Moralo oa Ts'ebetso ea Shell Body Die

Ho latela litšobotsi tsa sebopeho sa khetla, ts'ebetso ea ho betsa e entsoe. Ka papiso ea lipalo ea lits'ebetso tse peli tsa litheko tse sebelisang software ea ProCAST, libaka le lisosa tsa likhahla tsa shrinkage le porosity li ile tsa hlahlojoa, 'me ha khethoa sistimi e betere ho ntlafatsa ts'ebetso ea ho lahla ka ho e bapisa. Liphetho li bonts'a hore kamora ts'ebetso ea ts'ebetso, li-castings ha li na masoba a shrinkage kapa porosity defects, 'me li netefalitsoe ka tlhahiso, e fihlelang litlhokahalo tsa tekheniki

Die casting ke mofuta oa theknoloji ea ho lahla m e nang le degree e phahameng ea boiketsetso ebile e khona ho hlahisa likarolo tse ngata tse nang le libopeho tse rarahaneng. The castings e hlahisoang ke eona e na le menyetla ea ho sebetsa hantle, ho nepahala ho phahameng, kabelo e tlase ea machining le thepa e ntle ea mochini. E sebelisoa likoloing le mechineng. 1wl e sebelisitsoe haholo lisebelisoa le masimong a mang. Khetla ea casing ke sesebelisoa sa bohlokoa bakeng sa ho kenya likarolo tsa likoloi. Botenya ba eona ba lebota bo batla bo le bosesane, empa thepa ea eona ea mochini, ho nepahala, le ho thatafala ha moea ho hlokahala hore li be holimo, 'me tlhahiso ea bongata ea hlokahala. Ka hona, khatello ea khatello ke khetla e ntle bakeng sa tlhahiso. Khetho.

Pampiri ena e hlahloba sebopeho sa ho betsa, e rala sistimi ea ho betsa, ebe e e etsisa ka software ea PmCAST. Ka ho sekaseka liphetho tsa ketsiso, ts'ebetso e ntlafalitsoe ho felisa liphoso tse joalo ka ho fokotseha le porosity, e le ho fumana ts'ebetso ea ho lahla e fihlellang litlhokahalo tsa tekheniki ea khetla.

Lisebelisoa tse ntseng li ithutoa ke setulo sa likarolo tsa likoloi tse hlahisoang ke k'hamphani e itseng. Setšoantšo sa eona sa mekhahlelo e meraro se bonts'itsoe ho Setšoantšo sa 0.5. Sebaka se lefifi ke bokaholimo ba machining, karolo ea mechini ke 103 mm, le boholo ba kemiso ke 98 mm x 89 mm x 234 mm, ho lahla bophahamo ba modumo ke 108 632 mn r ', boima ke 5.5 g, lebota le tenya ka ho fetesisa ke 2.5 mm, lebota le lesesane ka ho fetesisa ke 3 mm,' me botenya ba karolelano ea lebota ke 113 mm. Lisebelisoa tsa ho lahla ke Al-Si-Cu alloy YL1.5 e nang le fluidity e ntle, moea o matla, le ho hanyetsa ho hoholo. Motsoako oa eona oa motsoako o bontšoa ho Tafole lw. Li-castings li hlokahala hore li be le bokaholimo bo boreleli, lehlakore le saloang ha lea lokela ho feta 0.6 °, sekhahla sa ho lahla ke XNUMX%, mme ha hoa lokela ho ba le liphoso tsa kahare tse kang masoba a shrinkage le porosity.

Ka moralo oa hlobo, ts'ebetso ea ho lahla die ke ea bohlokoahali, e amang ka kotloloho boleng ba ho betsa, tlhahiso le Cnc mochini theko, le bothata ba ho etsa thepa hlobo. Ts'ebetso ea ho lahla shoa e kenyelletsa khetho ea bokaholimo ba bokahohle, moralo oa sistimi ea gating, moralo oa sistimi e khaphatsehang le ho qeta monono

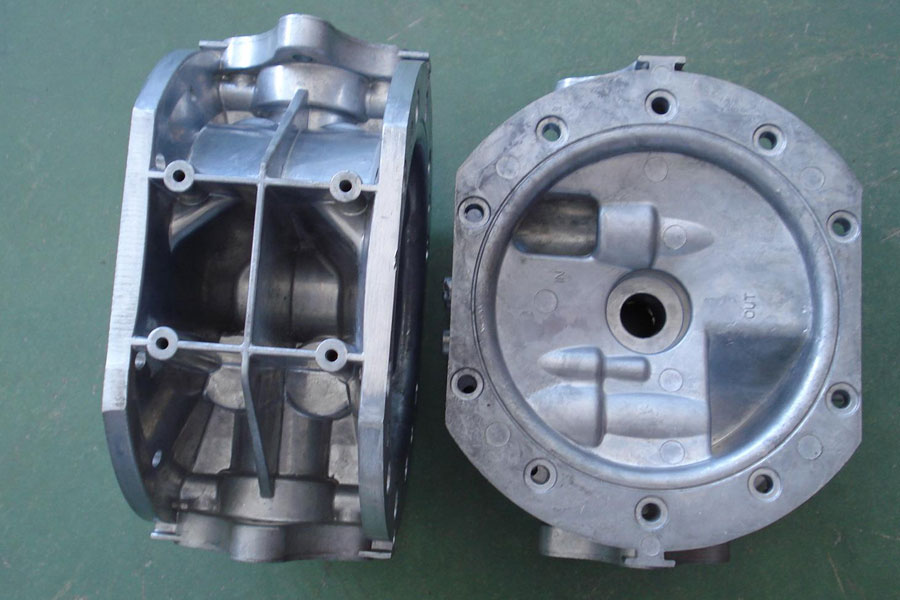

- Sebopeho sa casing se batla se le thata, 'me ho hlokahala mochini oa ho hula oa mantlha. Ka hona, ho thata ho etsa hlobo. Ka hona, ho betsa ho sebelisa mokhoa o le mong oa hlobo ea ho betla. Ho latela molao-motheo oa karolelano ea khetho ea bokaholimo, khetha sebaka se seholohali sa sebaka se hlahisitsoeng. Ho na le mekhoa e 'meli ea karohano ea bokaholimo bakeng sa ho betloa hona. Joalokaha ho bonts'itsoe ho Setšoantšo sa 2, ho sebelisa karohano holim'a metsi, ho hlokahala mochini o le mong feela oa konokono, empa ho lahla ho na le mokoti o tebileng le matla a maholo a ho tiisa, mme ho lahla ha ho bonolo ho oela; Taba ea bobeli, lebota le betlang le tšesaane, 'me ha ho bonolo ho kenya mochini oa ho ntša metsi. Ka karohano bokaholimo b, ho betsa ho hloka ho hlomelloa ka mekhoa e mengata ea ho hula ea mantlha, 'me hlobo ea hlobo e rarahane, empa ho lahla ho hlile ho lekana ka hodimo le tlase, mme ho lahla ho tletse hantle. Taba ea bobeli, ho bonolo ho theha mochini oa ho ntša metsi, o leng molemo ho sethaleng sa phallo e khaphatsehang le mokhatlong oa ho qeta, mme e sebetsa hantle ho feta ho fihlela litlhoko tsa ts'ebetso ea ho lahla, S sengoloa sa sengoloang se khetha bokaholimo ba b.

- Heke e kahare e ka aroloa ka: heke e sephara e kahare, heke e lehlakoreng la sefahleho e bohareng, heke e kahare e bohareng, heke e ka hare ea annular, jj. 16]. Khetla ke ea mofuta oa cylindrical. Bakeng sa ho qoba tšusumetso e tobileng ea tšepe e qhibilihisitsoeng mokokotlong le ketsahalong ea mamarello, lits'ebetso tse peli tsa ho koala li amohela fepa e kenang kahare ea heke e kenang, ke hore, semathi sa annular se behiloe ka lehlakoreng la ho betsa, 'me se qhibilihisitsoeng tšepe e tlatsoa Kamora semathi sa annular se kenella ka mokokotlong, tšepe e qhibilihisitsoeng e ka fumana lebelo le lekanang ho selikalikoe sa annular, hore tšepe e qhibilihisitsoeng e tlale hantle 'me khase e ka mokokotlong e lokolloe habonolo. Taba ea bobeli, ho a khonahala ho kenya molamu hekeng e kahare ho qoba mesaletsa ea molamu o sutumetsoang.

- Semathi ke mocha oa phetoho oa tšepe e qhibilihisitsoeng ho tloha sprue ho ea hekeng e kahare. Bakeng sa li-castings tse fapaneng tsa lefu, semathi se na le meaho e fapaneng, 'me bakeng sa li-castings tsa cylindrical, sebopeho sa konteraka se amoheloang. Bakeng sa ho thibela khatello e mpe ha tšepe e qhibilihisitsoeng e phalla, sebaka se parolang sa semathi se lokela ho fokotsoa hanyane ka hanyane

- Sprue ke mocha o ka sehloohong oa tšepe e entsoeng ka ho qhibilihisoa ho kena kahare ho tsoa mochini o lahlang. Boholo ba eona bo amana le bophara ba kamore ea khatello ea mochini oa ho lahla. Thutong ena, bophara ba kamore ea khatello ke 60 mm, botenya ba thepa e setseng bo behiloe ho 10 mm, 'me sekhahla sa moralo ke 10 °.

- Kenya mehlala ea 3D ka har'a software ea ketsiso ProCAST bakeng sa karohano ea marang-rang, seta boholo ba yuniti ea grid ho 2 mm, le boholo ba yuniti ea hlobo ho 10 mm

- Bakeng sa ho etsa hore ho betloa ho ts'oarelle ka mokhoa o ts'oanang le botenya ba lebota, thuto ena e thehile mocha oa metsi o pholileng ka kotloloho ka tlase ho shrinkage porosity le shrinkage cavity sebakeng sa ho betsa, mme e hlophise li-groove tse peli sebakeng sa moo shrinkage porosity le shrinkage Sebaka sa sekoti se tsepamisitsoe ho e etsa hore e felise ka botlalo khase le ho kenyelletsa, ho fetisetsa maemo a shrinkage, mme leano le ntlafalitsoeng la ts'ebetso le bonts'itsoe ho Setšoantšo sa 10. Kamora ho ntlafatsa, mekhahlelo ea ts'ebetso e beha mochini o tsamaisang mocheso oa mocheso oa mocheso oa metsi a batang le hlobo ho 2 000 / (• K), le mekhahlelo e meng e lula e sa fetohe

- Ho latela sebopeho sa khetla, ho entsoe meralo e 'meli ea li-gating bakeng sa li-castings, mme software ea ProCAST e sebelisetsoa ho etsisa lipalo ho tsona. Liphetho li bonts'a hore li-castings li na le masoba a shrinkage le liphoso tsa shrinkage leboteng la lebota; heke e ka hare e behiloe botenya ba lebota. Ho na le likoti tse fokolang tsa shrinkage sebakeng seo. Tlhatlhobo e fumane hore lebaka la ho senyeha ha mokoti le porosity ea ho betsa ke hore ho betsa ho tiisitsoe ka mokhoa o sa lekanang le botenya ba lebota, mme karolo e 'ngoe ea sebaka seo e arohane ebile e ke ke ea fepuoa.

Ka ts'ebetso ea ts'ebetso, li-castings li entsoe ntle le masoba a shrinkage le likoli tsa porosity, mme ts'ebetso e ntlafalitsoeng e sebelisetsoa netefatso ea tlhahiso. Ka tlhahlobo, ho fumanoe hore ha ho na masoba a shrinkage le shrinkage porosity defects kahare ho castings, mme e fihlela litlhoko tsa tekheniki, tse ka sebelisoang ho tataisa liqapi tse tšoanang tsa ts'ebetso ea ho lahla thepa.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Moralo oa Ts'ebetso ea Shell Body Die

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off