Mefuta e Meraro ea Magnesium Alloy Injection Molding Technology

Theknoloji ea tšepe ea Magnesium alloy e fetohile setsi sa lipatlisiso lefapheng lena ka lebaka la melemo ea eona e mengata. Ho na le mefuta e meraro ea mahlale a theknoloji ea ente a hlahileng haufinyane: mokhoa o chesang oa semathi, mokhoa oa ho betla le moemeli oa tokollo ea phofo.

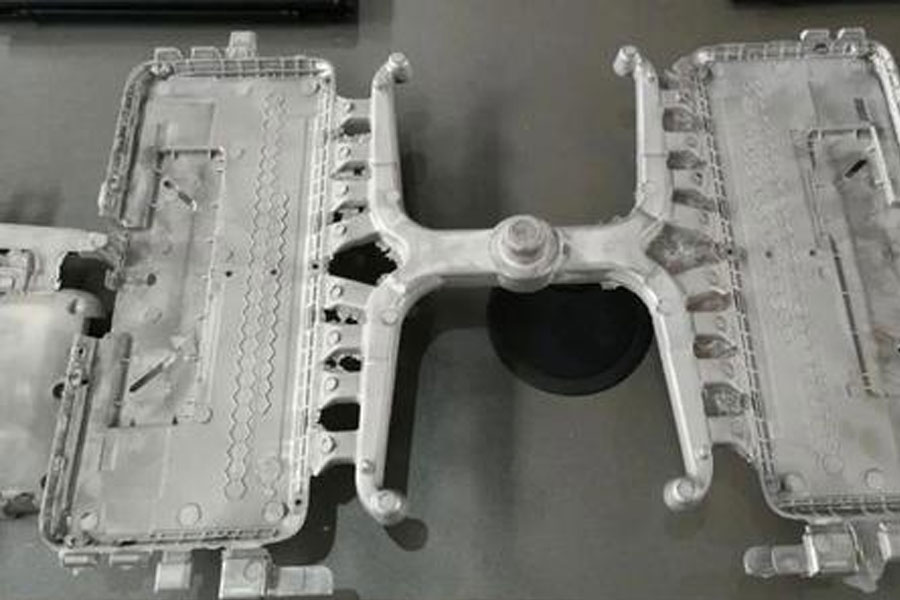

Molao-motheo oa polasetiki ea ente ke ho qhibilihisa mochini o qhibilihang o tlase ebe o o tlatsa ka hlobo ea tšepe ka lebelo le phahameng. Lisebelisoa tsa lihlahisoa tsa boholo ba lithollo tsa raese li fepuoa ho tloha boema-kepeng ba phepo, ebe li fepeloa ka silindara e futhumetseng mochesong o behiloeng ebe li isoa qetellong. Ka nako ena, matla a ho kuta a eketsoa ka ho potoloha terata, 'me motsoako o qhibilihisitsoeng o etsoa mobu o qhibilihisitsoeng, ebe o kenngoa ka hlobo ea tšepe ka lebelo le phahameng. Mocheso oa motsoako o qhibilihang o lula o le 560 ho isa ho 630 ° C, 'me sekhahla se tiileng sa karolo se laoloa. Seo Japan Steel e se hlahisang ke theknoloji ea patent ea American Thixomat Company, mme e etsa le ho rekisa mechini e etsang.

Ha e bapisoa le shoa lahla china Mokhoa, mofuta oa magnesium alloy molding o na le khatello e phahameng ea ho lahla, ka hona lithollo tsa kristale tse haufi le bokaholimo li hloekisitsoe, e le hore ho ka ba le ts'ireletso e phahameng ea ts'enyeho le matla a mochini. Ho ikatisa ha hlobo ea tšepe le hona ho molemo. Hobane mocheso oa motsoako o qhibilihisang o tlase ho 50 ho 70 ° C ho feta oa mokhoa oa ho lahla, phetoho ea boholo ba sehlahisoa se bopehileng ka mocheso oa mocheso e ka laoloa, ka hona ea eketsa bophelo ba ts'ebeletso ea filimi ea tšepe. Ntle le moo, ha ho sebelisoe sebōpi se qhibilihisang le khase e netefatsang lelakabe la SF6, ho phatloha le lerōle ho ke ke ha etsahala, 'me e fihlela litlhoko tsa polokeho le ts'ireletso ea tikoloho.

Morao-rao thekenoloji ente bōpa:

- Mokhoa o chesang oa semathi: Khafetsa futhumatsa semathi ka hlobo ea tšepe ho eketsa chai ea thepa ka ho boloka tšepe e qhibilihisitsoeng. E na le melemo ea ho khutsufatsa nako ea potoloho, ho sebetsana le hlobo e ngata, le ho etsa mochini o monyane mochini o monyane.

- Mokhoa oa ho lahla E na le monyetla oa ho se hlahise mapetso esita le ka lebelo le phahameng.

- Moemeli oa tokollo ea phofo: ka kakaretso fafatsa moemeli oa tokollo ea metsi, ho na le ts'ebetso ea moemeli oa tokollo ea fofang. Japan Steel Corporation e hlahisitse mokhoa oa ho monya leqhubu la moemeli oa tokollo ea phofo ka hlobo ea tšepe e koetsoeng. E na le phello ea ho khutsufatsa nako ea potoloho le ho ntlafatsa bophelo ba hlobo ea tšepe tikolohong e hloekileng.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape:Mefuta e Meraro ea Magnesium Alloy Injection Molding Technology

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off