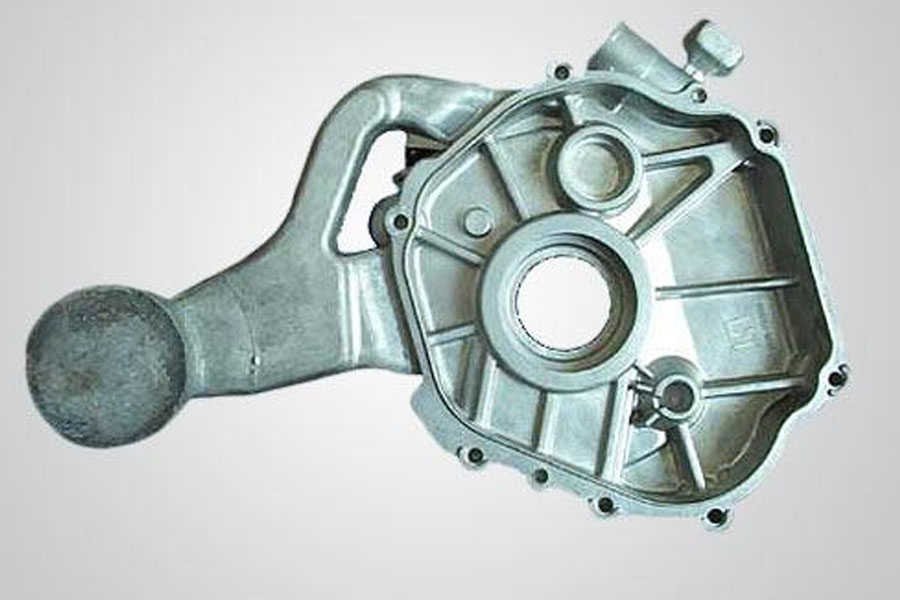

Lintlha Tsa Bohlokoa Tsa Moralo oa Aluminium Alloy Die Casting

Aluminium die castings e na le melemo ea ts'ebetso e phahameng ea tlhahiso, litšenyehelo tse tlase tsa ts'ebetso, ts'ebetso e bonolo ea mochini ts'ebetsong ea tlhahiso, ho nepahala ho phahameng ha likarolo tsa castings, boleng bo holimo ba holim'a metsi le thepa e ntle ea kakaretso; empa ho bonolo ho hlahisa masoba, matšoao a phallo, le mengoapo nakong ea ts'ebetso. Liphoso tse kang liphoso, meno, mapetso, ho betloa ka tlase, jj. E le ho qoba mathata a kaholimo ho ts'ebetso ea ho lahla likarolo, moetsi oa meralo o hloka ho lekola moralo esale pele moahong oa sebopeho sa karolo e shoang, mme a etse moralo o utloahalang moahong oa likarolo tsa likarolo, le fokotsa litšitiso bonyane ka ho ntlafatsa sebopeho.

The eaba ba etsa Molao-motheo oa Aluminium motsoako shoa lahla

Likarolo tsa ho lahla likarolo tsa Aluminium li tlameha ho theoa ka hlobo, tse kopantsoeng le mechini e lahlang le lits'epe tsa aluminium bakeng sa ts'ebeliso e phethahetseng. Molao-motheo oa ts'ebetso ea ho lahla litšepe ke ho sebelisa khatello e matla ho phallela tšepe e qhibilihisitsoeng ka har'a mochini oa tšepe o nepahetseng ka lebelo le phahameng, 'me tšepe e qhibilihisitsoeng e pholile ebile e tiisitsoe tlasa khatello ea ho etsa betsa. Batang le chesang kamoreng shoela'ng foromeletsoeng ke mekhoa e 'meli ea motheo ea thulaganyou e shoela'ng foromeletsoeng. Ka kamoreng e batang e-shoa-tšepe, tšepe e qhibilihisitsoeng e tšolleloa ka kamoreng ea khatiso ka sesebelisoa sa letsoho kapa sa othomathike, ebe setebele sa ente se tsoela pele ho hatella tšepe ka har'a motlakase. Ka kamoreng e chesang e shoa thulaganyou e lahla, kamore ea khatello e perpendicular ho tsoana le sebopi, le tšepe e qhibilihisitsoeng phallang ka kamoreng ea khatello ka tsela e iketsang ka koung fepa ka ka kamoreng khatello. Punch ea ente e theohela tlase ho sutumelletsa tšepe e qhibilihisitsoeng ka hara mokoti ka gooseneck. Ka mor'a hore tšepe e entsoeng ka ho qhibilihisoa e tiee, hlobo ea ho lahla e ea buloa ebe ho lahloa ho ntšoa ho phethela ts'ebetso eohle ea ho etsa lintho tse ling.

| Shoa lahla botenya leboteng | Matlafatso botenya |

| 0.8-2.5 | 1.5-3.5 |

| 2.0-3.5 | 2.5-3.5 |

Kamano pakeng tsa botenya ba likhopo le lefu la ho betsa lebota (mm)

Lintlha tsa moralo oa li-castings tsa aluminium alloy die

Rationality ea shoa-foromeletsoeng moralo e amana le kaofela thulaganyong shoa-foromeletsoeng bōpa. Ha o qapa likarolo tse shoang li lahla, litšobotsi tsa sebopeho sa likarolo tsa ho lahla le lits'ebetso tsa ts'ebetso ea ho lahla li lokela ho tsotelloa ka botlalo ho fokotsa likoli tsa likarolo tse entsoeng tsa ho lahla molemong oa ts'ebetso ea ho lahla. E etsahetse, boleng ba likarolo tsa batho ba shoang bo ntlafalitsoe ho isa tekanyong e kholo ka moralo o nepahetseng.

| Mofuta oa alloy | Qiqea zloy | motsoako aluminium | Motsoako oa koporo |

| Lahla cavity | 0'20 ' | 0'32 ' | 0'45 ' |

| Sekoti sa kantle sa ho betsa | 0'10 ' | 0'15 ' | 0'30 ' |

Min. Moqolo oa Die Casting

2.1 Moralo o utloahalang oa botenya ba lerako la li-cast cast

Botenya ba lebota bo lokela ho tsotelloa ka botlalo ha ho qaptjoa sebopeho sa aluminium alloy die. Botenya ba lebota ke ntlha ea bohlokoa bo ikhethang ts'ebetsong ea ho lahla thepa. Botenya ba lebota bo na le kamano e haufi le ts'ebetso eohle ea ts'ebetso, joalo ka lipalo tsa nako ea ho tlatsa le khetho ea lebelo la heke e kahare. Kakaretso ea nako ea ho tiisa, ho hlahloba mocheso oa mocheso oa hlobo, phello ea khatello (khatello ea ho qetela), bolelele ba nako ea ho boloka hlobo, boemo ba mocheso oa ho lahla mocheso le ts'ebetso ea ts'ebetso; haeba botenya ba lebota bo thehiloe haholo, ho tla hlaha masoba a masesaane, masoba a lehlabathe le masoba, liphoso tsa kantle tsa kantle tse kang lithollo tsa kahare tse fokotsang thepa ea mochini, ho eketsa boleng ba likarolo le ho eketsa litšenyehelo; moetso o mosesane haholo oa lebota o tla baka ho tlatsoa ha aluminium e futsanehileng, ho bopa thata, ho qhibiliha ha aluminium e futsanehileng, le bothata ba ho tlatsa bokaholimo ba castings. , Ho haelloa ke thepa le litšitiso tse ling, mme ho tlisa mathata ho ts'ebetso ea ho lahla; ka keketseho ea li-pores, li-pores tsa kahare, ho fokotseha le likoli tse ling tsa die castings lia eketseha. Ka hona, tlasa moralo oa ho netefatsa matla le botsitso ba ho betsa, lebota la ho betla le lokela ho fokotsoa le ho boloka botenya ba junifomo ea karolo e fapaneng.

2.2 Moralo o nang le kahlolo e molemo oa likhopo tsa matlafatso bakeng sa li-cast cast

Bakeng sa likarolo tse kholo tsa sefofane kapa marako a tšesaane, matla le ho tenyetseha ha tsona li futsanehile, 'me ho bonolo ho li holofatsa. Ka nako ena, ts'ebeliso ea li-stiffeners e ka thibela hantle ho lahla batho hore ba se ke ba nyenyefala le ho robeha, ho felisa ho fetoha, le ho matlafatsa matla le ho tia ha li-cast. Bakeng sa meaho e joalo ka sethala, likhopo tse matlafatsang li ka sebelisoa ho ntlafatsa phano ea khatello ea maikutlo le ho thibela ho robeha ha metso. Ka nako e ts'oanang, likhopo tse matlafatsang li ka thusa phallo ea tšepe e qhibilihisitsoeng le ho ntlafatsa ts'ebetso ea ho tlatsa. Botenya ba motso oa stiffener ha bo boholo ho feta botenya ba lebota mona, 'me botenya ka kakaretso bo etselitsoe ho ba 0.8 ~ 2.0mm; sekhahla sa moqapi oa stiffener hangata se etselitsoe hore e be 1 ° ~ 3 °, bophahamo bo phahame, e nyane lehlakoreng la moralo; Fillet e lokela ho eketsoa motso oa khopo ho qoba liphetoho tse matla karolong ea karolo, mme ka nako e ts'oanang ho thusa phallo ea tšepe e qhibilihisitsoeng, ho fokotsa khatello ea maikutlo ea karolo eo, le ho eketsa matla a karolo eo . Fillet ka kakaretso e haufi le botenya ba lerako mona; bophahamo ba khopo ka kakaretso ha bo fete botenya ba eona bo 5. Botenya ba li-stiffeners ka kakaretso bo hlokahala hore bo tšoane. Haeba moralo o le mosesaane haholo, ho thata ho robeha ho thatafatsa ka boeona, 'me haeba e le tenya haholo, ho ka ba bonolo ho ba le liphoso tse kang li-depression le li-pores. Tafole ea 1 e bonts'a kamano lipakeng tsa botenya ba khopo le botenya ba lebota la samente.

2.3 Kahlolo e molemo moralo oa angle tsa shoela'ng foromeletsoeng

Karolo e phethoang ke shoela betsa letsoapong ke ho fokotsa khohlano pakeng tsa betsa le hlobo cavity, etsa hore ho be bonolo ho nka ho betsa; ho etsa bonnete ba hore holim shoa shoa ha e mathata, 'me e ka lelefatsa bophelo ba hlobo ena. Ts'ekamelo ea lefu e amana le bophahamo ba samente e shoang. Ha bophahamo bo le boholo, litakatso tsa lefu li nyane. Tlas'a maemo a tloaelehileng, karolo e tsoang ka ntle ea karolo e kaholimo ea karolo e laoloang ke hoo e ka bang 1/2 ea karolo e ka hare ea phallo, empa ka sebopeho sa 'nete, bokahare bo kahare le kantle ba karolo e lahlang bo ka etsoa e ts'oanang e le ho boloka botenya ba lerako. Ho tšoana, ho nolofatsa moralo oa sebopeho. Mohlala, Tafole ea 2 ke boleng ba litšupiso ba bonyane ba moralo oa likarolo tse fapaneng tsa likarolo tsa mofuta oa alloy, 'me Tafole ea 3 e bonts'a kamano lipakeng tsa sekhutlo le botebo ba sekoti ka seng.

| Lahla botebo ba lehare / thepa ea ho betla | <6mm | 6-8mm | 8-10mm | 10-15mm | 15-20mm | 20-30mm | 30-60mm |

| zinki motsoako | 2 ° 30 ' | 2 ° | 1 ° 45 ' | 1 ° 30 ' | 1 ° 15 ' | 1 ° | 0 ° 45 ' |

| aluminium motsoako | 4 ° | 3 ° 30 ' | 3 ° | 2 ° 30 ' | 2 ° | 1 ° 30 ' | 1 ° 15 ' |

| koporo motsoako | 5 ° | 4 ° | 3 ° 30 ' | 3 ° | 2 ° 30 ' | 2 ° | 1 ° 30 ' |

Kamano pakeng tsa tšekamelo ea sekoti le botebo ba hlobo

2.4 moralo kahlolo e molemo ea kabelo machining

Ha o rala likarolo tse shoang li lahla, machining e lokela ho qojoa ka hohle kamoo ho ka khonehang. Machining e tla senya lera le teteaneng holim 'a karolo mme e ame likarolo tsa mochini oa karolo eo; e tla pepesa masoba a kahare a karolo e shoang, e ama boleng ba bokaholimo, mme e eketsa litšenyehelo tsa karolo eo. Ha machining ea likarolo tse shoang e ka qojoa, moralo o nang le molumo o moholo oa ho itšeha o lokela ho qojoa ka hohle kamoo ho ka khonehang, mme sebopeho sa sebopeho se lokela ho ba bonolo ka hohle kamoo ho ka khonehang bakeng sa machining kapa ho fokotsa sebaka sa machining le ho fokotsa litšenyehelo tsa machining.

Karolo e kaholimo ea karolo e shoang e hloka likarolo tse phahameng tsa ho nepahala, kapa litlhoko tse ling tse sephara tse phahameng li phahame, mme ts'ebetso ea ho lahla e thata ho fihlela litlhoko. Ka nako ena, ts'ebetso e latelang ea hlokahala. Bakeng sa karolo ena ea sebopeho, kabelo ea machining e lokela ho bolokoa ka hohle kamoo ho ka khonehang ha ho raloa. Bokaholimo ba matla le ho thatafala ha likarolo tsa ho lahla li phahame ho feta tsa kahare. Ela hloko ho boloka bokaholimo ba nako nakong ea machining, ka hona, kabelo ea machining ha ea lokela ho ba e feteletseng. Machining e feteletseng e ka baka masoba le likoli tse kantle tsa bokaholimo. Tafole ea 4 e boloketsoe moelelo oa mochini hammoho le thoko ho leqephe.

| Boholo ba lebitso | 0-30 | 30-50 | 50-80 | 80-120 | 120-180 | 180-260 |

| Margin ka lehlakoreng le leng | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 |

2.5 Spray design ea li-castings tsa aluminium alloy

Bokaholimo ba fafatsa moralo oa likarolo tse shoang li lahla ka kakaretso e sebelisa mokhoa oa ho fafatsa phofo, molao-motheo oa ona ke ho fafatsa ka motlakase: pente e silafatsoa haholo ke eleketrode, ebe ntho e lokelang ho nyanyatsoa e qosoa ka qoso e fapaneng, le phofo e kopantsoe ka mokhoa o ts'oanang le bokaholimo ba ntho tlasa tšebetso ea matla a motlakase. . Litšobotsi tsa ts'ebetso ea ho fafatsa phofo: ho fafatsa ka motlakase ho ke ke ha baka tšilafalo ea moea, phofo e ka sebelisoa hape ho fokotsa litšenyehelo tsa ts'ebeliso ea thepa, 'me filimi ea ho roala e na le acid e ntle, alkali le ts'enyeho ea ts'enyeho.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Lintlha Tsa Bohlokoa Tsa Moralo oa Aluminium Alloy Die Casting

Khamphani ea Minghe Casting e nehetsoe ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo (likarolo tsa tšepe tsa die die li kenyelletsa haholo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off