Ho sebelisa sesebelisoa se hloekileng sa oksijene ho fokotsa tšebeliso ea matla ea ho futhumatsa ka pele

Wu Steel Works e na le lithupelo tse peli, kokoano e le 'ngoe ea ho etsa litšepe le setsi sa bobeli sa ho etsa litšepe. Seboka sa bobeli sa ho etsa litšepe se hlahisa tšepe e tloaelehileng, mme setsi sa pele sa ho etsa litšepe se hlahisa lihlahisoa tse nyane tsa limaraka tsa tšepe joalo ka tšepe e khethehileng. Mekhoa ea tlhahiso e kenyelletsa ts'ebeliso ea tšepe e chesang pele ho nako, converter le RH. Ho lahla ka bongata le ho tsoelang pele ho hlahisa sebopi sa tšepe e qhibilihisitsoeng e ka bang 20 ka letsatsi.

Ts'ebeliso ea yuniti ea oli e boima ea mafura bakeng sa preheating ea ladle kopanong ea pele ea ho etsa tšepe e phahame haholo ho feta kopanong ea bobeli ea ho etsa tšepe. Haeba kokoano ea pele ea ho etsa tšepe e le 100, joale seboka sa bobeli sa ho etsa tšepe ke 6.8. Ka hona, ho fokotsa palo ea oli e boima e sebelisitsoeng ka har'a ladle preheating burner ea setsi sa ho etsa tšepe e fetohile taba ea bohlokoa. E le ho fokotsa tšebeliso ea matla ea ho futhumatsa ladle, Wu Iron & Steel Institute e hlahisitse licheso tse hloekileng tsa oksijene.

Ho ea ka papiso ea matla a ho tuka le litšobotsi tsa ho tuka ha boapeelo bo hloekileng ba oksijene le boapeelo ba moea, ho ka bonoa hore ha secheso sa moea se sebelisoa, naetrojene e sa hlokahaleng (e ikarabellang bakeng sa 79% ea moea) e fehloa, ka hona mocheso oa mollo oa lelakabe o tla theoha. , Eketsa palo ea khase ea ho qeta le ho eketsa tahlehelo ea mocheso. Ha u sebelisa sesebelisoa se hloekileng sa peterole, kaha boapeelo bo sebelisa feela oksijene e hlokahalang bakeng sa ho tuka, mocheso oa mollo oa lelakabe o ka eketsoa ho 3000 ℃, 'me palo ea khase ea ho qeta e fokotsehile haholo, ka hona tahlehelo ea mocheso e ka hatelloa' me mocheso o sebetsang o ka eketseha. Fokotsa tšebeliso ea oli e boima le ho fokotsa litšenyehelo tsa mafura.

Bokhoni ba ho futhumatsa bo hlokoang ke boapeelo bo hloekileng ba oksijene bo ts'oana le ba boapeelo ba moea, mme ho hlokahala hore o tsebe ho futhumatsa mocheso oa lesela le benyang la ladle ho tloha ho 600 ° C ho isa ho 1000 ° C hoo e ka bang 20 metsotso. Ha mocheso o tloaelehileng oa mocheso o sebelisoa, boholo ba matla a ho tuka ke 520L / hr, ha sesebelisoa se hloekileng sa oksijene se eketsa mocheso o sebetsang, ka hona boholo ba mollo ke 350L / hr, e lekanang.

Ha ho sebelisoa mocheso o tloaelehileng oa mocheso, matla a ho futhumatsa ke 20 ° C / min ha oli e boima e chesitsoeng e le 450L / h, 'me ha ho sebelisoa sesebelisoa se hloekileng sa oksijene, mocheso o sebetsang oa eketseha, le oli e boima ho chesoa ke 200 ~ 250L. Tabeng ea / hr, ho ka fumanoa mocheso o tšoanang oa ho futhumatsa joalo ka mocheso oa moea.

Kamora ho hlahisoa ha boapeelo bo hloekileng ba oksijene, ts'ebetso ea ho tuka e ea ntlafala. Ka hona, ho phahama ha mocheso oa ladle ho qhekella pele ho tlatsa tšepe e qhibilihisitsoeng ke e latelang. Kamora ho futhumatsa metsotso e 15, mocheso oa mohatelli o tla fihla ho 75 ° C, 'me kamora ho futhumatsa metsotso e 20, o tla fihla 100 ° C, o tla fihla 125 ° C kamora ho futhumatsa metsotso e 25.

Ha e bapisoa le boapeelo ba moea, ts'ebeliso ea yuniti ea mafura a boima e fokotsoa ke 46% kamora hore boapeelo bo hloekileng ba oksijene bo amoheloe, 'me matla a ho boloka matla a bohlokoa haholo.

Ho latela papiso ea litheko tsa mafura pele le kamora ntlafatso ea boapeelo, ha sesebelisoa sa mafura a hloekileng se sebelisoa, leha litšenyehelo tsa oksijene li eketsehile, litheko tsohle tsa mafura li theohile ka 37%. Ka nako e ts'oanang, e fokotsa moea o tsoang ho CO2 mme e kenya letsoho ho ntlafatsa tikoloho.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Ho sebelisa sesebelisoa se hloekileng sa oksijene ho fokotsa tšebeliso ea matla ea ho futhumatsa ka pele

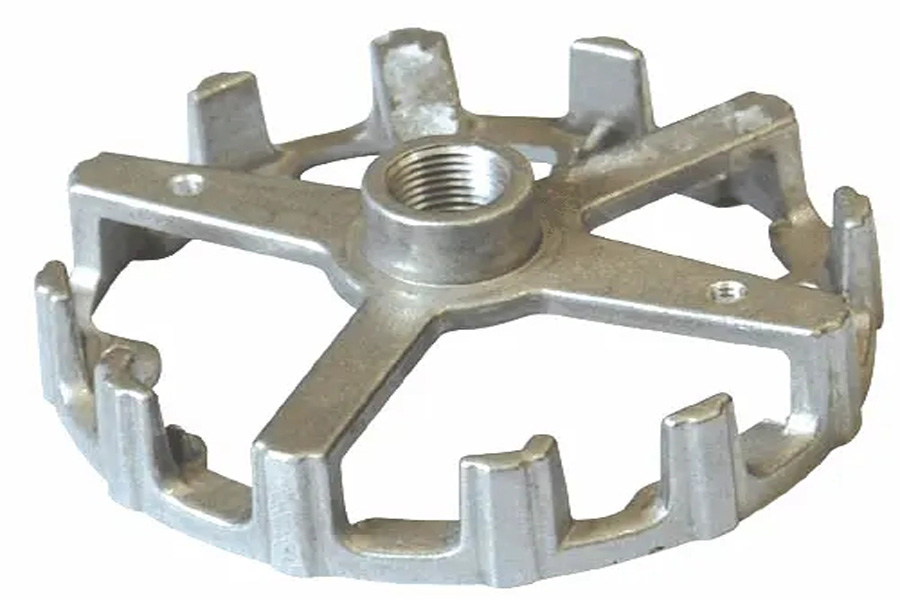

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off