Mokhoa oa ho Ntlafatsa oa Performance Performance

Ntle le tšebelisano e nepahetseng ea matrix ka matla a lekaneng le ho ba thata, thepa ea hlobo e bohlokoa haholo ts'ebetsong ea ts'ebetso le ts'ebetsong ea bophelo ba hlobo. Lintho tsena tse kaholimo li supa: ho itoanela, ho hanyetsa ts'enyeho, ho lekana ha likhohlano, ts'ebetso ea mokhathala, jj. Mahlale a morao-rao a kalafo a ka fumana sephetho habeli ka halofo ea boiteko. Ke lona lebaka le entseng hore theknoloji ea kalafo ea bokaholimo e tsoele pele ka potlako.

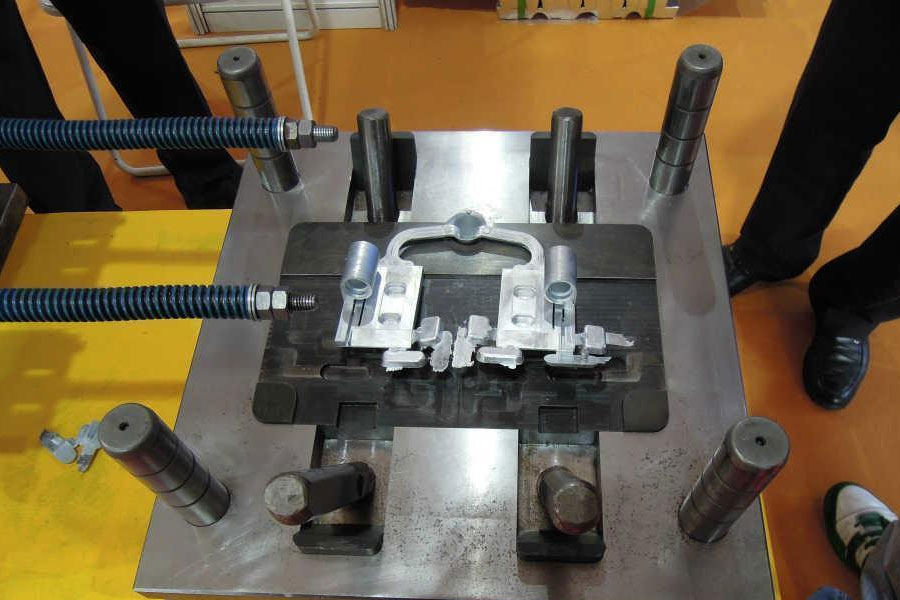

Mahlale a morao-rao a kalafo ea hlobo ke boenjineri bo hlophisehileng ba ho fetola morpholoji, sebopeho sa lik'hemik'hale, sebopeho le khatello ea sebopeho sa hlobo ka ho roala bokaholimo, phetoho ea bokaholimo kapa theknoloji e kopaneng ea kalafo ho fumana thepa e hlokahalang ea bokaholimo. Ho tsoa mokhoeng oa kalafo o kaholimo, e ka aroloa ka: mokhoa oa lik'hemik'hale, mokhoa oa 'mele, mokhoa oa lik'hemik'hale oa' mele le mokhoa oa mochini. Le ha theknoloji e ncha ea ts'ebetso e ikemiselitse ho ntlafatsa ts'ebetso ea hlobo ea hlobo e ntse e hlaha, lits'ebetso tse atileng haholo tlhahisong ea hlobo ke nitriding, carburizing le ho thatafatsoa ha filimi.

Ts'ebetso ea nitriding e kenyelletsa nitriding ea khase, ion nitriding, nitriding ea mokelikeli, jj. Mokhoeng o mong le o mong oa nitriding, ho na le mahlale a mangata a nitriding, a ka fihlelang litlhokahalo tsa mefuta e fapaneng ea tšepe le likarolo tse fapaneng tsa mosebetsi. Hobane theknoloji ea nitriding e ka theha bokaholimo bo nang le ts'ebetso e ntle haholo, mme ts'ebetso ea nitriding le ts'ebetso ea ho tima ea tšepe e na le tšebelisano e ntle, ka nako e ts'oanang, mocheso oa nitriding o tlase, ha ho na pholiso e matla e hlokahalang kamora nitriding, le deformation ea hlobo e nyane haholo. Ho matlafatsa bokaholimo ke theknoloji ea pejana ea nitriding, hape ke eona e sebelisoang ka ho fetisisa.

Morero oa hlobo ea carburizing ke haholo-holo ho ntlafatsa matla le ho thatafala ha hlobo, ke hore, bokaholimo bo sebetsang ba hlobo bo na le matla a holimo le ho itoanela. Mohopolo oa tekheniki o hlahisitsoeng ho sena ke ho sebelisa lisebelisoa tsa maemo a tlase, ke hore, ka ho chesa le ho tima. Ho nkela thepa ea boemo bo holimo sebaka, ka hona ho fokotsa litšenyehelo tsa tlhahiso.

Theknoloji e thata ea ho beha lifilimi hajoale e se e holile haholoanyane CVD, PVD. Bakeng sa ho eketsa matla a tlamahano a bokaholimo ba sethala sa filimi, ho se ho entsoe mefuta e fapaneng ea mahlale a ntlafalitsoeng a CVD le PVD. Theknoloji e thatafalitsoeng ea ho beha lifilimi e sebelisitsoe pele ho lisebelisoa (lithipa, lisebelisoa tsa ho itšeha, lisebelisoa tsa ho metha, jj.) Ka litholoana tse ntle. Mefuta e mengata ea lisebelisoa e sebelisitse liaparo tse thata tsa filimi e le mokhoa o tloaelehileng. Hlobo e koahetsoe ka theknoloji ea filimi e thata ho tloha lilemong tsa bo-1980. Tlas'a maemo a hajoale a tekheniki, litjeo tsa theknoloji e thatafalitsoeng ea ho beha lifilimi (haholo lisebelisoa) li batla li phahame, 'me e ntse e sebelisoa feela ho hlobo e nepahetseng le ea nako e telele. Haeba setsi sa kalafo ea mocheso se thehiloe, litšenyehelo tsa ho roala filimi e thata li tla fokotsoa haholo. , Haeba hlobo e eketsehileng e amohela theknoloji ena, boemo ba tlhahiso ea hlobo ka kakaretso bo ka ntlafatsoa.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape:Mokhoa oa ho Ntlafatsa oa Performance Performance

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off