Ts'ebetso ea Aluminium Alloy Die Casting Key Technology

Kakaretso ea Aluminium Alloy Shell Castings

Li-castings tsa Aluminium alloy li sebelisoa hangata indastering ea sejoale-joale ea likoloi. Ka lebaka la libopeho tsa tsona tse sa tloaelehang, ho thata hore meaho e meng e fihlelle maemo a boleng ka ho e sebelisa. Ka hona, li-castings tse ling tsa aluminium li sebelisoa feela bakeng sa sebopeho se thata sa bokaholimo ba likhetla tsa koloi. Ho latela pono ea polokeho ea ts'ebeliso ea likoloi, indasteri e na le litlhoko tse thata haholo tsa boleng bakeng sa li-castings tsa aluminium. Liqoso tsohle li na le litekanyetso tse thata tsa matla a thepa. Ho latela litlhoko tsa likhetla tsa khetla, bokaholimo, litekanyetso tse habeli tsa boleng ba kahare. Bakeng sa ho netefatsa boleng ba sehlahisoa, baetsi ba bang ba amohetse theknoloji ea ho bona phoso e sa sebetseng ho laola tšebetso eohle ea tlhahiso.

| Boitšoaro ba Mechini | Kereiti ya |

| Tensile matla Mpa (mets) | 240 |

| Fana ka matla Mpa (mets) | 140 |

| Elongation% (mets) | <1 |

| Brinell thatafala HB (mets) | 80 |

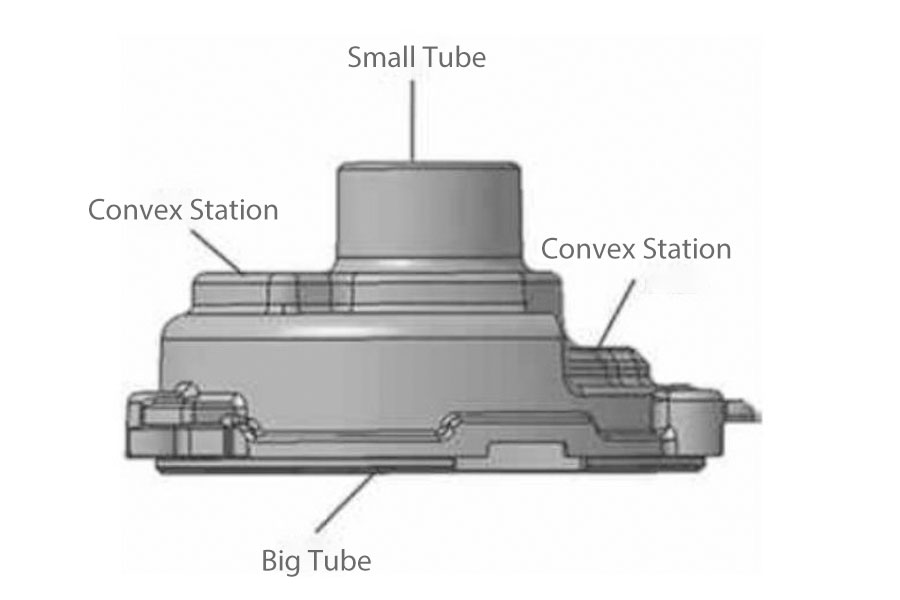

Sekoaelo sa aluminium alloy shell se hlahisitsoeng sengoloeng sena se na le sebopeho se batlang se le bonolo mme likarolo tse peli feela li hloka ho sebelisoa. Leha ho le joalo, ka lebaka la sebopeho se sa tloaelehang sa khetla, bophahamo ba baokameli ba babeli bo fapane. Har'a tsona, bophara bo phahameng ba kantle, bophahamo, Likarolo tse kholo tsa botenya ba lerako ke 105mm, 40mm le 3.5mm ka tatellano. Likarolo tse hlokang ho qaptjoa ke bokaholimo ba kantle ba likhetla tse kholo le tse nyane. Mefuta e meng ea mamello e tlameha ho laoloa kahare ho +/- 0.1mm. Kaha karolo ena ha e hloke ho sebetsana le sekoti se ka hare, bothata ba ho betsa lefu bo batla bo le nyane.

Bakeng sa ho netefatsa hore ts'ebetso ea ho betsa e ka fihlella litlhokahalo tsa ho mamella matla a sithabetsang a kaholimo ho 20kN, ts'ebetso ea tlhahiso e hloka ho laoloa ho latela GB6414-86 CT6 ho netefatsa hore ho betloa ha ho litšila le mapetso nakong ea Ts'ebetso ea ho lahla, mme ho tjheseletsa ha hoa lumelloa. Lokisa sehlahisoa ka ho se lokisa kapa ka ho ina.

Ts'ebetso ea Ts'ebetso ea Sehlahisoa

Tsamaiso ea tlhahiso

Ts'ebetso ea likarolo tsa likarolo ke: lisebelisoa tse kenang → ho qhibiliha / ho lahla → ho kuta / ho hloekisa → machining → ho hloekisa → kopano.

2.2 Tlhahlobo e fosahetseng

Leha aluminium alloy shell cast e hlahisitsoeng sengoloeng sena e na le sebopeho se bonolo, liphoso tse latelang tsa tlhahiso hangata li etsahala nakong ea tlhahiso:

- (1) Phapano: Phapang ea mocheso lipakeng tsa tšepe le hlobo, lebelo la ho tlatsa nakong ea ho qhibilihisa, le boholo ba palo ea spray nakong ea ts'ebetso ea ho thunya ha li laoloe hantle, tse bakang mmala oa ho betsa hore o fifale habonolo. batsho.

- (2) Bofokoli ba bofokoli: Mofuta ona oa bothata o ke ke oa qojoa ka botlalo ts'ebetsong ea tlhahiso ea aluminium alloy castings. Tlhokahalo ea taolo ea bothata ba porosity ea ho betsa ke ho netefatsa matla a khetla, 'me hoa hlokahala ho netefatsa hore sebaka se mahlonoko ha se hlahise porosity e fetang boemo ba 505 ba ASTME2. Lebala le amohelehang la li-pores ha le betloa ke -1.6mm, sekhahla sa pore se lokela ho laoloa kahare ho 6.2%, mme bophara ba masoba bo holim'a machined ha boa lokela ho ba kholo ho feta 2.0mm.

Mabapi le taolo ea boleng ba tlhahiso, tlhahlobo ea pono e ikarabella haholo bakeng sa tlhahlobo ea likoli tsa ponahalo, 'me tlhahlobo ea X-ray e ikarabella bakeng sa taolo ea boleng ba kahare ba castings. Leha ho le joalo, tlhahiso ea bongata, ho latela pono ea ho akofisa lebelo la tlhahiso le ho laola litšenyehelo tsa tlhahiso, mekhoa ena e 'meli e na le liphoso tse itseng. Ka hona, ts'ebetso ea ho lahla aluminium alloy e hlahlojoa le ho buuoa ka CAE le mahlale a mang a thusang ho ntlafatsa boleng ba tlhaho ba castings. Taolo ea mathata e sebetsoa mohatong o thata.

Mehato ea 2.3 ea ts'ebetso le khetho ea lisebelisoa

Ho latela litšobotsi tse sebopeho le ditlhoko tlhahiso ea ho lahla, khatello ea foromeletsoeng e behiloeng ka ho 350T. Ho ea ka boiphihlelo ba tlhahiso ea lihlahisoa tse tšoanang nakong e fetileng, joalo ka motsoako o sa utloahaleng oa hlobo le khetho e sa nepahalang ea mekhahlelo ea ts'ebetso, bothata ba lebelo la ho tlatsa tšepe ka mokelikeli bo tla etsahala nakong ea ts'ebetso ea ho lahla. Sephetho sa tšitiso ea ho tsoa ha khase ka mokokotlong, mme qetellong sa theha litšitiso tsa boleng bo joalo ka masoba kapa litšila tse feteletseng tsa oxide sehlahisoa se felileng, se amang sekhahla sa ho feta sa ho betsa.

Ho latela litlhoko tsa moralo oa ho betsa, botenya ba lera le teteaneng holim 'a sekotoana sa marako a tšesaane ke 0.8mm feela. Haeba e sebetsoa hantle, moaho oa setsi o tla hlepha, o tla lebisa phokotsong ea ts'ebetso ea khetla le khatello ea khatello. Ka hona, ha ho raloa hlobo, pini ea boemo e sebelisoa ho hokahanya boemo, 'me bophahamo ba modumo bo laoloa kahare ho 0.5mm. Sena se boloka nako ea machining mme se loketse ntlafatso ea boleng ba tlhaho ba ho betsa.

2.3.1 Khetho ea lenaneo la hlobo

Ho latela litlhokahalo tsa moralo oa aluminium alloy shell casting, moralo o ne o etsoa ho sebelisoa software ea AnyCast-ing, mme ho ile ha fumanoa meralo e meraro e fapaneng ea meralo ea inlet. Ha ho bapisoa, kanale e phallang e nang le phallo e boreleli e ile ea qetella e reriloe. Moralo oa moralo C ke ho hlahisa hlobo, mme ho fumaneha tlhahiso ea nnete hore leano lena le na le phello e ntle ho ntlafatseng likoli tsa ka hare tsa likhetla tsa khetla le ho eketsa chai ea khetla.

2.3.2 Ho beha mocheso o qhibilihang

E kopantsoe le boima ba sebopeho sa khetla, mochini o lahlang o batang oa 350T o sebelisoa bakeng sa ho lahla li-castings, 'me mocheso o behiloe kahara 640 ℃ +/- 20 ℃. E le ho etsa bonnete ba hore khatello ea ts'ebeliso ea mokelikeli oa tšepe e tsitsitse, leka ho qoba ho phalla hoa moferefere, ho fafatsa le mathata a mang a bakoang ke ho kenella ha slag ho kenella kapa khoholeho ea motheo, sekhahla sa khatello se behiloe ho 1.3kPa / s.

2.3.3 Ho hloekisoa ha mokelikeli oa motsoako

Bakeng sa ho ntlafatsa boleng ba aluminium alloy shell castings le ho fokotsa litlamorao tsa li-pores, pinholes le slag inclusions sekhahla sa mangolo a lihlahisoa, mohato oa bobeli oa ho hloekisa o sebelisoa ts'ebetsong ea ho lahla, ke hore, motsoako o hloekisoa hang pele le kamora hore sebopi se lokolloe. Ka nako e ts'oanang, sefahleho sa sefahleho sa faeba se sebelisoa lephakeng la riser, skrine ea ceramic e sebelisoa hekeng e tshekaletseng, 'me sekhechara sa fiber se habeli se beoa qetellong ea heke e tshekaletseng le lekhalo le bulehileng ho etsa Khethollo ea makhetlo a mararo ho laola ketsahalo ea liphoso tsa sehlahisoa sa slag. sekhahla.

Boemo ba 'Nete ba Tlhahiso le Phello

Ho ea ka morero le ts'ebetso e boletsoeng kaholimo, mehlala ea likhetla tse 6 e ile ea khethoa ka mokhoa o ikhethileng bakeng sa tlhahlobo tlhahlobisong ea 'nete,' me ha fumanoa hore sekema sa C se na le phello e ntle ho ntlafatseng likoli tsa kahare tsa likhetla tsa khetla le ho eketsa chai ea khetla. Ka tlhahlobo ea X-ray, ho fumanoe hore sekhahla sa taolo ea kahare se fihlile ho 100%; 'me joale tlhahlobo e nepahetseng ea ho fetoha e fumane hore index ea porosity ea bokaholimo ba mechini e fihlile boemong ba ASTM E505; ka tlhahlobo e silafatsang ea senya, ho fumanoe hore lisampole tsohle li ka fihlella Ho mamella khatello e kaholimo ho 2kN. Ho ka bonoa hore moralo oa aluminium alloy shell foromong le khetho ea ts'ebetso e hlahisitsoeng sengoloeng sena e batla e utloahala, mme litlamorao tse itseng li fihletsoe ho laoleng boleng ba sehlahisoa.

fihlela qeto e

Ka ntlafatso e tsoelang pele ea mahlale le theknoloji le lits'ebetso tse amanang le tsona, ts'ebetso ea ho lahla likarolo tsa likarolo tsa aluminium e ntlafalitsoe khafetsa. Phallo ea ts'ebetso ea setso e telele, e sa sebetseng ho taolo ea boleng ts'ebetsong ea ho betsa. Bakeng sa ho netefatsa ntlafatso ea boleng ba tlhahiso, ho bohlokoa ho qala taolo ea boleng ho tloha sethaleng sa thepa. Ts'ebetso ea tlhahiso le mahlale a morao-rao a li-castings tsa alloyum alloy tse ka holimo li fihletse maemo a utloahalang le a khonehang ka boqapi ba mahlale le khetho ea lenaneo, e leng se netefatsang hore mahlale le lits'ebetso tse amehang li ka fihlela litlhoko tsa boleng ba tlhahiso ea bongata bakeng sa lihlahisoa tse amanang tsa ho betsa, hape li netefatsa motsoako oa aluminium Karolo ea likarolo tsa bohlokoa tsa mahlale a ho lahla ho ntlafatsa boleng ba lihlahisoa tse amanang.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape:Ts'ebetso ea Aluminium Alloy Die Casting Key Technology

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off