Taolo ea Ts'ebetso ea ho lahla Die

Ka lebaka la phapano ea lintlha tse amang boleng ba ho betsa le ho rarahana ha ts'ebetso ea tlhahiso, hajoale mokhatlo o hlophisehileng, ts'ebetso ea taolo e na le karolo ea bohlokoa ho nts'etsapele moralo oa ts'ebetso, koetliso ea tekheniki le taolo ea tlhahiso, sepheo sa mantlha e le ho hlokomela thibelo e sebetsang le tharollo ea liphoso. Tlhahlobo e khuts'oane mabapi le taolo ea motsoako o qhibilihang, hlobo le taolo ea ts'ebetso ea ho lahla, tlhahlobo ea kahare le kantle ea lihlahisoa ea etsoa.

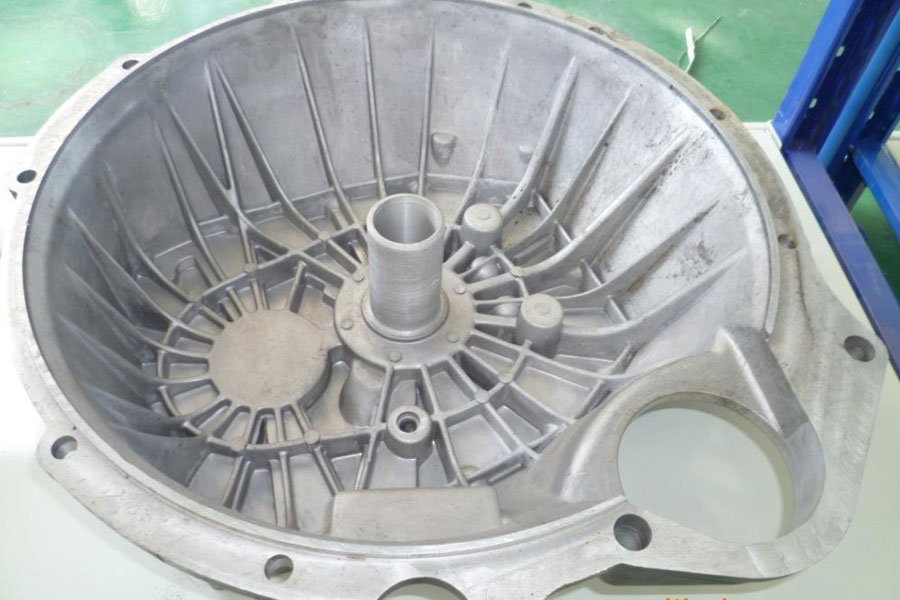

Moralo oa block ea enjine o ntse o tsoela pele ntlheng ea boima bo bobebe le ho rarahana. Ka lebaka la ts'ebetso ea eona e tlase le ts'ebetso e ntle ea ho lahla, motsoako oa aluminium o sebelisoa khafetsa ho hlahisa sepakapaka le likarolo tsa likoloi tse nang le libopeho tse rarahaneng, marako a masesaane le mejaro e mahareng. Letoto la li-block tsa enjene tse hlahisoang ke Changan Automobile Jiangbei Engine Factory li thehoa ka khatello e phahameng ea khatello ka hlobo e nang le alloyum ea boleng bo holimo ea aluminium (e ts'oanang le cha YL113). Moqomo oa li-engines tsa li-cylinder ke mofuta o phahameng oa matla, o mosesane o nang le marako a rarahaneng. Boholo ba masoba a sekontiri sa silindara a kentsoe pele ka li-cores tsa hlobo, tse sa hlokeng feela litlhoko tse phahameng bakeng sa lisebelisoa tsa Hardware tse kang hlobo le mechini e lahlang, empa taolo ea ts'ebetso eohle ea tlhahiso e tiisa ho tsamaisoa. ntlafatso ea boleng ba sehlahisoa le eona e bohlokoa haholo.

Tsamaiso ea Tsamaiso

Ts'ebetsong ea ts'ebetso ea tlhahiso ea ho shoa, ho bohlokoa haholo ho tsitsisa le ho ntlafatsa boleng ba sehlahisoa ho tsoa ho likarolo tsa taolo ea mokelikeli oa aluminium, taolo ea hlobo, taolo ea ts'ebetso ea ho lahla le tlhahlobo ea sehlahisoa.

Taolo ea Metsi ea Aluminium

Liphoso tsa ho tiea ha motsoako oa aluminium li ama ts'ebetso ea li-castings, 'me taolo kapa pheliso ea liphoso tsa solidification e bohlokoa haholo ho ntlafatsa lihlahisoa tsa castings. Ha litlhoko tsa lits'ebetso tse phethahetseng tsa lits'epe tse kopantsoeng li ntse li hola le ho feta,

Patlisiso ea ho eketsa mefuta e meng ea likarolo tsa ho kopanya litšepe ho ntlafatsa litšobotsi tse felletseng tsa lits'epe tse kopantsoeng e se e tebile haholoanyane, mme mokhoa oa taolo ea motsoako oa motsoako o se o bohlokoa le ho feta. Liphoso tse tloaelehileng tsa ho tiisa likaroloana tsa aluminium tsa boenjiniere, joalo ka khethollo, ho qhekella ho chesang, microporosity, shrinkage, jj., Li hloka ho laoloa ho tsoa mohloling. Ho arabela tlhahiso e tala, setsi sa tlhahiso ea mofuta ona ho Changan Automobile's Jiangbei Engine Plant se amohela phepelo e tobileng ea aluminium e qhibilihisitsoeng, ka hona boleng ba phepelo e tobileng ea aluminium e qhibilihisitsoeng e sebelisoa e le motheo oa hore na aluminium e qhibilihisitsoeng e fihlela litlhoko. Sesebelisoa sa ho itlhoekisa sa sampole se sebelisetsoa ho bona bongata ba litekanyo tsa aluminium alloy, mohlahlobi oa spectrum o sebelisetsoa tlhahlobo ea 'mele le lik'hemik'hale, mme tlhahlobo ea K-mode e etsoa metsing a lehlakoreng la mochini oa aluminium khafetsa ho lekola bongata e lekanang, lik'hemik'hale le bohloeki ba motsoako oa aluminium.

Taolo ea hlobo

Tsamaiso, tlhahlobo ea letheba le tlhokomelo ea hlobo ke karolo ea ho lahla, mme boemo ba hlobo bo bohlokoa haholo ho boleng ba sehlahisoa. Setsi sa hlobo se entsoe ka tšepe e entsoeng ka tšepe. Nakong ea ente, metsi a aluminium a phalla ka phapusing ea khatello, sprue, semathi sa sefapano, le semathi se ka hare sa ente ea ente ho tloha tlase ho ea holimo. Sisteme eohle ea gating ke moralo o koetsoeng ho fokotsa phallo ea metsi ea aluminium. Bokantle ba hlobo bo buloa ka metsi ho leka-lekanya mocheso oa mocheso oa hlobo, mme likarolo tsohle tsa 'mele oa silindara li tiisoa ka nako e le' ngoe, 'me khase e setseng metsing a aluminium ea qhalakana ebe ea ajoa. Ka hohle kamoo ho ka khonehang, masoba a betlang a lokela ho tšeloa pele ka metsi a pholileng. Mokhoa oa khatello e phahameng ea ho futhumatsa kapa mokhoa oa ho futhumatsa metsi o ka khethoa ho latela litlhoko tsa 'nete. Metsi a pholileng a ka fihla kaholimo ho phini, hore karolo e kaholimo le eona e ka pholisoa.

Ts'ebetsong ea tlhahiso, mocheso oa hlobo o na le tšusumetso e kholo ho sehlahisoa le bophelo ba hlobo, mme mocheso o phahameng o tloaetse ho khomarela hlobo, bokaholimo ba ho betla bo bobebe, 'me masoba a shrinkage le mapetso a ka ba teng. Ka lebaka la ho khomarela hlobo, khohlano.

Lebotho le ntseng le eketseha la khohlano le mena habeli matla a lehae a etsang hore motsamao oa lehae oa hlobo o se ke oa nepahala hape o senya hlobo. Taolo ea mocheso oa hlobo ka kakaretso e beoa ho latela botenya ba lebota le ho ajoa ha phallo ea aluminium e qhibilihisitsoeng. Bophahamo ba metsi le metsi a pholileng a likarolo tse fapaneng tsa hlobo li ka fetoloa. Ho bata ka ntle ho hlobo le hona ho bohlokoa, 'me ho amana haholo le boemo, tataiso le ts'ebetso (nako) ea moemeli oa moemeli oa tokollo. Khetho, boholo le palo ea moemeli oa tokollo li tla ama ts'ebeliso ea hlobo le boleng ba sehlahisoa. Tlhokomelo ea hlobo e arotsoe ka tlhokomelo ea thibelo, tlhokomelo ea ho bolela esale pele le tlhahlobo ea mabala. Khetholla potoloho ea tlhokomelo ea thibelo ea hlobo ho latela boiphihlelo bo bokelletsoeng, lekola nako ea tlhokomelo ea ts'ebetso ho latela mmuso le ts'ebeliso ea hlobo, 'me u etse tlhahlobo ea letsatsi le letsatsi nakong ea ts'ebetso ea tlhahiso. Likahare tsa tlhokomelo li koahela sistimi e futhumatsang (metsi, oli, khase), sistimi e hloekisang, ho tiisa, ho hloekisa bokaholimo, joalo-joalo.

Ts'ebetso ea Paramente ea Tsamaiso

Taolo le godisiwa tsa thulaganyou e shoa-foromeletsoeng ke karolo ea bohlokoa ea tlhahiso ea shoa-foromeletsoeng, eo ka ho toba ama bokaholimo le boleng hare tsa likarolo shoa-lahla. The entsprechen tsa shoa thulaganyou e lahla haholo-holo kenyeletsa khatello ea, lebelo le nako.

Mekhahlelo ea taolo ea tekheniki e laoloa ka bongata ho netefatsa hore phallo, ho tiisa, le phapanyetsano ea mocheso oa tšepe ea mokelikeli li etsoa ka mokhoa o behiloeng, ho netefatsa boleng ba likarolo tse lahlehang. Boleng ba kahare ba ho betsa bo ela hloko liphetoho tsa mekhahlelo ea ente. Haeba khatello e le tlase haholo, ho lahla ho tla ba le masoba a mangata, shrinkage le likoli tse ling. Haeba khatello e phahame haholo, leha sebopeho sa ho betsa se le boima, se tla hlahisa mahlaseli a maholo le li-burrs, tse tla senya hlobo. . Nakong ea tlhahiso, ho bohlokoa hape ho bonts'a hore ntlha ea phetoho ho tloha butle ho ea ho ente e potlakileng le eona e bohlokoa haholo. Ho fetoha pele ho nako, aluminium e qhibilihisitsoeng e feta hara semathi se kahare mme e kenella ka mokokotlong ka lebelo le phahameng. Tsela e telele, e baka phallo e ferekanyang ea aluminium e qhibilihisitsoeng, e kenyang palo e ngata ea khase, mme ho bonolo ho theha litšitiso tse ling tse sa tloaelehang; E se e le morao haholo hore e ka fetoha, mokelikeli oa aluminium o lula ka phapusing ea khatello nako e telele, mocheso o tlase, ho bonolo ho hlahisa litšitiso tse batang, ho tšollela ho sa lekanang le mathata a mang. Ebile, ho latela pono ea anatomiki, boteng ba masoba le masoba a shrinkage ha ho betloa ho ke ke ha qojoa. Senotlolo ke ho fetola mekhahlelo ea ente e le hore khase e mokelikeli oa aluminium e ka tsoa hantle ka hohle kamoo ho ka khonehang, mme palo e setseng ea li-pores e qhalakanngoa le ho ajoa kahare. Ho kenella kahare ha karolo ho baka ho dutla ha ho betloa. Lebelo la ente le kenyelletsa lebelo la litebele (ke hore, lebelo la motsamao oa silindara ea ente) le lebelo la ho tlatsa (ke hore, lebelo la sekhahla).

Ho tlatsa lebelo ho bolela lebelo le lekanang la motsoako o qhibilihisitsoeng o fetang hara semathi se kahare, e leng parameter ea bohlokoa ho netefatsa boleng ba li-castings tse shoang. Nako ea ente e entsoe ka nako ea ente e liehang, nako ea ente e potlakileng, nako ea khatello, nako ea khatello, le nako ea ho boloka hlobo. Ha ho etsoa, nako ea ho ts'oara le nako ea ho boloka hlobo hangata e laoloa le ho ntlafatsoa hammoho, ho thoeng ke khatello ea nako le poloko ea hlobo. Ho lekane ho ts'oara khatello le nako ea ho boloka hlobo ho bolela hore ho lahleloa ha shoa ha ho holofale kapa ho otlolla nakong ea ho buloa ha hlobo le ho ntšoa. Boemo bo hlokahalang ba ho petsoha. Mekhahlelo ena ea bohlokoa e hloka ho beoa leihlo letsatsi le letsatsi le ho ntlafatsoa ka ho tsoelang pele ho latela maemo a ho betsa.

Tlhahlobo ea Lihlahisoa

Tlhahlobo ea ho lahla e kenyelletsa ponahalo le boholo ba tlhahlobo, tlhahlobo ea boleng ba kahare, tlhahlobo ea boemo ba sekoti pele ho nako, tlhahlobo ea botenya ba lebota, tlhahlobo ea silinda ea lebota, ho lahla kalafo ea mocheso, tlhahlobo ea hoqetela, ho latela litokisetso tsa basebetsi le litlhoko tsa 'nete tsa tlhahiso ho latela maqhubu a sa fetoheng. standard Ho lahla hoa tšoaneleha.

Mehlala ea tlhahlobo ea lits'ebetso e ka bona mathata ka nako mme ea sebetsa kapele, 'me e ke ke ea baka mathata a methapo ka lebaka la ho haelloa ke nako ha ho sibolloa ha mathata.

sutras

Tlhahiso ea li-die-casting ke ts'ebetso e batlang e rarahane, e kenyelletsa boleng ba aluminium e qhibilihisitsoeng, boemo ba hlobo e lahlang, likarolo tsa mochini o lahlang, ts'ebetso ea ho lahla le tlhahlobo ea lihlahisoa, jj. haufi-ufi amanang le boleng ba likarolo shoa-lahla. Tlhahisong ea batho ba shoang, ts'ebetso e khetha sephetho, ts'ebetso e ntle ea ts'ebetso e tla lebisa boleng ba sehlahisoa se tsitsitseng, 'me tlhahiso e laoloang ea bongata e tla tlisa melemo e meholo ea moruo.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Taolo ea Ts'ebetso ea ho lahla Die

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off