Mekhoa ea Patlisiso Ho Phekolo ea Mocheso ea lits'epe tse kopanyang mocheso le li-Superalloys

E 'ngoe ea lintlha tsa bohlokoahali bakeng sa nts'etsopele ea lisebelisoa tsa jenereithara tsa A-USC tse 700 is ke nts'etsopele ea lits'epe tse sa keneleng mocheso bakeng sa li-impelekere tsa turbine. Bafuputsi ba bang ba ntlafalitse motsoako oa Ni-0.05C-18Cr-13Co-9Mo-1.3Al-1.4Ti-0.1Ta-0.3Nb o ipapisitse le Inconel 617 e le thepa ea mantlha mme ba ntlafatsa sebopeho sa alloy, mme ba hlahisa liteko tse kholo sampole e kenellang e etsisang mochini oa nnete oa mochini. Ho na le litlaleho tsa lipatlisiso ka thepa ea likarolo tse fapaneng tsa sampole e kenang.

E lekotse lisebelisoa tse ling tsa ho lahla tse ka sebelisoang ho li-generator tsa A-USC ka mocheso oa mouoane oa 700 ℃. Mabapi le alloy ea Ni-0.04C-26Cr-21Co-1Al-1.9Ti-1.8Nb, li-castings tse hlahisitsoeng ka liteko tse nang le mokato o marara a 3 o entsoe mme thepa e ile ea hlahlojoa. Tlaleho ea lipatlisiso e hlahisitse tšusumetso ea khethollo ho matla a kenang.

K'homphieutha e thehiloeng Ni-Fe e lebelletsoe ho ba lisebelisoa tsa lisebelisoa tsa motlakase bakeng sa tlhahiso ea motlakase oa A-USC. Leha ho le joalo, molemong oa ho netefatsa litšobotsi le tlhahiso ea lisebelisoa tsa motlakase, ho bohlokoa ho laola likarolo tsa tšebetso. Ho ntse ho na le lintlha tse ngata tse sa hlakang mabapi le tšusumetso ea likarolo tsa ts'ebetso ea li-superalloys tse thehiloeng Ni-Fe bakeng sa li-impelekere tsa turbine. Ka hona, bafuputsi ba bang ba batlile tšusumetso ea likaroloana tse mabapi le litšobotsi tse hahabang.

Ts'ebetsong ea ho nts'etsapele 700 ℃ -class A-USC jenereithara, molemong oa ho kenya lisebelisoa tse fapaneng tse nang le litšepe tse entsoeng ka Ni-based le Fe-based impellers ts'ebetsong, botsitso ba sebopeho le thepa ea mochini oa karolo e haelloang ke mocheso ka mocheso o phahameng. li ile tsa hlahisoa. Kleima. Bafuputsi ba bang ba hlahisitse lisebelisoa tse nyane tsa tšepe / Inconel 617 e le mokhoa oa sebopeho sa lisebelisoa tse fapaneng tsa Fe / Ni, mme ba lekola phello ea botsofali bo futhumetseng phetohong ea microstructure ea sehokelo sa tjheseletsa.

Bakeng sa ho fokotsa moea o tsoang moeeng oa CO2, ho entsoe lipatlisiso tse pharaletseng ka lisebelisoa tsa A-USC. 23Cr-45Ni-7W alloy (ASTM UNS N06674) ke sesebelisoa se ntlafatsang matla a ho kenella ka ho matlafatsa pula ea M23C6 le mekhahlelo ea Laves. E ka sebelisoa e le sesebelisoa se seng bakeng sa li-tubes tsa A-USC tse nang le mocheso o phahameng le li-tube tsa boiler. Bafuputsi ba bang ba ile ba lekola tšusumetso ea litšobotsi tse kenang tsa alloy ho boits'oaro ba boemo ba leholimo ba Laves.

Bakeng sa ho nts'etsapele disete tsa jenereithara tsa A-USC ka mocheso oa mouoane oa 700 ℃, monyetla oa ho sebelisa lits'epe tse kopantsoeng le Ni-based ha li ntse li ithuta likarolo tsa tanka, 'me ha suptjoa hore alloy 617, e leng alloy e matlafatsang pula , E na le boikhathollo nakong ea ts'ebeliso ea mocheso o phahameng. Mapetso (SR mapetso) le litaba tse ling tse amanang le ona. Ka lehlakoreng le leng, 23Cr-45Ni-7W alloy (ASME-CC2684), e sa sebeliseng mohato ona e le mohato o matlafatsang pula, e na le matla a fokolang a phatlohang hanyane ho 700 ° C ho feta a alloy 617, ha Motsoako oa 30Cr-50Ni-W ha o so ka o senyeha. E matlafalitsoe, empa matla a ho phatloha a kenang a phahame ho feta a 23Cr-45Ni-7W alloy. Ductility ea eona le ho hanyetsa ha SR ho lokile. E ka sebelisoa bakeng sa phala ea mantlha ea A-USC. Tlaleho ea lipatlisiso e hlahisitse mefuta e mene ea meaho, thepa ea mochini le litšobotsi tse kenang tsa lipoleiti le lipeipi tse hlahisitsoeng ka liteko tse kholo.

Hajoale, bothata ba matla e se e le taba ea bohlokoa haholo. Bakeng sa ho ntlafatsa tšebetso ea phepelo ea motlakase o futhumetseng joalo ka ha phepelo e kholo ea motlakase e bolela, ho entsoe lipatlisiso tse ngata le nts'etsopele ho lits'epe tse thehiloe tsa Ni. Bakeng sa botsitso ba karolo e matlafatsang ea superalloy e thehiloeng Ni, sebopeho sa karolo, eseng feela boits'oaro ba pula mohato ona bo tla ba le phello ea bohlokoa, empa le phetoho ea morpholoji e bakoang ke ho se tšoane ha lekhoakhoa pakeng tsa eona le karolo ea motsoali. E-ba le tšusumetso ea bohlokoa. Leha ho le joalo, lipatlisiso tsa li-microstructures tsena ke tsa lipatlisiso tsa li-superalloys tsa Ni-based tse nang le boholo ba mokhahlelo o phahameng, ha lipatlisiso tsa lits'epe tse kopantsoeng li fokola haholo. Ka hona, litlaleho tse ling tsa lipatlisiso li batlisitse kamano lipakeng tsa phetoho ea sebopeho sa karolo le phokotso ea marang-rang ho alloy e thehiloeng Ni.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Mekhoa ea Patlisiso Ho Phekolo ea Mocheso ea lits'epe tse kopanyang mocheso le li-Superalloys

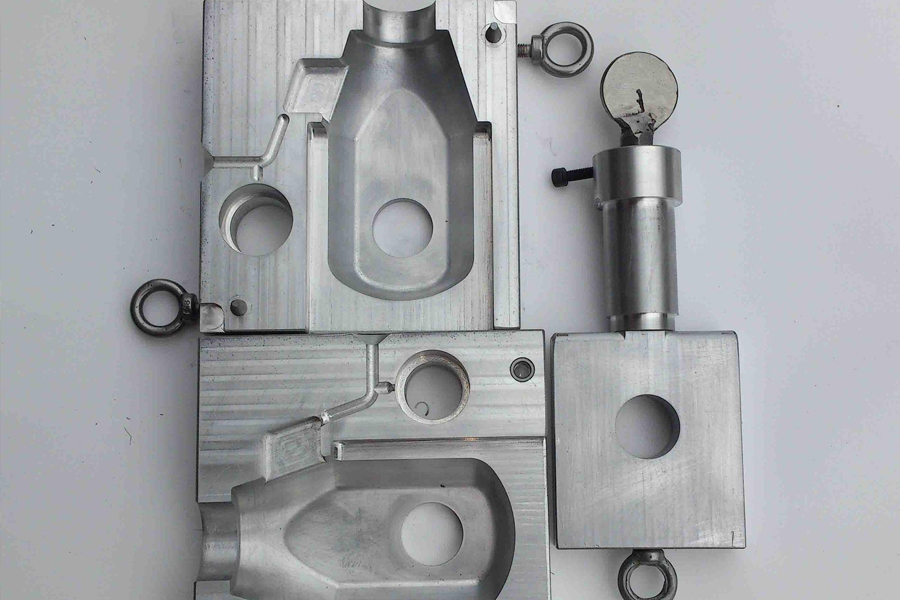

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off