Likarolo tsa Likoloi

Likoloi tsa Lisebelisoa tsa Likoloi Ka Ho lahla le Cnc Machining

IATF 16949 ETSA HLOKOMETSO HO ETSA LITLHAKU TSE KHOLO LE CNC HO ETSA LITLHAKU TSE KHOLO

E le motheo oa indasteri ea likoloi, likarolo tsa likoloi ke lintlha tse hlokahalang ho ts'ehetsa nts'etsopele e tsitsitseng le e phetseng hantle ea indasteri ea likoloi. Haholo-holo, nts'etsopele ea hajoale e ikemetseng le boiqapelo ba indasteri ea likoloi li ntse li hola ka matla le ka botlalo, mme e hloka sistimi e matla ea likarolo ho e tšehetsa. Baetsi ba likarolo tse kholo tsa likarolo tsa likoloi ba sebelisitse theknoloji ea Aerospace, Aviation le Elektroniki ho likarolo tsa likoloi le likopano. Theknoloji ea polokeho, theknoloji ea elektroniki, theknoloji e bolokang matla le ts'ireletso ea tikoloho li sebelisitsoe haholo likoloing. Haholo-holo, mahlale a macha a emeloang ke theknoloji ea tlhaiso-leseling ea elektroniki ha a sebelisoe haholo ho lihlahisoa tsa likoloi, empa a boetse a atoloha ho fihlela maemong a fapaneng joalo ka nts'etsopele le moralo, tlhahiso ea liteko, tlhahiso le tsamaiso; ha e sebelisoe feela likarolong tse ikemetseng tsa koloi, empa hape e sebelisitse kopano ea Sisteme.

Lisebelisoa tse ikemetseng tsa likoloi le boqapi ba mahlale bo hloka likarolo le likarolo joalo ka motheo. Boits'oaro bo ikemetseng ba likarolo le likarolo li na le matla a ho khanna bakeng sa nts'etsopele ea indasteri ea makoloi. Li na le tšusumetso ebile lia sebelisana. Ha ho na mofuta o ikemetseng oa likoloi tse felletseng, mme sistimi e matla ea likarolo R & D le boiphihlelo ba k'hamphani li thata ho phatloha. Ntle le ts'ehetso ea sistimi e matla ea likarolo, ho tla ba thata bakeng sa lihlahisoa tse ikemetseng ho ba kholo le ho ba matla.

Na o hloka likarolo tsa likoloi moetlo ho tloha ha motho a e-shoa?

Joaloka moetsi ea netefalitsoeng ea TS 16949, Minghe o nkile karolo lefapheng la machining le ho shoa likarolo tsa likoloi. Basebetsi ba rona ba nang le boiphihlelo ba ka u fa tšebeliso ea khotheishene bakeng sa ntho eo u e hlokang bakeng sa china kapa esita le mose ho maoatle ho theha koloi. Litaba tse monate ke mefuta e mengata ea likarolo tsa likoloi, hape re na le likarolo tsa likoloi tsa boleng bo holimo le tse theko e tlase tse nang le boiphihlelo ho likoloi tsa kantle ho naha tsa likoloi, joalo ka Toyota, Mazda hammoho le Hyundai.

Ikopanye le moenjiniere oa karolo ea likoloi kajeno ho buisana ka lintlha tse ikhethang tsa merero ea hau e rarahaneng.

Likopo tsa 1.Commonly Automotive Components.

Boiphihlelo ba MINGHE ha bo tšoane le boqapi, nts'etsopele le tlhahiso ea tharollo ea mochini o nepahetseng le lisebelisoa tsa ho betla cnc bakeng sa lits'ebetso tse fapaneng tsa likoloi, ho kenyeletsoa empa ho sa lekanyetsoe ho:

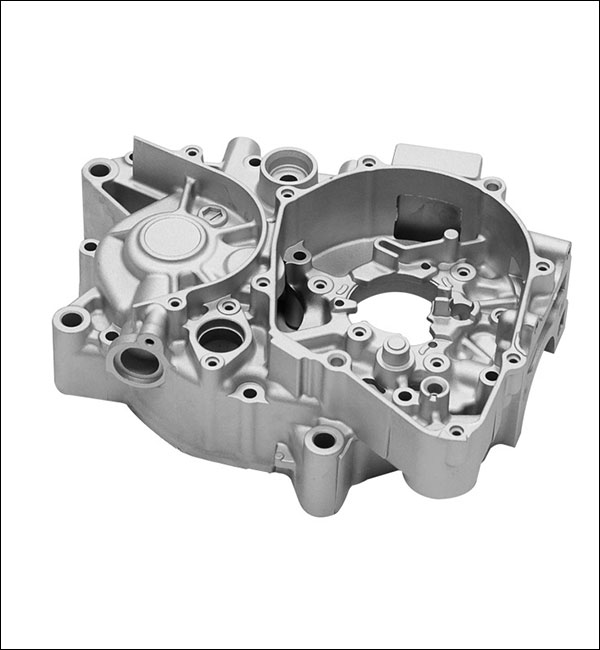

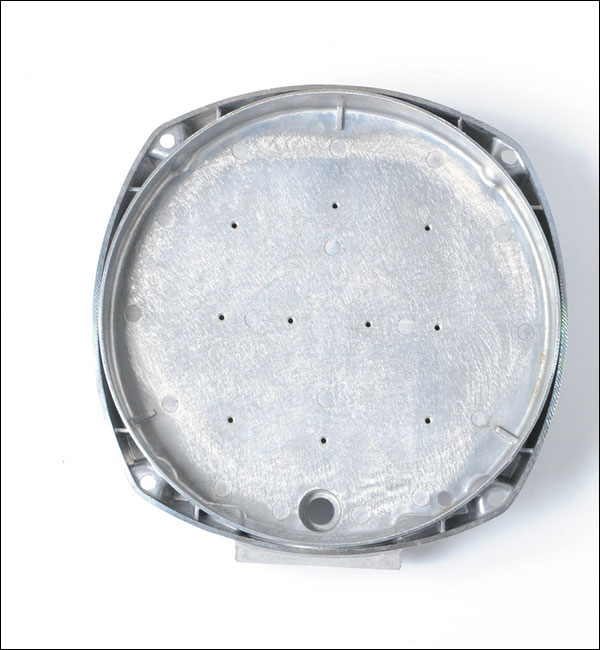

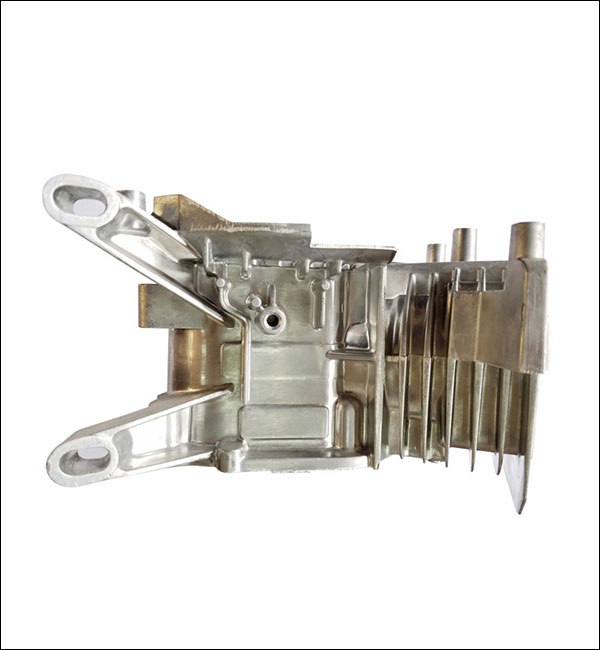

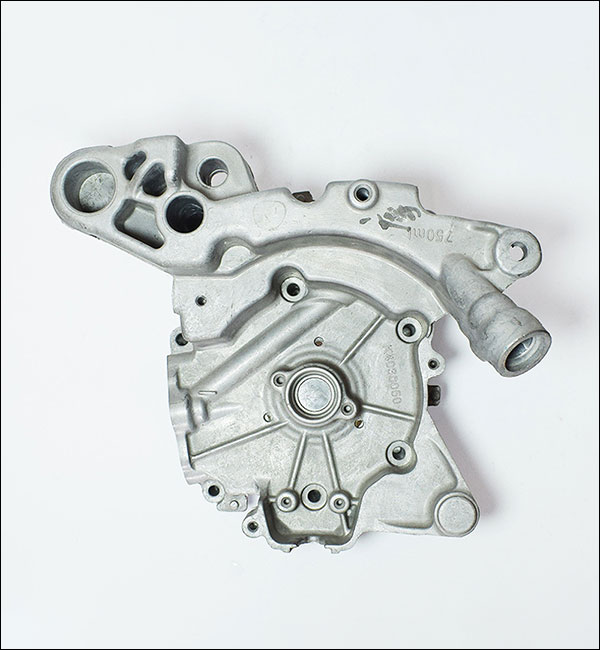

- Lisebelisoa tsa Enjene: 'Mele oa' mele, enjene, kopano ea enjene, pompo ea mafura, nozzle ea mafura, tensioner, block cylinder, e nang le sehlahla, pompo ea metsi, ente ea mafura, gasket, camshaft, valve, crankshaft, kopanyo ea molamu, piston, lebanta, Muffler, carburetor, mafura tanka, tanka ea metsi, fan, tiiso ea oli, radiator, sefa

- Lisebelisoa tsa Powertrain: phetiso, kopano ea lever switch, reducer, clutch, pneumatic, lisebelisoa tsa motlakase, lisebelisoa tsa motlakase, lisebelisoa tsa elektroniki, clutch disc, sekoaelo sa clutch, bokahohle ba bokahohle, bolo ea bokahohleng, bolo ea bolo, bolo Cage, poleiti ea clutch, nyeoe ea phetisetso, ho nka matla- off, synchronizer, selika-likoe sa synchronizer, lebanta la nako, phapang, phapang ea phapang, meno a fapaneng a disc, meno ea lipolanete, sesebelisoa sa mabili, flange, lebokose la li-gear, shaft e bohareng, li-gear, fereko ea li-gear, koloi ea shaft, drive shaft flange, lebanta

- Lisebelisoa tsa Brake System: Lieta tsa mariki, liphaephe tse robehileng, li-disc, li-brake, li-compressor, likopano tse robehileng, likopano tse robehileng, li-cylinders tsa brake, li-cylinders, li-control tsa ABS-ECU, lipompo tsa motlakase oa motlakase, Brake camshaft, brake roller, pini ea brake tellurium, phetoho ea brake letsoho, kamore ea Brake, booster ea vacuum, kopano ea brake ea letsoho, kopano ea ho paka makoloi, kopano ea ho paka makoloi e sebetsang

Lisebelisoa tsa Tsamaiso ea Tsamaiso: Lisebelisoa tsa ho tsamaisa, lenonyeletso la bolo ea maoto, lebidi la setereng, li-steering gear, booster ea kopano, molamu oa thaere, pompo ea motlakase ... - Lisebelisoa tsa ho Tsamaea: li-axle tse ka morao, sistimi ea ho emisa moea, boima ba 'mele, poleiti ea tšepe, lebili, selemo sa lekhasi, halofo ea li-axle, absorber e makatsang, kopano ea lesale la tšepe, halofo ea li-axle, matlo a axle, foreimi, kopano, sethala sa mabili, Borokho ba pele

Lisebelisoa tsa lisebelisoa tsa motlakase: li-sensors, mabone a likoloi, li-buzzers, li-spark plugs, libeteri, li-wiring, li-relays, li-audio, li-alarm, li-regulator, barekisi, li-starters (li-motor), lisebelisoa tse sa sebetseng, lisebelisoa tsa likoloi, li-switch, fuse, lifter ea khalase, jenereithara coil, motlakase oa ho khantša, mochini oa thotheletso - Mabone a Likoloi: mabone a khabisitsoeng, mabone a mabone, mabone a ho batla, mabone a siling, mabone a khahlanong le moholi, mabone a lisebelisoa, mabone a brake, mabone a mohatla, mabone a mabone

- Phetoho ea koloi: lipompo tsa mabili, liraka tsa marulelo a koloi, mabokose a marulelo a koloi, li-winches tsa motlakase, likoloi tsa koloi, li-sunroofs, lisebelisoa tsa ho kenya molumo, li-bumpers, mapheo a moea a sa fetoheng, li-fenders, lipeipi tsa ho qeta, moruo oa mafura

- Ts'ireletso Le Khahlano le bosholuSenotlolo sa mabili a tsamaisang, senotlolo sa mabili, sesebelisoa se khahlanong le bosholu, seiponeng se shebileng morao, sistimi ea pono e ka morao, kh'amera, lebanta la setulo, sehatisi sa ho khanna, senotlolo sa taolo e bohareng, GPS, ABS, radar e khutlisetsang morao

- Koloi Hare: K'hapete ea koloi (sebaka sa maoto) sekoaelo sa lebidi la setereng, bolo ea boere ea booster, likharetene, likere tsa letsatsi ...

- Kantle ea Koloi: sekoaelo sa mabili, setikara sa 'mala oa' mele, sepoleiti sa laesense, sekoaelo sa pula le pula .. Sisteme ea ho lekola khatello ea mabili, decoder, bonts'a, intercom ea koloi ...

- 'Mele le Lisebelisoa: wiper, khalase ea koloi, lebanta la setulo, mokotla oa moea, phanele ea seletsa, static antenna static belt ...

- Lisebelisoa tsa Tlhokomelo: Sesebelisoa sa tlhoekiso ea lisebelisoa tsa tšepe, sesebelisoa se fetolang mabili ...

- matla Tools: Punch ea motlakase, sethunya sa moea o chesang, jack ea motlakase, wrench ea motlakase ...

2.Hobaneng ha o re khetha bakeng sa merero ea hau ea likarolo tsa likoloi

Minghe o na le boiphihlelo bo fetang lilemo tse 30 a thusa baetsi ba likoloi ho rala likarolo tse bolokang chelete tsa likoloi. Ha o sebelisana 'moho le Minghe o ka fumana melemo e latelang ho tsoa ts'ebetsong ea rona ea ho betsa lefu:

- Ts'ebetso ea ho betsa ea Minghe e na le likhatiso tse 40 ho tloha ho 250 ho isa ho 3000 ton. Re amohela tse ling tsa likarolo tsa likoloi tse boima ka ho fetesisa ho latela bophahamo ba modumo, boholo ba karolo, le ho rarahana. Ka lebaka la bokhoni ba rona ba boenjiniere le ho etsa mohlala, re tsejoa ke bareki ba rona re le k'hamphani e ka fokotsang ho rarahana ha karolo, mme ea etsa hore ts'ebetso ea tlhahiso e sebetse hantle.

- Minghe e ka thusa ho kopanya phepelo ea hau ea thepa ka ho fana ka lits'ebeletso tse felletseng tsa lits'ebeletso tsa ho lahla batho ho kenyelletsa ts'ehetso ea boenjiniere, moralo oa hlobo le ho rarolla mathata, ho sebetsana le lisebelisoa.

- Minghe ke Moetsi oa Casting ea Die Casting ea netefalitsoeng mme o na le boiphihlelo bo pharalletseng ba ho rala le ho etsa likarolo tsa zinki le aluminium ho litlhaloso tsa boleng ba likoloi.

- Ka mechine ea khatiso ho tloha ho e meholo ho isa ho e menyenyane, re na le bokhoni ba ho etsa likarolo tsa likoloi tsa boholo bohle, ho tloha sekoahelong sa belofo ho ea ho matlo a maholo a literaka.

- Re netefalitsoe ke ITAF 16949 mme re ka fana ka karolo ea tlhahiso bakeng sa lits'ebetso tsa sesole le tsa Aerospace.

- Theknoloji ea rona e thusa ho tsamaisa tlhahiso. Suite ea rona ea mahlale e kenyelletsa AutoCAD, Pro-E, MAGMAsoft®, CAD / CAM le ts'ebelisano ea EDI, le FARO Laser Scanning.

Lisebelisoa tse tloaelehileng tsa 3.Ka tloaelo bakeng sa Likarolo tse Ikhethileng tsa Likoloi Ka Ho Lahleloa ha Die

Minghe o na le boiphihlelo ba ho u thusa ho khetha motsoako o nepahetseng bakeng sa ts'ebeliso ha ho hlokahala. Re sebelisa lits'epe tse fapaneng tse fapaneng ho fihlela maemo a mocheso, tšebeliso le matla. Tse ling tsa lits'epe tse kopantsoeng hangata tsa aluminium le zinc-aluminium li kenyelletsa AL360, AL380, AL383, le AL413, ZA-8, ZA-12, ZA-27. Re boetse re fana ka lits'ebeletso tsa ho betsa re sebelisa K-Alloy. Ntle le li-alloys tse fapaneng, PHB e fana ka lits'ebeletso tsa ho phethela ho kenyeletsoa ho roala phofo, pente e metsi, ho phatloha ha sefaha, EMI / RFI ho sireletsa, chrome le tse ling.

Tšebeletso e 'ngoe ea Lihlahisoa bakeng sa Likarolo tse Ikhethileng tsa Likoloi

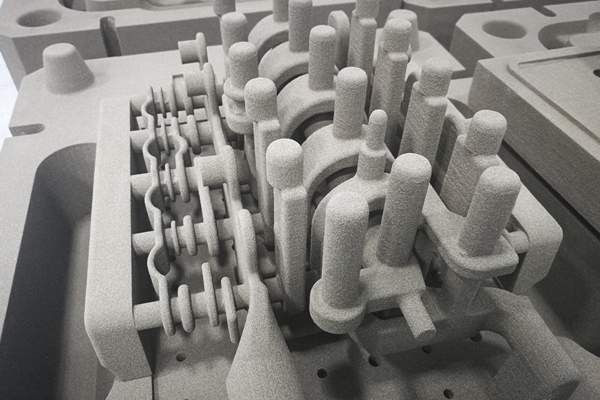

Ntle le moo, Minghe o boetse a fana ka machining ea CNC, ho betsa matsete, ho betsa lehlabathe le lits'ebeletso tse ling tse amanang le likarolo tsa likoloi tse ikhethileng.

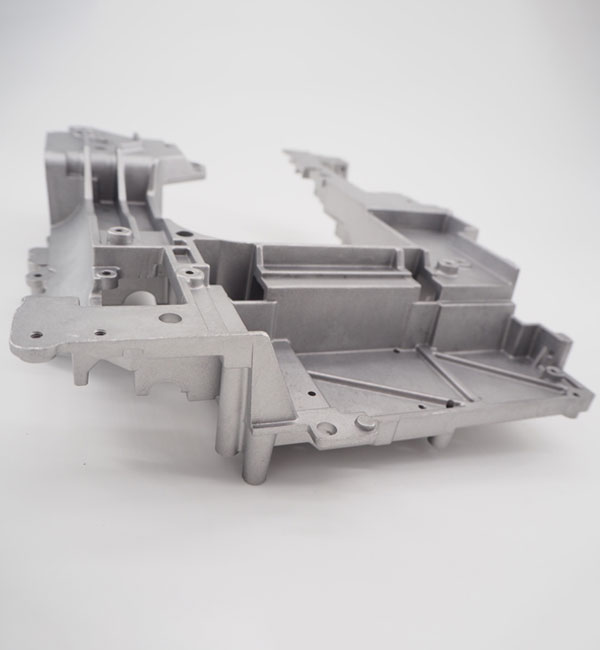

| Likarolo tsa Cnc Machining tsa Likoloi |

|

| Likarolo tsa Investment tsa ho lahla likoloi |

|

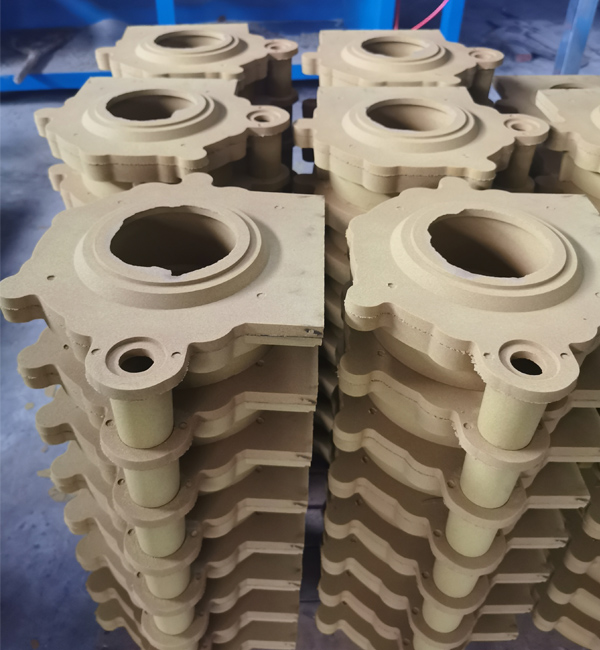

| Likarolo tsa Likoloi tsa Lehlabathe |

|

5.Bokhoni ba tlhahiso ea rona ea Precision bakeng sa likarolo tsa likoloi

Ntle le moo, Minghe o boetse a fana ka machining ea CNC, ho betsa matsete, ho betsa lehlabathe le lits'ebeletso tse ling tse amanang le likarolo tsa likoloi tse ikhethileng.

AL360, AL380, AL383, le AL413, ZA-8, ZA-12, ZA-27, Aluminium A356,

Botšo, Bosoeu, Silevera, Bokhubelu, Tlhaho, Botala, Botala le mebala e fapaneng e le litlhoko tsa moreki

Ho qhomisa lehlabathe, ho qhomisa ka lithunya, ho bentsa, anodizing, oxidation, electrophoresis, chromate, ho roala phofo le ho penta

Ho lahla Die, Mold Manufacturing, CNC ho sila, CNC ho reteleha, CNC ho cheka

Likarolo tse ka hare, hlobo ea Die, literene tsa ho khanna, li-Piston, li-Camshafts, lijaja tsa Turbo, mabili a Aluminium, li-Starter, lihlooho tsa Moqomo, li-axles tsa Drive, Li-gearbox, Likarolo tsa Tloaelo le Likopo tsa Prototyping

Litaba tsa Minghe tsa likarolo tsa likoloi

U na le moralo oa karolo e rarahaneng, Khamphani ea Minghe Casting e ka u thusa ho e fetola. Ka thepa e nepahetseng, tsebo e matla ea tekheniki, le ho tsepamisa mohopolo boleng .. Ho tloha ho meralo ea lisebelisoa ho fihlela qetellong le ho romelloa, Minghe Casting e netefatsa hore projeke e ngoe le e ngoe e phethetsoe ka mokhoa o phahameng le hore liodara tsa hau li fanoa ka nako, nako le nako .

Eya ho Bona Litaba Tse Eketsehileng tsa Likarolo tsa Likarolo >>>

Khetha Tšebeletso e Khabane ka ho Fetisisa ea Likoloi

Hajoale, likarolo tsa rona tsa likoloi tsa ho betla le tsa machining li romelloa Amerika, Canada, Australia, United Kingdom, Jeremane, Fora, Afrika Boroa le linaheng tse ling tse ngata lefats'eng lohle. Re ISO9001-2015 e ngolisitsoeng hape e netefalitsoe ke SGS.

Custom china shoa lahla tšebeletso e fana ka li-castings tse tšoarellang le tse theko e tlaase tse fihlellang litlhaloso tsa hau bakeng sa likoloi, bongaka, sepakapaka, elektroniki, lijo, kaho, polokeho, likepe tsa leoatle le liindasteri tse ling. Potlako ho romella potso ea hau kapa ho kenya litšoantšo tsa hau ho fumana qotsulo ea mahala ka nako e khuts'oane haholo thekiso@hmminghe.com ho bona hore na batho ba rona, lisebelisoa le lisebelisoa li ka tlisa boleng bo holimo joang bakeng sa theko e ntle bakeng sa projeke ea hau ea likarolo tsa likoloi.

Re fana ka litšebeletso tsa ho lahla ho kenyelletsa:

Litšebeletso tsa Minghe Casting li sebetsa ka ho betsa lehlabathe, ho betla tšepe, ho tsetela matsete ho lahlile foam

Ho Cast Cast

Ho Cast Cast ke moetlo oa ho betla o sebelisang lehlabathe e le sesebelisoa sa mantlha sa ho etsa mefuta. Ho betsa matla a khoheli ho sebelisoa ka bongata bakeng sa hlobo ea lehlabathe, le ho lahla ka khatello e tlase, ho lahla centrifugal le lits'ebetso tse ling ho ka sebelisoa ha ho na le litlhoko tse ikhethang. Ho lahla lehlabathe ho na le mefuta e mengata e fapaneng ea ho ikamahanya le maemo, likotoana tse nyane, likotoana tse kholo, likotoana tse bonolo, likotoana tse thata, likotoana tse le 'ngoe le bongata bo boholo li ka sebelisoa.

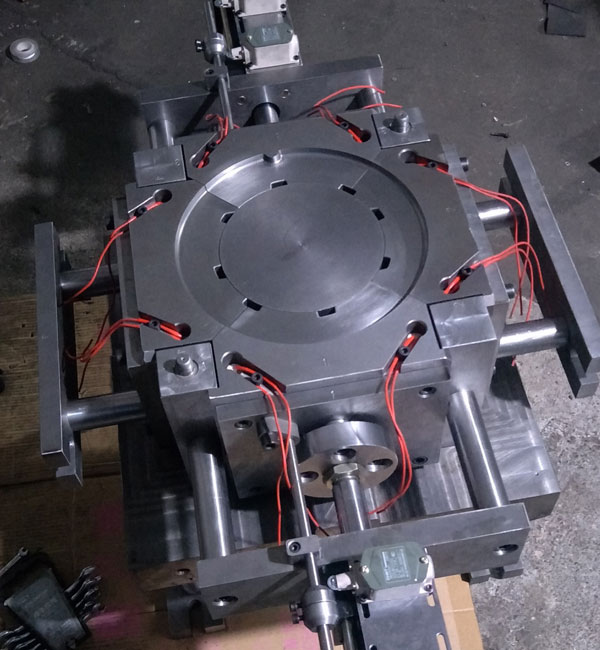

Sa Feleng hlobo lahla

Sa Feleng hlobo lahla ba na le bophelo bo bolelele le ts'ebetso e phahameng ea tlhahiso, ha ba na ho nepahala hantle feela 'me ba boreleli, empa hape ba na le matla a phahameng ho feta ho lahla lehlabathe mme ha ba na monyetla oa ho senyeha ha tšepe e tšoanang e qhibilihisitsoeng. Ka hona, tlhahiso ea bongata ba litšepe tse mahareng le tse nyane tse se nang litšepe, ha feela ntlha ea ho qhibiliha ea thepa e sa phahama haholo, hangata ho lahloa ka tšepe ho khethoa.

Ho etsa chelete

Monyetla o moholo oa ho lahla lichelete ke hobane castings dipeeletso na phahameng tlhakore ho nepahala le holim fihlela qetellong, ba ka fokotsa machining mosebetsi, empa siea e nyenyane machining kabelo ka likarolo le ditlhoko tse phahameng. Ho ka bonoa hore ts'ebeliso ea mokhoa oa ho lahla lichelete e ka boloka lisebelisoa tse ngata tsa mochini le ho sebetsana le lihora tsa motho, mme ea boloka lisebelisoa tse tala tsa tšepe.

Lahlehileng bubble lahla

E lahlehetsoe ke foam ke ho kopanya boka ba parafini kapa mefuta ea foam e ts'oanang le boholo ba sebopeho le sebopeho ho lihlopha tsa mohlala. Kamora ho hlatsoa le ho omisa liphahlo tse haelloang, li patoa lehlabatheng le ommeng la quartz bakeng sa mohlala oa thothomelo, 'me li tšeloa ka khatello e mpe ho felisa mohlala. , Sesebelisoa sa mokelikeli se maemong a mohlala mme se theha mokhoa o mocha oa ho lahla kamora ho tiisa le ho pholisa.

Ho Casting

Die foromeletsoeng ke tšepe tshepe thulaganyou e, e tšoauoa ka ho sebelisa khatello e phahameng ea tšepe entsoeng ka ho qhibilihisoa sebelisa cavity ea hlobo ena. Hlobo hangata e entsoe ka lits'epe tse kopantsoeng ka matla a holimo, 'me tšebetso ena e batla e tšoana le ho bopa ente. Boholo ba batho ba shoang ha ba na tšepe, joalo ka zinc, koporo, aluminium, magnesium, lead, tin le li-alloys tsa lead-tin le lits'epe tsa tsona. Minghe e bile moetapele oa China shoa lahla tšebeletso ho tloha 1995.

Ho ts'oaroa ha Centrifugal

Ho ts'oaroa ha Centrifugal ke mokhoa le mokhoa oa ho kenya tšepe ea mokelikeli ka hlobo e potolohang ka lebelo le leholo, e le hore tšepe ea mokelikeli e sisinyehe ho tlatsa hlobo ebe e etsa tšepe. Ka lebaka la motsamao oa centrifugal, tšepe ea mokelikeli e ka tlatsa hlobo hantle tseleng ea maqhubu mme ea theha sebaka sa mahala sa ho betsa; e ama ts'ebetso ea kristale ea tšepe, ka tsela eo e ntlafatsa likarolo tsa mochini le tsa 'mele tsa ho betsa.

Lahla Khatello e tlase

Lahla Khatello e tlase ho bolela hore hlobo hangata e behiloe kaholimo ho tsoana le sebopi se tiisitsoeng, 'me moea o hatelletsoeng o hlahisoa ka har'a tsoana le' mele ho baka khatello e tlase (0.06 ~ 0.15MPa) holim a tšepe e qhibilihisitsoeng, hore tšepe e qhibilihisitsoeng e nyolohe ho tsoa phala e nyolohelang ho tlatsa hlobo le taolo Mokhoa oa ho betsa o tiileng. Mokhoa ona oa ho betsa o na le phepo e ntle le sebopeho se teteaneng, ho bonolo ho lahla li-castings tse kholo tse nang le marako a tšesaane, ha ho na risers, le sekhahla sa ho hlaphoheloa ha tšepe sa 95%. Ha ho na tšilafalo, ho le bonolo ho elelloa itsamaise.