Theknoloji ho fokotsa khohlano ea likarolo tsa enjene ea likoloi

E le mohato oa ho fokotsa khohlano lipakeng tsa likarolo tsa enjene ea likoloi, e ka aroloa ka mefuta e meraro e latelang.

E 'ngoe ke ho fokotsa sebaka sa ho ikopanya se pakeng tsa likarolo;

Ea bobeli ke ho etsa khatello ea kelello e tlase lipakeng tsa likarolo;

Ea boraro ke ho fokotsa mojaro oa ho kenya pakeng tsa likarolo.

Ho fokotsa bokaholimo ba likarolo ho thusa ho fokotsa kamano ea 'nete lipakeng tsa likarolo. Motheong oa ho se fetole ho hlohlona hoa pele ha bokaholimo, bokaholimo ba thepa ea ho nyalanya bo ka ntlafatsoa ka ho thellela, e leng ho ka fokotsang matla a khohlano.

Hajoale, boholo ba li-bores tsa silindara tsa enjene li hahiloe ka ho lahla li-bushings tse entsoeng ka tšepe e bohlooho ka hara block ea aluminium alloy cylinder. Mocheso oa tšepe o entsoeng ka tšepe (50W / (m · k)) o tlase ho feta oa aluminium (100W / (m · k)), 'me botenya ba tšepe e entsoe ke limilimithara tse' maloa. Haufinyane, molemong oa ho ntlafatsa phokotso ea mocheso ka phapusing ea mollo, ho sebelisoa matsoho a tšepe ho e-na le li-cylinder bores, mme tšepe ea cast e fafatsoa. Sena se ka ntlafatsa ho tiisoa ha segokanyimmediamentsi sa tšesaane leboteng la tube, se ntlafatsang phetiso ea mocheso le phetiso ea mocheso karolong ena. Phetiso ea mocheso.

Ntle le moo, joalo ka ts'ebetso e ikhethileng ea ho fafatsa ka mocheso, ho hlahisoa sekhahla se itseng sa lifilimi filiming, 'me likheo li pepesoa bokaholimo ba metsi, bo ka ntlafatsang ho boloka oli ka holim'a siling ea silinda.

Kaha ha ho hlokahale ho sebelisa letlooeng le tloaelehileng la silindara sa enjine ho netefatsa ho boloka oli, bokaholimo ba silinda bo ka boreleli. Ntle le melemo e boletsoeng kaholimo ea litšobotsi tse ntle tsa phetiso ea mocheso, e ka fokotsa le khohlano ho tloha moeling ho ea sebakeng se kopaneng sa lubrication.

Mabapi le ho ikopanya lipakeng tsa likarolo tse kaholimo tsa likarolo tsa karolo, bokaholimo bohle bo kenyeletsang li-protrusions bo sebelisoa e le sesebelisoa sa khatello ea moriri o tlase. E le mokhoa oa ho fokotsa ho ba thata le ho fokotsa khohlano feela, ho ka sebelisoa li-lubricants tse tiileng.

Ka ho khetheha, ha khatello ea bokaholimo e se holimo haholo, ho ka sebelisoa se bitsoang seaparo se bonolo, ke hore, granular molybdenum disulfide (MoS2) kapa graphite, 'me tetrafluoroethylene e le setlolo se tiileng e qhalakantsoeng ka polyamide resin (PAI) ka seaplane, kapa seaparo se fumanoang ka ho khantša ka kotloloho likaroloana tsa MoS2 khahlano le mosebetsi ka lebelo le phahameng. Mofuta ona oa ho roala o ka sebelisoa mokatong o kaholimo oa molamu oa piston le crankshaft e nang le alloy e nang le sebaka se seholo sa ho ikopanya le likarolo tsa enjine.

Ka lehlakoreng le leng, bakeng sa likarolo tse nang le khatello e phahameng ea bokaholimo, re hlahisitse seaparo sa DLC se nang le coefficient e lekanang e tlase ea khohlano joalo ka setlolo se tiileng ha se le thata ebile se sa tlotsoa, e le hore sephetho se tšoanang se ka fumanoa tlasa setlolo. Ho roala.

Sengoloa sena se tla tsebisa filimi ea DLC e se nang hydrogen (filimi ea DLC e senang hydrogen) le filimi ea DLC e nang le Si (Si-DLC). Tsena li fapane haholo le tsa nako e fetileng ka kalafo ea bokaholimo le moralo oa ho nahana ka hore seaparo ka bosona ha se na litšobotsi tse arohaneng, mme kopanyo ea oli e tlotsang kapa mongobo oa oli e tlotsang e ka fokotsa khohlano haholo.

Bakeng sa ho fokotsa khohlano lipakeng tsa lesale la piston le cylinder bore, lilemong tsa morao tjena, filimi ea CrN e sebelisitsoe ho khutlisa theknoloji ea pele ea Cr plating kapa nitriding. Botenya ba filimi ea Cr-plated e ka ba 100, ha botenya ba filimi ea CrN e nang le khanyetso e ntle ea ho roala ke 25 feela, e ka fokotsang bophahamo ba bophahamo ba filimi. Ka lebaka leo, ntle le ho fetola moeli o tlase oa tsitsipano ea lesale la piston, 'me feela ho beha boleng ba lipakeng hore bo be nyane, khohlano lipakeng tsa lesale la piston le silinda e ka fokotsoa.

Ntle le moo, kaha palo ea ho roala ha filimi ea CrN e nyane, ho kobeha hoa pele ha bokaholimo ba piston ho ka bolokoa, 'me leqhubu la mabitso le eketsehang ka lebaka la ho roala le ka hatelloa, le lona le thusang ho fokotsa khohlano.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Theknoloji ho fokotsa khohlano ea likarolo tsa enjene ea likoloi

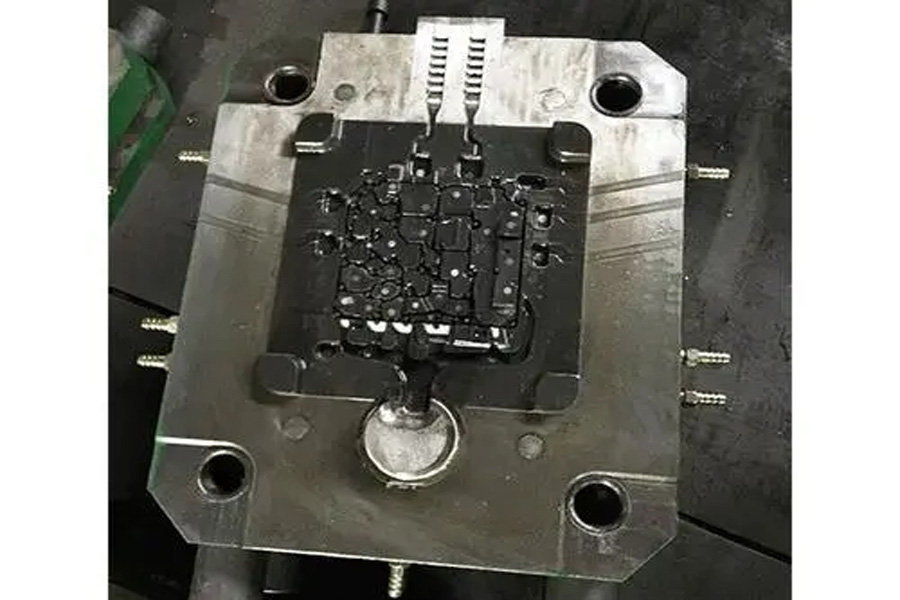

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off