Kenyelletso ho Tsamaiso e Bobebe ea Likoloi

Hajoale, ka phetoho ea sebopeho sa matla le ntlafatso ea litlhoko tsa ts'ireletso ea tikoloho, indasteri ea likoloi e ntse e tsoela pele ka lehlakoreng la boima bo bobebe. Boitsebiso bo bonts'a hore ho fokotseha ha 10% ho boleng ba makoloi, ts'ebeliso ea mafura e fokotseha ka 3% ho isa 5%. Boima ba koloi ha bo khone ho fokotsa ts'ebeliso ea matla le ho eketsa ts'ebetso ea ts'ebeliso ea koloi, empa hape bo fokotsa litšenyehelo tsa tlhahiso le ho ntlafatsa boleng ba koloi. E fetohile tataiso ea bohlokoa bakeng sa tlhahiso ea likoloi ho fokotsa boima ba koloi.

Mokhoa oa bohlokoa oa ho tseba boima ba makoloi

Ehlile, bobebe ba koloi ha se taba e bonolo feela ea ho fokotsa boima ba koloi, empa ke ho netefatsa boleng ba koloi, ho sebelisa lisebelisoa tse ling tse ncha likarolong tse sebetsang le tsa sebopeho tsa koloi ho etsa ts'ebetso ea likarolo tsa koloi ho feta khabane ka ho fetisisa. Ka nako e ts'oanang, boima bo bobebe, bo netefatsang hore ts'ebeliso ea matla a koloi e fokotsehile nakong ea ts'ebetso ea ho khanna, mme e fihlela litlamorao tse ngata.

E tsamaellanang le ho theoha ha boleng ba koloi ka boeona, theknoloji e bobebe ea koloi e fihlelleha haholo-holo ka litsela tse latelang: karolo ea lisebelisoa tse bobebe e ntse e tsoela pele ho phahama, lits'epe tse kopantsoeng ka aluminium, lits'epe tsa tšepe tsa magnesium, lits'epe tsa tšepe tsa thaethaniamo, litšepe tse matla haholo, lipolasetiki , metallurgy ea phofo, le thepa e nang le likarolo tse ngata tsa tikoloho Le ts'ebeliso ea letsopa, jj .; Ntlafatso ea sebopeho le boemo ba moralo oa likarolo le likarolo li ntse li tsoela pele ho ntlafala, joalo ka ts'ebeliso ea mabili a ka pele, sebopeho se phahameng le sebopeho sa ho emisa marang-rang ho fihlela sepheo sa theknoloji e kopaneng e bobebe, e thusitsoeng ke khomphutha (ho kenyelletsa CAD / Nts'etsopele ea mahlale a kang CAE / CAO) le tlhahlobo ea sebopeho li khothalelitse boiphihlelo bo tsoelang pele mokhoeng oa ho theha le theknoloji ea khokahano ea indasteri ea tlhahiso ea makoloi.

Ka mekhoa e meraro e kaholimo ho tseba boima ba likoloi, ts'ebetso ea lisebelisoa tse ncha, moralo le sebopeho sa likoloi le ho li hlophisa, le tsoelo-pele ea mahlale a khokahano kaofela e hloka boqapi bo tšoanang ba mahlale ho fihlela. Har'a mekhoa ena e meraro, ho itšeha ka laser le laser welding ho na le menyetla ea tsona e ikhethang 'me e ba mekhoa ea bohlokoa ea tekheniki ea ho hlokomela boima ba likoloi.

Laser tjheseletsa le tham mong bang laser ho itšeha popontshwa theknoloji e bobebe bobebe

Ho etsa likoloi ke boenjiniere bo boholo ba sistimi bo hlokang letoto la lits'ebetso le mahlale ho phetheloa. Lilemong tsa morao tjena, theknoloji e tsoetseng pele e emeloang ke ho khaola laser, liroboto tsa indasteri, le taolo ea dijithale li ntse li tsoela pele ho khothaletsa ntlafatso ea indasteri ea tlhahiso ea likoloi. Joalo ka mokhoa o tsoetseng pele oa ts'ebetso, laser e reretsoe ho tlisa liphetoho tse kholo ho nts'etsopele ea indasteri ea tlhahiso ea likoloi. . Hajoale, theknoloji ea laser lebaleng la tlhahiso ea likoloi e shebana haholo le lits'ebetso tse kang laser welding, laser cutting, laser weakening, laser marking, laser trimming le laser remanufacturing.

Monyetla oa bohlokoa ka ho fetesisa oa laser tlhahisong ea likoloi ke mokhoa oa eona o tsoetseng pele oa ho sebetsana le batho o sa sebetsaneng le ona, o phethang karolo ea bohlokoa ho poponong ea theknoloji ea ts'ebetso masimong a likoloi tse tšoeu, likoloi tsa elektroniki, ts'ebetso ea tšepe joalo-joalo. Ts'ebelisong ea lisebelisoa tse ncha tse kang lits'epe tse kopantsoeng ka aluminium, lits'epe tse kopantsoeng ka magnesium, lits'epe tse kopantsoeng tsa thaethaniamo, ho itšeha ka laser ho potlakile ebile ho nepahetse ho feta mekhoa ea ho itšeha e fetileng. Bakeng sa lisebelisoa tsena tse thata ho sebetsa, ho itšeha ka laser ho bonolo ho e fihlela. Tsoelo-pele ea mahlale e boetse e fetotse ts'ebeliso ea lisebelisoa tsena tse ncha ho tloha boemong ba nnete ho ea ho ba nnete, e le hore lisebelisoa tse ncha li ka bonoa bobebe ba likoloi.

Sebopeho le modularization ke kopanyo ea likarolo tse arohaneng le likarolo tsa tlhahiso ea setso ea likoloi ho hlokomela mesebetsi ea mantlha ea koloi ka kakaretso, ka tsela eo e fokotsa boima ba 'mele le ho hlokomela boima bo bobebe. Ho phethahala ha moralo le modularization ho latela boholo ba tsoelo-pele ea mahlale a khokahano. Mekhoa e meng ea setso ea tlhahiso e hoketsoe ka lisepa, 'me e meng e hokahantsoe ke sekhomaretsi. Mekhoa ea setso e ke ke ea fihlela litlhoko tsa ho nepahala le ho tiea tlhahisong ea makoloi ea sejoale-joale, mme ts'ebeliso ea lisebelisoa tse ncha e boetse e etsa hore mekhoa ea setso e be mpe hanyane. Laser tjheseletsa ke bao e seng o ikopanye. Nakong ea ts'ebetso, ho tjheseletsa ka nepo ho ka fihlelleha ntle le ho ama sehlahisoa. E fihlelletse tsoelopele e tlohang pele ho botsitso, ho hloka botsitso, ho nepahala le bohloeki ba khokahano. Eba mokhoa oa bohlokoa oa ho bōpa nakong e tlang.

Mahlale a laser a phethile karolo ea bohlokoa bobebe ba likoloi, ka tsela eo a ntlafatsa ts'ebetso le polokeho ea likoloi. Nakong e tlang, theknoloji ea laser e na le menyetla e pharaletseng ea ts'ebeliso lebaleng la likoloi.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Kenyelletso ho Tsamaiso e Bobebe ea Likoloi

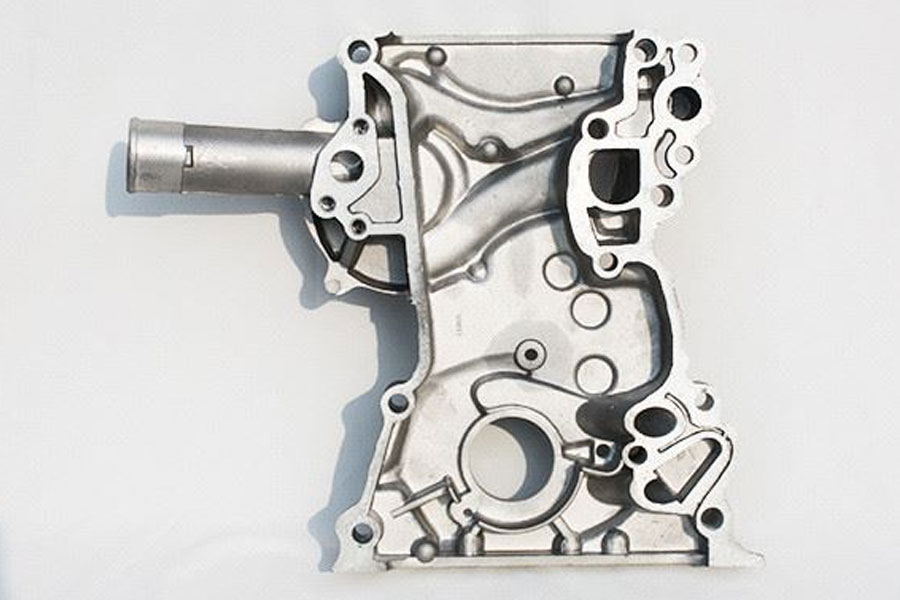

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off