lephaka lahla

Lahla lephaka ke eng

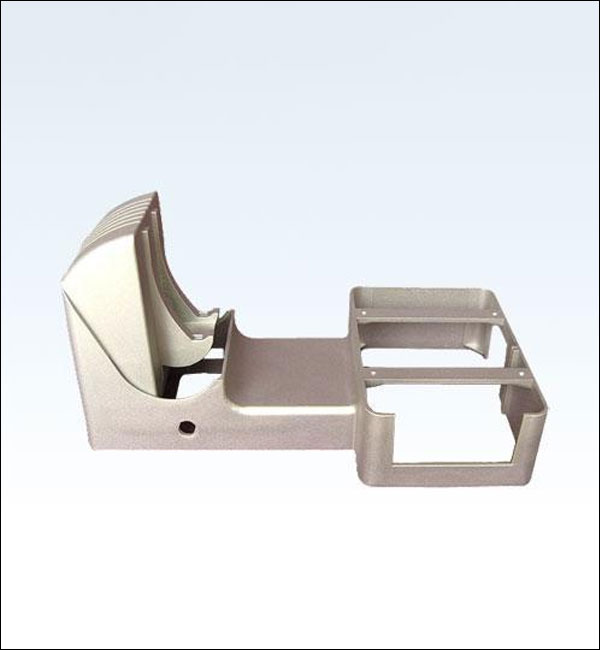

lephaka lahla ke mokhoa oa ho lahla oo tšepe e qhibilihisoang, e tšolleloang le ho khabisoa ka phapusing e lephaka. Lepolanka lahla ka fokotsa dikahare khase ka tšepe le ho thibela tšepe ho kena moea. Mokhoa ona o ka hlahisa casting e khethehileng ea tšepe ea tšepe le likarolo tse bonolo haholo tsa oxidized titanium. Lepolanka lahla ho bitsa chelete e ngata, 'me hangata ho sebelisoa ho qhibiliha lits'epe tse kopantsoeng le castings boleng bo phahameng le khatello e phahameng ea mouoane le bonolo volatilization tahlehelo. Hlobo ha ea lokela ho ba le volatiles.

Lahla lephaka ka kakaretso arotsoe ka mefuta e 'meli:

- lephaka fire lahla

- lephaka shoela'ng foromeletsoeng.

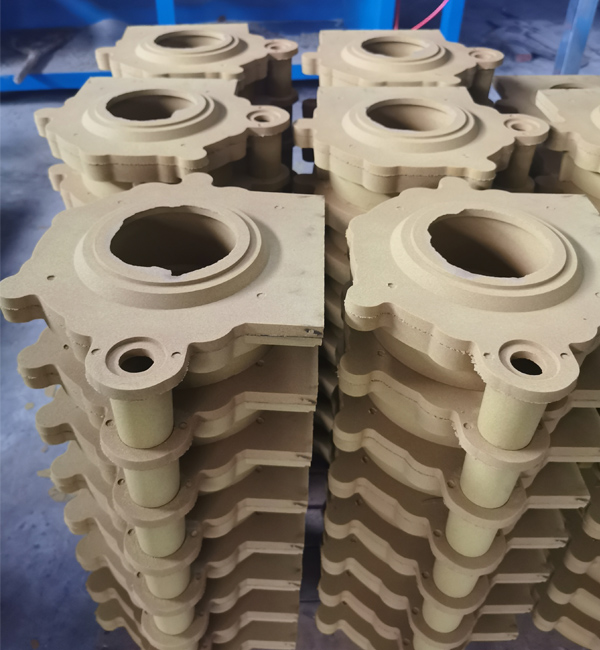

Molao-motheo oa ho lahla lephaka ke ho sebelisa filimi ea polasetiki ho tiisa lebokose la lehlabathe, 'me u sebelise pompo e hloekisang ho hula moea kahare ho hlobo ho theha phapang ea khatello lipakeng tsa kahare le kantle ho hlobo, e le hore lehlabathe le ommeng le tiisitsoe ho theha mokoti o hlokahalang. Monyetla o moholo ka ho fetesisa oa mokhoa oa V o fapaneng le oa ho lahla lehlabathe ke hore ha o sebelise likhomaretsi, ka hona o fokotsa mosebetsi oa ho sebetsana le lehlabathe, mme palo ea basebetsi ea ho etsa mohlala le ho lahla lehlabathe le thetsitsoeng e fokotsehile haholo, 'me sekhahla sa ho hlaphoheloa ha lehlabathe la khale le ka fihla ho feta 95%.

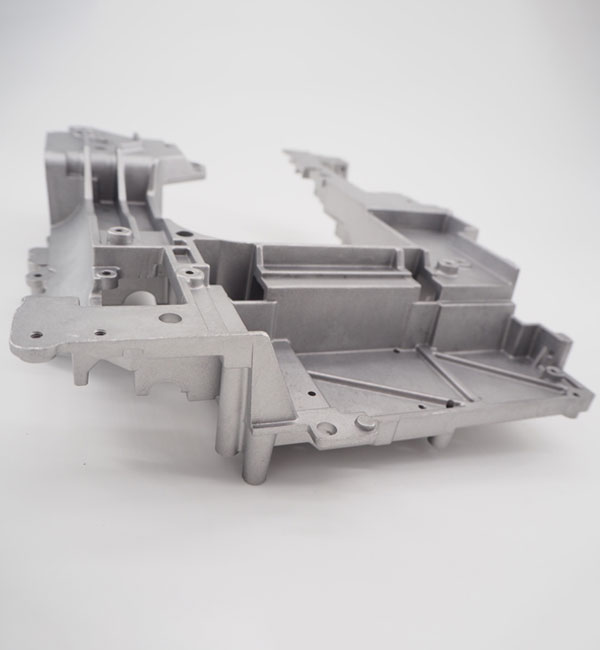

The castings hlahisoang ke lephaka thulaganyou e foromeletsoeng ke tsa boleng bo botle, bokaholimo boreleli, kemiso e hlakileng, boholo nepahetseng, junifomo thatafala, 'me ka katleho atolosa bophelo ba tšebeletso ea castings ea

Haeba u batla ho fumana tharollo e sa bitseng chelete e ngata le e potlakileng bakeng sa litlhoko tsa hau tsa tlhahiso, Minghe e ka ba khetho e ntle ho uena. Ho ipapisitsoe le liphihlelo tse pharalletseng le boiphihlelo ba botsebi, lits'ebeletso tsa rona tsa ho lahla lesela li a fumaneha bakeng sa mefuta e mabeli le e tlase ho isa bophahamong bo phahameng ba tlhahiso. Ho sebetsa le Minghe, mochini oa maiketsetso o tsoetseng pele ka ho fetesisa o re lumella ho iqapela likarolo tsa ho qhala le lihlahisoa tse sebetsang hantle haholo ha re ntse re boloka boleng ba boleng bo holimo, bo bolokang chelete le nako bakeng sa bareki ba rona haholo. Lisebelisoa le lisebelisoa tse fapaneng tsa bokaholimo li re nolofalletsa ho etsa khetho e ntle bakeng sa projeke ea hau, lisebelisoa tse tala tse kenyeletsang empa li sa lekanyetsoe ho tšepe e sa hloekang, aluminium, koporo, koporo, tšepe, polasetiki, jj.Polishing, pente, sandblasting, plating, anodizing, ho roala phofo le lits'ebeletso tse ling tsa ho phethela li tlisa boleng bo holimo ba likarolo tsa hau. Ts'ebeletso ea rona ea ho qhekella e reretsoeng ho fana ka litšila e fana ka likarolo tse tšoarellang le tse theko e tlaase tse fanang ka lintlha tsa hau bakeng sa likoloi, bongaka, sepakapaka, elektroniki, lijo, kaho, ts'ireletso, leoatle le liindasteri tse ling. Potlako ho romella potso ea hau kapa ho kenya litšoantšo tsa hau ho fumana qotsulo ea mahala ka nako e khuts'oane.

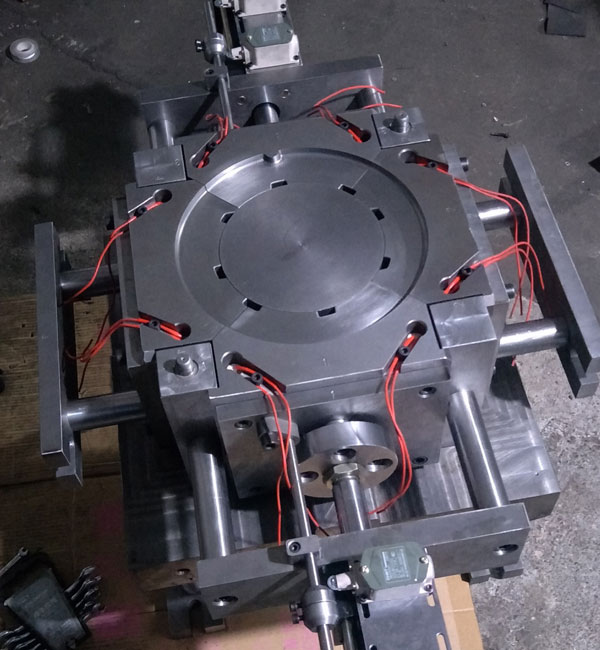

Ts'ebetso ea ho lahla lephaka

- - Mohlala: Beha paterone poleiting ea sekoti. Ho na le masoba a mangata a tsoang holima paterone. Ha lephaka le sebelisoa, masoba ana a thusa ho etsa filimi ea polasetiki hore e khomarele paterone.

- - Ho futhumatsa filimi: Filimi ea polasetiki e nang le sekhahla se phahameng sa sekhahla le sekhahla se phahameng sa polasetiki e futhumetse ebile e nolofatsoa ke hitara. Mocheso oa ho futhumatsa ka kakaretso o pakeng tsa 80 le 120 ° C.

- - Ho theha filimi: Koahela filimi e nolofalitsoeng holim'a mofuta, ka lesoba la moea, tlasa matla a ho leleka a 200 ~ 400mmHg, etsa hore filimi e be haufi le mohlala.

- - Beha lebokose la lehlabathe: Kamora ho fafatsa pente le ho omisa (ts'ebetso ha e hloke ho ba joalo), beha lebokose le khethehileng la lehlabathe motšoantšong o koahetsoeng ke filimi.

- - Ho hlaba lehlabathe le ho tlanya: Eketsa lehlabathe le ommeng ka botlalo bo botle ba ho tlatsa le boholo ba phatsa ea 100-200 letlooeng ka lebokoseng la lehlabathe, ebe o etsa vibrate e nyane ho etsa hore lehlabathe le kopane ka bongata.

- - Sekoahelo sa sekoahelo: Bula senoelo sa sekhahla, boreleli holim 'a lera la lehlabathe,' me u koahele ka filimi ea polasetiki ho koala lebokose la lehlabathe.

- - Ho ntšoa ha hlobo: botlolo e ntšitsoe sebakeng 'me hlobo e thatafatsoa tlasa khatello ea sepakapaka ka thuso ea filimi e koahelang bokaholimo ba botlolo. Ha hlobo e lelekoa, ho lokolloa lephaka la lebokose le lebe la khatello ho lokolla matla a adsorption a template ho filimi, ebe lebokose le holimo le lelekoa ho tlatsa hlobo.

- - Ho koaloa lebokose le koetsoeng: Pele ho koala lebokose, tšepe ea mantlha le e batang e ka theoloa ho latela litlhoko tsa ts'ebetso, 'me mabokose a kaholimo le a tlase a ka kopanngoa ho etsa hlobo e nang le sesepa se tšollang le sekoti, se tšeloang kahare boemo ba lephaka.

- - Ka ntle ho lebokose le lehlabathe le oelang: Kamora nako e loketseng ea ho pholisa, lephaka lea hlakoloa 'me khatello e tloaelehileng ea khutlisoa, e le hore lehlabathe le phallang la mahala le phalle,' me ho lahloa ho hloekileng ho se na hlama ea lehlabathe le lehlabathe la mochini. Lehlabathe le ka sebelisoa hape kamora ho phola.

Mefuta e fapaneng ea Tšoantšiso ea Boemo ba ho lahla lephaka

Minghe o lula a latela litlhoko tsa moreki le litekanyetso tsa ts'ebeletso tsa k'hamphani. Khokahanong efe kapa efe ea moralo oa hlobo, kopano ea hlobo, ho lokisa hlobo, tlhahiso ea liteko tsa hlobo, ts'ebetso ea ho lahla, jj., Ho na le baenjiniere ba inehetseng ba u bolokang fonong;

| 1. Mohlala▶ |

| 2.Filimi-Heating ▶ |

| 3.Film etsang ▶ |

| 4.Beha Lebokose la Lehlabathe▶ |

| 5.Ko lora▶ |

| 6.Ho tsukutla lebokose▶ |

| 7.Boiler ▶ |

| 8.Mocheso Machine▶ |

| 9.Intelligent tsoelang pele lahla▶ |

| 10.Vacuum lahla Machine▶ |

| 11.Vacuum lahla Machine▶ |

| Sistimi ea Vacuum ea 12▶ |

Litaba tsa Minghe tsa ho lahla lephaka

Litšebeletso tsa masela tsa Minghe li fumaneha bakeng sa boqapi ho 'nete ebile li tlase ho hlahisa lihlahisoa tse phahameng tsa likarolo tsa hau tsa ho lahla, lehlabathe, likarolo tsa ho lahla lichelete, likarolo tsa tšepe, likarolo tse lahliloeng tsa foam le tse ling.

Eya ho Bona Litaba Tse Eketsehileng tsa Likarolo tsa Likarolo >>>

Khetha Mofani oa Molemo ka ho Fetisisa oa Lahla

Hajoale, likarolo tsa rona tsa ho lahla lephaka li romelloa Amerika, Canada, Australia, United Kingdom, Jeremane, Fora, Afrika Boroa le linaheng tse ling tse ngata lefats'eng lohle. Re ISO9001-2015 e ngolisitsoeng hape e netefalitsoe ke SGS.

Ts'ebeletso ea rona ea ho qhekella e qhekellang e fana ka litšepe tse tšoarellang le tse theko e tlase tse fihlelang lintlha tsa hau bakeng sa likoloi, bongaka, sepakapaka, elektroniki, lijo, kaho, ts'ireletso, likepe tsa lewatle le liindasteri tse ling. Potlako ho romella potso ea hau kapa ho kenya litšoantšo tsa hau ho fumana qotsulo ea mahala ka nako e khuts'oane haholo thekiso@hmminghe.com ho bona hore na batho ba rona, lisebelisoa le lisebelisoa li ka tlisa boleng bo holimo joang bakeng sa theko e ntle bakeng sa projeke ea hau ea ho lahla.

Re fana ka litšebeletso tsa ho lahla ho kenyelletsa:

Litšebeletso tsa Minghe Casting li sebetsa ka ho betsa lehlabathe, ho betla tšepe, ho tsetela matsete ho lahlile foam

Ho Cast Cast

Ho Cast Cast ke moetlo oa ho betla o sebelisang lehlabathe e le sesebelisoa sa mantlha sa ho etsa mefuta. Ho betsa matla a khoheli ho sebelisoa ka bongata bakeng sa hlobo ea lehlabathe, le ho lahla ka khatello e tlase, ho lahla centrifugal le lits'ebetso tse ling ho ka sebelisoa ha ho na le litlhoko tse ikhethang. Ho lahla lehlabathe ho na le mefuta e mengata e fapaneng ea ho ikamahanya le maemo, likotoana tse nyane, likotoana tse kholo, likotoana tse bonolo, likotoana tse thata, likotoana tse le 'ngoe le bongata bo boholo li ka sebelisoa.

Sa Feleng hlobo lahla

Sa Feleng hlobo lahla ba na le bophelo bo bolelele le ts'ebetso e phahameng ea tlhahiso, ha ba na ho nepahala hantle feela 'me ba boreleli, empa hape ba na le matla a phahameng ho feta ho lahla lehlabathe mme ha ba na monyetla oa ho senyeha ha tšepe e tšoanang e qhibilihisitsoeng. Ka hona, tlhahiso ea bongata ba litšepe tse mahareng le tse nyane tse se nang litšepe, ha feela ntlha ea ho qhibiliha ea thepa e sa phahama haholo, hangata ho lahloa ka tšepe ho khethoa.

Ho etsa chelete

Monyetla o moholo oa ho lahla lichelete ke hobane castings dipeeletso na phahameng tlhakore ho nepahala le holim fihlela qetellong, ba ka fokotsa machining mosebetsi, empa siea e nyenyane machining kabelo ka likarolo le ditlhoko tse phahameng. Ho ka bonoa hore ts'ebeliso ea mokhoa oa ho lahla lichelete e ka boloka lisebelisoa tse ngata tsa mochini le ho sebetsana le lihora tsa motho, mme ea boloka lisebelisoa tse tala tsa tšepe.

Lahlehileng bubble lahla

E lahlehetsoe ke foam ke ho kopanya boka ba parafini kapa mefuta ea foam e ts'oanang le boholo ba sebopeho le sebopeho ho lihlopha tsa mohlala. Kamora ho hlatsoa le ho omisa liphahlo tse haelloang, li patoa lehlabatheng le ommeng la quartz bakeng sa mohlala oa thothomelo, 'me li tšeloa ka khatello e mpe ho felisa mohlala. , Sesebelisoa sa mokelikeli se maemong a mohlala mme se theha mokhoa o mocha oa ho lahla kamora ho tiisa le ho pholisa.

Ho Casting

Die foromeletsoeng ke tšepe tshepe thulaganyou e, e tšoauoa ka ho sebelisa khatello e phahameng ea tšepe entsoeng ka ho qhibilihisoa sebelisa cavity ea hlobo ena. Hlobo hangata e entsoe ka lits'epe tse kopantsoeng ka matla a holimo, 'me tšebetso ena e batla e tšoana le ho bopa ente. Boholo ba batho ba shoang ha ba na tšepe, joalo ka zinc, koporo, aluminium, magnesium, lead, tin le li-alloys tsa lead-tin le lits'epe tsa tsona. Minghe e bile moetapele oa China shoa lahla tšebeletso ho tloha 1995.

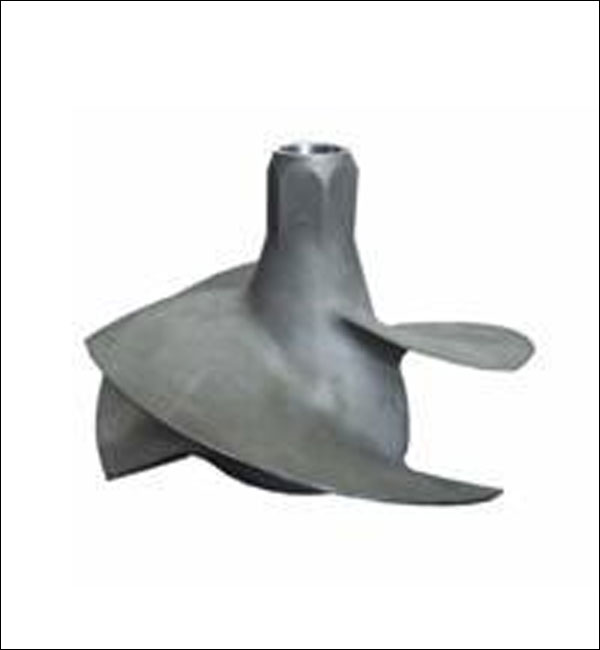

Ho ts'oaroa ha Centrifugal

Ho ts'oaroa ha Centrifugal ke mokhoa le mokhoa oa ho kenya tšepe ea mokelikeli ka hlobo e potolohang ka lebelo le leholo, e le hore tšepe ea mokelikeli e sisinyehe ho tlatsa hlobo ebe e etsa tšepe. Ka lebaka la motsamao oa centrifugal, tšepe ea mokelikeli e ka tlatsa hlobo hantle tseleng ea maqhubu mme ea theha sebaka sa mahala sa ho betsa; e ama ts'ebetso ea kristale ea tšepe, ka tsela eo e ntlafatsa likarolo tsa mochini le tsa 'mele tsa ho betsa.

Lahla Khatello e tlase

Lahla Khatello e tlase ho bolela hore hlobo hangata e behiloe kaholimo ho tsoana le sebopi se tiisitsoeng, 'me moea o hatelletsoeng o hlahisoa ka har'a tsoana le' mele ho baka khatello e tlase (0.06 ~ 0.15MPa) holim a tšepe e qhibilihisitsoeng, hore tšepe e qhibilihisitsoeng e nyolohe ho tsoa phala e nyolohelang ho tlatsa hlobo le taolo Mokhoa oa ho betsa o tiileng. Mokhoa ona oa ho betsa o na le phepo e ntle le sebopeho se teteaneng, ho bonolo ho lahla li-castings tse kholo tse nang le marako a tšesaane, ha ho na risers, le sekhahla sa ho hlaphoheloa ha tšepe sa 95%. Ha ho na tšilafalo, ho le bonolo ho elelloa itsamaise.