Mekhoa le Mehato ea Stamping Die Design

Hona le mefuta e mengata ea hlobo e ka aroloang ka:

- Mefuta ea tšepe e ipapisitse le lipehelo tsa ts'ebetso le mekhoa ea ho e lokisa.

- E sebetsana le hlobo ea tšepe ea tšepe.

Kajeno, mohlophisi o bua ka mokhoa le ts'ebetso ea ho hatakela moralo oa die.

Ts'ebetso ea ho tapa likarolo tsa likarolo

Likarolo tsa litempe li tlameha ho ba le theknoloji e ntle haholo ea ho tapa molemong oa ho hlahisa likarolo tse tšoanelehang tsa litempe ka tsela e bonolo le e bolokang chelete. Ts'ebetso ea ts'ebetso ea likarolo tsa stamp e ka phetheloa ho latela mekhoa e latelang:

- Bala likarolo tse takiloeng. Ntle le sebopeho le boholo ba likarolo, ho bohlokoa ho utloisisa litlhoko tsa ho nepahala ha likarolo le ho kobeha ha bokaholimo.

- Hlahloba hore na sebopeho le sebopeho sa likarolo li loketse ts'ehetso ea stamp.

- Hlahloba hore na khetho ea litšupiso le ho tšoauoa ka sekhahla sa likarolo li nepahetse, le hore na sekala, boits'oaro le ho nepahala ha sebopeho li loketse tšebetso ea ho hatakela.

- Hore na litlhoko tsa bokaholimo ba karolo ea karolo e koalang li holimo haholo.

- Hore na ho na le lihlahisoa tse kholo tse lekaneng tsa tlhahiso.

Haeba tlhahiso ea karolo eo e le mpe haholo, o lokela ho buisana le moralo ebe o etsa tlhahiso ea leano la ho ntlafatsa moralo. Haeba sehlopha sa tlhahiso se le nyane haholo, mekhoa e meng ea tlhahiso e lokela ho tsotelloa bakeng sa ts'ebetso.

Ho hatakela Morero oa Ts'ebetso le Moralo o Ntle oa Ts'ebetso

- Ho latela sebopeho le boholo ba likarolo tsa litempe, qala ho tseba mofuta oa ts'ebetso ea ho hatakela, joalo ka: ho otla ka litebele, zigzag, ho taka ka botebo, bulging, reaming le mekhoa e meng ea ho rala lefu. Ho hatakela mekhoa le lits'ebetso tsa lefu.

- Bala sekhahla sa ho fetoha ha mokhoa o mong le o mong oa stamping. Haeba tekanyo ea ho fetoha e feta moeli oa phetoho, palo ea litebele tse ts'ebetsong ena e lokela ho baloa.

- Ho latela litšobotsi tsa ho fetoha le litlhoko tsa boleng ba ts'ebetso e ngoe le e ngoe, hlophisa tatellano e nepahetseng ea ho tapa. Tlhokomelo e lokela ho fuoa ho netefatsa hore libaka tsa deformation ts'ebetsong e ngoe le e ngoe ke sebaka se fokolang. Karolo e seng e ntse e thehiloe (ho kenyeletsoa le lesoba le bopehileng kapa sebopeho) e ke ke ea nka karolo ho deformation ts'ebetsong e latelang. Karolo ea polygonal zigzag e tlameha ho kobeha kantle ebe e koalehile kahare, ho a hlokahala ho hlophisa lits'ebetso tse thusang tse kang ho bopa, ho batalatsa le kalafo ea mocheso.

- Morero oa ho netefatsa ho nepahala ha likarolo, etsa qeto ea mokhoa o utloahalang oa ho kopanya mekhoa ho latela sehlopha sa tlhahiso le boemo bo se nang letho le litlhoko tse hlahisang.

- Ho rala merero ea ts'ebetso e 'meli kapa ho feta,' me u bapise boleng, litjeo, sekhahla sa tlhahiso, ho leotsa le ho lokisa hlobo, bophelo ba hlobo le polokeho ea ts'ebetso, jj., Ho khetha moralo oa ts'ebetso o motle.

- Qala ho tseba lisebelisoa tsa ho tapa tsa ts'ebetso e ngoe le e ngoe.

Morero o sa reroang le moralo oa likarolo tsa litempe

- Ho latela sebopeho sa likarolo tsa litempe, bala litekanyo tsa likheo ebe o etsa litšoantšo tse se nang letho

- Ho latela sebopeho le sekala sa sekheo, rera moralo oa ho taka 'me u bale sekhahla sa ts'ebeliso ea data. Ho rera meralo e fapaneng ea moralo, khetha moralo o motle ka ho fetisisa hara bona ka ho o bapisa.

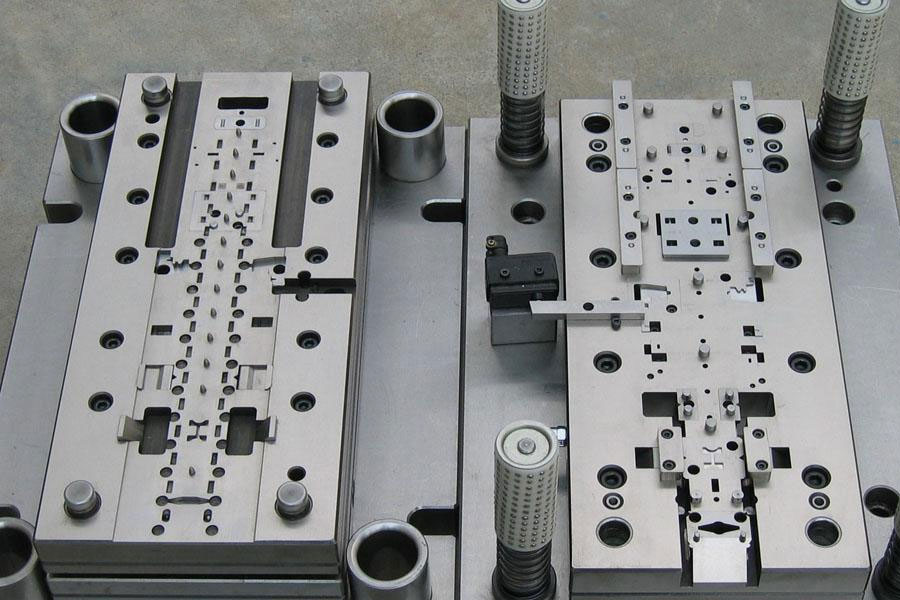

Tapa shoa moralo

1. Fumana mokhoa oa sebopeho sa hlobo molemong oa ts'ebetso e ngoe le e ngoe ea ho tapa, 'me u etse setšoantšo sa sebopeho sa hlobo.

2. Etsa moralo o ikhethileng oa sebopeho sa moetso o boletsoeng oa 1-2, 'me u etse lits'oants'o tsa ts'ebetso ea hlobo.

Mokgwa wa ho rala o tjena:

- Fumana mofuta oa hlobo: na ke hlobo e bonolo, hlobo e tsoelang pele kapa hlobo e kopaneng.

- Hlobo sebetsa likarolo moralo: a bale litekanyo tsa khonvekse le concave shoa bohale le bolelele ba khonvekse le hlobo concave, fumana sebopeho sa khonvekse le hlobo concave le mabapi le fixation mekhoa.

- Etsa qeto ea sebaka le sebaka sa sebaka se se nang letho, 'me u rale hore na boemo ba sebaka le likarolo li tla lekana joang.

- Fumana mekhoa ea ho tobetsa, ho laolla, ho lahla le ho sututsa likarolo, 'me u rale lipoleiti tse ts'oanang tse ts'oereng, ho laolla lipoleiti le ho sututsa.

- Moralo oa motheo oa hlobo: ho kenyelletsa moralo oa metheo e holimo le e tlase ea hlobo le mekhoa e tataisang, le metheo e tloaelehileng ea hlobo le eona e ka khethoa.

- Motheong oa ho phethela mesebetsi e kaholimo, setšoantšo sa ts'ebetso ea hlobo se etsoa ho latela karolo. Pele sebelisa mola o nang le marontho a mabeli ho etsa letho, ebe o etsa likarolo tse sebetsang, ebe o etsa likarolo le likarolo tsa hole, sebelisa likarolo tse hokahanyang ho hokela likarolo tse kaholimo, mme qetellong o etse likarolo tse hatellang le tse laolang maemong a loketseng. Ho latela maemo a ikhethileng a hlobo, tatellano e kaholimo le eona e ka fetoloa ka nepo.

- Ts'ebetso ea ts'ebetso e lokela ho bonts'a litekanyo tsa mochini o ka ntle oa hlobo, bophahamo ba ho koaloa ha hlobo, sekala sa tšebelisano, le mokhoa oa ts'ebelisano mofuta oa ho hatakela moralo oa hlobo le moralo oa ts'ebetso ea hlobo. 'Mapa oa mosebetsi o lokela ho bonts'a litlhoko tsa ho nepahala ha tlhahiso ea hlobo le maemo a tekheniki. 'Mapa oa mosebetsi o lokela ho etsoa ho latela maemo a naha a ho taka, ka mola o tiisitsoeng oa sehlooho le lenane le qaqileng la mabitso. Haeba e le lefu le se nang letho, etsa setšoantšo se raliloeng k'honeng e kaholimo ho le letšehali ea mosebetsi oa ho taka.

- Sebelisa setsi sa khatello ea hlobo ebe u sheba hore na setsi sa khatello le mola o bohareng oa mochini oa hlobo li lumellana joang. Haeba li sa tsamaisane, etsa litokiso tse tsamaellanang le sephetho sa hlobo.

- Sebelisa matla a otlang, 'me qetellong khetha lisebelisoa tsa ho tapa,' me u hlahlobe litekanyo tse amehang tsa lisebelisoa tsa die le stamp (bophahamo bo koetsoeng, bokaholimo ba mosebetsi, litekanyo tsa lisebelisoa tsa sesebelisoa, jj.).

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Mekhoa le Mehato ea Stamping Die Design

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off