Phello ea tirila le nikele ka Thermal Tšenyo Khanyetso ea 4Cr5Mo2V shoa lahla Die Tšepe

4Cr5 Mo2V ke tšepe e sebelisoang hangata e sebelisoang ha e sebelisoa. Ha ho ntse ho etsoa alloy ea aluminium e bolaeang, ka lebaka la khoholeho ea mobu le khokahano ea aluminium e qhibilihisitsoeng, hlobo e tla ba le tšenyo ea mocheso, joalo ka mokhathala oa mocheso le tahlehelo ea qhibilihiso ea mocheso, e lebisang ho fokotseheng ha thatafalo ea eona esita le ho hloleha pele ho nako.

Bakeng sa ho ithuta hore na nikele kapa ho omella ho ka ntlafatsa tšenyo ea mocheso oa aluminium alloy hlobo e lahlang, 4Cr5 Mo2V tšepe le li-block tsa 4Cr5Mo2V tse nang le 1% Ni le 1% Co (karoloana ea boima) li lokiselitsoe tima le ho halefa. Ka shoeleng e sa fetoheng ea hlobo e lahlang, ADC12 aluminium alloy e nang le thempereichara ea 800 ℃ e ile ea bolaoa makhetlo a 200 ho isa ho a 1,000 XNUMX, mme morpholoji e kholo le thatafalo ea bokaholimo ba teko ea liteko li ile tsa hlahlojoa.

Liphetho li bonts'a hore kamora ho lahla aluminium alloy makhetlo a 1,000 4, 5Cr2Mo1V tšepe block block e ile ea latela aluminium haholo 'me ea hlahisa mapatso a seng makae a kang letlooa; teko ea tšepe e nang le Ni e nang le tšepe e latelletsoeng hanyane ho aluminium, 'me koporo e nang le tšepe e kopantsoeng le aluminium e latela bonyane, e bonts'a hore litaba tsa 4% Co 5Cr2Mo1,000V tšepe li na le ts'ireletso e ntle ka ho fetesisa ea mocheso ho li-alloys tsa aluminium tse shoang. Ho ekelletsa moo, ha ho bapisoa le thatafala pele shoa-foromeletsoeng motsoako aluminium, ka mor'a makhetlo a 4 shoa-foromeletsoeng, bokaholimo ba thatafala ha 5Cr2Mo4V tšepe, e nang le nikele le omileng tse nang le 5Cr2Mo2.8V tšepe disampole fokotsehile ka 1.8, 1.4 le 4 HRC, ke hore, li-alloys tse ngata tsa die-cast tsa aluminium. Phello e mpe holim 'a thatafala ha tšepe e nang le nikele le e ommeng ea 5Cr2Mo4V e ka tlase ho ea tšepe ea 5Cr2MoXNUMXV, e amanang le tharollo e tiileng ea matlafatso ea Co le Ni, e leng molemo ho ntlafatsa khanyetso ea khoholeho ea mokelikeli oa aluminium ea hlobo le ho etsa hore hlobo e se ke ea angoa habonolo ke mocheso.

Aluminium alloy die-casting ke mokhoa o rarahaneng oa mocheso o phahameng le khatello e phahameng. Ho na le lintlha tse ngata tse amang tšenyo ea mocheso (ho kenyelletsa mokhathala oa mocheso le tahlehelo ea mocheso) ts'ebetso ea hlobo ea aluminium alloy e bolaeang. Har'a tsona, ho hlophisoa ha tšepe e sebetsang ka tšepe e bohlokoa ho bohlokoa haholo.

Tlas'a maemo a tloaelehileng, ho hloleha ha shoa lahla shoa ka lebaka la ho petsoha le deformation polasetiki ka qojoa. Ho petsoha ha hlobo hangata ho bakoa ke ho jarisoa ka phoso ha mochini o feteletseng kapa ho ba le mocheso o feteletseng, ho bakang khatello ea maikutlo e matla. Mokhathala oa pele oa mokhathala o futhumatsang le tahlehelo ea tjheseletsa (tšenyo e kaholimo ea mocheso) ea hlobo e lahlehang ke mekhoa e meholo ea ho hloleha, mme hangata tse peli lia ameha. 4Cr5Mo2V tšepe ke tšepe e sebelisoang haholo e sebelisoang haholo, e nang le khanyetso e ntle ea ho roala le polasetiki. Sebowela le nikele li sebelisoa hangata ho kopanya likarolo, tse ka eketsang matla le thatafalo ea tšepe, mme li na le phello e itseng ho haneleng tšenyo ea mocheso. Ka hona, tšepe ea 4Cr5Mo2V, 4Cr5Mo2V e nang le 1% Ni le 1% Co (karoloana ea boima, e ts'oanang ka tlase) ea ithutoa. Ho hanyetsa tšepe ho ts'enyo ea aluminium e qhibilihisitsoeng ho bohlokoa haholo ho tataisa tlhahiso ea 'nete.

Leha ho le joalo, mekhoa e mengata ea ho ithuta tšenyo e futhumetseng ea tšepe e shoang ka pel'a molomo e etsisa ho futhumatsa le ho futhumatsa. Sampole ea tšepe e shoang ha e kopane ka kotloloho le aluminium e qhibilihisitsoeng, mme ha e kenyeletse phello e otlang ea aluminium e qhibilihisitsoeng, joalo ka ho futhumatsa ka kotloloho ha sampole ea tšepe. -A. Leqepheng lena, likarolo tse tharo tsa likarolo tsa tšepe tsa tšepe li ile tsa hlophisoa 'me tsa kenella ka har'a hlobo e lahlang ho etsa liteko tsa lefu la ADC12 aluminium alloy. Ts'ebetso ea tšenyo ea aluminium e qhibilihisitsoeng.

Lisebelisoa tsa 1.Test le Mekhoa

1.1 Lisebelisoa tsa Teko

Sebopeho sa lik'hemik'hale sa tšepe ea 4Cr5Mo2V, tšepe ea 4Cr5Mo2V e nang le 1% Ni (eo ho tloha mona e tla bitsoa 4Cr5Mo2V + Ni tšepe) le tšepe ea 4Cr5 Mo2V e nang le 1% Co (eo hamorao e tla bitsoa 4Cr5Mo2V + Co tšepe) e bontšoa ho Tafole ea 1. Teko e ne e le Samente le ADC12 Motsoako oa lik'hemik'hale oa motsoako oa aluminium o bonts'oa ho Tafole ea 2.

| Tafole 1 | |||||||

| lintho tse bonahalang | C | Cr | Mo | V | Co | Ni | Si |

| 4Cr5Mo2V tšepe | 0.39 | 4.65 | 2. 21 | 0.46 | - | - | 0. 23 |

| 4Cr5Mo2V + Ni tšepe | 0.38 | 4.72 | 2.34 | 0. 51 | - | 1.02 | 0. 21 |

| 4Cr5Mo2V + Co tšepe | 0.41 | 4.67 | 2.40 | 0.48 | 1.03 | - | 0. 24 |

| Tafole ea 2 Sebopeho sa Lik'hemik'hale sa ADC12 Aluminium Alloy% | |||||||||

| elements | Cu | Mg | Mn | Fe | Si | Zn | Ti | Pb | Sn |

| Karolo ea boleng bo phahameng | 1.74 | 0.22 | 0.16 | 0.76 | 10.70 | 0.87 | 0.064 | 0.035 | 0. 010 |

1.2 Mokhoa oa Teko

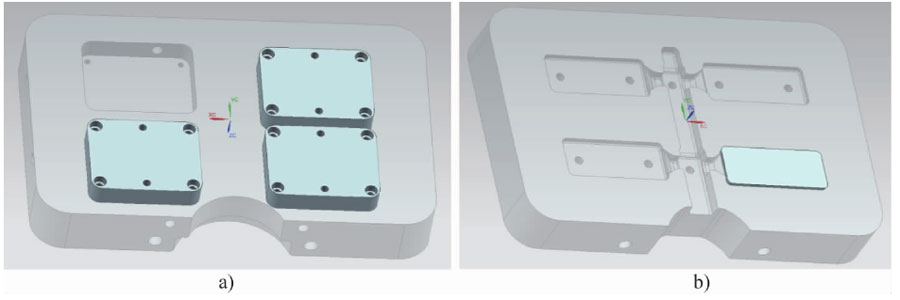

Tšepe ea annealed 4Cr5Mo2V, 4Cr5Mo2V + Ni tšepe le 4Cr5Mo2V + Co tšepe li ile tsa sebetsoa ka lithibelo tsa liteko joalo ka ha ho bonts'itsoe Setšoantšong sa 1. Kamora ho tima ha lephaka, li ile tsa halefisoa habeli, ka thata ea hoo e ka bang 47 HRC, le mobu o khabisitsoeng hantle ho tlosa sekala sa oxide.

Palo ea sehlopha ea "block block" e kentsoe ka har'a foropo ea hlobo e sa fetoheng, 'me mokoti oa alloy aluminium e shoeleng e behiloe ka hlobo e ka tsamaisoang, joalo ka ha ho bonts'itsoe setšoantšong sa 2. Mochini o batang o batang oa 500 t. 'me hlobo e iketselitseng e sebelisitsoe bakeng sa teko ea ho lahla sesebelisoa sa ADC12 aluminium alloy sheet, mme alloyum aluminium e sebelisitsoe bocha. Mocheso oa aluminium e qhibilihisitsoeng o phahame, 800 ° C, molemong oa ho potlakisa teko (ka kakaretso, mocheso oa die casting oa ADC12 aluminium alloy ke (650 120) ° C). Kaha mocheso oa aluminium e qhibilihisitsoeng ke 800 ℃, e sa fihleleng ntlha e qhibilihang ea komporo ea Fe-A1, kompone e hlahisoang e tla ba teng ka aluminium e qhibilihisitsoeng e le litšila kamora ho oela. Ts'ebeliso e phetoang ea aluminium e qhibilihisitsoeng e tla baka keketseho ea litšila le ho matlafatsa aluminium. Phello e nyarosang ea mokelikeli, ka hona e potlakisa tlhahlobo.

Kamora teko ea ho lahla lefu, microscope ea stereo e ile ea sebelisoa ho boloka ts'ebetso ea mamarello ea aluminium ka holim'a lebala la teko; microscope e tebileng-ea-tšimo e sebelisitsoe ho ntšetsa pele boemo ba khomaretsi ea aluminium le hore na ho na le mapetso holim 'a teko ea teko.

Liphetho tsa liteko le tlhahlobo

2. 1 Bokaholimo ba Morpholoji ba The Test Block

2.1.1 Bokaholimo ba Aluminium

Setšoantšo sa 3 se bonts'a sebopeho sa bokaholimo ba litheko tse tharo tsa tšepe ntle le ho betloa ha lefu le kamora makhetlo a 600,1000 a ho betloa ha lefu. E ka bonoa ho tsoa Setšoantšong sa 3 (b, e, h) hore kamora makhetlo a 600 a ho betloa ha lefu, 4Cr5Mo2V block block e na le sekhomaretsi se tebileng sa aluminium.

Teko ea tšepe ea 4Cr5Mo2V + Co e khomarela aluminium e nyane. Setšoantšo sa 3 (c, f, i) se bonts'a hore mamarello ea aluminium e kaholimo ho litene tse tharo tsa liteko e eketsehile kamora makhetlo a 1,000 a ho betloa ha lefu. Bokaholimo ba 4Cr5Mo2V tšepe block block e na le khokahano e hlakileng ea aluminium, ha li-block tse ling tse peli li na le khomaretsi e nyane ea aluminium. Teko ea tšepe ea 4Cr5Mo2V + Co Lump ea aluminium ke e nyane ebile e ts'oere junifomo, e bonts'a tšepe ea 4Cr5Mo2V e nang le taemane e na le ts'ireletso e ntle ho feta ea ts'enyo ea aluminium ea metsi, ha tšepe ea 4Cr5Mo2V e le mpe ka ho fetesisa. Ho eketsoa ha lisebelisoa tsa ho betla le tsa nickel ho bohlokoa ho tsitsisa mocheso o phahameng oa mocheso oa tšepe e shoeleng 9-10, 'me bokaholimo ha bo bonolo ho "nolofatsa" nakong ea ha o kopana khafetsa le aluminium e qhibilihisitsoeng, ka hona, ho hanyetsa khoholeho ea mokelikeli oa aluminium ho betere,' me ho khomarela aluminium e nyane. Nakong ea teko ea ho lahla, aluminium e qhibilihisitsoeng e kenella kahare ho ikopanya le block block, mme sebopeho se sa lekanang sa block test, sebaka se nang le sekoli sa machining le libaka tse ling tsa lehae li tla khomarela aluminium hanyane. Aluminium e sebakeng se kopantsoeng ka aluminium e tla sebetsana le tšepe ho theha Fe.} Al brittle e bohareng e kopaneng, e tla robeha le ho eboloa tlasa ho phatloha ha mokelikeli o phahameng oa aluminium, o hlahisang likoti holim 'a hlobo, le tse ling aluminium e tebileng e tlamahane tlasa ho shapuoa ha mokelikeli oa aluminium.

2.1.2 Mapatso a Bokaholimo

Setšoantšo sa 4 se bonts'a botebo bo phahameng ba tšimo ea 4Cr5Mo2V tšepe, 4Cr5Mo2V + Ni tšepe le 4Cr5Mo2V + Co lipapiso tsa tšepe kamora makhetlo a 1,000 4 a ho betloa ha lefu. E ka bonoa ho tloha Setšoantšong sa 4 (a) hore ho na le palo e nyane ea mapetso a manyane a ajoeng ka sebopeho se batlang se le holim'a metsi a 2 Cry Mot V test block. Aluminium e khomarelang le aluminium e qhibilihisitsoeng e sebetsa ka tšepe ho theha Fe.} Al metsoako. Coefficient ea katoloso ea mocheso oa Fe.} Al e fapane le ea matrix, e hlahisang li-microcracks tse nyane haholo ho aluminium e latelletsoeng le Fe.} Al le metsoako. Phello e nyarosang ea aluminium e qhibilihisitsoeng e etsa hore li-microcracks li jale, mme aluminium e qhibilihisitsoeng e kenella kahare ebe e itsoara hantle ka matrix ho theha metsoako ea Fe 4 Al. Ts'ebetsong e lateloang khafetsa ea ho akhela lefu, Fe.} Metsoako e meng e kaholimo ho teko ea liteko e ea phunya. Kamora ho hloekisa le ho hloekisa ka mahlaseli, bokaholimo ba teko ea liteko bo ile ba hlaha bo ts'oana le litšobotsi tsa marang-rang tse ts'oanang le aluminium. Setšoantšo sa 4 (b, c) se bonts'a hore ha ho na mapetso ho 5Cr2Mo4V + Co tšepe le 5Cr2Mo1V + Ni liteko tsa liteko tsa tšepe, tse bonts'a hore ho eketsoa ha 3% tirila kapa molybdenum ho ke ke ha fokotsa feela khokahano ea bokaholimo ea aluminium, empa hape e fokotsa tloaelo ea ho petsoha ea hlobo le ho ntlafatsa ts'ebetso ea tšenyo ea aluminium Metsi. Ho eketsoa ha likarolo tsa nickel le daemane tse se nang carbide ho ka ntlafatsa boleng bo phahameng ba mocheso oa hlobo, 'me daemane e ka khothaletsa ho hasana le pula ea molybdenum carbide nakong ea ts'ebetso ea tempering, le ho matlafatsa phello ea ho thatafatsa ha pula' z-} 4. Patlisiso ea Ling Qian et al. e bonts'itse hore ho eketsoa ha likarolo tse tsitsisang tsa austenite ho lahla tšepe ho ka fokotsa khatello ea maikutlo. Bobeli tirila le nikele ke likarolo tse atolosang libaka tsa austenite, kahoo 5Cr2Mo4V + Ni tšepe le 5Cr2MoXNUMXV + Co tšepe die die lahla hlobo bokaholimo ha e tloaetse ho petsoha.

Aluminium e qhibilihisitsoeng e ts'ebetsong ea ho lahla e matla haholo khahlanong le hlobo. Ho latela setšoantšo sa karolo ea Fe-A1, metsoako ea Fe-Al e kopantsoeng ka tšebetso ea tšepe le aluminium e qhibilihisitsoeng ke FeAlz, Fez A15, FeA13, jj, tse brittle. arohana le matrix ebe o kenya aluminium e qhibilihisitsoeng tlasa ho ts'oaroa ha aluminium e qhibilihisitsoeng, e siea likoti holim 'a hlobo. Ha e kopana le karolo ea motsoako oa aluminium le likoti tsa hlobo li batla li le matla ebile ha li oe, ebe li theha metsoako ea Fe A1. Aluminium, Fe.} Al le metsoako e khomarelang moo e tloaetse ho ba le li-microcracks nakong ea pholileng. Letlapa la ho lahla le na le aluminium e nyane ea metsi, ka hona e tiisa kapele, mme karabelo lipakeng tsa hlobo le aluminium ea mokelikeli e butle butle. Ka hona, bokaholimo ba teko ea liteko bo na le likoti tse fokolang ka lebaka la karabelo ea Fe le Al, mme aluminium e khomaretseng e hlahisoa ke khoholeho ea metsi ea aluminium.

2. 2 Bokaholimo ba thatafala ha

Tafole 3 ke boleng karolelano ea thatafala ha holim'a metsi a mararo a li-block a liteko tsa tšepe kamora linako tse fapaneng tsa ho betloa ha lefu. Lintlha tse ho Tafole ea 3 li bonts'a hore ho thatafala ha bokaholimo ba mefuta e meraro ea lithibelo tsa liteko ho fokotseha hanyane. Ha palo ea lisosa tse shoang li ntse li eketseha, e lekana le ho thunya khafetsa ha teko ea liteko, ka hona thatafalo ea fokotseha. Kamora makhetlo a 1,000 4 a lahla-shoa, thatafalo ea 5Cr2Mo1.4V + Co tšepe block block e na le phokotso e nyane haholo, e leng 4 HRC; 5Cr2MoXNUMXV tšepe block block e na le phokotso e totobetseng ka ho fetesisa.

Ho hlakile hore e theohile ka 2. 8 HRC; thatafala ha holim'a metsi ea 4Cr5Mo2V + Ni tšepe block block e theohile ka 1. 8 HRC. Ho tiea ha hlobo ea hlobo ho molemo ho fokotsa ho khomarela aluminium, ke hore, ho molemo ho hanela tšenyo ea mocheso o shoang.

| Tafole 3: Bokaholimo ba litene tsa teko kamora ho lahla ka linako tse fapaneng% | ||||||

| lintho tse bonahalang | Ha ho na Cast Cast | Times ea 200 | Times ea 400 | Times ea 600 | Times ea 800 | Times ea 1000 |

| 4Cr5Mo2V tšepe | 48.6 | 48.4 | 48.1 | 47.2 | 46.9 | 45.8 |

| 4Cr5Mo2V + Ni tšepe | 47.5 | 47.4 | 47.2 | 46.8 | 46.9 | 46.1 |

| 4Cr5Mo2V + Co tšepe | 47.7 | 47.5 | 47.1 | 46.5 | 46.2 | 45.9 |

Kamora nako e telele ea tšepe e shoang, martensite ea bola 'me li-carbide tsa bobeli li fetoha tse bobebe, tse bakang ho fokotseha ha thatafalo ea holim'a metsi. Bobeli tirila le nikele ke bao e seng carbide eaba ba etsa thepa ea motheo, e ka nka sebaka Fe liathomo ho etsa tšepe tharollo tiileng matlafatsa '5 ho' 8, e le hore hlobo e na le phahameng matla a phahameng mocheso le ho boloka thatafala phahameng ka mor'a ho pheta-pheta futhumatsang ka potlako le tsidifatso. China Die Casting Association e ithutile kabo ea thepa ka tšepe ea Cr-Mo-V-Ni e tima le ho halefa, mme ea fumana hore nakong ea bohale, likarolo tsa Ni li tla ntlafatsoa ho potoloha le li-carbides, ka hona li sitisa liathomo tsa khabone ho ferrite e potileng The carbides Phallo e tsoelang pele ea carbides e eketsa matla a ts'ebetso ea carbide coarsening, e sitisa kholo ea carbides, ka tsela eo e fokotsa ho thatafala ha tšepe ea 4Cr5Mo2V e nang le nikele, le ho ntlafatsa ho hanela tšenyo ea aluminium e qhibilihisitsoeng.

China Die Die Casting Association e ithutile botsitso ba mocheso le microstructure ea tšepe e shoeleng ka 1% Ni le ntle le Ni, mme ea fumana hore mothating oa morao oa teko ea botsitso ea mocheso, nickel e tla fokotsa boima ba tšepe e shoang, ka hona e etsa tšepe e tsitsitse moeeng ka thobalano. Ho cheka ke ntho e eketsang sebaka sa karolo ea austenite. Ho eketsa sesebelisoa sa 4Cr5Mo2V tšepe ho ka khothaletsa ho qhibiliha ha carbides nakong ea ts'ebetso ea matlafatso, ho eketsa khabone ea austenite, le ho eketsa botsitso ba austenite, ka hona ho eketsa austenite e bolokiloeng Palo ea tensite le thatafalo ea martensite, 'me tirila e ka ntshetsa pele ho hasana le pula ea carbide ea molybdenum nakong ea ts'ebetso ea tempering, le ho ntlafatsa phello ea ho thatafatsa ha pula z'-1.

Matla a matlafatsang a nickel le boora ho matrix a etsa hore block block ea tšepe e ntse e na le thatafalo e phahameng kamora ho shapuoa khafetsa ka aluminium e qhibilihisitsoeng, e le hore e mamelle khoholeho ea mobu haholo, e leng molemo ho ntlafatsa khanyetso ea teko ea liteko ho senya aluminium e qhibilihisitsoeng. Boima ba bokaholimo ba teko ea teko le boemo ba khomaretsi ea aluminium le tsona lia bontša (bona Setšoantšo sa 3, Tafole ea 3): Sebaka se entsoeng ka tšepe sa 4Cr5 Mo2V se na le likoti tse nyane tsa holim'a metsi le khokahano ea aluminium kamora makhetlo a 1,000 1 a ho betloa ha lefu, ke hore, ho hanyetsa tšenyo ea metsi ea aluminium ke eona e ntle ka ho fetisisa. Ka hona, matla a matlafatsang a ho eketsa 1% Co ho tšepe e kholo ho feta ho eketsa XNUMX% Ni, tseo ka bobeli li leng molemong oa ho ntlafatsa ts'ebetso ea tšenyo ea anti-aluminium ea die steel.

3.Conclusion

- Kamora ho lahla aluminium alloy makhetlo a 1 000, sampole ea tšepe ea 4Cr5 Mo2V e nang le tirila e khomarela aluminium e nyane haholo, mme sampole ea tšepe ea 4Cr5Mo2V e khomarela aluminium e ngata, ke hore, tšepe ea 4Cr5 Mo2V e nang le drill e na le ts'ireletso e ntle ka ho fetesisa ea mocheso.

- Kamora ho shoa ha aluminium alloy makhetlo a 1,000 4, ho thatafala hoa tšepe ea 5Cr2Mo4V, 5Cr2Mo4V + Ni tšepe le 5Cr2Mo2.8V + Co lipapatso tsa tšepe li fokotsehile ka 1.8, 1.4 le 4 HRC, ke hore, tlatsetso ea nickel kapa drill e ka ntlafatsa haholo ho hanyetsa tšenyo ea mocheso. tsa 5Cr2MoXNUMXV shoa-lahla shoela'ng tšepe.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Phello ea tirila le nikele ka Thermal Tšenyo Khanyetso ea 4Cr5Mo2V shoa lahla Die Tšepe

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off