Tlhaloso ea Moralo oa Aluminium Alloy Shell Die Casting Tooling

Sengoloa sena se qala ka ho sekaseka sebopeho le mochini oa ho lahla oa aluminium alloy shell, mme se sebelisa software ea UG ho phethela moralo oa aluminium alloy shell die-casting hlobo. Ho netefalitsoe ka boikoetliso, ho lahla mochini o shoeleng hoa utloahala, bokaholimo ba se betliloeng bo boreleli ebile bo hloekile, 'me boleng ba sehlahisoa bo fihlela litlhoko.

Tlhatlhobo ea sebopeho le ts'ebetso ea likarolo tse lahlehang tsa likarolo tsa aluminium alloy shell e ka morao

- 1.1 Mochini oa ho lahla o ka bonoa ho tsoa Setšoantšong sa 1 hore sebopeho se ka morao sa khetla se koahelang se batla se le bonolo, botenya ba lebota bo kopaneng bo tšoana hantle, ho na le masoba a mabeli a betlang, empa hobane lebota la mokoti o betlang o motenya hanyane, oa chesa matheba a ba bonolo ho hlaha, The kakaretso leboteng botenya ba likarolo shoa-foromeletsoeng ke batlang e le junifomo. Ha u khetha botenya ba lebota, ho lokela ho nahanoa ka lintlha tse fapaneng: sebopeho sa ho lahla thepa, thepa ea thepa, le ts'ebetso e entsoeng ea ho lahla. Ke bophara ba marako a tšesaane kapa a junifomo feela a ka fihlelang likarolo tsohle. tlhokeho.

- 1.2 Botenya bo tlase ba lebota la bohale bo kantle ba samente. Ho lahla maemo a nepahetseng ho hloka botenya bo itseng ba kantle ba lebota. Kamano lipakeng tsa botenya ba lerako le botebo h ke s≥ (1/4 ~ 1/3) hmm. Ha h <4.5mm, ebe s≥1.5mm.

- 1.3 Lisebelisoa tsa ho lahla thepa Boitsebiso ba mofuta oa die-cast ke die-cast aluminium alloy, sehlopheng ke YZAlSi9Cu4, matla a tensile ke 240MPa, Brinell thatafala ke 85HBS, mme sekhahla sa shrinkage se tloaelehileng ke 0.6%. Sephetho sa motsoako o khethiloeng ka thepa e ntle ea ho lahla ebile se loketse haholo ho betsa lefu.

- 1.4 Rasta ea fillet Bakeng sa ho etsa hore tšepe e qhibilihisitsoeng e thelle ka mokhoa o boreleli hape e be bonolo ho ntša khase, sebopeho se etselitsoe ho sebelisa li-fillet, mme ts'ebeliso ea li-fillets ho nkela likhutlo tse bohale tsa sebopeho le eona e ka qoba mapetso. Radiamo ea likhutlo tse chitja tsa sebopeho se entsoeng e ipapisitse le botenya ba lerako la sebopeho, mme bophara ka kakaretso ke 0.5 ho isa ho 1 mm.

- 1.5 Motsoako oa ho ngola o lokela ho khethoa ka ho nahanisisa ka botlalo ka lintlha tse ngata: ho lahla jiometri (botebo, botenya ba lebota, sekoti kapa bokahare ba mantlha), ho ba thata, ho sebetsana le tataiso ea lijo-thollo, jj Ho nahaneloa lintlha tse kaholimo, moralo oa sethapo se thellisang mobu ea ho lahla: α = 30 'bokaholimo ba kantle, le β = 1 ° bokaholimo ba kahare.

Moralo oa parameter ea ho lahla

2.1 Khetho ea mochini oa li-die-cast Ha u khetha mochini o lahlang thepa, matla a ho ts'oara a tlameha ho khethoa pele. Matla a ts'oarellang a na le mesebetsi e 'meli: o mong o sebelisetsoa ho lekanya khatello ea morao ho fihlela sepheo sa ho notlela bokaholimo ba karohano; e 'ngoe ke ho thibela ho fafatsa tšepe e qhibilihisitsoeng ho fihlela sepheo sa ho fihlela sepheo sa ho nepahala. Ha ho na leeme katoloso ea matla ka betsa etselitsoeng, hobane hlobo ena ha e na lehlakoreng hula konokono hula (ho betsa shoela'ng ha e na masoba lehlakoreng le undercuts). Ka hona, F notlela ≥ KF ka sehloohong = 1.25 × 1288.352 = 1610.44kN. Ho latela lipalo tse boletsoeng ka holimo, boleng ba matla a ho ts'oara le boima ba ho betla boa fumaneha. Ho latela lintlha tsena tse peli tsa mantlha, mochini oa ho lahla o khethiloe, 'me ea ho qetela e khethiloeng ke: mochini o batang o batang oa kamore ea ho lahla (2500kN) ——— J1125 mofuta, mekhahlelo e meholo:

- Boholo ba tšepe e tšollang bophahamo ba modumo ——— 3.2Kg,

- OldMold botenya———- 250 ~ 650mm,

- OvingMoving hlobo setulo poleiti leqeba ———— 400mm,

- Matla a ente—— -143 ~ 280kN.

2.2 Ho lahla khatello ea khatello ea khatello ke e 'ngoe ea mekhahlelo e meholo ts'ebetsong ea ho lahla. Ka hona, ho bohlokoa haholo ho utloisisa phetoho ea khatello ea tšepe ea mokelikeli nakong ea shoa-lahla ts'ebetso, le ho laola khatello ka mokhoa o utloahalang mohatong o mong le o mong oa ts'ebetso ea ho lahla:

- T Fumana libapali tse tšoanelehang—— - Mokhatlo o teteaneng, kemiso e hlakileng;

- CalPalo ea pele ea khatello e itseng ea ente - Bala ho latela matla a khethiloeng a ente. Khatello e khethehileng ea ente e boetse e amana le sebaka sa hlobo ea hlobo, botenya ba lebota la samente, ts'ebetso ea tšepe e qhibilihisitsoeng le lintlha tse ling. Ho kopanya mekhahlelo e ikhethileng ea hlobo e raliloeng le boleng ba pele, khatello ea ente e khethehileng ea hlobo ena e lahlang qetellong e behiloe ho 90MPa.

2.3 Lebelo la ho lahla likhetho Khetho ea lebelo la ho lahla e na le lintlha tse peli tse latelang: khetho ea lebelo la ente le khetho ea lebelo la ho tlatsa. Khetho ea mabelo a mabeli e bohlokoa haholo, e khethollang ka kotloloho boleng ba kahare le kantle le tlhaloso ea moeli oa ho betsa. Lintlha tse lokelang ho tsotelloa ha ho khethoa lebelo la ho tlatsa:

- Boholo ba ho betsa,

- Ho rarahana ha sebopeho sa ho betsa,

- Mofuta oa motsoako o khethiloeng bakeng sa ho betsa,

- Boemo ba khatello ea ente.

Likhetho tse ikhethileng:

- Likarolo tse bonolo ho li tlatsa --- castings ka botenya bo bonolo ba lebota kapa litlhoko tse phahameng tsa boleng ba kahare, khetha: lebelo le tlase, khatello e khethehileng, heke e kholo;

- Ho tlatsoa ka potlako hoa hlokahala - ho rarahane ka marako a mosesane kapa Bakeng sa ho akheloa ka litlhoko tse phahameng tsa boleng ba holim'a metsi, khetha: lebelo le phahameng, khatello e khethehileng. Tlhatlhobo e felletseng, ho latela litšobotsi tse ikhethileng tsa karolo ena ea mochini o lahlehang, sebopeho se batla se le bonolo, khetha lebelo le mahareng, bophara ke 20 ~ 90m / s.

Nako ea ho lahla lefu e khetholla nako ea ho lahla, e nang le likarolo tse tharo tsa nako e hlokahalang: nako ea ho tlatsa, nako ea ho ts'oara le nako eo karolo e laoloang ka eona e lulang ka har'a hlobo e lahlang. Lintho tse 'maloa li kopantsoe ho hlahisa sephetho sena: khatello, lebelo, mocheso, litšobotsi tsa tšepe tse qhibilihisitsoeng, hammoho le sebopeho sa ho betsa (haholo botenya ba lebota le bophahamo ba modumo) le sebopeho sa hlobo (haholoholo sistimi ea ho cheka le ho tsoa ha metsi) le lintlha tse ling. Nako ea ho tlatsa e lipakeng tsa 2.4 le 0.01s. Bolelele bo khethoa ke boholo ba ho betsa le ho rarahana ha sebopeho: ho lahla ka sebopeho se bonolo le molumo o moholo ho hloka nako e batlang e le telele ea ho tlatsa; ho betloa ka sebopeho se rarahaneng le botenya bo bonyenyane ba lebota ho hloka nako e khuts'oane. Kamora liteko tse sebetsang, nako ea ho tlatsa e behiloe ho li-0.2s, e leng ho utloahalang bakeng sa li-castings tsa aluminium alloy tse mahareng le tse nyane tse entsoeng pampiring ena. Mosebetsi oa ho tšoara nako ea khatello ke hore: litebele tsa ente li na le nako e lekaneng ea ho kenya khatello ho tšepe e sa kopaneng, e le hore ts'ebetso ea kristallishene e ka etsoa tlasa khatello, e ntlafatsang phepo le ho fumana sebopeho se teteaneng ka katleho. Lintho tse amang bolelele ba nako: ntlha e qhibilihisang ea alloy e khethiloeng, mocheso oa crystallization le botenya ba lebota. Li-castings tse nang le ntlha e phahameng e qhibilihisang, bophara bo boholo le botenya bo boholo ba lerako li hloka nako e telele, 0.2 ~ 2s; ha nako e behiloeng e le khutšoane haholo, shrinkage e tla hlaha, empa ha e na tšusumetso e kholo haeba nako ea ho ts'oara e lelefatsoa. 3 ~ 1s ke kakaretso ea nako ea ho ts'oara nako. Boima ba lebota la ho betla moqapi ona ke 2mm. Ho nahanoa ka sebopeho sa eona le thepa ea eona ea alloy, li-3 li khethoa e le nako ea ho ts'oara. 3 Mocheso oa ho lahla Mehato e ka sehloohong ea ts'ebetso ho netefatsa hore castings e tšoanelehang — mocheso o tšolotsoeng oa tšepe e qhibilihisitsoeng le mocheso o sebetsang oa hlobo. Ho na le lintlha tse ngata tse e amang: sebopeho sa ho betsa, botenya ba lebota, khatello ea ho tlatsa, lebelo le mefuta ea alloy. Hoa hlokahala ho nahana ka botlalo ka mekhahlelo e kaholimo ho netefatsa hore thempereichara ea ho lahla e tsitsitse kahare ho maemo a utloahalang le ho fana ka maemo a matle a ho tlatsa. Haeba mocheso o tšollang o se maemong a lekaneng, boleng ba sehlahisoa bo tla senyeha kapa bo se ke ba tšoaneleha:

Mocheso o tšollang o fetelletseng - o tla baka ho fokotseha ho fetelletseng nakong ea ho futhumatsa, sehlahisoa se tloaetse ho petsoha, lithollo tse kholo, le ts'ebetso e nyane ea ts'ebetso, mme se bile se baka ho khomarela ha hlobo, ho fokotsa bophelo ba hlobo;

Pour Mocheso o fokolang haholo o baka litšitiso tse kenyelletsang mokoallo o batang, sebopeho sa holim'a metsi le ho tšela ho sa lekanang. Bakeng sa ho fumana li-castings tse tšoanelehang, ntle le ho tšolla mocheso, khatello, mocheso oa hlobo ea ho lahla, lebelo la ho tlatsa le motsoako o khethiloeng bakeng sa li-castings le tsona li lokela ho tsotelloa ka nako e le 'ngoe. Likarolo tse lahlang li entsoe ka aluminium-silicon alloy. Ho latela litšobotsi tsa eona tsa fluidity le hlobo, 620 ℃ e khethoa e le mocheso oa ho lahla.

Sebopeho sa moralo oa li-die tsa ho lahla li-die tsa ho lahla khetla ea morao

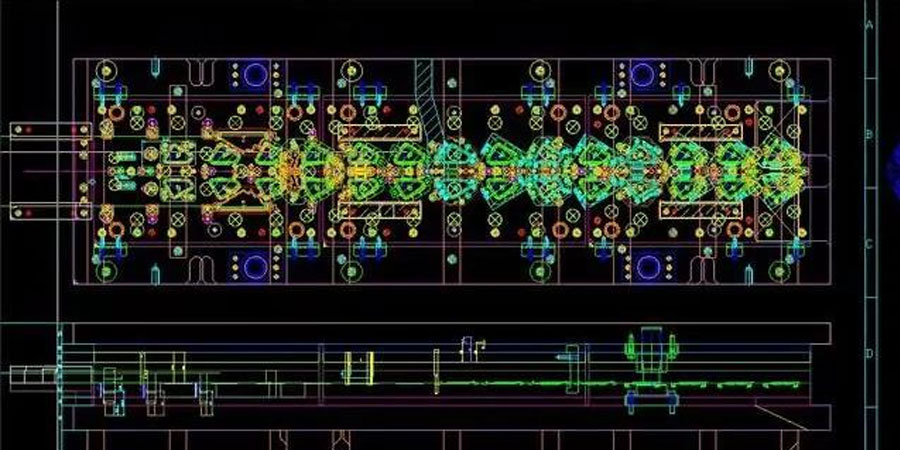

3.1 Boikemisetso ba bokaholimo ba karohano Karolo e na le sebopeho se bonolo. Ho latela molao-motheo oa khetho ea bokaholimo ba karolo, karolo e kholo ea projeke e lokela ho khethoa, joalo ka ha ho bonts'itsoe ho Setšoantšo sa 2.

3.2 Moralo oa sistimi ea litheko Sisteme ea litheko e entsoe ka likarolo tse 'ne:

- Semathi se otlolohileng

- Ner semathi se rapameng

- Heke e kahare,

- Sekoti se batang sa slug.

Moralo o ikhethileng:

- “Kamore ea khatello e kopaneng —— mokhoa oa khokahano oa phaposi ea khatello le ho hlaha ha bushing;

- Sebopeho sa sefapano sa semathi—— trapezoid e sephara;

- Heke e kahare —— heke e mahlakoreng e bōpehileng joaloka lesale;

- IdeSide tšollela Molomo-lokiselitsoe holim 'a karohano ea betsa;

- Mold hlobo e le 'ngoe e nang le likoti tse' ne, Setšoantšo sa 3 se bonts'a sebopeho se ikhethang.

Moralo oa tanka e khaphatsehang le sistimi ea ho qeta monono Moralo oa tanka e khaphatsehang oa etsoa, 'me sebopeho sa likarolo tse khethiloeng ka ho hlahloba lintlha tse fapaneng ke trapezoidal (Setšoantšo sa 3.3). Sebopeho se nang le kahlolo e molemo se na le mesebetsi e latelang:

- Rove Ntlafatsa botsitso ba mocheso oa hlobo-fetola maemo a mocheso hohle moo hlobo e leng teng, fokotsa matšoao a phallo, lithibelo tse batang le ho tšolleloa ho sa lekanang ha li-castings, ho fetisa likoti tsa shrinkage, porcelain shrinkage, le ho kenella ha vortex;

- Ho tsoa ha khase e ka mokokotlong ho felloa ke matla kapele

- Ho boloka mokelikeli oa tšepe e litšila e batang - motsoako oa masala a pente le khase.

3.4 Moralo oa sistimi ea ho qhekella litebele, tse hlokang ho tlosoa. Mosebetsi ona o hloka mofuta o mong oa lisebelisoa tse holimo ho o etsa. Sistimi ea ejector e maemong a bohlokoa mohahong oa sebopeho sa hlobo. Ho na le likarolo tse tharo tsa mantlha tsa sistimi ea ejector:

- Tlohela,

- Seta bocha

- ③ tataisa. Sehlopha sena sa hlobo se sebelisa mekhoa e 'meli ea ho lahla ejector, e sebelisetsoang ho lahla le ho ntša eue. Bophara ba lithakhisa tsa ejector ke 6mm le 8mm ka ho latellana.

Lisebelisoa tsa moeli oa boqapi tsamaisong:

- Boloka moeli,

- ② reset Lever ho ntlafatsa ho nepahala ha seta ea mochini le ho thibela stroke ho feta moeli nakong ea motsamao oa likarolo tsa mochini.

3.5 Palo ea boholo ba karolo e entsoeng

3.5.1 Cavity le boholo ba mantlha:

3.5.2 Fumana sebaka sa bohareng le boholo ba boemo: moo: L-bohare ba sebaka sa karolo le boholo ba boemo ba (mm); L-boholo ba karolelano ea sebaka sa setsi sa ho lahla die le boemo (mm).

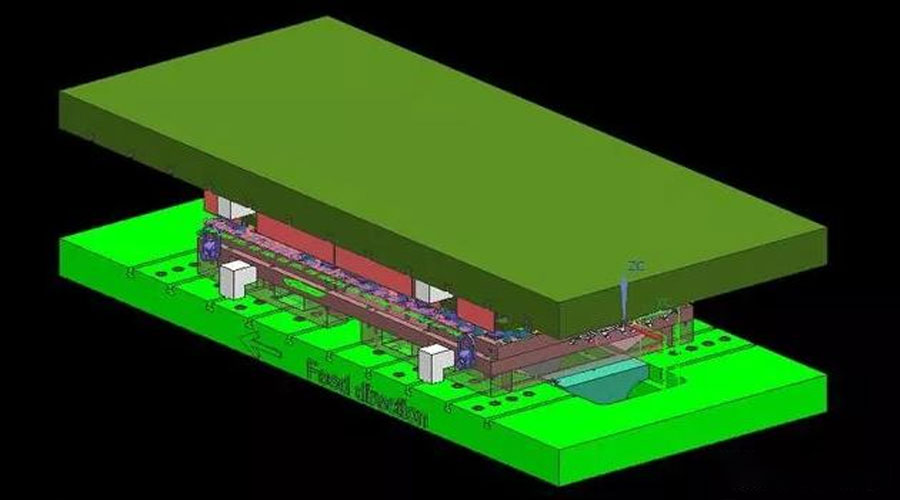

3.6 Moralo oa sistimi ea ho futhumatsa o khetha mokhoa o sebetsang hantle le o bonolo oa ho laola hlobo ea ho futhumatsa-ho pholisa metsi ho fumana li-castings tsa boleng bo holimo le bophelo bo bolelele ba hlobo. Matla a ho futhumatsa ha metsi a pholileng a ipapisitse le sebopeho sa mocha o pholileng, o hlophisitsoeng kahare.

- Mocheso o phahameng ka ho fetisisa,

- Mocheso o tsitsitse haholo,

- Tlas'a hlobo,

- Lehlakore le shebaneng le mosebelisi. Bakeng sa ho ntlafatsa ts'ebeliso ea pompo ea phaephe ea phepelo ea metsi, ho hlokahala hore ho hokahane litekanyo tsa jiometri tsa bophara ba kantle ba kanale ea metsi. Tlhophiso ea eona ea sebopeho e bonts'oa ho Setšoantšo sa 5.

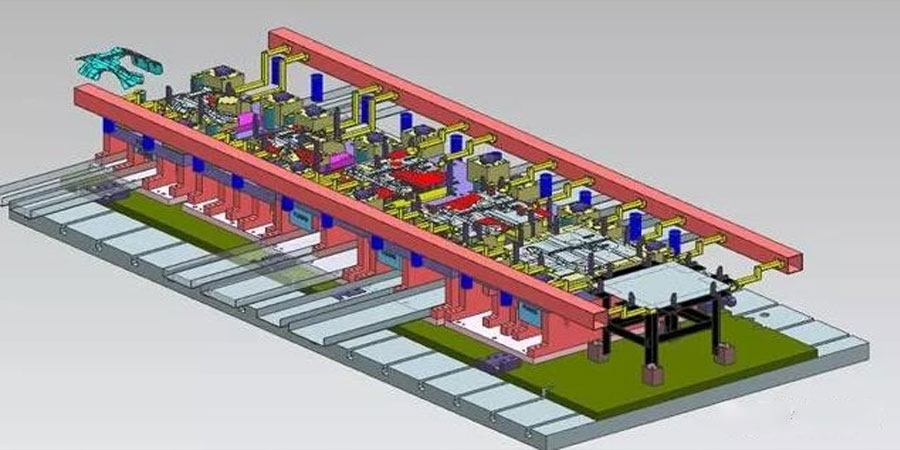

3.7 Setšoantšo sa Kopano e Akaretsang Se entsoeng ka Mochini o Lahlang Likokoana-hloko Etsa setšoantšo se akaretsang sa hlobo e lahlang sekoahelo sa sekhetla se ka morao (Setšoantšo sa 6). Hlobo e lahlang e entsoe ka likarolo tse peli: hlobo e tsitsitseng le hlobo e tsamaeang. Hlobo e tsitsitseng e eme 'me e teng holim'a poleiti e tsitsitseng hlobo. Hlobo e tsamaeang e tsamaea le poleiti ea molateli 'me e fumaneha holima poleiti ea molateli. Hlobo e koetsoe ebile e buloa ke motsamao oa hlobo e ka tsamaisoang ha e bapisoa le hlobo e ka tsamaisoang.

Cl Tšoara hlobo: tse peli li koetsoe ho etsa mokoti, 'me mokoti o tlatsitsoe ka tšepe e qhibilihisitsoeng tlasa khatello e matla e sebelisa sistimi ea gating; Opening Ho buloa ha hlobo: tse peli li arohane kamora khatello e lula e le teng, 'me mochini oa ho kha o qeta mosebetsi oa ho lahla lihlahisoa ho tsoa mokokotlong.

Sengoliloeng sena se sebelisa software ea UG ho etsa likarolo tsa sekoaelo se ka morao, mme se phethela tlhahlobo ea ts'ebetso, ho shoa likarolo tsa ts'ebetso le sebopeho sa sebopeho sa hlobo ea likarolo tse ka morao. Lehare le lekantsoe ke lintlha tse latelang: tlhahiso, ts'ebetso le ts'ebetso ea tlhahiso, jj. Tlhahiso e sebetsang e bonts'a khatello e khethehileng ea 90MPa e khethiloe, lebelo la ho lahla lefu le khethoa ka bongata ba 20-90m / s, nako ea ho lahla ea 0.2s, nako e ts'oereng ea bo3, le ho lahla batho thempereichara ea 620 ℃, sekoaelo se koahetsoeng ka morao sa khetla e na le bokaholimo bo boreleli mme e fihlela litlhoko tsa boleng ba sehlahisoa.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Tlhaloso ea Moralo oa Aluminium Alloy Shell Die Casting Tooling

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off