Kemiso ea Mechini ea Die Casting le Ts'ebetso ea Ts'ebetso

Mochini oa li-die-casting ke sesebelisoa sa bohlokoa sa theknoloji ea tlhahiso ea ho shoa, e nang le tšusumetso e tobileng ho boleng, ts'ebetso ea tlhahiso, litšenyehelo tsa ts'ebetso, matla a basebetsi, tikoloho le bohloeki ba likarolo tse lahlehang. Ka hona, ho lokela ho ba le kutloisiso e hlakileng ea mochini o lahlang, e le hore mochini o lahlang o ka sebelisoa ka mokhoa o ts'oanang le o utloahalang ho netefatsa tsoelo-pele e ntle ea tlhahiso ea ho lahla le ho eketsa tlhahiso ea basebetsi.

Classification Of shoa lahla Machine

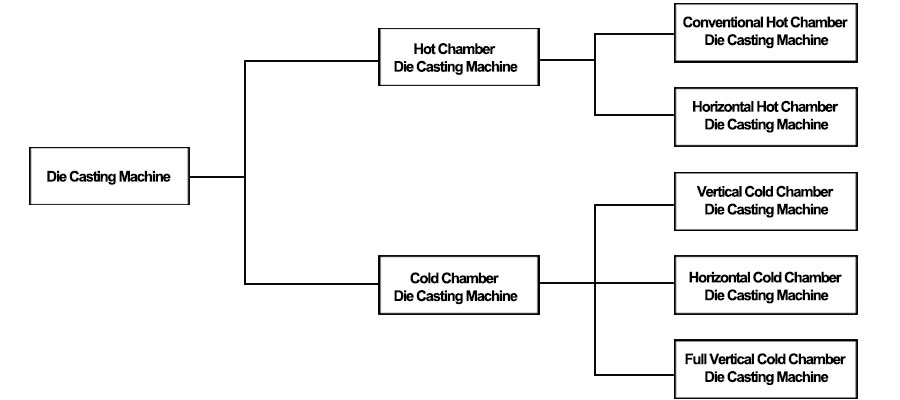

Ho na le mekhoa e mengata ea tlhophiso ea mechini e lahlang li-die. Ho latela boholo ba ts'ebeliso, li arotsoe ka mechini e akaretsang ea ho lahla le mechini e khethehileng ea sepheo sa ho lahla; ho latela matla a tlamang, a arotsoe ka mechini e menyenyane (≤4 000 kN), mechini e mahareng (4 000 ~ 10 000 kN) le mechini e meholo. Mochini (≥10 000 kN); Ka kakaretso, e arotsoe haholo ho latela mochini oa mochini le boemo ba phaposi ea ente (eo hamorao e tla bitsoa kamore ea khatello) le maemo a eona a ts'ebetso. Mabitso a mefuta e fapaneng ea shoa-lahla Mechini e bonts'oa ho Setšoantšo sa 1.

Setšoantšo sa 1

Mochini oa ho betla o chesang o chesang o chesang o ka holimo ho Setšoantšo sa 1 o behiloe ka mokhoa o rapameng. E qapiloe ka lekhetlo la pele ke Khampani ea Harvill e United States ka 1981, 'me ea phatlalatsoa ka 1982. Ka 1983, e ile ea bontšoa Sebokeng le Pontšong ea Li-casting tsa 12 tsa Machabeng tse neng li tšoaretsoe United States. Horizontal chesang kamore mochine ente. Ka lebaka la mabaka a fapaneng, mofuta ona oa mochini ha o e-so tsebahale, ka hona nke ke ka o tsebisa hajoale.

Sebopeho sa The shoa lahla Machine

- The hlobo clamping mochini kganna shoa-lahla hlobo ho koala le bulehileng. Ha hlobo e koetsoe, e na le bokhoni bo lekaneng ba ho notlela hlobo ho netefatsa hore bokaholimo ba hlobo bo ke ke ba hola nakong ea ts'ebetso ea ho tlatsa ente. Matla a ho tlama hlobo e bitsoa clamping force (eo hape e tsejoang e le matla a koalang), mme yuniti ke kilonewton (kN), e leng parameter e ka sehloohong e khethollang boholo ba mochini o lahlang.

- Mochini oa ente o sutumetsa tšepe e qhibilihisitsoeng ka phapusing ea khatello ka lebelo le boletsoeng, 'me o na le matla a lekaneng ho e tsamaisa ka semathi le kahare ea hlobo, ebe oe tlatsa kahare ea hlobo, ebe o boloka khatello e itseng ho fetisetsa ho tšepe e entsoeng ka ho qhibilihisoa e ntse e tiea ho fihlela ho thehoa tšepe. Kamora hore ts'ebetso ea ente e phethetsoe, setebele sa ente se khutlela ho reset.

- Sisteme ea hydraulic e fana ka matla le matla a lekaneng bakeng sa ts'ebetso ea mochini o lahlang li-die.

- Sisteme ea taolo ea motlakase e laola ho etsoa ha mochini o mong le o mong oa mochini o lahlang o tla sebetsa ho latela lenaneo le reriloeng esale pele.

- Likarolo tsohle le likarolo tsa setsi sa mochini li kopane ebile li bokelletsoe ho theha mochini oohle oa ho lahla 'me o tsitsitse mochini oa mochini.

- Lisebelisoa tse ling Mochini o tsoetseng pele oa ho lahla mochini o boetse o na le phumano ea parameter, alamo ea phoso, ho lekola ts'ebetso ea ho lahla thepa, polokelo ea tlhahiso ea tlhahiso ea likhomphutha e thusitsoeng.

- Sesebelisoa se thusang se na le lisebelisoa tse kang ho tšollela, ho fafatsa le ho khetha ho latela degree ea automation.

Mochini oa Die Casting o Sebetsa Joang

Hot kamoreng shoela'ng foromeletsoeng mochini

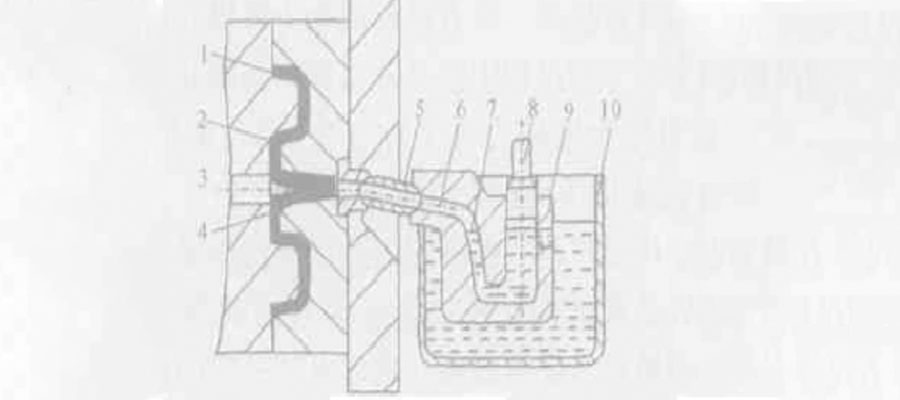

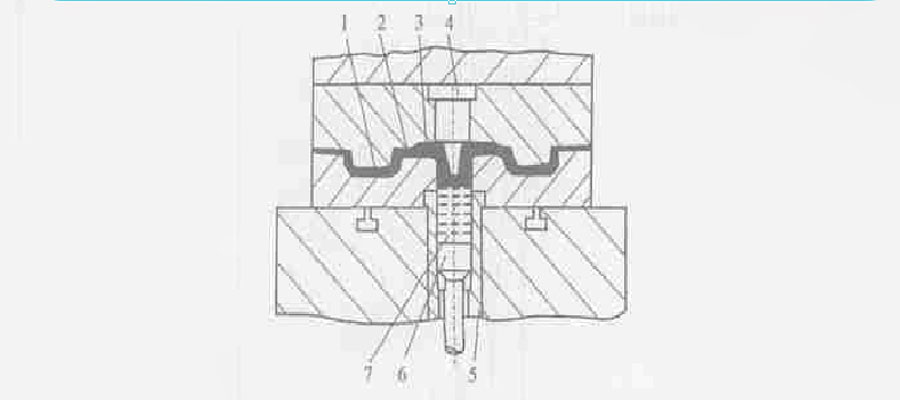

Mokhoa o tloaelehileng oa ho sebetsa oa mochini o chesang oa kamore ea ho chesa o bonts'oa ho Setšoantšo sa 2. Sebōpi sa 10 sa mochini o chesang oa kamore ea ho chesa se behiloe mochini.

Ho tšela seboping, pitsa e tšollang 9 e nang le phaposi ea khatello le kanale ea gooseneck le setebele sa ente 8 kaofela li qoelisitsoe ka tšepe e qhibilihisitsoeng 7. Liketso tsa ho bula le ho koala ha hlobo li ea holimo. Ka mor'a hore hlobo e buloe, lahla shoela'ng lula ka hlobo e etsoang ka mechine. Mehato ea ho sebetsa e tjena:

- Poleiti ea hlooho ea mochini le sesepa sa hlobo sa hlobo li haufi le nozzle (mechini e meng ha e na lenaneo lena);

- Koala hlobo;

- Ha litebele tsa jekete li le boemong bo bonts'itsoeng setšoantšong, tšepe e qhibilihisitsoeng e kena libakeng tse fapaneng ka pitseng e tšolotsoeng ho tloha mekhabisong e ka lehlakoreng. Kamora ho phalla, kanale ea gooseneck

- Boemo ba mokelikeli kahare bo ntse bo tšoloha ka mokelikeli sebōping;

- Punch ea ente e theoha butle ka lebelo la ente ho fihlela lesoba le lehlakoreng le tiisitsoe;

- Punch ea ente e sutumetsa tšepe e qhibilihisitsoeng ka lebelo le phahameng, 'me e feta setopong sa gooseneck 6, nozzle 5, sprue 4 ea hlobo, splitter 3 le heke e kahare

- 2 Tlatsa ka hlobo ea mokokotlo, ebe o tiisa hore e be sesebelisoa sa 1;

- Punch ea ente ea phahamisoa, 'me tšepe e qhibilihisitsoeng ka har'a nozzle le channel ea gooseneck e khutlela pitseng e tšelang;

- Bula hlobo, tlohela karolo e shoang e lahleloa le heke ka hlobo e tsamaeang, ebe o ntša karolo e lahlehang;

- Sejana sa hlooho ea mochini le sesepa sa hlobo sa hlobo se siea nozzle (mechini e meng ha e na lenaneo lena); ho fihlela joale, potoloho ea batho ba shoang e phethetsoe.

Figure 2 sebetsa mode ya kamoreng chesang chesa shoela'ng foromeletsoeng mochini

1. Ho shoa li-castingparts

2. Heke e ka hare

3. Ho arohana

4. Fafatsa

5. Molomo

6. Mocha oa Gooseneck

7. Mokelikeli oa tšepe

8. Letlalo la ente

9. Ho tšela pitsa

10. Sebopi

Mochine oa Cold Chamber Die Casting

Enjene ea mantlha ea phaposi e batang ea mochini o batang e arotsoe seboping, sebōpi se beoa ka lehlakore, mme tšepe e qhibilihisitsoeng e tlosoa seboping ho ea kamoreng ea khatiso ea enjene e kholo. Sebōpi hangata se netefalitsoe hobane ha se sebelisetsoa ho futhumala, hangata se bitsoa sebōpi se ts'oereng. ha feela palo ea mechini e le lihlahisoa tse nyane kapa tse nyane tsa lihlahisoa, sebōpi se ts'oereng se sebetsa e le sebaka sa ho qhibiliha. Kamore e batang ea ho lahla mochini e arotsoe ka phapusi e batang, kamore e batang e batang le kamore e batang e batang.

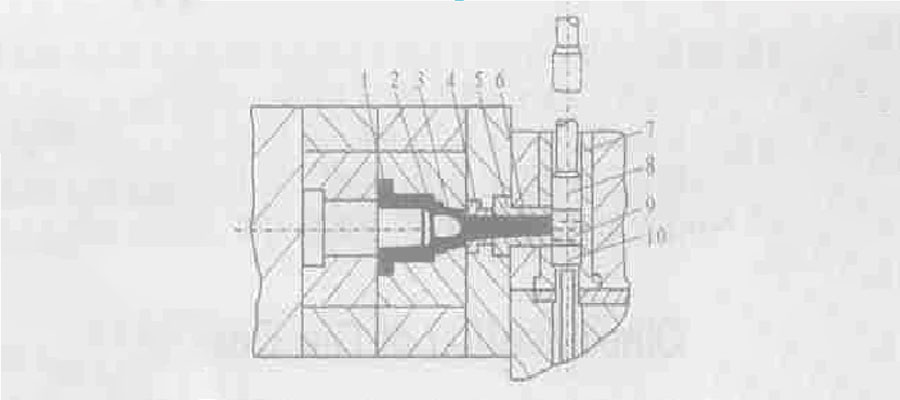

Sebetsa mokgwa wa tsa paatsepama kamoreng batang shoela'ng foromeletsoeng mochini

Mokhoa o sebetsang oa mochini o batang oa kamore e batang o bontšoa ho Setšoantšo sa 3. Kamore ea khatello ea 7 e behiloe holimo, mme litebele tse kaholimo tsa 8 li kaholimo ho kamore ea khatello (boemo bo kaholimo ho palo), 'me litebele tse tlase tsa 10 li teng sebakeng seo nozzle 5 bose e koetsoeng ho sona, e le ho thibela tšepe e qhibilihisitsoeng hore e se tšele ka phapusing ea khatello ebe e phalla ka sekoting sa nozzle ka boeona. Monyako le koalang hlobo e tshekaletseng. Mehato ea ho sebetsa e tjena:

Figure 3 sebetsa mokgwa wa tsa paatsepama kamoreng batang shoela'ng foromeletsoeng mochini

1. shoa likarolo lahla

2. Shunte

3. Heke e ka hare

4. Sleeve ea letsoho

5. Molomo

6. Fafatsa

7. Kamore ea khatiso

8. Bokete bo holimo

9. Kuku ea masalla

10. Punch e tlase

- Koala hlobo;

- Tšela tšepe e qhibilihisitsoeng ka phapusing ea khatiso ka letsoho kapa ka mekhoa e meng;

- Punch e kaholimo e theohela tlase ka lebelo le tlase la ente, e kena ka phapusing ea khatello ebe e ama feela tšepe e qhibilihisitsoeng;

- Punch e kaholimo e fetoloa lebelo le phahameng la ente ho hatella tlase, ha e tlase le e holimo e boloka sebaka se batlang se lekana pakeng tsa karolo e bohareng le tšepe e qhibilihisitsoeng ebe e theohela tlase kapele;

- Ha kotlo e tlase e theohela tlase ho ntša bono ea nozzle, e theohela tlase feela mme e ts'ehelitsoe; ka hona, litebele tse holimo le tse tlase li pepeta tšepe e qhibilihisitsoeng ka lebelo le leholo ho ea lesobeng la nozzle (karolo ea sprue 6) Jet;

- Ts'epe e entsoeng ka ho qhibilihisoa e feta ka sehlotšoana sa 6, se entsoeng ka nozzle, sleeve ea 4, sekoti se koahetsoeng sa hlobo e sa fetoheng, 'me se khelosa 2,' me se tlatsitsoe kahare ea hlobo ho tloha hekeng e ka hare ea 3;

- Ho tlatsa ho phethiloe, empa litebele tse holimo li ntse li boloka khatello e itseng ho fihlela tšepe e qhibilihisitsoeng ka hara mokoti e tiile ka botlalo hore e be karolo ea 1; tšepe e qhibilihisitsoeng semathi le phapusi ea khatello e tiisa hekeng e otlolohileng le kuku e setseng ea 9;

- Punch e kaholimo e phahamisitsoe ebe e seta bocha; ka nako e ts'oanang, kotlo e tlase e ea holimo ho ea khaola kuku e setseng e ntseng e hoketsoe hekeng e otlolohileng;

- Punch e tlase e ntse e tsoela pele ho phahama, e phahamisa kuku e setseng e tsoang bokaholimo ba kamore ea khatello, ebe e e tlosa ka letsoho kapa ka mekhoa e meng;

- Tsamaisa litebele tse tlase ebe u li seta bocha ho thibela sebono sa nozzle;

- Bula hlobo, karolo e shoang e lahleloa le heke e otlolohileng e lula mohloeng o tsamaeang hammoho, ebe o ntša karolo ea ho lahla; hang ha kuku e setseng ea thepa e khaotsoe, mohato oa ho bula hlobo o ka etsoa hanghang, kapa o ka fokotsoa hanyane ho fihlela nako e loketseng Ho etsoa ha ho na letho le amanang le ho phahamisa le ho seta setebele se ka tlase; Mothating ona, ho phetheloa potoloho ea batho ba shoang.

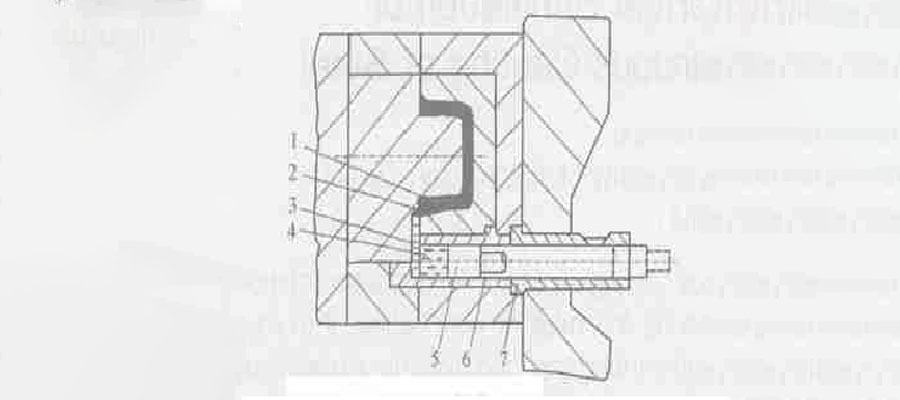

Sebetsa mokgwa wa tsa tshekaletseng batang kamoreng shoa shoela'ng foromeletsoeng mochini

Mokhoa oa ho sebetsa oa mochini o batang o batang oa kamore e batang o bonts'oa ho Setšoantšo sa 4. Kamore ea khatello ea 7 e behiloe ka mokhoa o rapameng, mme setebele sa ente sa 5 se moleng o nang le matheba pheletsong e nepahetseng ea kamore ea khatello. Metsamao ea ho bula le ho koala ha hlobo e ea holimo. Kamora hore hlobo e buloe, karolo ea ho lahla e lula e le ka hlobo e ka tsamaisoang. Mehato ea ho sebetsa e tjena:

- Koala hlobo;

- Tšela tšepe e qhibilihisitsoeng ka phapusing ea khatiso ka letsoho kapa ka mekhoa e meng;

- Punch ea ente e sutumetsa mokelikeli oa tšepe ka lebelo le reriloeng esale pele le khatello e itseng, e le hore e fete semathi sa 3 sa hlobo, ebe e tlatsoa kahare ea hlobo ho tloha hekeng e ka hare ea 2;

- Kamora ho tlatsa, litebele li boloka khatello e itseng ho fihlela tšepe e qhibilihisitsoeng e tiile ka botlalo hore e be sesebelisoa sa 1; ka nako ena, semathi le sesepa sa sekontiri 6 (hlobo e se nang sleeve ea sekhahla ke phaposi ea khatello e kopaneng mona)) Ts'epe e qhibilihisitsoeng kahare le eona ea tiisa ka nako e ts'oanang, e ba heke le kaka e setseng ea 4;

- Bula hlobo, litebele li tsamaee ka tsela e lumellanang le ts'ebetso ea hlobo ea hlobo, e le hore kaka e setseng e sutumetsoe hammoho le karolo e shoang le heke ea ho lula ka hlobo e tsamaeang ebe o tlohela boemo bo tsitsitseng.

- Ha o fihla hole, litebele li tla khutla ho seta bocha;

- Ka mor'a hore hlobo e buloe, karolo e shoang e lahla, heke le kaka e setseng ea lintho tse bonahalang e lula hlobo, e ntše 'me e ntše karolo e shoang; Mothating ona, ho phetheloa potoloho ea batho ba shoang

Figure 4 sebetsa mokgwa wa tsa tshekaletseng batang kamoreng shoela'ng foromeletsoeng mochini

1. shoa likarolo lahla

2. Heke e ka hare

3. Semathi

4. Kuku ea masalla

5. Letlalo la ente

6. Sleeve ea letsoho

7. Kamore ea khatiso

Sebetsa mokgwa wa feletseng paatsepama kamoreng batang shoela'ng foromeletsoeng mochini

Mokhoa o sebetsang oa mochini o batang o batang o batang o bontšoa ho Setšoantšo sa 5. Kamore ea khatello ea 5 e beoa ka lehlakoreng le ka tlase la mochini, mme ho buloa le ho koaloa ha hlobo ho ea holimo le tlase, ka hona e bitsoa mochini o felletseng oa ho lahla o otlolohileng. Hangata hlobo e tsamaeang ea hlobo e ts'oaroe

Kamora hore hlobo e buloe, karolo ea ho lahla e lula e le ka hlobo e ka tsamaisoang. Mehato ea ho sebetsa e tjena:

- Tšela tšepe e qhibilihisitsoeng ka phapusing ea khatiso ka letsoho kapa ka mekhoa e meng;

- Koala hlobo;

- Punch 6 e tsamaisa le ho hatella tšepe e entsoeng ka ho qhibilihisoa hore e fete ho semathi 3 diverter 4, ebe ee tlatsa ho tloha hekeng e ka hare ea 2 ho kena kahare ea hlobo;

- Kamora ho tlatsa, litebele li boloka khatello e itseng ho fihlela tšepe e qhibilihisitsoeng e tiile ka botlalo hore e be sesebelisoa sa 1; ka nako ena, tšepe e qhibilihisitsoeng semathi le kamore ea khatello e boetse e tiile ka nako e ts'oanang, 'me khatello e ka phapusing ea khatello e fetoha kaka ea masala 7;

- Bula hlobo, 'me litebele li tsamaea li nyolohele hodimo ka synchronously ka mohato oa ho bula hlobo, e le hore kaka e setseng ea thepa e latela mofuta oa lefu le heke hammoho le hlobo e tsamaeang ebe e siea hlobo e tsitsitseng. Ha u fihla hole, litebele li theoha. Khutlisa hape;

- Ka mor'a ho bula hlobo, hang-hang ntša 'me u ntše karolo ea ho lahla; Mothating ona, potoloho ea batho ba shoang e phethetsoe.

Figure 5 Feletseng paatsepama kamoreng batang shoa shoela'ng foromeletsoeng mochini

1. shoa likarolo lahla

2. Heke e ka hare

3. Semathi

4. Shunte

5. Kamore ea khatiso

6. Letlalo la ente

7. Kuku ea masalla

Litekanyetso tse nepahetseng tsa mochini oa China oa ho lahla

Bakeng sa ho ntšetsa pele nts'etsopele ea tlhahiso ea mochini oa naha ea heso, mafapha a amehang a indasteri ea naha ea heso a phatlalalitse litekanyetso tsa mochini o lahlang ka 1980 mme a e nchafatsa ka 1990. Hona selemong seo, litekanyetso tsa ho nepahala le Maemo a tekheniki ea mochini o lahlang le ona a phatlalalitsoe, a fanang ka sesupo sa moralo, tlhahiso le kamohelo ea mochini o lahlang. Ho tloha ka nako eo, e ntlafalitsoe makhetlo a 'maloa ho e etsa hore e be e felletseng le e sebetsang haholoanyane. Litekanyetso tsa indasteri ea mechini bakeng sa mechini e lahlang li-die le linomoro tsa bona tsa serial tse phatlalalitsoeng kamora ntlafatso ea 2000 ke tse latelang. Mefuta ea mochini oa li-die-casting (JB / T 8083 -2000) Tekanyetso e hlalosa mekhahlelo ea mochini o lahlang li-die. Mochine oa ho lahla o arotsoe ka mefuta e meraro: mochini o lahlang o batang oa kamore e batang, mochini o batang o batang oa kamore ea ho betla le mochini o chesang oa kamoreng. Mekhahlelo ea mantlha le litekanyetso tsa mantlha tsa parameter tsa mefuta e meraro li thathamisitsoe sehlomathisong.

- Ho nepahala ha mochini o batang oa ho lahla mochini o batang (JB / T 8084.1 -2000) Tekanyetso ena e thathamisa mokhoa oa ho nepahala le oa ho hlahloba oa mochini o batang oa kamore ea ho lahla.

- Maemo a tekheniki ea mochini o batang oa kamore e batang (JB / T 8084.2 -2000) Tekanyetso ena e thathamisa mantsoe le litlhaloso tse nepahetseng, litlhoko tsa tekheniki, mekhoa ea liteko, melao ea tlhahlobo, jj.

- Ho nepahala ha mochini o chesang oa kamore ea ho chesa (JB / T 6309.2 -2000) Tekanyetso ena e thathamisa mokhoa oa ho nepahala le oa ho hlahloba oa mochini o chesang oa kamore e chesang.

- Maemo a tekheniki ea mochini o lahlang likamore tse chesang (JB / T 6309.3 -2000) Tekanyetso ena e thathamisa mantsoe le litlhaloso tse nepahetseng, litlhoko tsa tekheniki, mekhoa ea tlhahlobo, melao ea tlhahlobo, jj.

- Litlhokahalo tsa polokeho ea mochini o lahlang (JB 10145-1999) Tekanyetso e thathamisa lipehelo le litlhaloso tsa tsona, lintho tsa bohlokoa tse kotsi, litlhoko tsa polokeho le / kapa mehato, le boikemisetso ba litlhoko tsa polokeho le / kapa mehato.

- Litekanyetso tse nepahetseng bakeng sa mochini o felletseng o batang oa kamore e batang ha li so phatlalatsoe. Ka nts'etsopele ea mahlale a ho lahla, litlhoko tse ncha li tsoela pele ho beoa bakeng sa mechini e lahlang, mekhoa e sebetsang ea mechini e lahlang e tla ntlafatsoa khafetsa, 'me mefuta ea mechini e lahlang e tla fetoha butle-butle.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Kemiso ea Mechini ea Die Casting le Ts'ebetso ea Ts'ebetso

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off