Tšebeliso ea Theknoloji ea Aluminium Alloy Alloy Aluminium Alloy

Ka nts'etsopele e matla ea lihlahisoa tsa thekiso ea lifofane tsa machabeng, tšebelisano lipakeng tsa bareki le eona e se e le haufi. Bothata ba likarolo tsa ts'ebetso bo boetse bo fetohile ho tloha likarolong tsa pele tse le 'ngoe le tse nolofalitsoeng ho likarolo tse phahameng tse nang le mocheso o phahameng le likarolo tse nepahetseng tsa kopano. Le likarolo tse thata ho feta tsa mabokose a tšepe tse ngata. Ka lebaka la moeli oa boima ba sefofane, lisebelisoa tsa likarolo tse ngata tsa likhetla li sekametse ho lisebelisoa tsa aluminium alloy. Mohlala, limaraka tsa thepa ke L168, 6061, 2024 le lits'epe tse ling tsa machaba tse sebelisoang ke machabeng. Mefuta ena ea lisebelisoa e ka fihlela katleho e ntle ea ts'enyeho le ho roala ha e bata haholo. Li sebelisoa likarolong tse ling tsa lifofane tsa lehae tse kang Airbus, Boeing esita le C919 ea naha ea heso. Kajeno re ntse re ithuta ka mokhoa oa ho sebetsana le likhetla tsa aluminium alloy le porous, tšesaane-marako shoa lahla sebopeho se sa lekanang.

1. Tlhaloso ea Mathata a Ts'ebetsong

- Ho na le likoti tse 49 kaofela, 'me karolo e tšesaane ea lebota ke 3mm feela.

- Kakaretso ea masoba a 14 e na le mamello kahare ho 0.01mm, eo likoti tse 7 tsa kahare li nang le mamello ea ± 0.004mm.

- Mamello ea boemo ba likoti tse nyane tse 4 ha ea lokela ho feta 0.025mm.

2. Moralo oa Ts'ebetso

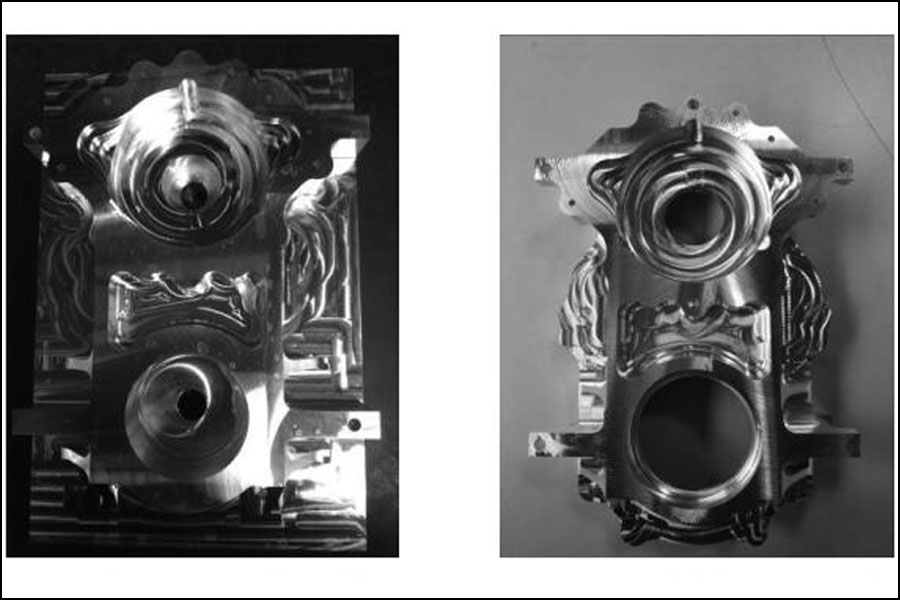

Ts'ebetso ea likarolo tse nang le mabota a masesaane e ka latela melaoana e akaretsang ea likarolo tsa likhetla, joalo ka ha ho bonts'itsoe ho Setšoantšo sa 2. hara tsona, litlhokahalo tsa hoqetela li ka fihlelleha ka lits'ebetso tse ling tsa ho phethela tse kang ho koala, ho sila, ho sila le ho bora ho latela ponahalo, sebopeho le litlhoko tsa mamello ea boholo ba karolo eo nakong ea ho qeta. . E ka sebetsoa ka kotloloho ho saese ea ho qetela haeba boemo ba ho nepahala ha lisebelisoa bo lumella. Ho qala ka lisebelisoa tse tala, likheo tsa ho lahla kapa li-block tsa aluminium tsa mantlha li ka sebelisoa ho qala ho sebetsana ho latela litlhoko tsa moreki. Ts'ebeliso ea castings e ka boloka nako e ngata ea ho sebetsana le mochini oa pele o thata.

- Ts'ebetsong e thata ea machining, botenya ba lebota le litekanyo tsa botebo e lokela ho ba 3mm e boloketsoeng machining ea ho qeta, mme 0.5mm e boloketsoe litekanyo tse nepahetseng tsa lesoba. Mabapi le likarolo tse ho Setšoantšo sa 1, ts'ebetso ea ho beha masoba bakeng sa ts'ebetso ea morao-rao e tlameha ho etsoa ka nako e ts'oanang. Sebelisa ts'ebetso ea ho beha masoba le lipini bakeng sa ts'ebetso ea likarolo tse ling. Mokoti oa ts'ebetso o khothaletsoa hore o etsoe ka sekhahla sa 60 ° lipakeng tsa marako a mabeli a karolo ho netefatsa matla a ts'oanang le botsitso nakong ea ts'ebetso ea morao-rao. Boholo ba lesoba ke 5mm, mme mamello ke +0.005. Haeba maemo a lisebelisoa a sa e lumelle ho sebetsana le mahlakore ka bobeli ka nako e le 'ngoe, bonyane likoti tse ling tse peli tsa ts'ebetso le masoba a mabeli a ho beha ka lehlakoreng le leng le le leng a lokela ho eketsoa ho eketsa botsitso ba likarolo molemong oa ho phethela hamorao.

- Boemong ba ho qeta halofo, litekanyo tsohle tse nang le mamello e kholo ho feta 0.01mm li ka sebetsoa sebakeng sa tsona, ho kenyeletsoa botenya ba likarolo tsa lebota, sekoti le litekanyo tse ling tse nang le mamello e kholo ho feta ± 0.1mm. Bakeng sa ho boloka nako ea ts'ebetso, 0.5mm e ka bolokeloa boholo bohle ba likoti. E etsoa nakong ea ho qeta. Hoa lokela ho hlokomeloa mona hore likarolo li hloka ho ts'oaroa kalafo ea khatello ea maikutlo nakong ea lihora tse 4 kamora ho qeta ho qeta ho qeta, ho seng joalo kamora ho itšeha ho hoholo, khatello ea maikutlo e tla lokolloa mme karolo e tla holofala.

- Ho latela lisebelisoa tse fapaneng tsa likarolo le boholo ba likarolo, khetha mocheso o fokotsang khatello ea maikutlo le nako ea ho tlosa khatello ea mochini oa likarolo le ho fana ka netefatso e sebetsang bakeng sa ho phethela hamorao.

- Bakeng sa ho netefatsa ts'ebetso e phahameng le botsitso ba ho phethela, kamora ho qeta ho phethela, ho ka etsoa ts'ebetso e le 'ngoe ea ho sila lifahlehong tse peli tsa karolo ho netefatsa hore ho otloloha ha lifahleho tse peli ho ka hare ho 0.01mm.

- Boemong ba ho phethela, mokhoa oa ts'ebetso o ka khethoa ho latela maemo a lisebelisoa tsa ona. Ha ho na le setsi sa machining sa li-axis tse tharo feela, ho hlokahala hore mochini o qete boholo ba sebaka se le seng pele. Haeba ho khonahala, khetha ho sebelisa sesebelisoa se chesang se chesang shank clamping; ho latela litlhoko tsa sets'oants'o, boemo ba masoba a mane bo tlameha ho netefatsoa hore e tla ba 0.025mm Ka hona, kamora ho sebetsana le bokaholimo, o hloka ho sebelisa masoba a mabeli holim'a sebaka sena e le ho beha masoba ho fapana le masoba a ts'ebetso ao re a bolokileng nakong mochini o thata. Ke ka tsela ena feela moo lesoba la 0.025 le ka netefatsoang ka nepo. Tekanyo ea boemo

- Ha ho khonahala, setsi sa machining sa axis tse nne se ka sebelisoa ho sebetsana le libaka tse peli ka kotloloho. Ehlile, sete ea lisebelisoa tse bataletseng lia hlokahala bakeng sa ts'ehetso. Ka liteko tse ngata, molemong oa ho fokotsa ho fetoha ha likarolo nakong ea ho ts'oara le ho sebetsa, ts'oarello e bataletseng e hloka ho phekoloa mocheso feela, HRC ≥ 35, 'me boreleli ba sebaka se holimo se ka hare ho 0.01mm. Kamora hore sethala sa poleiti se kengoe, se lekanye ebe o se fetosa hore se be ka hare ho 0.01.

3. Litaba Tse Hlokang Tlhokomelo

- Kaha likarolo ka botsona li thata ho sebetsoa, 'me mamello e thata haholo, ka hona litlhoko tsa tikoloho ea ts'ebetso le tsona li beha litlhoko tse holimo. Ka lebaka la lisebelisoa tsa karolo ka boeona ke likarolo tsa aluminium, 'me kakaretso ea likarolo tsa likarolo e telele, setsidifatsi se holim'a metsi se lokela ho hloekisoa kamora hore likarolo li sebetsoe; ka nako e ts'oanang, nakong ea ts'ebetso le ho emela ts'ebetso, ho kgothaletswa ho sebelisa mekotla e netefatsang mafome bakeng sa ho e lokisa. tshireletso.

- Boemong ba ho phethela likarolo, bo anngoeng ke mamello ea likarolo, likarolo li tlameha ho etsoa tikolohong e nang le mocheso oa kamore ea 20 ° C ± 1 ° C.

- Bakeng sa ho lekanya masoba a nepahetseng, ho kgothaletswa hore o sebelise pontsho ea dijithale ea micropeter e kahare ea mehlahare e meraro ho e bapisa le gauge ea lesale, mme o sebelise gauge ea polasetiki ea alloy e hlophisitsoeng bakeng sa litekanyo tse thusang ho netefatsa hore litekanyo tsa likarolo li tšoaneleha.

Qetello

Hoo e ka bang selemo se le seng sa tlhahiso ea liteko le phetoho, ho 'nile ha hlahlojoa litsela tse batlang li felletse tsa theknoloji ea ho sebetsa, e fanang ka boiphihlelo ba bohlokoa ba ho sebetsana le likarolo tsa mofuta ona.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape:Tšebeliso ea Theknoloji ea Aluminium Alloy Alloy Aluminium Alloy

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off