Mefuta e Leshome ea Mekhoa ea ho lahla ho Li-Foundries

Sehlopha sa ho Lahlela

- Ho lahla ha lehlabathe

- Ho etsa chelete

- Ho lahla lefu

- Low lahleloa khatello ea

- Lahla Centrifugal

- Matla a khoheli shoa lahla

- Lahla lephaka

- Pepeta ho lahla

- E lahlehetsoe ke foam

- Tsoelang pele ho betsa

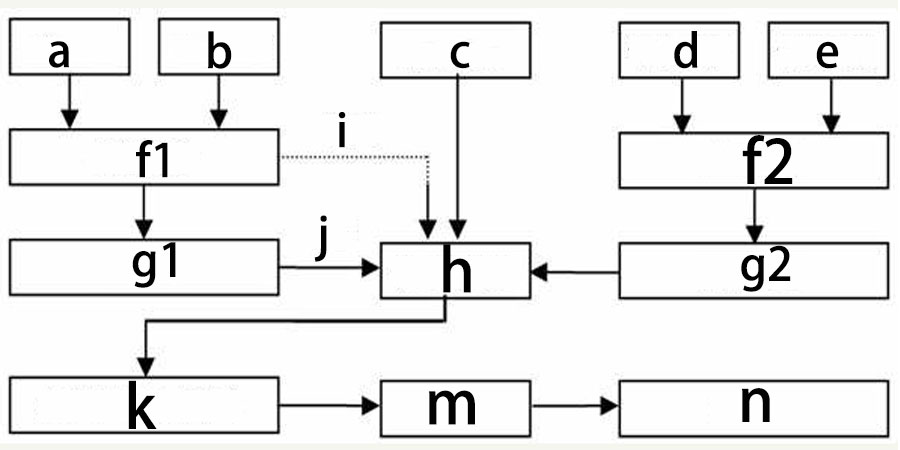

Ho lahla lehlabathe

Ho lahla lehlabathe: Mokhoa oa ho lahla lehlabathe. Lisebelisoa tsa tšepe, tšepe le likarolo tse ngata tse se nang litšepe li ka fumanoa ka mekhoa ea ho lahla lehlabathe.

Ho phalla:

- a: Moetso oa Mochini oa hlobo

- b: Litokisetso tsa Sand Sand

- c: tšepe e qhibilihisitsoeng

- d: Ho etsa lehlabathe la Core

- e: Lebokose la Tlhahiso ea Core

- ke: Mofuta o metsi

- j: Mofuta o omileng

- f1: Lehlabathe la Tlhahiso

- g1: Ho omisa lehlabathe

- f2: Ho etsa Sand Core

- g2: Ho omisa Core Core

- h: Hlobo e Thehiloe Joaloka hlobo

- k: Tlosa ho lahla hlobo

- m: Hloekisa

- n: Likarolo tsa tlhahlobo

Likarolo tsa Tlhahlobo:

- E loketse ho etsa likheo tse nang le libopeho tse rarahaneng, haholoholo ka likoti tse ka hare tse rarahaneng;

- Ho ikamahanya le maemo ka bophara le theko e tlase;

- Bakeng sa lisebelisoa tse ling tse nang le polasetiki e futsanehileng, joalo ka tšepe ea tšepe, ho lahla lehlabathe ke ona feela mokhoa oa ho etsa likarolo tsa ona kapa likheo.

- Kopo: enjene ea koloi silindara le literata, hlooho silindara, crankshaft le castings tse ling

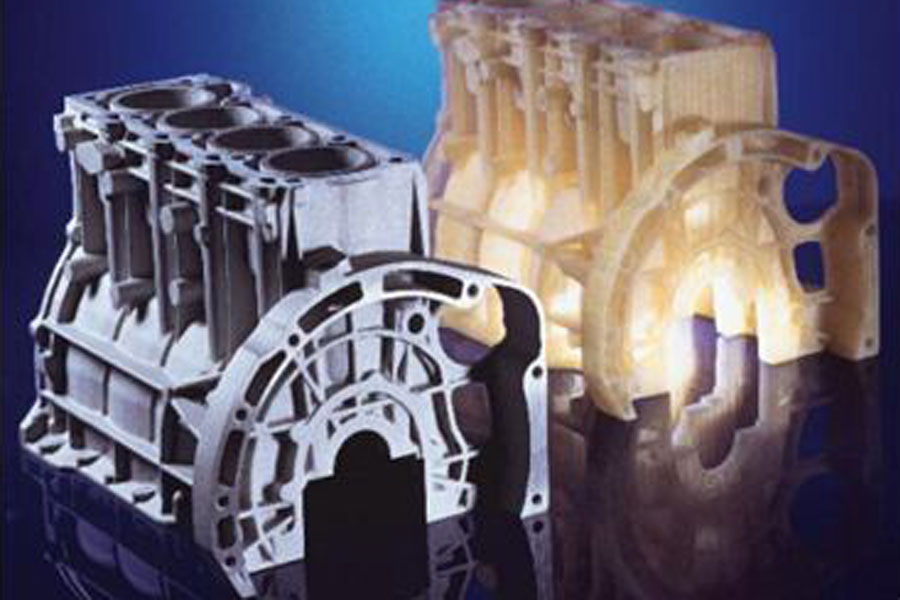

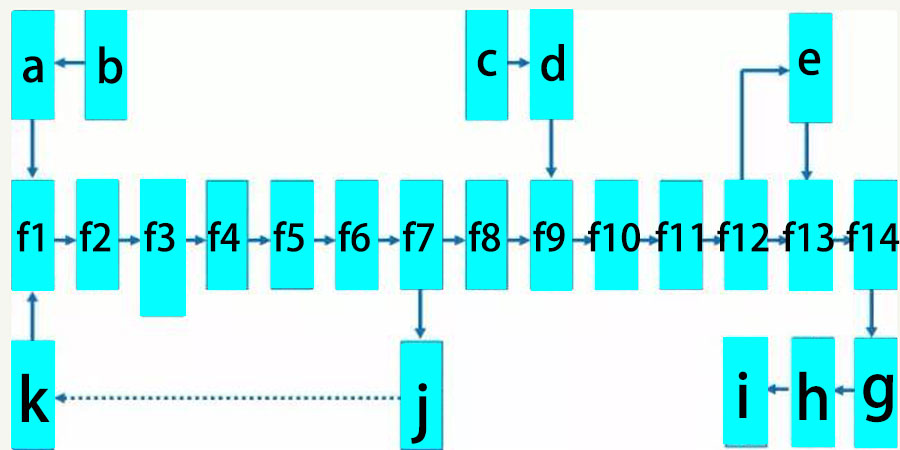

Lisebelisoa tsa 2.Investment

Ho lahla matsete: hangata ho bolela ho etsa paterone e entsoeng ka thepa e ka bonoang, e koahelang bokaholimo ba paterone ka likarolo tse 'maloa tsa lisebelisoa tse sa sebetseng ho etsa khetla, ebe e qhibilihisa paterone ho tsoa khetla ho fumana hlobo ntle le bokaholimo. Kamora ho baka ho chesa haholo, E ka tlatsoa ka lehlabathe ebe ea tšeloa. Hangata e bitsoa "ho lahla boka ba linotsi".

- a: Hlobo Etsa

- b: Setšoantšo se lahlang

- c: Ho qhibiliha

- d: Tlhatlhobo ea likarolo

- e: Pickling Passivation

- f1: Ente ea boka

- f2: Mohlala oa boka

- f3: Ho tjheseletsa Riser

- f4: Pente e leketlileng

- f5: Lehlabathe le Lahlahileng

- f6: Ho thatafatsa

- f7: Ho qhekelloa

- f8: Baking ea Shell ea hlobo

- f9: Ho lahla

- f10: Likhetla

- f11: Hloekisa

- f12: Phekolo ea mocheso

- f13: Tlhahlobo

- f14: Ho boloka matlo

- g: Mochini oa Cnc

- h: Tlhahlobo ea Likarolo

- ke: Ho boloka matlo

- j: boka ba linotsi

- k: boka ba linotši

Mekhoa ea ts'ebetso

Molemo:

- Phahameng tlhakore ho nepahala le thutatekanyo ho nepahala;

- Boreleli bo phahameng;

- E ka lahla castings e rarahaneng, 'me motsoako oa cast ha o felle.

Go tlhoka mesola: mekhoa e rarahaneng le theko e phahameng

Kopo: E loketse tlhahiso ea likarolo tse nyane tse nang le libopeho tse rarahaneng, litlhoko tse phahameng tsa ho nepahala, kapa mathata a mang a ts'ebetso, joalo ka li-enjini tsa turbine.

3.Ho lahla

Shoa lahla: E sebelisa khatello e phahameng ea ho tobetsa tšepe e qhibilihisitsoeng ka sebetsa ka ho nepahetseng tšepe hlobo cavity ka lebelo le phahameng. Tshepe e qhibilihisitsoeng e pholile 'me e tiisitsoe ka tlas'a khatello ea ho etsa foromo.

Ts'ebetso ea ho lahla Die:

- Hloekisa hlobo

- Penta pente

- Ho ts'oara

- Tšela

- ho tiisa

- Mold

- Ehla

- Ntša betsa

Mekhoa ea ts'ebetso

Molemo:

- Mokelikeli oa tšepe o jara khatello e phahameng nakong ea ho betloa ha shoela, 'me sekhahla sa phallo se potlakile

- Boleng ba sehlahisoa bo botle, boholo bo tsitsitse, mme ho fapanyetsana ho molemo;

- The bokgoni tlhahiso ea e phahameng, 'me hlobo-shoa-foromeletsoeng hlobo e sebelisoa ka makhetlo a mangata;

- E loketse tlhahiso ea bongata ka melemo e metle ea moruo.

go tlhoka mesola:

- Li-castings li tloaetse li-pores tse nyane le shrinkage porosity.

- Li-castings tsa Die li na le polasetiki e tlase ebile ha li tšoanelehe ho sebetsa tlasa mojaro oa tšusumetso le ho thothomela;

- Ha phahameng qhibiliha ntlha motsoako e shoa-lahla, bophelo hlobo e tlaase, e leng se ama katoloso ea tlhahiso ea shoela-foromeletsoeng.

Kopo: Likotlo tse shoang li ile tsa sebelisoa ka lekhetlo la pele indastering ea likoloi le indastering ea liletsa, 'me hamorao ea atolosoa butle-butle ho ea liindastering tse fapaneng, joalo ka mechini ea temo, indasteri ea lisebelisoa tsa mochini, indasteri ea elektroniki, indasteri ea ts'ireletso, khomphutha, lisebelisoa tsa bongaka, lioache, lik'hamera le lisebelisoa tsa letsatsi le letsatsi. , jj.

4.Low Khatello lahla

Ho lahla khatello e tlase: ho bolela mokhoa oa ho tlatsa hlobo ka tšepe e mokelikeli tlasa khatello e tlase (0.02 ~ 0.06MPa) le ho hlakisa tlasa khatello ea ho etsa castings.

Likarolo tsa botekgeniki:

- Khatello le lebelo nakong ea ho tšela li ka fetoloa, ka hona e ka sebelisoa ho hlobo e fapaneng ea ho lahla (joalo ka hlobo ea tšepe, hlobo ea lehlabathe, jj.), Ho lahla lits'epe tse kopantsoeng tse fapaneng le li-castings tsa boholo bo fapaneng;

- Tlase mofuta oa mofuta oa tlatsetso oa amoheloa, ho tlatsoa ha tšepe e qhibilihisitsoeng ho tsitsitse mme ha ho na ketsahalo e phatlohang, e ka qobang ho kenella ha khase le khoholeho ea lerako le mokokotlo, e ntlafatsang sekhahla sa mangolo a castings;

- Ho lahla ho hlakisa tlasa khatello, sebopeho sa ho betsa se teteaneng, kemiso ea puo e hlakile, bokaholimo bo boreleli, 'me thepa ea mochini e phahame, e leng molemo haholo bakeng sa ho betsa likarolo tse kholo le tse otileng;

- Sesepa sa feeder ha se sebetse, 'me sekhahla sa ts'ebeliso ea tšepe se ekelitsoe ho 90-98%;

- Matla a tlase a mosebetsi, maemo a matle a ho sebetsa, lisebelisoa tse bonolo, ho bonolo ho elelloa mechini le boiketsetso.

Kopo: Haholo-holo lihlahisoa tsa setso (silindara hlooho, lebili setsi, foreime silindara, joalo-joalo).

5.Centrifugal lahla

Ho lahla Centrifugal: ke mokhoa oa ho betsa oo tšepe e qhibilihisitsoeng e tšeloang ka har'a hlobo e potolohang, 'me hlobo e tlatsoa tlasa tšebetso ea matla a centrifugal ho tiisa le ho theha.

Mekhoa ea ts'ebetso

Molemo:

- Ha ho na ts'ebeliso ea tšepe ts'ebetsong ea gating le sistimi ea riser, e ntlafatsang sekhahla sa tlhahiso ea ts'ebetso;

- Ha ho hlokahale hore u sebelise mantlha ha u hlahisa li-castings tse sekoti, ka hona bokhoni ba ho tlatsa tšepe bo ka ntlafatsoa haholo ha u hlahisa li-tubular castings tse telele;

- Li-castings li na le letsoalo le phahameng, likoli tse fokolang tse joalo ka li-pores le slag inclusions, le thepa e phahameng ea mochini;

- Ho bonolo ho etsa moqomo le sleeve le likarolo tse ngata castings tšepe.

go tlhoka mesola:

- Ho na le meeli e itseng ha e sebelisoa ho hlahiseng libapali tse nang le sebopeho se ikhethileng;

- Bophara ba lesoba le kahare la ho betla ha boa nepahala, bokaholimo ba lesoba le kahare bo batla bo le thata, boleng bo futsanehile, 'me kabelo ea ho e sebelisa e kholo;

- Li-castings li tloaetse ho aroloa ka matla a khoheli a itseng.

kopo:

Ho lahla Centrifugal ho sebelisitsoe ka lekhetlo la pele tlhahiso ea lipeipi tsa samente. Lapeng le kantle ho naha, ho lahla li-centrifugal ho ne ho sebelisoa metallurgy, meepo, lipalangoang, nosetso le mechini ea drainage, ho fofa, ts'ireletso ea naha, likoloi le liindasteri tse ling ho hlahisa tšepe, tšepe le likarolo tse seng tsa feri tsa carbon alloy castings. Har'a tsona, tlhahiso ea li-castings joalo ka lipeipi tsa tšepe tsa centrifugal, liphahlo tsa kahare tsa enjene ea mollo le matsoho a shaft ke tsona tse tloaelehileng haholo.

6.Gravity shoa lahla

Gravity Die Casting: e bua ka mokhoa oa ho bopa oo tšepe e nang le mokelikeli e tlatsitsoeng ka hlobo ea tšepe tlasa tšebetso ea matla a khoheli ebe e pholile ebile e tiisoa ka hlobo ho fumana ho betloa.

Mekhoa ea ts'ebetso

Molemo:

- Mocheso oa mocheso le mocheso oa hlobo ea tšepe li kholo, sekhahla sa ho futhumatsa se potlakile, sebopeho sa ho betla se teteaneng, mme thepa ea mochini e ka ba 15% ho feta ea lehlabathe.

- Li-castings tse nang le ho nepahala ho phahameng ka mokhoa o phahameng le boleng bo tlase ba bokaholimo li ka fumanoa, 'me botsitso ba boleng bo botle.

- Hobane li-cores tsa lehlabathe ha li sebelisoe ebile ha li sebelisoe hangata, tikoloho ea ntlafatsoa, lerōle le likhase tse kotsi lia fokotseha, 'me matla a basebetsi a fokotsehile.

go tlhoka mesola:

- Sebopeho sa tšepe ka boeona ha se na moea o kenang, 'me mehato e meng e tlameha ho nkuoa ho fumana moea ka lehare le khase e hlahisoang ke mokokotlo oa lehlabathe;

- Hlobo ea tšepe ha e na moo e ikhutlang teng, 'me ho betloa ha eona ho ka etsahala hore e be le mapetso ha e tiisitsoe;

- Potoloho ea tšepe ea tšepe e telele ebile litšenyehelo li phahame. Ka hona, ke tlhahiso ea bongata feela, e ka bonts'ang litholoana tse ntle tsa moruo.

Kopo: Ho betloa ha hlobo ea tšepe ha ho loketse feela tlhahiso ea bongata ea li-castings tsa alloy tse se nang litšepe tse kang lits'epe tsa aluminium le alloys ea magnesium e nang le libopeho tse rarahaneng, empa hape e loketse tlhahiso ea tšepe le tšepe ea tšepe le li-ingots.

7.Vacuum shoa lahla

Lephaka foromeletsoeng: E tsoetseng pele shoela'ng-foromeletsoeng thulaganyou e hore felisa kapa haholo fokotsa pores le qhibiliha likhase ka likarolo shoa-lahla ka ho tlosa khase ho tloha shoela'ng-foromeletsoeng hlobo cavity nakong ea ho etsa-shoa lahla, ka tsela eo ho ntlafatsa thepa phetha molao le bokaholimo boleng ba likarolo tse shoang li lahla.

Mekhoa ea ts'ebetso

Molemo:

- Felisa kapa fokotsa pores ka hare ho lahla shoela'ng, ho ntlafatsa thepa phetha molao le boleng holim 'a betsa shoa, le ho ntlafatsa tshebetso plating;

- Ho fokotsa khatello ea mokokotlo oa mokoti, khatello e khethehileng le li-alloys tse nang le thepa e sa sebetseng e ka sebelisoa, 'me hoa khonahala ho shoa-cast castings kholo ka mochini o monyane;

- Maemo a ho tlatsa a ntlafalitsoe, 'me ho ts'oaroa ho tšesaane ho ka shoa;

go tlhoka mesola:

- Sebopeho sa tiiso ea hlobo se thata, 'me ho thata ho e etsa le ho e kenya, ka hona theko e holimo;

- Haeba mokhoa oa ho lahla li-vacuum o laoloa hampe, phello ha e bohlokoa haholo.

8.Squeezing shoa lahla

Pepeta ho lahla: ke mokhoa oa ho tiisa, ho phalla le ho etsa tšepe e mokelikeli kapa e tiileng ka tlas'a khatello e matla ho fumana likarolo kapa likheo ka kotloloho. E na le melemo ea sekhahla se phahameng sa ts'ebeliso ea tšepe ea mokelikeli, ts'ebetso e nolofalitsoeng le boleng bo tsitsitseng. Ke theknoloji ea tšepe e bolokang matla e nang le menyetla ea ts'ebeliso.

- Otlolla ka ho otloloha: pente ea spray, alloy alloy, hlobo e haufi, khatello, ts'oara khatello, khatello ea khatello, hlobo e arohaneng, demold e se nang letho, seta bocha;

- Ka tsela e sa tobang, pepeta

Likarolo tsa botekgeniki:

- E ka felisa liphoso tsa kahare joalo ka masoba, masoba a shrinkage le shrinkage porosity;

- Botle bo holimo ba bokaholimo le ho nepahala ho holimo ha tlhakore;

- E ka thibela ketsahalo ea ho lahla mapetso;

- Ho bonolo ho hlokomela mechini le boiketsetso.

Kopo: E ka sebelisoa ho hlahisa mefuta e fapaneng ea lits'epe tse kopantsoeng, tse kang motsoako oa aluminium, alloy zinc, alloy ea koporo, tšepe ea ductile, jj.

9.Lost bubble lahla

Ho lahla foam Kamora ho hlatsoa le ho omisa liaparo tse bonoang, li patoa lehlabatheng le ommeng la quartz bakeng sa mohlala oa thothomelo. Ke mofuta o mocha oa mokhoa oa ho lahla oo hlobo e kenngoang ke moea ka ona ka ho o tšela ka tlas'a khatello, tšepe ea mokelikeli e maemong a hlobo, mme ho lahla ho thehoa kamora ho tiisa le ho pholisa.

Ts'ebetso ea phallo: pele ho phophoma → e foka makoeba → ho roala ka tlung → ho omisa → ho etsa mohlala → ho tšela → ho oa → ho hloekisa

Likarolo tsa botekgeniki:

- The foromeletsoeng na sebetsa ka ho nepahetseng phahameng le ha ho na konokono lehlabathe, e leng ho fokotsa nako e lokisa;

- Ha ho na sebaka sa karohano, moralo o tenyetsehang le tokoloho e phahameng;

- Tlhahiso e hloekileng, ha ho na tšilafalo;

- Fokotsa litšenyehelo tsa matsete le tlhahiso.

Kopo: E loketse tlhahiso ea likarolo tse nepahetseng tsa boholo bo fapaneng ka meaho e rarahaneng, mefuta e sa lekanyetsoang ea lits'epe tse kopantsoeng, le lihlopha tsa tlhahiso tse se nang moeli. Tse kang lebokose la enjene ea tšepe e bohlooho, litsoeng tse phahameng tsa mankanese, joalo-joalo.

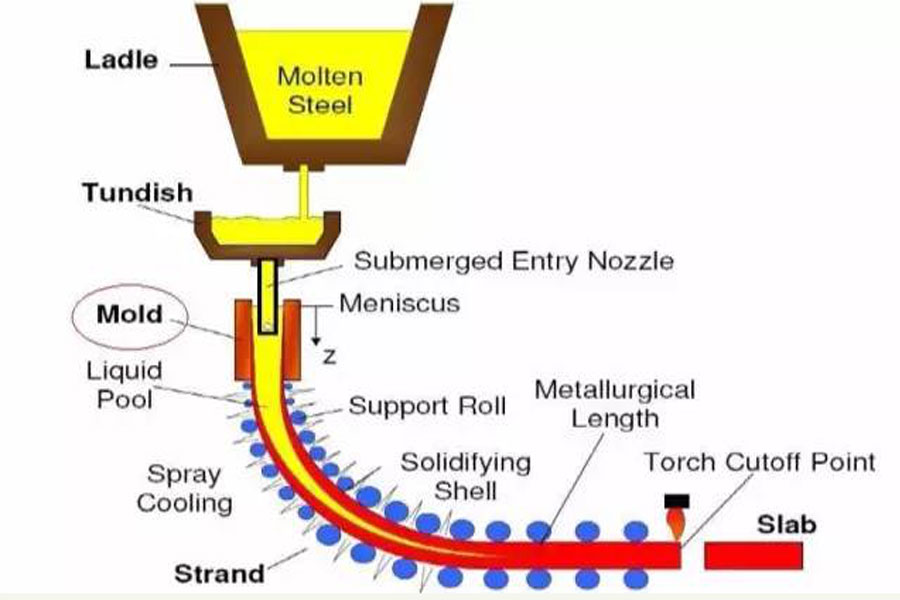

10.Continental lahla

Tsoelang pele foromeletsoeng: Ke mokhoa o tsoetseng pele foromeletsoeng. Molao-motheo oa eona ke ho tšela tšepe e entsoeng ka ho qhibilihisoa ka har'a hlobo e khethehileng ea tšepe e bitsoang hlobo. Li-castings tse tiisitsoeng (tse kobehileng) li tlosoa khafetsa hlobo. Hula ntlha e le 'ngoe, e ka fumana bolelele kapa bolelele bo itseng.

Ts'ebetso e tsoelang pele ea ho lahla:

Likarolo tsa botekgeniki:

- Ka lebaka la ho phola ka potlako ha tšepe, kristale e teteaneng, sebopeho se ts'oana, mme thepa ea mochini e betere;

- Boloka tšepe 'me u eketse chai;

- Ts'ebetso e nolofalitsoe, 'me ho etsa mohlala le lits'ebetso tse ling lia felisoa, ka hona ho fokotsa matla a basebetsi; sebaka se hlokahalang sa tlhahiso le sona se fokotsehile haholo;

- Tsoelang pele foromeletsoeng tlhahiso ea ho bonolo ho hlokomela mechine le itsamaise, le ho ntlafatsa tlhahiso ea bokgoni.

Kopo: Ho lahla ho tsoelang pele ho ka sebelisoa ho betla tšepe, tšepe, lits'epe tse kopantsoeng, lits'epe tse kopantsoeng tsa aluminium, lits'epe tse kopantsoeng tsa magnesium le li-castings tse ling tse telele tse nang le libopeho tse sa fetoheng tsa sefapano, joalo ka li-ingots, matlapa, li-billet, methapo, jj.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape:Mefuta e Leshome ea Mekhoa ea ho lahla ho Li-Foundries

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off