Kopano le Teko

KOPANO LE TEKO

Tsoelo-pele ea Kopano ea Minghe

Minghe Die Casting e fana ka tharollo e feto-fetohang, e bolokang chelete e ngata ka tlhahiso e kopaneng ea likopano le likopano tse seng li lokile tsa tlhahiso.

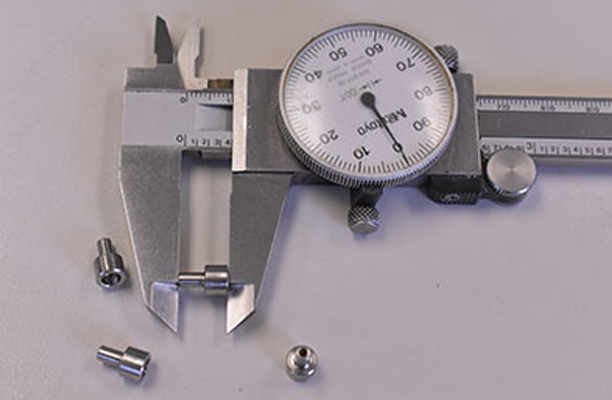

Rona MINGHE CASTING re na le lisebelisoa le boiphihlelo ba ho etsa mefuta e mengata ea kopano le liteko. Sehlahisoa sa Kopano se netefalitsoe hore se boloka boleng bo holimo ka ho fetesisa, hape le linako tse sebetsang tsa ho hetla nako ho sebelisa mela ea kopano ka bongata.

Ho tloha kopanong e bonolo ea mochini le liteko tsa khatello, ho ea kopanong ea motlakase le ho hlahlojoa ka mohlahlobi oa marang-rang. Sena se tla u lumella ho reka sehlahisoa se feliloeng eseng feela karolo.

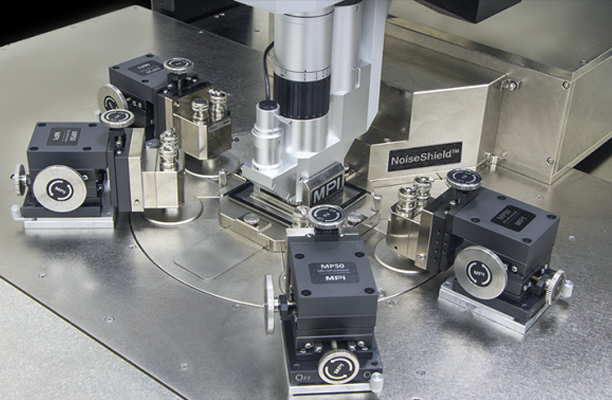

Lisebelisoa tsa liteko tsa elektroniki li sebelisetsoa ho theha matšoao a hlasimollang le ho fumana likarabo ho tsoa ho Lisebelisoa tsa elektroniki. Ts'ebetso e nepahetseng ea sesebelisoa sa elektroniki e ka netefatsoa kapa e na le phoso sesebelisoa, e ka fumanoang le ho lokisoa. Ts'ebeliso ea lisebelisoa tsa tlhahlobo ea elektroniki e bohlokoa bakeng sa mofuta ofe kapa ofe oa mosebetsi ho litsamaiso tsa elektroniki.

|

|

|

|

Boiteko ba Rona le Boiteko ba Kopano e Bonolo

Hore na o hloka kenyelletso e bonolo ea Hardware kapa kopano e rarahaneng ea mochini, Minghe Die Casting e ka fana ka nako ea ho boloka, lits'ebeletso tse theko e tlase bakeng sa projeke ea hau. Re tsamaisa projeke ea hau e felletseng ho tloha ho prototyping, die casting, machining, phumants'o ea thepa le kopano. Re ka boela ra fana ka kitting ea likarolo tse potlana-li kopane bakeng sa mohala oa hau oa tlhahiso le lisebelisoa tsa ho lokisa. Ho tloha likopanong tse nyane tsa mochini ho ea ho masakaneng a rarahaneng a motlakase, re hlophisa tharollo ea kopano ho latela litlhoko tsa hau.

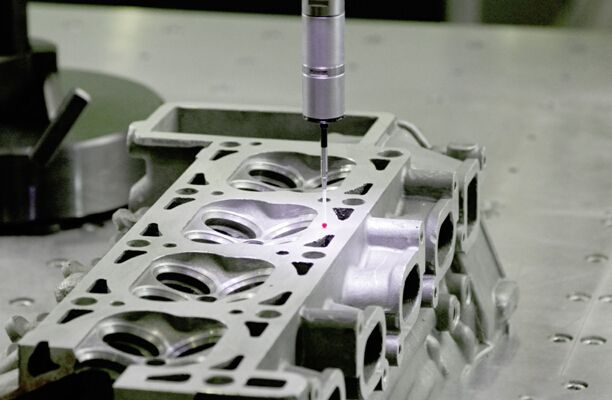

1. Sebopeho sa Die lahla

Ka ts'ebeliso e pharalletseng ea mahlale a machining a CNC, ho rarahana ha sebopeho sa li-die castings ho ntse ho eketseha. Ha ho sebetsoa ka li-cast cast tse ling, maemo le ho ts'oara li thata haholo, 'me ha li tšoanelehe bakeng sa maemo a mangata le ho ts'oara. The nako e 'ngoe eaba ba etsa theknoloji ea machining ka kakaretso ke ho potoloha le ho retelehela worktable ho ea ka hlaha ka lehlakoreng le ka tse tshekaletseng kapa paatsepama-tse tshekaletseng ho sokoloha setsi machining sesebelisoa ho sebetsa lifahleho tsohle le masoba a shoa-lahla karolo ka nako e' ngoe, le joale kopana le litlhokahalo tsohle tsa mamello ea jiometri ea setšoantšo. Karolo e hokahantsoeng le mochini oa ts'ebetso e koahetsoe mme e silafalitsoe ho arola mochini oa ts'ebetso le sehlahisoa.

2.Molao-motheo oa Ts'ebetso

Sebelisa melemo e mengata ea menyetla ea ho sebetsana le likarolo tse ngata tsa likarolo tsa CNC, sebelisa litšobotsi tsa sehang sa carbide ho sebetsana le likarolo tse nang le deformation e tlase ka lebelo le phahameng le fepa e nyane, sebelisa karolo e setseng ea karolo ea boemo mokhoa oa ho beha le ho hatella, 'me u sebelise software ea UG ho iketsa Ts'ebetso ea mananeo e netefatsa ho ts'oana ha likarolo tse sebetsitsoeng ka kakaretso le momahano e ntle ea mahlakore ohle.

3. Phello ea Ts'ebetsong

Likarolo shoa-lahla amohela machining bohlokoa le theknoloji e le 'ngoe-eaba ba etsa. Ha likarolo tsa ho lahla li hlahisoa ka bongata, kamora tlhahlobo ea likhokahanyo tse tharo, lipalo-palo tsa sebopeho le ho nepahala ha maemo ke tse latelang: K base sefofane flatness ≤ 0.012mm, M base sefofane flatness ≤ 0.01mm, M backside parallel The degree of ≤0.015mm, boholo ba φ30mm botlaaseng ba M ke ≤0.013mm, boholo ba of32mm botlaaseng ba K ke -0.015mm, mateano a of30mm le selekane sa φ32mm ke ≤0.014mm. Ka tlhahiso ea boima, sebopeho le ho nepahala ha maemo a likarolo li tsitsitse, mme ts'ebetso ea tlhahiso e ntlafalitsoe haholo.

4. Kopo le Katoloso

Nako e le 'ngoe ea ts'ebetso ea theknoloji ea likarolo tsa machining e ka sebelisoa eseng feela litsing tsa machining tse tshekaletseng, empa hape le litsing tsa machining tse otlolohileng le tse otlolohileng. Likarolo tsa ho lahla li ka sebetsoa le ho theoa ka mohato o le mong ho setsi sa machining sa li-axis tse hlano, mme mehato ea ts'ebetso e ka siloa ka likarolo; likarolo shoa-lahla ka sebetswa ke poleiti inverted ka setsi sa selekane tharo-selekane machining. Ho tlosa sethala sa ts'ebetso ea masalla.

5. Ts'ebeliso ea Machining e akaretsang

Nako e le 'ngoe ea ts'ebetso ea theknoloji ea likarolo tsa likarolo e sebelisoa haholo ts'ebetsong ea likarolo tse nang le maemo a thata le ho ts'oara. Mekhoa ea ts'ebetso e ka kopanngoa ho ntlafatsa katleho ea mosebetsi le ho netefatsa ho nepahala ha sebopeho le boemo; e ka sebelisoa bakeng sa ho itšeha ka bobeli ea likarolo tse fapaneng tsa sebopeho ho fokotsa palo ea ho ts'oara, ho boloka litšenyehelo tsa tlhahiso ea lisebelisoa; a loketse bakeng sa phahameng-lebelo le tse nyenyane-fepa ka anthivaerase lera sebetsa ka lera, ho itšeha lebotho la ke tse nyenyane, ho itšeha mocheso e nyenyane nakong ea ho e lokisa, 'me likarolo shoa-lahla ha ba le tsekamelo ea ho khatello ea kelello deformation. Khopolo ena ea ho sebetsa e ntse e khothaletsoa butle-butle lifemeng tsa batho ba shoang.

Lethathamo la lisebelisoa tsa rona tsa ho lekanya

|

|

|

|

|

|

|

|

|

|

|

|