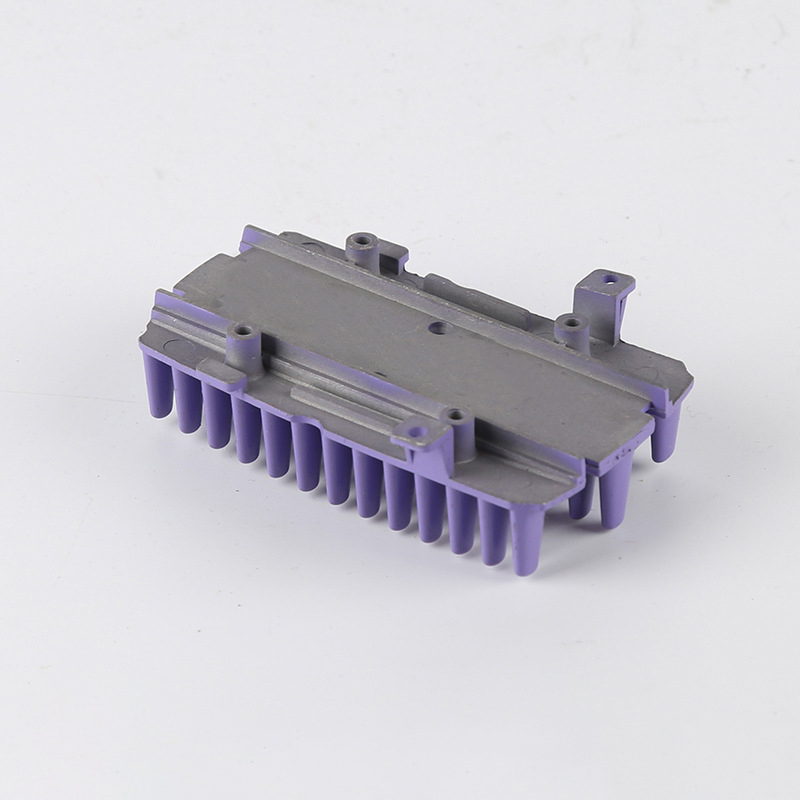

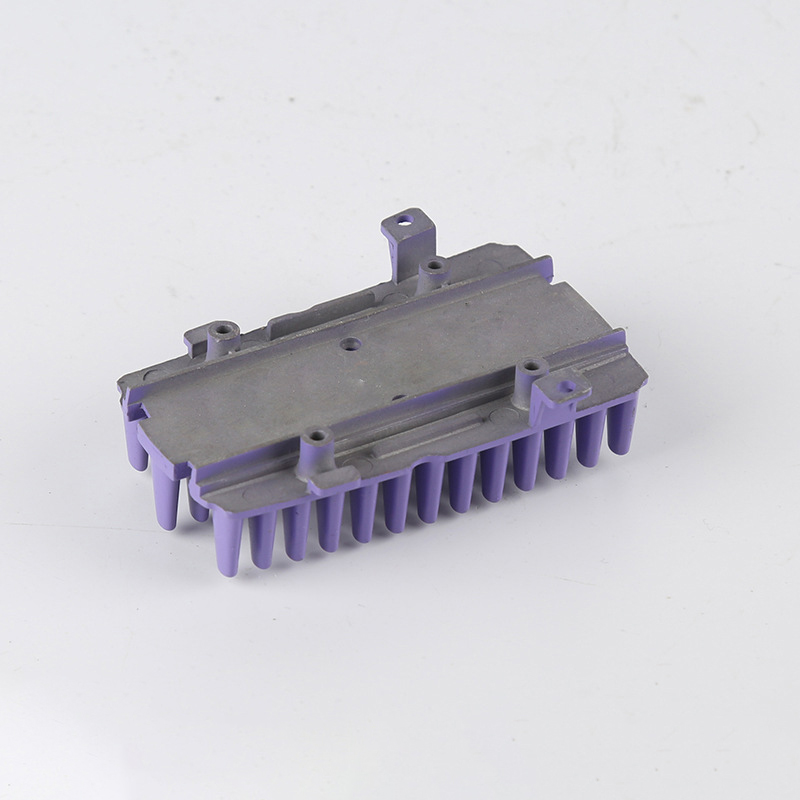

Likarolo tsa Mechini ea Ponahalo ea Mechini e Ikhethileng bakeng sa Foundry Die Castings

- Process difeme

- Ho Casting

- Karolo ea Boitsebiso

- aluminium

- Lefapha la Kopo

- Likarolo tsa mechine

- Phekolo ea bokaholimo

- Anode oxidation

- Setereke sa Metal

- Tsohle mokelikeli shoela'ng foromeletsoeng

- Mofuta o Sebelisitsoeng ka Mochini

- Mochine oa khatello oa Cold Chamber

- Thatafala Of Parts

- Ho latela kopo ea moreki

- Fillet

- Ho latela kopo ea moreki

- Angle e senyehang

- Ho latela kopo ea moreki

- Bohale

- Ho latela kopo ea moreki

- ho nepahala

- 0.005 limilimithara

- Linako tsa 8h tsa ho lahla

- 800-1200

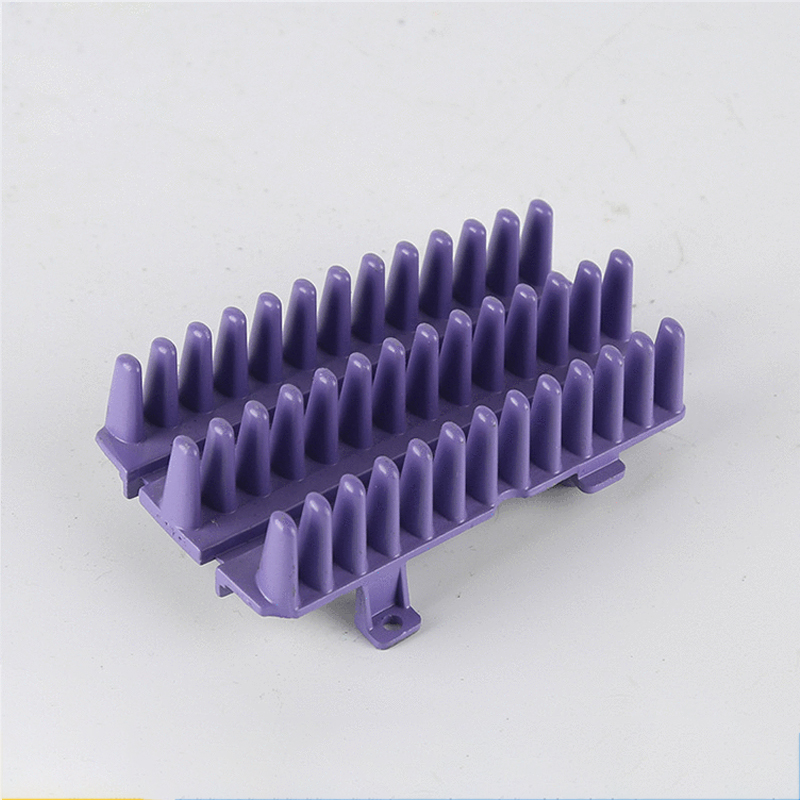

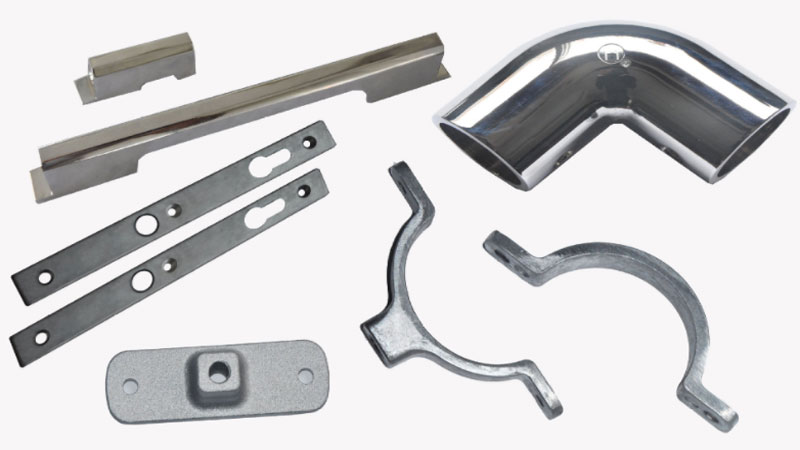

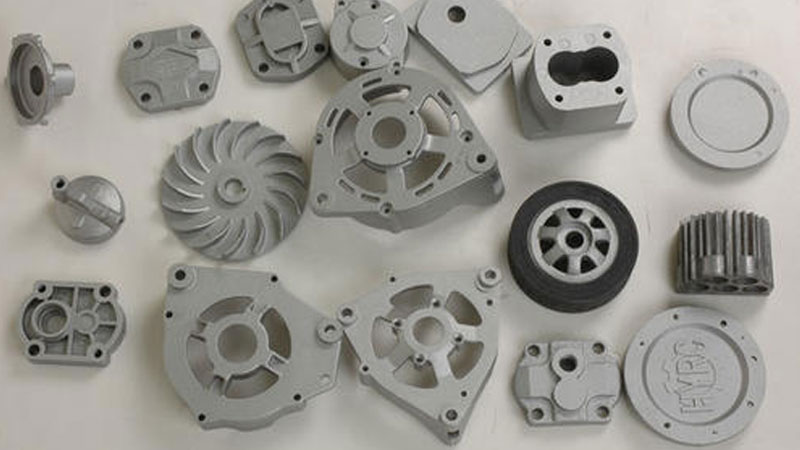

Lisebelisoa tsa Custom Machining Ponahalo ea Mechini

Likarolo tsa Mechini ea Ponahalo ea Mechini e Tloaelehileng bakeng sa Foundry Die Castings, Moetsi oa li-castings ho kenyelletsa le meralo, hlobo e sa feleng, zinki le li-cast cast. Bokgoni bo kenyelletsa machining ea bobeli, ho phethela, litšebeletso tsa polishing. Litsamaiso tsa boleng li lumellana le ISO.

Likarolo tsa rona tsa Manufacturing Advance

Hlobo rona li sebetswa le nosi, ntle le phaello e eketsehileng, theko e itekanetseng, potoloho lekgutshwanyane, 'me sampole tsoa ka lebelo ka ho fetisisa matsatsi a 20,' me bohle ba khampani ya rona ya mehleng fektheri dikarolo tse lahlang 'me lihlahisoa tse sa tšoanelehang lia khutlisoa ebe li fapanyetsanoa ntle le mabaka ntle le lebaka.

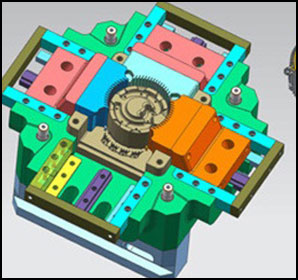

1. Moralo oa Litšoantšo

DFM ke e 'ngoe ea mekhoa e metle ka ho fetisisa e lateloang ke baenjiniere ba Minghe ho ntlafatsa ts'ebetso ea li-castings ha e ntse e boloka tšebetso. Minghe o na le sehlopha sa baenjiniere ba fetang leshome ba litsebi ba tla fana ka litlhahiso tse sebetsang mabapi le sebopeho sa thepa le ho fumana botsitso lipakeng tsa moralo, litšenyehelo le ts'ebetso ea karolo.

2. Hlobo Design

Sethala sa hlobo se etsisa ts'ebetso ea ho tlatsa le ho tiisa, e bolela esale pele liphoso tse tla hlaha molemong oa ho lahla, mme e bolela esale pele tšepe e nyane le thepa ea mochini, le matla a phini ea ejector ea hlobo. Lokisa semathi le moralo oa liheke, ntlafatsa mekhahlelo ea tlhahiso, ho fokotsa R & D le litšenyehelo tsa tlhahiso, le ho ntlafatsa boleng ba sehlahisoa.

3. Tlhahiso ea hlobo

Sekhechana sa Minghe ho etsa hlobo mahlale a morao-rao a re lumella ho beha karolo ea sebopeho ka hlobo haholo ha re etsa hlobo, mme likarolo li theoa ka nako e le ngoe, ho fokotsa litšenyehelo tsa tlhahiso ea likarolo tse ngata le kopano le ts'ebetso ea bobeli.

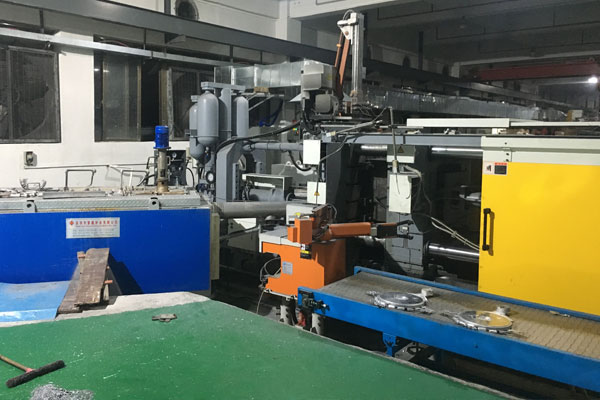

4. Bokhoni ba ho Shoela

Minghe ke e 'ngoe ea lik'hamphani tse' maloa tse nang le bokhoni ba ho holisa lethathamo la li-casting, ka mechini e shoang ea li-ton tsa 58-3000 tsa lithane tse fapaneng. E ka hlahisa likarolo tse boima ba 5g-35kg. Sebōpi se ikemetseng sa mochini o mong le o mong oa ho lahla se re nolofalletsa ho fana ka aluminium, zinki, magnesium le lits'epe tsa tsona tse fapaneng ho fihlela litlhoko tse ikhethang tsa bareki.

5. Cnc Machining Matla

Minghe o na le boiphihlelo ebile o holile tsebong mochini oa cnc sehlopha, tse fetang tse leshome tse tsoang linaheng tse ling e lokisa libaka le lathes, 'me e lokisa lona cha PTJ Shop ke e mong oa baetsi holimo e leshome tse nyenyane le tse mahareng e lokisa China. E fana ka ts'ebetso e nepahetseng ea ts'ebetso. Mamello e fokolang e laoloa ke 0.22mm ho fihlela litlhoko tsa likarolo. Litlhoko tsa kopano ka lehlakoreng la moreki.

6. Bokhoni ba Phekolo ea Bokaholimo

Minghe ka tlatsa kalafo holim 'mele le kalafo phofo fafatsa kang thunngoa ho qhomisa e, lehlabathe o motle, lehlabathe mahoashe joalo joalo. Ka nako e ts'oanang, Minghe o nkile karolo e kholo ho phepelo ea lehae ka lilemo tse fetang 30, a kopanya maqheka a mangata a barekisi ba kalafo ea lik'hemik'hale, le ka taolo ea liketane tse rarahaneng tsa phepelo, ho fa bareki kalafo ea bokaholimo joalo ka ho fafatsa ka polasetiki, ho penta, anodizing, electrophoresis, chrome plating, jj.

7. Matla a Kopano

Minghe shoa lahla khampani e fa bareki mefuta e fapaneng ea lits'ebeletso tsa kopano le likopano tse nyane. Re na le boiphihlelo bo pharalletseng ba ho bokella lisebelisoa tsa marang-rang, ho kenyeletsoa li-screws, li-screws, li-bolts, lithakhisa, ho kenya, gaskets le O-rings, le liteko tsa khatello ea tiiso ho netefatsa ts'ebetso ea sehlahisoa.

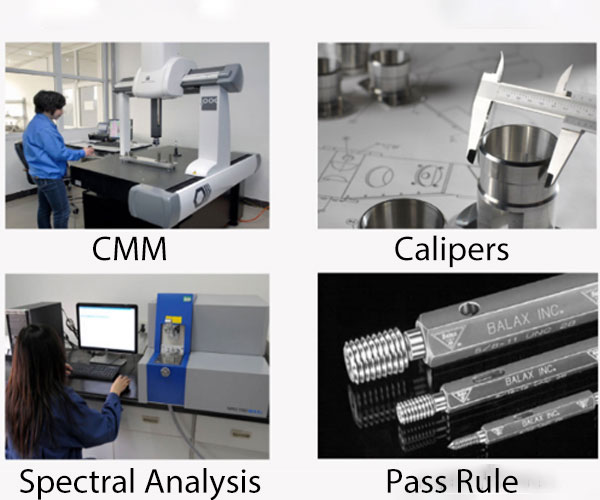

8. Sisteme ea tlhahlobo ea boleng

Minghe o ela hloko ka ho khetheha taolo ea boleng ba ts'ebetso ea tlhahiso ea bongata mme o thehile ts'ebetso le sistimi e phethahetseng ea tlhahlobo. Lisebelisoa tse hlano li sebelisoa hangata: PPAP, APQP, PFMEA, SPC, le MSA. Lihlahisoa tsohle li hlahlojoa ka botlalo kapa li hahiloe ho latela maemo. Lisebelisoa tsa ho etsa liteko li kenyelletsa: spectrometer, mochini o lekang oa Testing, khokahano e meraro ea CMM, gauge ea ho feta, seteishene se tšoanang, likhalipa tse fapaneng, jj, ho fihlela bokhoni ba taolo ea sistimi ea boleng.

|

| Mochini oa rona oa Die Casting |

|

| Mochine oa rona oa Cnc Machining |

|

| Quipment ea Teko |

|

| Mokhoa oa rona oa ho paka |

|

| Setšoantšo sa Moreki |

|

| Pontšo ea Rona e Bonolo |

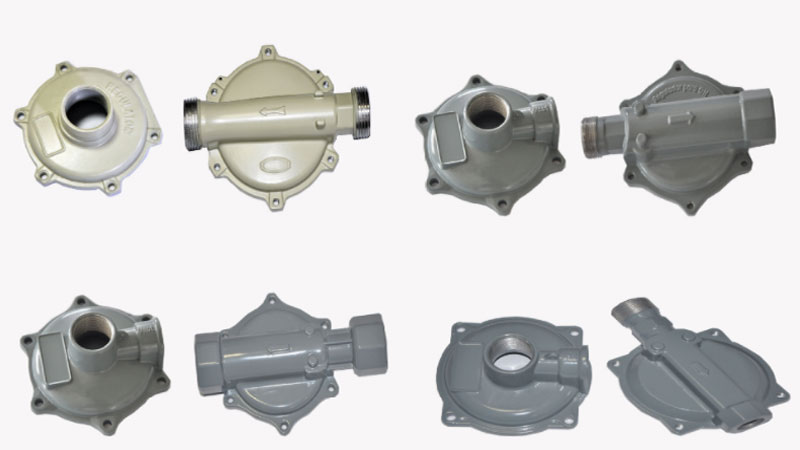

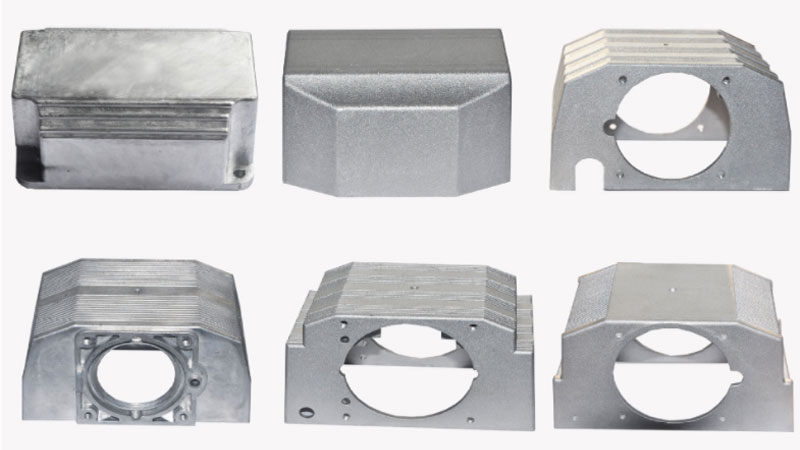

Pontšo ea rona ea Die Casting Profucts

- Li-castings tsa aluminium tse phahameng tse nepahetseng haholo, tse nang le mamello e laolehang ea + -0.1mm.

- Mochini o mocha oa ho lahla likarolo tsa aluminium alloy o ka laoloa ntle le masoba a lehlabathe, ha ho na matšoao a metsi, ha ho na blistering, ha ho na pitting, ha ho mafome, ha ho na oxidation.

- Sekhahla sa shoa lahla tšebeletso ke junifomo, sehlahisoa ha se bonolo ho se senya, se holofala, 'me boleng bo tsitsitse.

- Fektheri ha e koale lihora tse 24 ka letsatsi, nako ea hau ea ho fana le boleng ke sepheo sa rona

|

| Likarolo tsa Likoloi li Lahleloa |

|

| Jarolla ka ho iketsa belofo Natural Gas |

|

| Likarolo tsa thepa ea ts'ireletso ea Die Casting |

|

| Moea di-pump Housing shoa lahla |

|

| Bolulo ea Casting Lighting |

|

| Lisebelisoa tsa Die Casting Motor |

|

| Kaho Hardware shoa lahla |

|

| Mabenyane a Zinc Die |

|

| Likarolo tse ling tsa Die Casting |

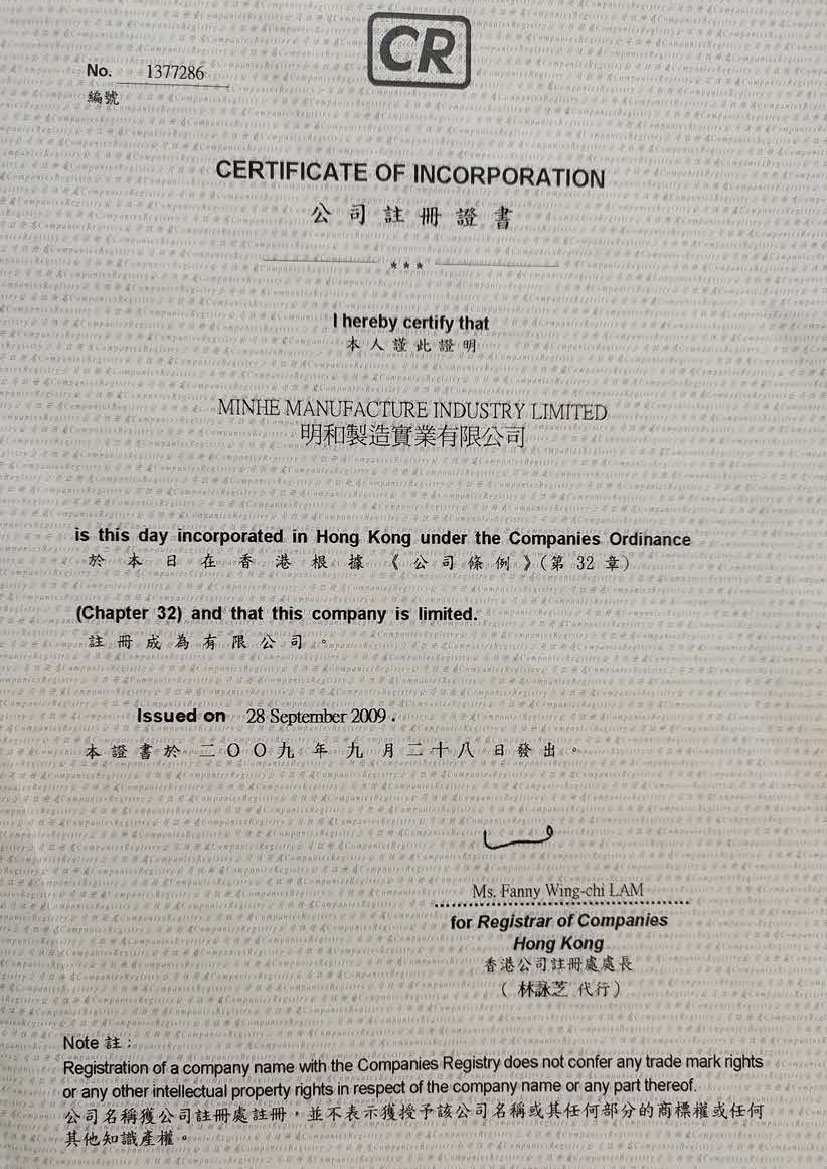

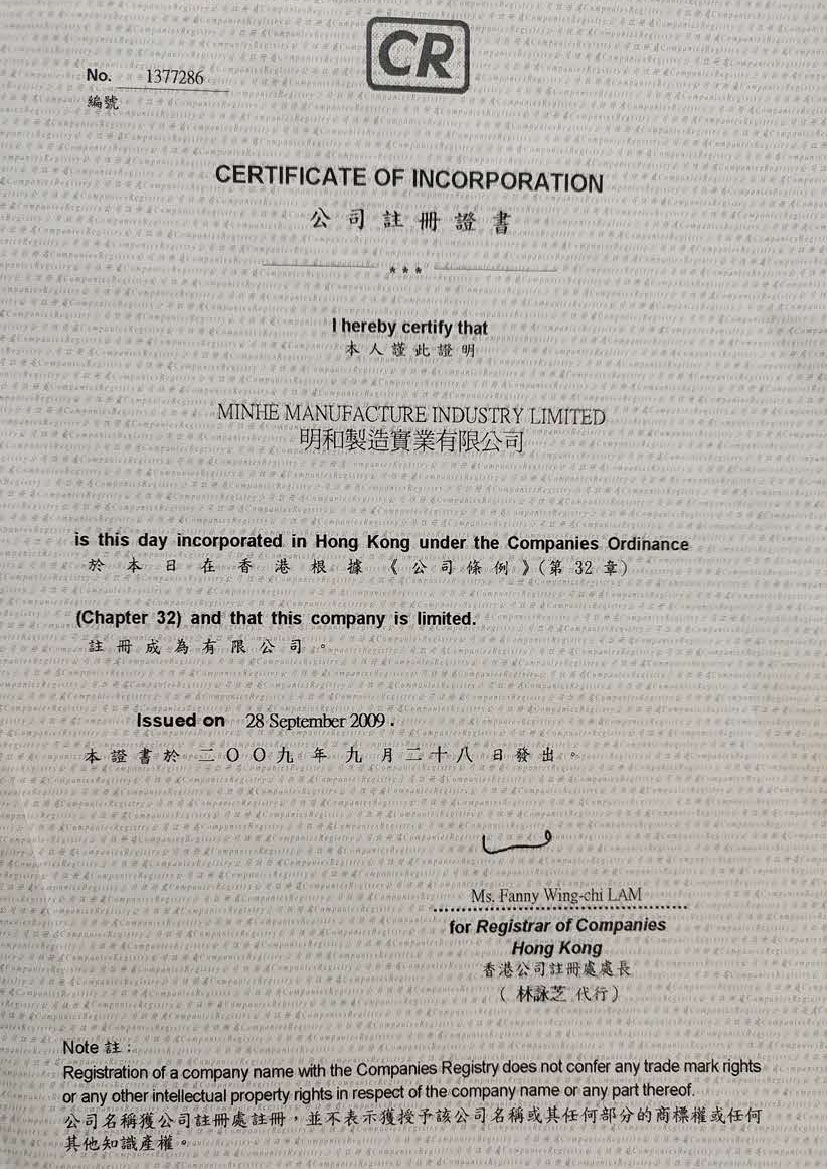

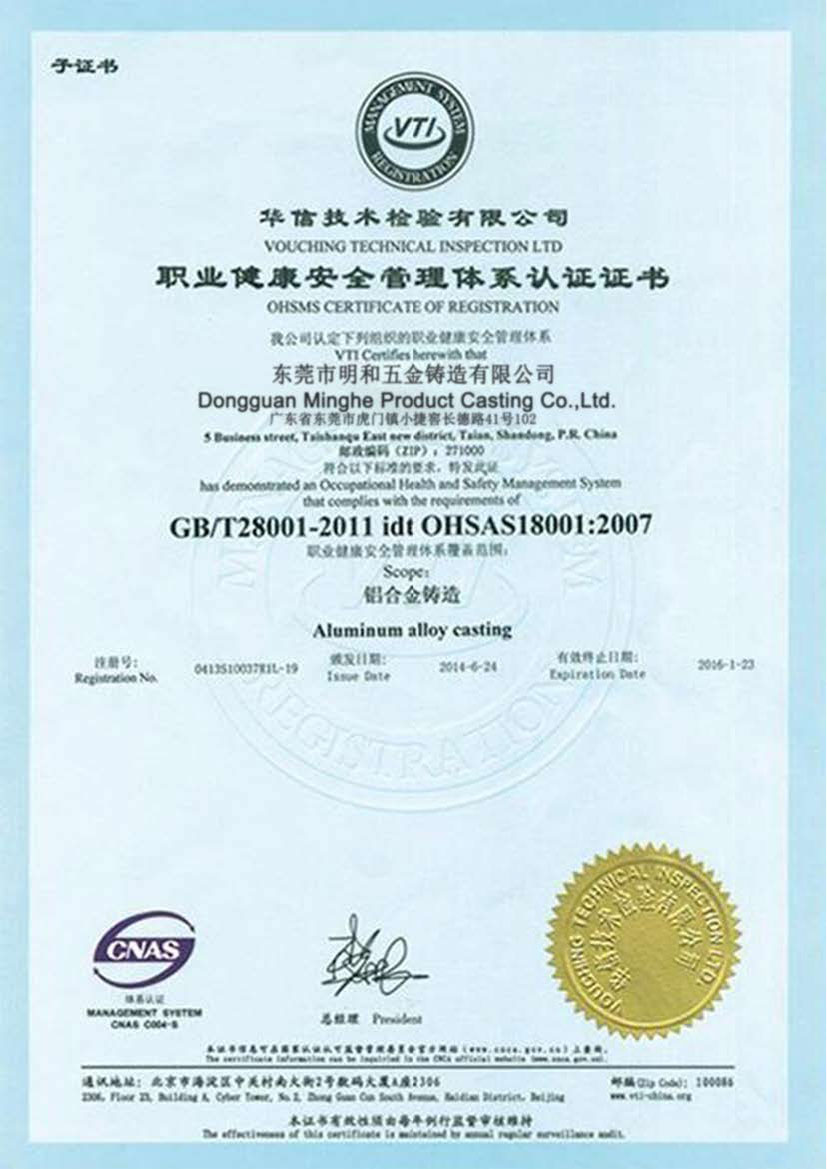

Tlhompho le Litifikeiti

HapeKopana le Minghe Die Casting Workshop

HapeLikarolo tse ling tsa Die Casting le Mechini ea Machining

MingO lahla Molemo

- Software e felletseng ea ho lahla le moenjiniere ea nang le boiphihlelo e etsa hore sampole e etsoe matsatsing a 15-25

- Sete e felletseng ea lisebelisoa tsa tlhahlobo le taolo ea boleng li etsa lihlahisoa tse ntle tsa Die Casting

- Ts'ebetso e ntle ea ho tsamaisa thepa le netefatso e ntle ea mofani oa thepa re ka lula re tsamaisa thepa ea Die Casting ka nako

- Ho tloha lipapaling ho isa likarolong tse ling, kenya lifaele tsa hau tsa CAD, qotsulo e potlakileng le ea boiphihlelo ka lihora tse 1-24

- Bokhoni bo pharalletseng bakeng sa ho rala li-prototypes kapa likarolo tse kholo tsa tšebeliso ea pheletso qetellong

- Mekhoa e tsoetseng pele ea Die Casting (180-3000T Machine, Cnc Machining, CMM) e sebetsana le lisebelisoa tsa tšepe le polasetiki

Lingoloa tsa Thuso

Mokhoa oa ho bala khatello ea khatello ea khatello ea khatello

Mokgwa wa ho Bala: Palo ea palo ea khetho ea mochini o lahlang li-die:

Tsamaiso ea ho Itšeha ka Linomoro ea Khoele

Ts'ebetso ea ho itšeha ka khoele e ipapisitse le sebopeho sa likarolo tsa machined le sesebelisoa sa mochini sa CNC u

Hoo e ka bang Loketseng And NC Machining Of Ellipse Gear

Likoloi tsa oval li sebelisoa haholo indastering ea mechini le lisebelisoa, mme ke mofuta oa bao e seng c

Karolo le Ts'ebetso ea Ts'ebetso ea Moqomo oa Moqomo oa Telescopic

Silinda telescopic sheath ke karolo e sireletsang e kentsoeng moqomong oa oli, cyli

Tshekatsheko ya Wavelet Of Overcut In Free-Form Surfaces CNC Machining

Potoloho ea tlhahiso e telele. Basebetsi ba tloaetse ho khathala. Hang ha ho hloleha ho etsahala, hangata ho nka

Ho sebelisa sesebelisoa se hloekileng sa oksijene ho fokotsa tšebeliso ea matla ea ho futhumatsa ka pele

Wu Steel Works e na le lithupelo tse peli, kokoano e le 'ngoe ea ho etsa litšepe le setsi sa bobeli sa ho etsa litšepe.