Boleng Control ka tima le litšila Mocheso mora betloa ha

Linaha ho potoloha le lefats'e li buella ka matla leano la ho fokotsa mesi le ts'ebeliso ea metsi: litsebi le likhamphani tse ngata tsa malapeng li nkile mehato ho tsoa maemong a fapaneng, mme ho tima mocheso oa litšila kamora ho betla ke e 'ngoe ea mehato ea bohlokoa.

Ho tima mocheso o setseng kamora ho betla ke kalafo e futhumatsang ea mocheso o phahameng oa kalafo kalafong ea mocheso. Lintlha [1, 2, 3] li na le litlhaloso tse ikhethang. Ho fihla hajoale, baetsi ba bangata ba malapeng ba sebelisitse ho tima mocheso oa litšila ka mora 'ona,' me baetsi ba 'maloa ba se ba qalile → ba theotse → ba theotsoe kapa ba phahamisa → ba theotsoe → ba ntse ba tsoela pele ho theoha ka lebaka la methati e tlase ea taolo ea boleng.

Ha e bapisoa le kalafo e tloaelehileng ea mocheso, ka lebaka la mocheso o phahameng oa mocheso le ho lahla deformation, moeli oa martensite o monyane oa lijo-thollo oa tšepe oa eketseha, segokanyipalo sa dislocation sea eketseha, haedrojene ea mantlha e ea phonyoha, mapetso a mantlha a folisoa le ho fokotsoa, le carbides li hasane ebile li na le pula. Ho thatafala ho tima ha likarolo tsa tšepe ho ntlafetse haholo (ka kakaretso ho ntlafalitsoe ka 10%). Nakong ea mocheso, likarolo tsa tšepe li na le moea o matla oa ho futhumatsa (mocheso o futhumetseng o ntlafatsoa ha o bapisoa le o tloaelehileng, ka kakaretso 20 ℃ -30 ℃).

- 1. Ha re ne re ea setsing sa kalafo ea mocheso ka mabaka a fapaneng, baenjiniere ba bangata le basebetsi ba mahlale ba ile ba etsa tlhahiso ea hore lisebelisoa tse tala le likarolo tse ling li lokile, re ka bolela esale pele ketsahalo e tla tima ea ho robeha kamora ho shebana? Ena ke kakaretso ea litlamorao tse tharo tse kholo (litlamorao tsena tse tharo tse kholo le tsona li na le boleng ba litšupiso bakeng sa ho amoheloa ha haedrojene le khatello ea ts'enyeho ea ts'oaetso ts'ebetsong ea kalafo ea bokaholimo).

- 1.1 Phello ea sebopeho sa lik'hemik'hale: Mohlala: tšepe ea khabone: boholo bo lekanang ф6, metsi a letsoai a tšoanang: tšepe ea 35, tšepe ea 40, tšepe ea 45, tšepe ea 50, tšepe ea 55, tšepe ea 60, tšepe ea 65, sephetho ke hore tšepe ea 45 ~ tšepe ea 60 e robeha ha bonolo. Hobane ho phahamisa khabone ea martensite, khatello ea maikutlo e ba kholo, mme boholo ba khabone bo ka ba 0.6%. Ha kh'habone ea tšepe e le holimo haholo, e tla ba ho feta 0.6%, 'me masala a A a tla hlahisoa, a liehisang tokollo e khethiloeng ea khatello ea martensite mme ha ho bonolo ho robeha. Ka kakaretso: Alloy steel ke eona e kotsing ea ho tima le ho petsoha. Mohlala: 42CrM. Ha boholo bo le kholo ф100, metsi a tima a ke ke a petsoha. Ena ke phello ea boholo e hlalositsoeng ka tlase.

- 1.2 Phello ea boholo: Mohlala: tšepe ea 45: ф1, ф2, ф3 ...... ф10 liphetho tsa ho tima li fumane hore ф6 ke eona e ka tingoang ka ho fetisisa. Hobane ka tlase ho ф6, ka kakaretso e ka tima ka martensite. Le ha ho le joalo, phetoho e akaretsang ea ф6 ho ea martensite e na le khatello ea maikutlo e kholo ka ho fetisisa, ka hona ho bonolo ho e robeha. . Ka hona, qala ka ho hlahloba index ea hardenability ea tšepe e itseng ea alloy, ebe o sheba sebopeho sa mosebetsi. Boholo bo kotsi ka ho fetisisa ke bofe?

- Matla a 1.3 Joalo, asymmetry ea libaka tse parolang, jj.

- 2. Khetho ea mocheso oa pele ho pholile: Motho e mong le e mong oa tseba hore lithollo tsa sebopeho sa martensite tse tima ka kotloloho ntle le ho futhumatsa kamora ho betloa li nyane. E ka kopana le litlhoko tsa hajoale tsa lapeng tse akaretsang tsa metallographic, mme ts'ebetso e boetse e ntle, empa bakeng sa likarolo tse kholo le tse rarahaneng, ho tima oli ho ke ke ha fihlela litlhoko, ho tima ka metsi kapa ho tima metsi ho tla baka ho petsoha habonolo. E tima oli, molemong oa ho thibela tšilafalo le ho boloka litšenyehelo, e lokela ho fetoloa hore e be setsi sa ho tima metsi ka hohle kamoo ho ka khonehang; 42CrM kopanong ea literaka tse boima tsa Steyr e hlahisitsoeng ke k'hamphani e Chongqing. Tšepe; Forgings tsa pele barrel toloki le ho leka-lekana theko, e itseng basebetsi botekgeniki ba khamphani unilaterally fetoloa pele ho tsidifatso ≈800 ℃ ho -850 ℃ tima tima, e leng ile a etsa hore ka bang 80% ea mapetsong kgolo tima. Ehlile, sesosa sa ho robeha ho ile ha hlahlojoa, 'me litaba tsa B tsa thepa e tala li fihlile ho 0.0022% ea tlaleho ea tlhahlobo ea Chongqing Construction Group, le Sehlopha sa Changan sa Setsi sa Bophirimela sa' mele le K'hemik'hale sa Lefapha la Libetsa se tlalehiloe 0.0042%. Tlhokomeliso: (1). Tekanyetso ea naha ea sesole GJB2720-1996, maemo a boron a tšepe ea boron ke 0.0005 ~ 0.0035%; (2). Maemo a tekheniki ea tšepe e hahelletsoeng ka khauta GB3077-88 boron standard ea boron steel ke 0.0005 ~ 0.0035%. Khethollo ea sehlopha ho ea boemong ba I ... hape ke le leng la mabaka. Bothata ba karohano e matla ea libaka ka lihlahisoa tse sa fihleheng ke ntlha ea bohlokoa bakeng sa mapetso (khethollo e boima e baka ho se lekane ha lik'hemik'hale le kalafo ea mocheso e felisang khatello ea khatello, e bonolo ho baka mapetso a tima);

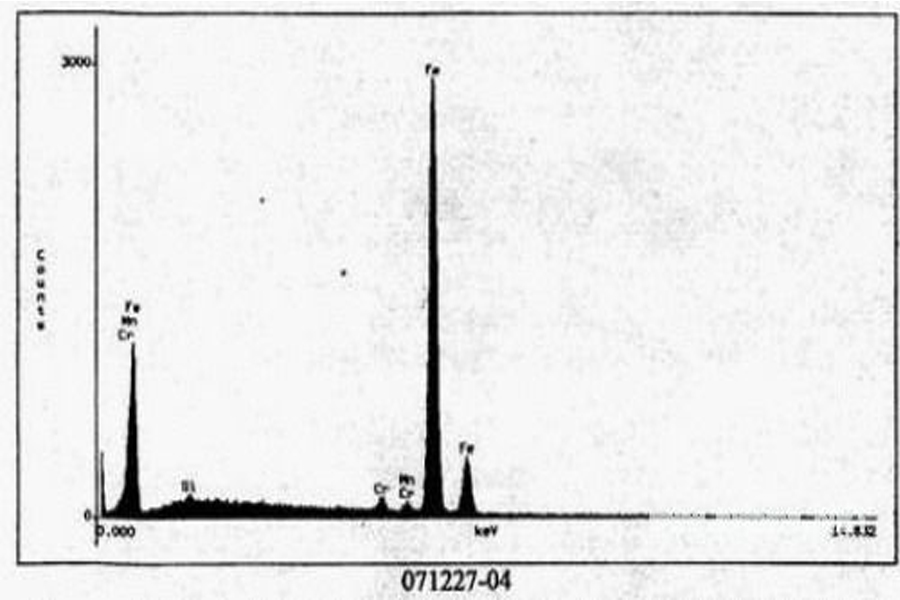

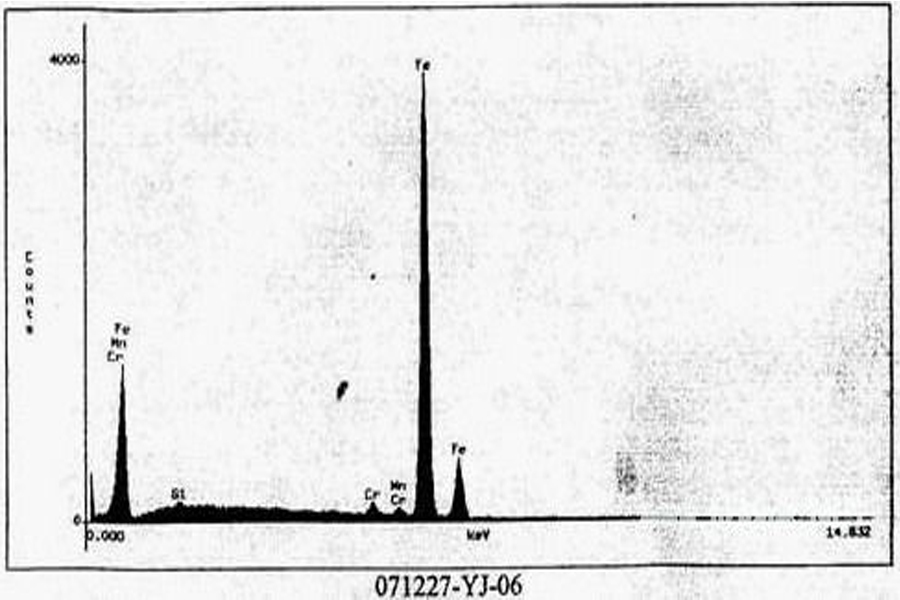

Ho sebelisa tlhahlobo ea matla a X-ray: Meeli ea lijo-thollo le matrix mohahong o hlophisitsoeng oa metallographic sampole li ile tsa hlahlojoa ka boleng le ka bongata le Vantage X-ray energy spectrum analyzer. Liphetho tsa tlhahlobo li bonts'itsoe ho Setšoantšo sa 1, Setšoantšo sa 2 le Tafole ea 1.

Leha ho le joalo, tšepe e 'ngoe ea sebōpi e na le likorone tse ngata tsa boron le khethollo e kholo. Khokahano ea PAG e fetoloa ka ho theola mocheso oa pele ho pholile, ka hona ha ho mapetso a etsahetseng.

Khetho ea mocheso oa pele ho pholile: Pele ho tsohle, ho latela litlamorao tse tharo tse boletsoeng kaholimo, khetholla karolo e tlokotsing haholo. Mehato ea ts'ebetso e lokela ho fetoloa ka nepo. Mohlala:

- (1) "Ka holim'a sefate se ka pele sa barrel" 42CrM. Pele ho pholile ≈800 ℃ ho tima PAG, mme ho bonolo ho laola HRC ho 48-52.

- (2) Fektheri e kholo ea mokokotlo oa lithuthuthu e Chongqing: e sebelisa mokhoa oa ho emisa le ho phomola kamora ho betla ho fihlela pele-pele ≈770 ℃ bakeng sa ho tima PAG, 'me e sebelisa mochini o phahamisang lebanta ho tlohela bokaholimo ntle le ho bata. ho itaola hanyane. Kamora ho koala, mocheso oa pele ho pholile oa tšepe ea 45 le 40Cr oa tšoana, empa mohopolo oa PAG o fapane.

- (3) Fektheri ea crankshaft e Chongqing: e sebelisa sesebelisoa se kenang seboping sa mocheso o sa feleng kamora ho se boloka se pholile ho -770 ℃ le ho tima tharollo e thehiloeng metsing ...

Khetho ea mokhoa oa ho tima: e ipapisitse le lipatlisiso tsa moraorao tse tsoang lefats'eng lohle, se bitsoang "shell shell". Litlhokahalo: Sekhahla sa pele sa phodiso ea pearlite se tlameha ho potlaka ho theha phello e thata ea khetla ka khatello ea maikutlo. Martensite e fetoha butle, e le hore mapetso a se ke a ba bonolo ho etsahala, 'me letoto la liphetho tsa lipatlisiso tse kang ts'ebeliso ea pholiso ea spray e laoloang ke lenaneo ho laola lebelo le lokeloa ke ho tsebahala le ho sebelisoa.

Metsi a timang a PAG-ⅢA le PAG-ⅢB a ntlafalitsoeng ke rona a ipapisitse le tlhoko e potlakileng ea mofuta o mocha oa lebelo la phetoho ea pearlite o ts'oanang le metsi a letsoai le metsi a alkaline, le lebelo la phetoho ea martensite le ts'oanang le oli, le nkang sebaka sa ho tima metsi le oli ho phola. Ho tima mokelikeli, 'me bokhoni ba ho thibela mafome bo lula matsatsi a fetang a 5. Ho etsa hore pearlite e fetohe e ts'oanang le metsi a letsoai le a alkaline, filimi ea bubble e thehiloeng ha mosebetsi o tima o kenella mokelikeli o tlameha ho qhoma ka potlako, e le hore sekhahla sa ho pholisa se potlake. Mohlala, nakong ea khatello ea 3%, sekhahla sa pele sa ho futhumatsa ha se tšoane le metsi a brine le alkaline, ke hore, litlatsetso tse kopaneng tse le 'ngoe kapa tse' maloa li tlameha ho eketsoa ho fihlela litlhoko tse kaholimo. Ebile, mohopolo oa PAG-ⅢA o fihla lebelo la pele kapele ho feta metsi le polyvinyl joala, mme lebelo la bobeli le lieha ho feta la baetsi ba bang tlasa mohopolo o tšoanang oa PAG ....... Ho chesa le ho tima mesh Lits'oants'o tsa lebanta: PAG-ⅢA e ntlafalitsoe le ho sebelisoa ka mekhoa e mengata ... Hajoale, ho na le sebopi sa mabanta a fetang 20 se sebelisoang ho pholletsa le naha; haholo-holo letlooeng lebanta sebōpi carburizing e rarolla bothata ba matheba a bonolo, thatafala ho lekaneng, deformation kholo ...…. Bokhoni ba ho thibela mafome bo feta matsatsi a 5, mme ts'ebeliso ea PAG e fokotsoe ka 20%.

Ho na le lits'ebetso tse 6 tsa PAG-ⅢA ho Chongqing. Hobane baetsi ba bang ba sebelisa mofuta ona, lihlahisoa tse ling tse ikhethang li rarolla mathata ao ho leng thata ho a rarolla ka media o mong, mme tlhahiso e ntse e eketseha. Molemong oa lekunutu, re ke ke ra ba tsebisa ka bonngoe. E sebelisoa haholo ho maqhubu a phahameng; shaft ea maqhubu a mahareng e tima koloi.

Ho tsepamisa mohopolo, mocheso le ho hlohlelletsa mokelikeli o tima

Yuniti eo re e sebeletsang: mohopolo oa PAG oa mokelikeli o tima, ho latela boemo ba tšepe, boholo ba likarolo, le litekanyo tsa kantle ho latela khopolo le boiphihlelo ba ho lokisa mohopolo oa eona ....

Mocheso oa metsi o laoloa ho 30-50 ℃, 'me letamo le leholo le potolohang kantle ho semela le sebelisetsoa ho potoloha phapanyetsano ea mocheso. Ho hlohlelletsa le ho potoloha hoa mali ke karolo ea bohlokoa.

Taolo ea thatafala kamora ho tima

Ho thatafala kamora ho tima ke sesupo sa bohlokoahali sa ho thibela ho petsoha: haholo-holo ha ho sebelisoa mokelikeli o tima metsi, ho phahamisa thatafalo, mapetso le keketseho ea ho fetoha ho bonolo ho etsahala. Nka 42CrMo. Mohlala, toloki ea axle e ka pele e lokela ho laoloa ho HRC48 ~ 52.

Tempering e lokela ho etsoa hang kamora ho tima

Nako ea ho tima le ho futhumatsa: ≤ Metsotso e 30 (Lihlahisoa tsa sesole le tsa sechaba tsa Chongqing Construction Group li hloka hore ho tima metsi ka lebaka la ho khutla ha metsi ho feta metsotso e 30, ebe e tla hlakoloa) Tlhahiso ea likarolo tse nyane e ka sebelisoa mochesong o tsoelang pele mela ea tlhahiso.

Sebopeho le litšobotsi tsa Metallographic kamora ho betla le ho tima

Ho betla mocheso, haeba ho hlokeha pele ho nako, lithollo li kholoanyane. Boitsebiso [1, 2, 3] ka lebaka la teko ea sengoloa sa baithuti sa ho fumana mangolo selemong seo, lipapiso tse nyane tse sebelisoang hangata ha li folisoe ebile ha li timme ka kotloloho, e leng se fanang ka motheo oa thuto ea bohlokoahali.

Ka boqapi le nts'etsopele ea batho: theknoloji ea hajoale ea tlhahiso e se e sebelisa ho futhumatsa le ho tima, mme boholo ba lijo-thollo ka kakaretso ke 2-3, empa ts'ebetso e ntle haholo. Nka sefate se ka pele sa axle se boletsoeng ka holimo e le mohlala: Lijo-thollo li nyane, 'me tlhaiso-leseling e tloaelehileng ea mokhathala ke hore e lumelloa ho robeha kamora makhetlo a 900,000,' me potoloho ea mokhathala ea pele le ho tima e thehiloe ho fihlela 1.3 makhetlo a limilione ntle le ho roba.

Hobaneng ha ho betloa, ho futhumatsa le ho tima mabele a mahoashe le ts'ebetso e ntle ea liteko? Lebaka le ka sehloohong ke hore meeli ea lijo-thollo tse likhutlo li nyane e eketseha mme sekhahla sa phallo se eketseha, se sa bonahaleng tlasa microscope e akaretsang ea tšepe. Ka hona, lihlopha tse ngata tsa ho betla le ho tima li tlameha ho "ruta mathata" le yuniti e fetileng ea tlhahlobo. Ka lebaka lena, ke taba e potlakileng bakeng sa boenjiniere le basebetsi ba mahlale ba seng ba ntse ba le maemong a metallographic ho potlakela ho theha le ho tima litekanyetso tsa metallographic ...

fihlela qeto e

- Ts'ebeliso ea mokhoa oa pele ho pholiso bakeng sa ho tima mocheso oa mocheso kamora ho betla Khetho ea mocheso oa pele ho pholile e ipapisitse le sebopeho le ts'ebetso e hlokahalang, ha feela e fihlela litlhoko, e ea tlase.

- Kamora ho betla, sethala se tima bakeng sa ho tima ka mocheso o setseng se khethoa hohle kamoo ho ka khonehang ho sebelisa sekhahla sa pele sa ho pholisa (sekhahla sa phetoho ea pearlite) ho theha phello e thata ea khetla. Mokelikeli oa bobeli o tima o nang le sekhahla se pholileng butle (sekhahla sa phetoho ea martensite).

- Ha lisebelisoa tse tala le likarolo tse ling li le hantle, hore na moralo oa pele ho nako ke ho hlahisa mapetso ho lokela ho utloisisa litlamorao tse tharo tse kholo.

- Sebopeho sa lik'hemik'hale le karohano ea lisebelisoa tse tala li tloaetse ho ba le mapetso. Ho khothalletsoa hore ha palo ea sebopi e fetotsoe, ho hlahisoe liteko tse nyane le tlhahlobo ea 100% ea matla a khoheli. Sebelisa monyetla oa ho fumana mehato ea ho thibela likhechana tse ngata ho etsahala.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Boleng Control ka tima le litšila Mocheso mora betloa ha

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off