Theknoloji ea Tlhahiso ea Lisebelisoa tsa Tšepe

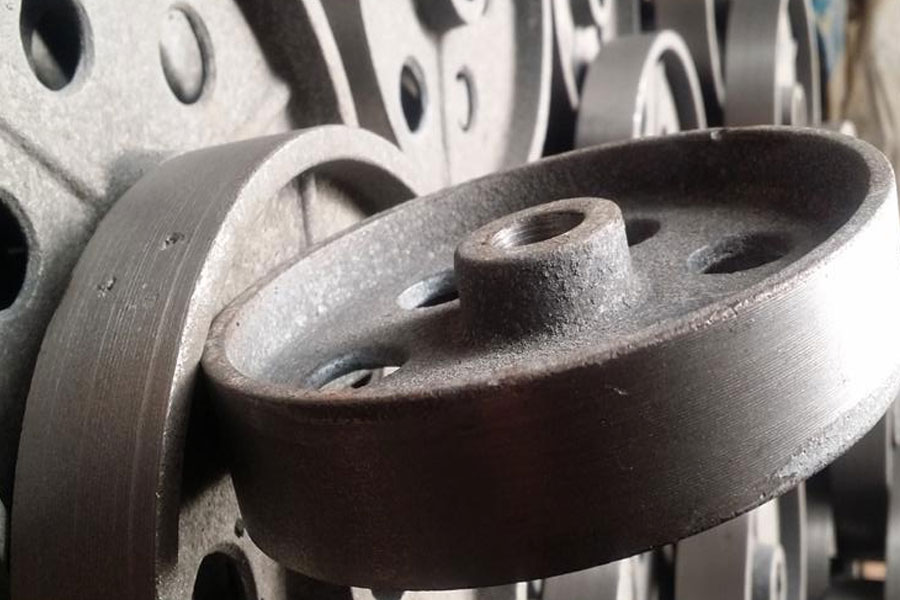

Bakeng sa likarolo tsa mochini tse hlokang matla a phahameng, polasetiki le ho ba thata, ho hlokahala litšepe tsa tšepe. Tlhahiso ea li-castings tsa tšepe ke ea bobeli ho latela tšepe feela, e ikarabellang bakeng sa 15% ea kakaretso ea lihlahisoa.

Ho latela sebopeho sa lik'hemik'hale, tšepe e ka aroloa ka mekhahlelo e 'meli: tšepe ea carbon le tšepe e entsoeng ka alloy. Har'a tsona, tšepe ea khabone e sebelisoa ka ho fetisisa, e ikarabellang ho feta 80% ea kakaretso ea tšepe e entsoeng.

1.Khabone Cast Tšepe

Ka kakaretso, tšepe e nang le khabone e tlase e na le ntlha e phahameng e qhibilihisang le ts'ebetso e mpe ea ho lahla, 'me e sebelisoa feela ho etsa likarolo tsa makoloi kapa likarolo tsa carburized; seaplane-k'habone tšepe ZG15, ZG25 na thepa akaretsang phahame ho feta mefuta eohle ea tšepe liheloe, ke hore, matla a phahameng le tshebetso babatsehang. Ka lebaka la polasetiki ea eona le ho thatafala ha eona, e loketse likarolo tsa tlhahiso e nang le libopeho tse rarahaneng, matla a phahameng le litlhoko tsa ho ba thata, joalo ka mabili a terene, ho betla liluloana tsa hamore le li-anvils, li-roll le li-valve tse phahameng. Ke mofuta o sebelisoang ka ho fetisisa oa tšepe ea khabone; Tšepe e nang le khabone e phahameng ZG45 e na le ntlha e qhibilihang e tlase, 'me ts'ebetso ea eona ea ho betla e betere ho feta ea tšepe e nang le khabone e mahareng, empa polasetiki ea eona le ho thatafala ha li hantle,' me e sebelisoa feela ho etsa likarolo tse 'maloa tse sa keneng.

2.Alloy Cast Tšepe

Ho latela palo yohle ea likarolo tse kopantsoeng, tšepe e entsoeng ka motsoako e ka aroloa ka mekhahlelo e 'meli: tšepe e tlaase ea alloy le tšepe e phahameng ea alloy.

- Tšepe e nang le motsoako o tlase, naha ea rona e sebelisa li-manganese series, li-manganese silicon series le chromium series. Joalo ka ZG40Mn, ZG30MnSi1, ZG30Cr1MnSi1, jj E sebelisetsoa ho etsa likarolo tse joalo ka likere, li-cylinders tsa khatiso ea hydraulic le li-rotor turbine tsa haeteroliki, mme ZG40Cr1 e sebelisoa haholo ho etsa likarolo tsa bohlokoa tsa khatello ea maikutlo joalo ka likere tse matla haholo le lithepa tse matla haholo. .

- Sesebelisoa se phahameng sa tšepe se nang le alloy, se nang le thepa e ikhethang e kang ho hanyetsa, ho hanyetsa mocheso kapa ho hanyetsa kutu. Mohlala, tšepe e phahameng ea manganese ZGMn13 ke mofuta oa tšepe e loantšang ho roala, e sebelisetsoang haholo ho etsa likarolo tse sebelisoang tlasa maemo a omileng a ho sebetsa, joalo ka lebota le ka pele le ho tšoara meno a lintho tse epollang, tse khasang tsa literekere le litanka, jj .; chromium-nikele celik ZG1Cr18Ni9 le chromium celik ZG1Cr13 le ZGCr28, jj, na le phahameng ts'enyeho hanyetsa acid e nitric, 'me ba haholo-holo sebelisoa ho etsa lik'hemik'hale, oli e tala, lik'hemik'hale faeba le likarolo thepa lijo.

Lahla litšobotsi tse thulaganyou e tšepe liheloe

Lisebelisoa tsa tšepe tse entsoeng ka tšepe li phahame ho feta tšepe ea tšepe, empa thepa ea eona ea ho betsa e mpe ho feta tšepe ea tšepe. Ka lebaka la ntlha e phahameng e qhibilihang ea tšepe e qhibilihisitsoeng, tšepe e qhibilihisitsoeng e bonolo ho e kopanya, mokelikeli oa tšepe e qhibilihisitsoeng o futsanehile, mme shrinkage e kholo. Sekhahla sa 'mele oa eona sa shrinkage ke 10-14% mme shrinkage e lekanang ke 1.8-2.5%. Bakeng sa ho thibela litšitiso tse joalo ka ho ts'ela ho sa lekaneng, karohano e batang, ho fokotseha le porosity, mapetso le ho khomarela lehlabathe ha litšepe, ho tlameha ho nkuoa mehato e thata ho feta tšepe ea tšepe:

- 1. Ka lebaka la phallo e futsanehileng ea tšepe e qhibilihisitsoeng, molemong oa ho thibela litšitiso tse batang le ho tšolleloa ho sa lekanang ha litšepe tsa tšepe, botenya ba lebota ba litšepe ha boa lokela ho ba tlase ho 8mm; sebopeho sa ts'ollo se lokela ho ba bonolo mme boholo ba sefapano se lokela ho ba kholo ho feta ba tšepe; ho lahla ho omileng ho sebelisoa Kapa hlobo e chesang; eketsa ka nepo mocheso o tšollang, ka kakaretso 1520 ° ~ 1600 ° C, hobane mocheso o tšollang o phahame, tšepe e qhibilihisitsoeng e na le mocheso o phahameng haholo, 'me boemo ba mokelikeli bo bolokiloe nako e telele,' me mokelikeli o ka ntlafatsoa. Leha ho le joalo, haeba mocheso o tšollang o phahame haholo, o tla baka likoli tse joalo ka lithollo tse harelaneng, mapetso a futhumatsang, masoba le ho manama ha lehlabathe. Ka hona, mocheso o lahlang oa litšepe tse nyane, tse marako a masesaane le sebopeho se rarahaneng o mabapi le mocheso o qhibilihang oa tšepe + 150 ° C; mocheso oa ho lahla o moholo, o nang le marako a maholo o ka ba 100 ° C ho feta sebaka sa oona se qhibilihang.

- 2. Ha shrinkage ea tšepe e lahleloa e feta haholo ea tšepe ea tšepe, ho thibela mekhabiso ea shrinkage le litšitiso tsa shrinkage ho castings, boholo ba lits'ebetso tsa ho betsa li amohela mehato e joalo ka risers, tšepe e batang le lithuso ho fihlela tatellano e latellanang. Bakeng sa ho thibela ho hlaha ha likheo tsa shrinkage, shrinkage porosity, pores le mapetso a litšepe tsa tšepe, botenya ba lebota bo lokela ho ba junifomo, likhutlo tse bohale le meaho ea likhutlo tse nepahetseng li lokela ho qojoa, sawdust e eketsoa lehlabatheng, coke e eketsoa ho ea mantlha, 'me ho sebelisoa li-cores tse Hollow le li-cores tsa lehlabathe tsa oli ho ntlafatsa ho khutla le ho kenella hoa moea ha hlobo ea lehlabathe kapa li-cores. Qhibiliha tsa tšepe liheloe e phahameng, 'me mocheso lona foromeletsoeng ke ka tsela e tšoanang phahameng. Tšebelisano lipakeng tsa tšepe e qhibilihisitsoeng le thepa ea hlobo mocheso o phahameng e ka hlahisa liphoso tsa lehlabathe habonolo. Ka hona, lehlabathe la maiketsetso la quartz le nang le ts'ireletso e phahameng le lokela ho sebelisoa joalo ka hlobo, 'me bokaholimo ba hlobo bo lokela ho hlatsoa ka seaparo se entsoeng ka phofo ea quartz kapa phofo ea lehlabathe la zirconium. E le ho fokotsa mohloli oa khase, ntlafatsa fluidity ea tšepe e qhibilihisitsoeng le matla a hlobo, boholo ba litšepe tse entsoeng ka tšepe li lahleloa ka hlobo e omileng kapa e omisang kapele, joalo ka hlobo ea lehlabathe ea silicate ea CO2 e thata.

- 3. Mocheso kalafo ea castings tšepe: All castings tšepe lokela ho sebelisoa ka mor'a kalafo mocheso. Hobane ho na le liphoso tsa ho lahla joalo ka porosity, mapetso, shrinkage cavity le shrinkage porosity, lithollo tse mahoashe, sebopeho se sa lekanang le khatello ea kahare ea masale ho castings ea tšepe seterekeng sa as-cast, matla, haholo polasetiki le boima ba litšepe tsa tšepe li E le hore e ntlafatsoe lijo-thollo, sebopeho sa junifomo le ho felisa khatello ea maikutlo ea kahare, litšepe li lokela ho hlophisoa kapa ho tlatsetsoa. Tšepe e tloaelehileng e na le thepa e phahameng ea mochini le theko e tlase ho feta tšepe e koetsoeng, ka hona e na le lits'ebetso tse ngata. Leha ho le joalo, hobane ho tloaela kalafo ho tla baka khatello ea maikutlo e kholo ho feta ho annealing, e loketse feela litšepe tse nang le khabone e ka tlase ho 0.35%. Hobane castings e nang le khabone e tlase e na le polasetiki e ntle, ha ho bonolo ho petsoha nakong ea pholileng. Bakeng sa ho fokotsa khatello ea maikutlo ea kahare, litšepe li lokela ho futhumatsoa ka mocheso o phahameng kamora ho tloaela maemo. Bakeng sa li-castings tsa tšepe tse nang le khabone ≥ 0.35%, sebopeho se rarahaneng ebile se bonolo ho petsoha, ho ka etsoa kalafo e kenyang feela. Lisebelisoa tsa tšepe ha lia lokela ho tima, ho seng joalo li tla petsoha habonolo.

- 4. ho qhibiliha ha tšepe e qhibilihisitsoeng: Ho qhibilihisoa ha tšepe e entsoeng ka tšepe ho sebelisa lits'oants'o tse bulehileng tsa leifo, lihokelo tsa motlakase tsa arc le sebopi sa motlakase. Leifo le bulehileng le khetholloa ka matla a lona a maholo, ts'ebeliso ea tšepe e setseng e le lisebelisoa tse tala, bokhoni ba ho laola ka nepo sebopeho sa tšepe le bokhoni ba ho qhibilihisa tšepe ea boleng bo holimo le tšepe e nang le alloy e tlase. E sebelisoa haholo ho qhibilihisa tšepe e qhibilihisitsoeng bakeng sa li-castings tse kholo tsa tšepe tse nang le litlhoko tsa boleng bo holimo.

Sebōpi sa selikalikoe sa mekhahlelo e meraro se bonolo ho qala le ho emisa sebōpi, se ka netefatsa sebopeho le boleng ba tšepe e qhibilihisitsoeng, litlhoko tsa tefiso ha li thata haholo, 'me ho bonolo ho li futhumatsa, ka hona e ka nyolohela holimo. tšepe ea boleng bo phahameng, tšepe ea alloy ea maemo a holimo le tšepe e ikhethileng, jj Ke sebopeho sa tlhahiso e Tloaelehileng ea lisebelisoa tsa tšepe.

Ntle le moo, maqhubu a motlakase kapa sebōpi sa maqhubu a maqhubu a motlakase a ka sebelisoa ho qhibilihisa litšepe le lisebelisoa tse fapaneng tsa maemo a holimo tse nang le khabone e tlase haholo. Sebōpi sa ho kenella se na le lebelo la ho qhibilihisa ka potlako, karolo e tlase ea alloy e chesang tahlehelo, tšebeliso e tlase ea matla, le boleng bo holimo ba tšepe e qhibilihisitsoeng, ke hore, litšila tse tlase le tse kenyellelitsoeng tse fokolang. E loketse lithupelo tse nyane tsa tšepe.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape:Theknoloji ea Tlhahiso ea Lisebelisoa tsa Tšepe

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off