Mocheso Phekolo Tsamaiso Puisano Of Aluminium-Magnesium motsoako motsoako shoa-lahla hlobo

Ts'ebeliso ea kalafo e thatafatsang le ts'ebetso e matlafatsang ea kalafo ke tsela ea bohlokoa ea tlhahiso ho ntlafatsa ts'ebetso le bophelo ba hlobo. kalafo ea mocheso le lits'ebetso tse tloaelehileng ka botlalo, mme e supa hore sebopeho se hlakileng sa ts'ebetso ea kalafo ea mocheso se ka netefatsa ho thatafala ha hlobo, ho roala, matla a mantlha le ho tiea, le ho thibela ts'enyeho ea tšepe ea tšepe. Ho khomarela hlobo ho ka fokotsa sekhahla sa litšila le ho eketsa haholo bophelo ba ts'ebeletso ea hlobo.

Li-alloys tsa aluminium-magnesium li sebelisoa ka bongata le ho feta ka lebaka la letsoalo la tsona le matla a holimo. Har'a tsona, theknoloji ea die-casting ea aluminium-magnesium, e le ts'ebetso e tsoetseng pele ea ho itšeha, e na le litšobotsi tsa ts'ebetso e phahameng ea tlhahiso, ho boloka lisebelisoa tse tala, ho fokotsa litšenyehelo tsa tlhahiso, ts'ebetso e ntle ea sehlahisoa, le ho nepahala ho phahameng. , Haholo-holo sebelisoa ka elektronike, likoloi, likoloi, lisebelisoa lapeng le liindasteri tse ling, ba bang ba tshebetso e phahameng, phahameng sebetsa ka ho nepahetseng, phahameng boleng ba boleng bo phahameng lihlahisoa tsa aluminium-magnesium motsoako le tsona li 'nile tsa sebelisoa ho lifofane tse khōlō, likepe le liindasteri tse ling le batlang e le litlhokahalo tse phahameng tsa tekheniki.

Maemo a ho sebetsa le litlhokahalo tsa ts'ebetso ea hlobo ea aluminium-magnesium alloy

Aluminium-magnesium alloy die-cast hlobo ke sesebelisoa se sebelisoang ho shoa li-cast-aluminium-magnesium alloy castings mochini o lahlang. Qhibiliha ea motsoako aluminium ke 600 ~ 750 ℃, 'me ntlha qhibilihang ea motsoako magnesium ke 600 ~ 700 ℃. Mocheso o sebetsang holim'a metsi o ka nyolohela ho 500 ~ 600 ℃. Lifahleho tsa sekoti, mandrel le nozzle kaofela li na le liphetoho tse matla tsa mocheso, 'me bokaholimo ba hlobo bo na le mapetso a mokhathala o futhumetseng. Ntle le moo, motsoako oa aluminium-magnesium o bonolo ho latela bokaholimo ba hlobo nakong ea ts'ebetso ea ho lahla, e amang tšebetso e tsoelang pele ea tlhahiso ea li-die-casting. Mokelikeli oa aluminium-magnesium alloy o na le phello e matla ea khoholeho ea metsi holim'a hlobo. Ka hona, ho etsa hlobo ea aluminium-magnesium alloy e laoloang, thepa ea hlobo e hlokahala ho ba le botsitso bo phahameng ba moea le ho hanela mokhathala o batang le mocheso hoo e ka bang ka 600 ° C, 'me u hanele hantle mocheso o phahameng, khatello e phahameng, lebelo le phahameng. le khoholeho e phahameng ea khoholeho ea mobu ea alloys ea aluminium-magnesium. Matla le ho thatafala ha hlobo, 'me ka nako e ts'oanang, kalafo e nepahetseng ea mocheso ea hlokahala ho tlanya bokhoni ba thepa ea hlobo le ho ntlafatsa bophelo ba ts'ebeletso ea hlobo. Hajoale, lisebelisoa tse sebelisoang haholo tsa aluminium-magnesium alloy die-casting die li kenyelletsa: 3Cr2W8V tšepe, 4Cr5MoSiV1 tšepe, tšepe ea 4Cr3Mo3SiV, tšepe ea 4Cr5MoSiV, le mefuta e mecha ea tšepe 4Cr5Mo2MnSiV1 tšepe le 3Cr3Mo3VNb steel.

Tsela ea ho etsa thepa ea aluminium-magnesium alloy e lahla hlobo

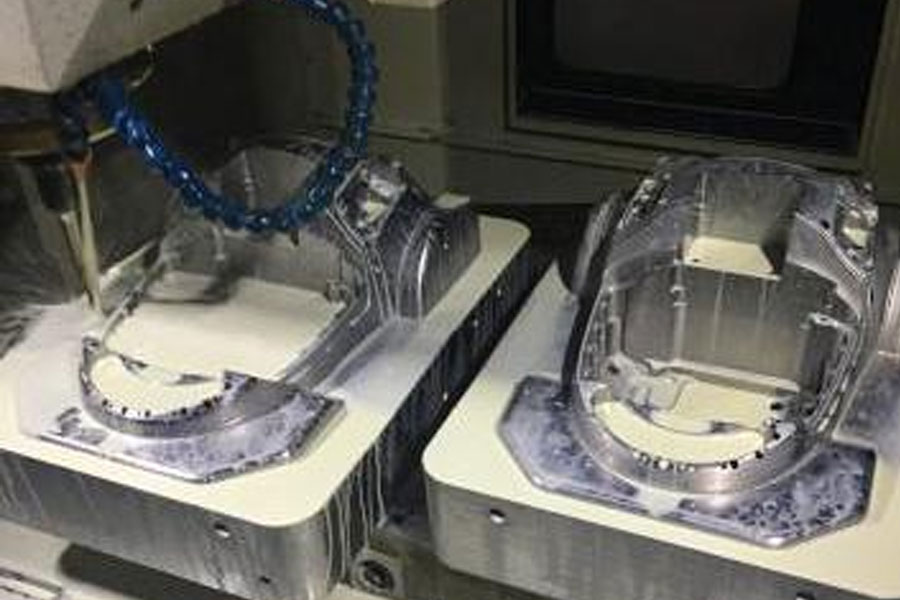

Ts'ebetso ea tlhahiso ea aluminium-magnesium alloy die-casting hlobo ke: ho koala → ho betla → ho khothaletsa lintho tse ling → ho e sebelisa

Ho matlafatsa le ho thatafatsa kalafo thulaganyou e aluminium-magnesium motsoako shoa-lahla hlobo

Phekolo e thatafatsang ea hlobo ea aluminium-magnesium e lahlang ke ho fetola sebopeho sa tšepe ho fumana sebopeho le ts'ebetso ea hlobo. Kalafo ea mocheso e lokela ho ipapisa le thepa ea hlobo, sebopeho sa hlobo, boholo, le ho rarahana ho tseba lintlha tsa ts'ebetso ea kalafo ea mocheso.

3.1 Phekolo ea pele ho mocheso

Kalafo ea pele ho mocheso ea hlobo e lahlang e ka amohela lits'ebetso tse tharo: ho kenya annealing, ho koala le ho tima mocheso le ho futhumatsa mocheso. Morero ke ho fumana sebopeho sa junifomo le carbide e qhalakaneng pele ho kalafo ea ho qetela ea mocheso ho ntlafatsa matla le ho thatafala ha tšepe. Ts'ebetso e tsoelang pele ea ho koala e batla e le bonolo, mme sebopeho se betliloeng sa perela e ka fumaneha hape. Bakeng sa hlobo e lahlang e nang le libopeho tse rarahaneng le litlhokahalo tse phahameng, annealing e sa tloaelehang e ka sebelisoa ho fumana sebopeho se loketseng haholo sa pearlite.

3.2 Ho tima le ho futhumatsa

Tšepe e lahloang ke tšepe e nang le alloy e ngata e nang le mafura a futhumetseng a futhumetseng. Mehato ea ho futhumatsa hangata e nkuoa nakong ea ho tima le ho futhumatsa. Palo ea ho futhumatsa pele le mocheso ho latela sebopeho sa tšepe ea tšepe le litlhoko tsa phetoho ea hlobo. Bakeng sa hlobo e nang le mocheso o tlase oa ho tima, sebopeho se bonolo le litlhoko tse tlase tsa deformation, ho hlokahala hore ho futhumale pele (800 ~ 850 ℃) nakong ea ho tima le ho futhumatsa ntle le ho petsoha. Bakeng sa hlobo e nang le mocheso o phahameng oa ho tima, libopeho tse rarahaneng le litlhoko tse phahameng tsa deformation, ho hlokahala hore ho futhumatsoe ha bobeli (600-650 ° C, 800-850 ° C). Morero ke ho fokotsa khatello ea maikutlo e hlahisoang nakong ea ho futhumatsa mme ka nako e ts'oanang e etse sebopeho sa kakaretso ea seaparo sa hlobo.

3.3 Ho tima mocheso

Mocheso o futhumatsang o futhumatsang oa hlobo e laoloang o ka kenngoa ts'ebetsong ho latela mokhoa oa ho tima o futhumatsang oa sehlopha ka seng sa tšepe. Mohlala, mocheso o tima oa tšepe ea 3Cr2W8V ke 1050 ~ 1150 ℃, 'me mocheso o tima oa tšepe ea H13 ke 1020 ~ 1100 ℃. Ho eketsa mocheso o tima oa li-steels tse peli ho ka eketsa matla a phahameng a mocheso le mokhathala o chesang oa mokhathala oa hlobo e lahlang, empa e tla eketsa ho fetoha ha hlobo. Ha o futhumatsa ka sebōping sa ho tola ka letsoai, ho qoba ho theola moea ka bokaholimo, holim'a metsi a nang le letsoai la barium chloride le nang le deoxidation e ntle ho lokela ho sebelisoa khafetsa. Ha ho futhumatsoa ka sebopi sa mofuta oa ho hanyetsa lebokose, ho lokela ho amoheloa sepakapaka se sirelletsang; kapa ho futhumatsa ka lebokoseng la mofuta oa bohanyetsi kamora ho paka. Bakeng sa ho netefatsa ho felisoa ha carbides ka botlalo, fumana austenite ea junifomo, le ho fumana ts'ebetso e ntle ea mocheso o phahameng, ho tima le ho futhumatsa nako ea ho ts'oara hlobo e lokela ho eketsoa ka nepo. Ka kakaretso, coefficient ea ho futhumatsa e nang le mocheso oa sebōpi sa letsoai ke 0.8-1.0 min / mm.

3.4 Tima tsidifatso

Sekhahla sa ho tima oli se potlakile mme ts'ebetso e ntle e ka fumaneha, empa tloaelo ea ho fetoha le ho peperana e ntle. Ka kakaretso, hlobo e qhibilihisitsoeng ka oli e pholileng e nang le libopeho tse bonolo le litlhoko tse tlase tsa deformation li sebelisoa; bakeng sa hlobo e lahlang e nang le libopeho tse rarahaneng le litlhoko tse phahameng tsa deformation, ho tima maemo a phahameng ho lokela ho sebelisoa ho thibela ho fetoha ha hlobo le ho petsoha. Tima tsidifatso e lokela ho ba e liehang ka hohle kamoo ho ka khonehang ho fokotsa ho tima, ho futhumatsa le ho tima ka sebeng sa ho itšireletsa, ho futhumatsa ho ka sebelisoa ho tima khase. Ho futhumatsa le ho tima ka bateng ea letsoai, 'me ho koala sekhahla ho ka amoheloa ha ho pholile. Ha hlobo e tima le ho pholile, hangata e pholile ho isa ho 150 ~ 200 ℃ ebe e halefa hang kamora ho inama. Ha ea lumelloa ho pholile ho fihlela mocheso oa kamore.

3.5 Bohale

Ho thatafala ha hlobo-foromeletsoeng hlobo e fihlellwa ka tempering, le thatafala ha shoa-lahla hlobo cavity ka ho toba ama chesang le a batang bophelo mokhathala bophelo hlobo. Lisebelisoa tse fapaneng, mocheso o fapaneng oa ho tima le mocheso o futhumatsang le tsona li fapane. Mohlala, ho thatafala ha 3Cr2W8V tšepe aluminium-magnesium alloy die-cast hlobo ke ka kakaretso 42 ~ 48HRC, 'me mocheso oa eona o futhumatsang ka kakaretso o khethoa lipakeng tsa 560 ~ 620 ℃, empa haeba ho sebelisoa mocheso o phahameng, mocheso o futhumetseng o phahame joalo ka 670 ℃. Thata kamora ho tima ka 1150 ° C le tempering ho 650 ° C ke 45HRC; ha boima ka mor'a ho tima ka 1050 ° C le tempering ho 650 ° C ke 35HRC. Ho thatafala ha H13 tšepe aluminium-magnesium motsoako shoa-lahla hlobo e hlokahala hore e be 44 ~ 50HRC. Tlhoro ea bobeli e thatafatsang ea tšepe ea H13 e hlaha ha e futhumala ho 500 ℃, empa boholo ba tlhoro bo amana le mocheso o tima. Mocheso o futhumatsang ka kakaretso ke 560 ~ 620 ℃. Bohale bo lokela ho etsoa makhetlo a 2 ho isa ho a mararo. Mocheso oa tempering ea pele o ka ba tlase. Ka mor'a hore tempering pele, lekanya boleng thatafala. Ha tlhokahalo ea ho thatafala e fihlile, mocheso oa tempering o lokela ho theoloa ke 3, 20 ℃ ho qoba The thatafala ea fokotseha. Haeba thatafala e phahameng haholo, fetola thempereichara tempering ka nepo ho kopana le tlhokahalo ea thatafala ho latela thatafala phahameng. Bohale ba boraro ke ho ntlafatsa ho thatafala, mocheso o futhumetseng o lokela ho ba holimo ho feta oa bobeli

Mocheso oa bobeli oa tempering o tlase ho 30 ~ 50.. Nako ea ho halefa le ho ts'oara e lokela ho lekana ho felisa khatello ea maikutlo e tlisoang ke ho tima le ho fokotsa sebopeho sa mapetso a hlobo. Nako ea ho ts'oara e ngoe le e ngoe ke 2h, 'me nako ea ho ts'oara hlobo e kholo e atolositsoe ka nepo. Ka lebaka la khatello e phahameng ea mocheso le khatello ea "microstructure" ea "die-casting" e shoang kamora ho tima, lefu leo hangata le halefisoa hang kamora ho phola ho 150-200 ° C.

Holim 'a matlafatsa kalafo thulaganyou e aluminium-magnesium motsoako shoa-lahla hlobo

Kamora ho tima le ho halefa, bokaholimo ba bokahare ba aluminium-magnesium alloy die-cast ha e phahameng haholo. E le hore ho fumana thatafala phahameng le apara ho hanyetsa holim 'a hlobo e, ha karolo ea mantlha e ntse e boloka matla a lekaneng le toughness, le ho ntlafatsa tshebetso-ba khahlanong le ho khomarela ea aluminium-magnesium motsoako shoa-lahla hlobo, holim nitriding kapa nitriding ka etsoa ka hlobo ena. Kalafo ea Carburizing.

4.1 Phekolo ea nitriding

Nitriding ke ts'ebetso ea kalafo ea mocheso oa nitriding ka holim'a tšepe ho eketsa mohopolo oa naetrojene karolong e kaholimo ea lera. Morero oa nitriding ke ho fokotsa ho fetoha ha likarolo tsa hlobo, ho ntlafatsa bokhabane ba bokaholimo, ho roala ho hanyetsa, matla a mokhathala le ho hanela ho ts'oaroa ha hlobo ea aluminium-magnesium alloy le ho ntlafatsa ho hanyetsa bohale le ho nolofatsa. Notch nahanela. Nitriding e tiileng, nitriding ea metsi le nitriding ea khase ke mekhoa e tloaelehileng ea nitriding. Mahlale a macha a kang ion nitriding, vacuum nitriding, electrolytic nitriding le high-frequency nitriding a ka khutsufatsa potoloho ea nitriding, a fumana boleng bo phahameng ba nitriding le ho ntlafatsa ts'ebetso ea moruo ea likhoebo, ka hona li sebelisoa haholo tlhahiso.

4.2 Nitrocarburizing

Nitrocarburizing ke ammonia hammoho le lino tse tahang (methanol, ethanol) le mecha ea phatlalatso e kenang e kang urea, formy glue le triethanol glue. Ts'ebetso ea ho bola ha mocheso e etsahala mochesong o itseng ho hlahisa liathomo tse sebetsang tsa naetrojene le khabone, tse bolailoeng ke lits'epe tse kopantsoeng ke aluminium-magnesium. Kamora hore hlobo e kenngoe kahare, e a arohana ebe e kenella ka holim'a lera la hlobo ho fumana lera la nitrocarburizing le nang le naetrojene, e le hore hlobo e fumane thatafalo e phahameng ea bokaholimo, ho hanyetsa mokhathala, ho itšireletsa le ho hanyetsa ts'enyeho. Mekhoa ea nitrocarburizing e kenyelletsa mekhoa ea mokelikeli le khase, mme mekhoa e mengata e sebelisoang tlhahiso ke khase ea nitrocarburizing. The H13 steel aluminium alloy die-casting hlobo e futhumetse ka mekhahlelo e 'meli ea kalafo ea pele ho mocheso ho 550 ℃ × 40min le 850 ℃ × 40min ka seboping se nang le mocheso o phahameng oa letsoai, e tima ka 1030 ℃, e haelloang ke 600 ℃, ebe e fuoa ho phekola kalafo ea mocheso oa khase ea nitrocarburizing ho 580 ℃. Thatafala e kaholimo ho 900HV, popeho thatafala ke 46 ~ 48HRC, qhoaele hanyetsa, mokhathala ho hanyetsa, le ts'enyeho ho hanyetsa hlobo li ntlafalitsoe haholo, 'me ha ho mamarello, ebola, mengoapo le ts'enyeho, e leng se atlehang ho ntlafatsa bophelo ba hlobo.

fihlela qeto e

E le lisebelisoa tsa bohlokoa tsa ho sebetsana, hlobo ea aluminium-magnesium alloy e nang le tšusumetso e tobileng boleng ba sehlahisoa le melemo ea moruo ea k'hamphani. Phuputso le lipalo-palo li bonts'a ho hloleha ha hlobo ka lebaka la ts'ebetso e sa nepahalang ea kalafo ea mocheso ho etsa liperesente tse ka bang 50% tsa mefokolo eohle. Ka hona, khetho e utloahalang ea kalafo e matlafatsang le e matlafatsang le lits'ebetso tsa kalafo tse matlafatsang bokaholimo le taolo e thata ea litlatsetso tsa kalafo ea mocheso ke litsela tsa bohlokoa tsa ho ntlafatsa ts'ebetso ea hlobo le bophelo. Ha ho hlahisoa hlobo ea aluminium-magnesium e lahlang, ho hlokahala hore ho hlahlojoe le ho ithuta lisosa tsa ho hloleha ho latela maemo a ts'ebetso ea hlobo, 'me ho hlophisoe ka mokhoa o utloahalang lits'ebetso tsa kalafo ea mocheso ho netefatsa ho thatafala ha hlobo, ho roala ho hanyetsa, matla a mantlha le ho thatafala, ho thibela tšepe mokelikeli ts'enyeho le hlobo khomarelang, 'me ka tsela e atlehang fokotsa sekhahla hana, Haholo ntlafatsa bophelo tšebeletso ea hlobo ena.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Mocheso Phekolo Tsamaiso Puisano Of Aluminium-Magnesium motsoako motsoako shoa-lahla hlobo

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off