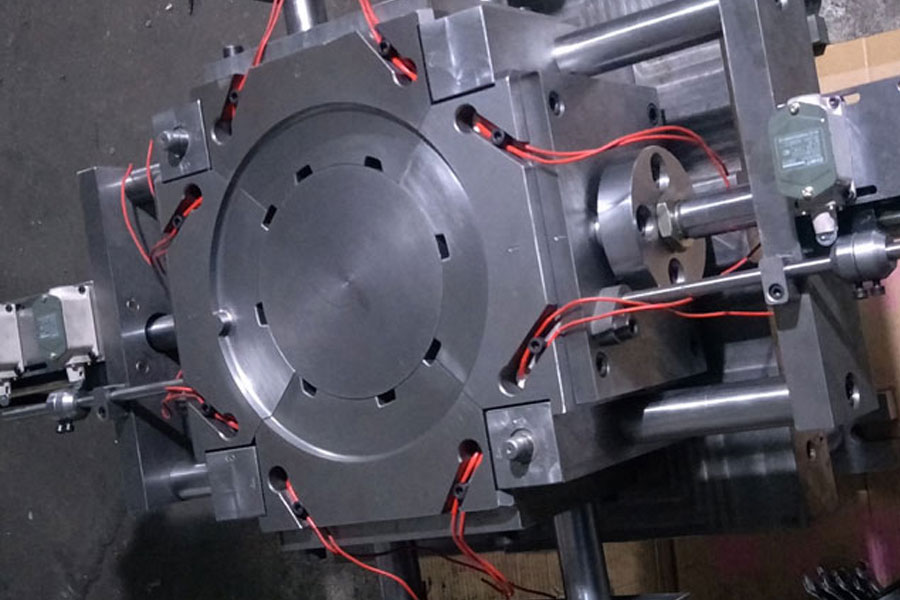

Minghe ltd ke k'hamphani e lahlang tšepe ea China e nang le boiphihlelo ba lilemo tse fetang 35 boqapi ba lihlahisoa le likarolo tsa indasteri. Prototyping e potlakileng le tlhahiso e kholo ea boleng bo phahameng ka ho fetesisa ba likarolo tse nepahetseng li lumelloa ho phethahala ka thuso ea lits'ebeletso tsa ho betla tšepe le mekhoa ea maiketsetso. Baqapi ba rona ba nang le boiphihlelo ba tseba ka botlalo li-software tse ngata tsa projeke, tse khonang ho boloka lebelo le boleng ba lihlahisoa. Moqapi oa sehlahisoa o tsoetseng pele le o qaqileng o tla netefatsa qotsulo e potlakileng ea marang-rang.

Hore na o hloka feela litšoantšo tsa moralo oa sehlahisoa kapa karolo ea ho qetela e tiileng ka lintlha tse tobileng, Minghe e ka khotsofatsa litlhoko tsa hau ka litheko tsa tlholisano, ts'ebetso e ikhethang le lits'ebeletso tse ntle tsa bareki.

Hobaneng ha u khetha Litšebeletso tsa ho lahla tšepe tsa China?

- Sebopeho sa tšepe se na le sekhahla se phodileng ka potlako le sebopeho se teteaneng sa ho betsa, se ka matlafatsoang ke kalafo ea mocheso, mme thepa ea eona ea mochini e ka ba 15% e phahameng ho feta ea ho betsa lehlabathe.

- Tšepe hlobo foromeletsoeng, boleng lahla e tsitsitse, roughness holim ke molemo ho feta ho betsa lehlabathe, 'me sekhahla hana e tlaase.

- Maemo a matle a ho sebetsa, tlhahiso e phahameng, ho bonolo hore basebetsi ba e tsebe.

Bakeng sa lilemo tse fetang 35, setsi sa Minghe se ntse se fana ka lits'ebeletso tsa tšepe tsa tšepe bakeng sa liindasteri le mefuta ea projeke. Ho etsa hlobo ha rona ka tlung, kalafo ea mocheso, le lits'ebeletso tse nepahetseng tsa ho betsa ho tlisa boiphihlelo le boleng morerong o mong le o mong.

Bokgoni ba rona ba sehlahisoa bo tloha ho projeke ea merero ea moetlo ho isa merero e meholo ea likoloi, sepakapaka le merero ea literene.

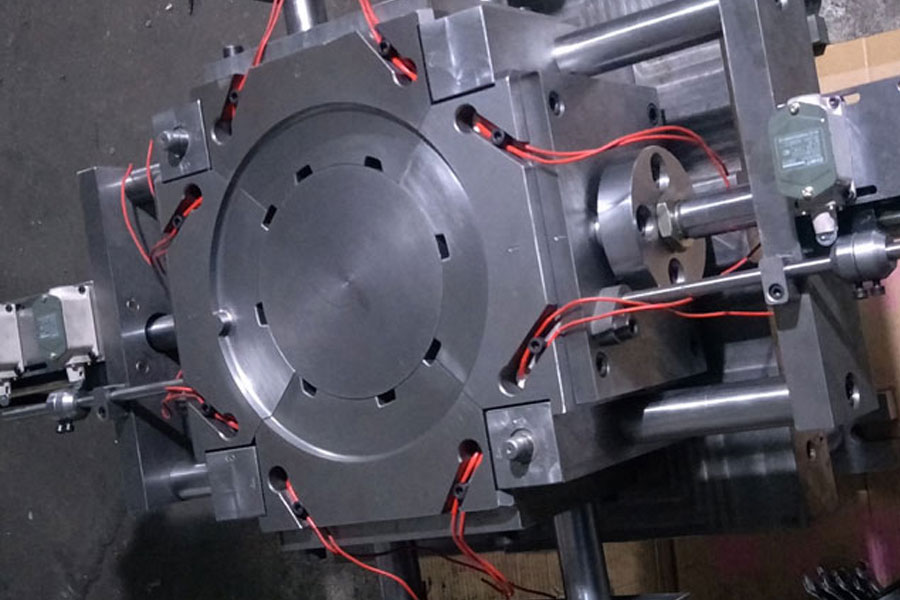

Bokhoni ba Ts'ebeletso ea Metal Casting

E le e 'ngoe ea lits'ebeletso tsa tlhahiso ea China tse ntseng li hola ka potlako, barekisi ba China le khamphani ea ho lahla, litsebo tse latelang tsa Minghe lia fumaneha ho sebeletsa litlhoko tsa hau tsa likarolo tsa tšepe, ho tloha ho prototyping e potlakileng ho isa likarolong tse nepahetseng le ho sebelisa machining, ho emisa tlhahiso.

| Ho Casting |

| Die casting ke mokhoa oa ho etsa thepa oo tšepe e qhibilihisitsoeng e tšeloang kapa e qobelloang ka hlobo ea tšepe .. |

| Ho etsa chelete |

| Ts'ebetso ea matsete e fana ka phetoho e kholo ea meralo ea likarolo tse rarahaneng haholo tse entsoeng ka alloys e kholo. |

| Ho Cast Cast |

| Ho lahla lehlabathe ke mokhoa oa ho sebelisa lehlabathe e le sesebelisoa sa mantlha ho bopa lihlahisoa tse fapaneng tsa tšepe |

| Lahlehileng bubble lahla |

| Lahla foam e lahlehileng ke ho kopanya boka ba parafini kapa meetso ea foam e ts'oanang le boholo le sebopeho sa likarolo tsa mefuta. |

| Ho ts'oaroa ha Centrifugal |

| Lahla Centrifugal ha ba chenchana a selekane sa hlobo e ka boemo paatsepama o bitsoa paatsepama centrifugal betsa. |

| Lahla Khatello e tlase |

| Mokhoa ona oa ho betsa o na le phepo e ntle le sebopeho se teteaneng, ho bonolo ho lahla li-castings tse kholo tse nang le mabota a masesaane |

| Sa Feleng hlobo lahla |

| Permanent hlobo foromeletsoeng e na le bophelo bo bolelele le ts'ebetso e phahameng ea tlhahiso, eseng feela hore e na le tlhakore e ntle ebile e boreleli |

| lephaka lahla |

| Lephaka lahla ke mokhoa oa ho betsa oo tšepe e qhibilihisoang, e tšolleloang le ho khabisoa ka phapusing e lephaka |

| Matla a khoheli |

| Litšebeletso tsa Minghe Gravity Casting li ka fihlela litlhoko tsa bareki ho hlahiseng likarolo tsa boleng bo phahameng le tse theko e tlase. |

Bokaholimo ba China Minghe bo phethela

O ka khetha khetho e pharalletseng ea litšebeletso tsa ho qeta litšepe ka mora ts'ebeliso ea mochini oa tšepe oa Minghe ho ntlafatsa likarolo tsa ponahalo, boreleli ba bokaholimo, ho hanyetsa ts'enyeho le ts'ebetso e ngoe ea likarolo tsa hau tsa tšepe.

| Electroplating / Plating ▶ |

| Ho roala phofo / Kobo ea phofo ▶ |

| Ho qhotsa lifaha / Ho phatloha hoa sefaha ▶ |

| Ho qhoma ho hoholo / sandblasting▶ |

Likopo tsa MINGHE Lits'ebeletso tsa ho lahla tšepe

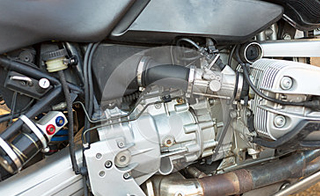

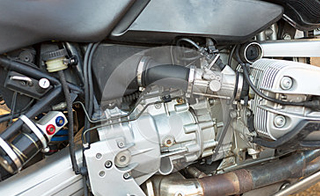

Likarolo tsa Metal Casting li u pota-potile, e kanna ea ba likarolo tsa bohlokoa tsa koloi ea hau hape li ka etsa mesebetsi ea bohlokoa lisebelisoa tsa hau tsa motlakase. Minghe ke setsebi se atlehileng sa ho betsa se sebelisitseng lits'ebetso tse ngata tsa tšepe.

Likarolo tsa rona tsa tlhahiso li loketse liindasteri tse latelang:

|

LIEKETSENG KHALELE

TSIETSO |

|

LIEKETSI

TSIETSO |

|

LIEKETSO

TSIETSO |

|

LITŠOANTŠISO LA LED

TSIETSO |

|

HO OELA HA MOCHESO

TSIETSO |

|

KEKETSO KITITI

TSIETSO |

|

Pompo belofo

TSIETSO

|

|

LITLHAKU LITS'ELISO

TSIETSO

|

|

Telecom

TSIETSO

|

|

BONOLO

TSIETSO

|

|

LEFAPA

TSIETSO

|

|

LEKHETHO

TSIETSO

|

|

BONTS'A KABABE

TSIETSO

|

|

ROBOTS

TSIETSO

|

|

HAPE

TSIETSO

|

Melemo ea Minghe Metal Casting Services

- Sehlopha le meralo ea lihlahisoa tse fihletsoeng le tse koetlisitsoeng li maemong a morao-rao ka mahlale a morao-rao le lisebelisoa

- Nako ea karolelano ea matsatsi a 7 le 99.85% ho isa nakong

- E khona ho bona le ho rarolla mathata a mangata nakong ea moralo oa moralo habonolo

- Fast mahala khotheishene ka hare ho lihora tse 24 ka mor'a botsisisa

- Khotsofalo e phahameng ea bareki le botšepehi

- Moralo o ruileng le boiphihlelo ba tlhahiso

- itsamaise e eketsehile.

- Liphoso tse nyane

- Litšebeletso tsa rona li na le litšenyehelo tse ngata.

- Meralo e tšepahalang ea CNC ho fihlela litlhoko tsa hau tsa likarolo tse tloaelehileng bakeng sa liindasteri tse ngata

- Ho qotsa: Pele ho feta lihora tse 24

- Nako etella pele: Ka potlako joalokaha 3 letsatsi

- Etsa bonnete ba hore mohato o mong le o mong o felile ka har'a kemiso mme o fihlella boleng bo batlang

- Boholo ba karolo: Ho tloha ho 10 ho. X 7 ho. X 3.75 ho. Ho isa ho 22 ho. X 14 ho. X 1.25 ho

- Tolerances e tloaelehileng: +/- 0.1mm