Tlhatlhobo e Felletseng le Taolo ea Boleng ba Likoloi tsa Aluminium Die Castings

Tlhatlhobo le taolo e felletseng ea boleng ba likoloi tsa aluminium alloy die die li hlahlojoa le ho batlisisoa, 'me ho fumanoe litšitiso le likoli tse latelang. Bakeng sa likarolo tsa ho lahla koloi tsa aluminium, koloi ea silindara e na le khokahano e batlang e le kholo, haholo-holo sekoaelo sa hlooho sa sekontiri se nka sebaka se seholo mme sebopeho se thata haholo. Likarolo tse ling tsa lihokela tse sebetsitsoeng le bokaholimo ba silindara ha lia lokela ho ba le masoba le likoti, tse amang boleng ba litlamorao tsa lefu ka botebo. Taba ea bobeli ke hore, ka lebaka la likarolo tse rekiloeng kantle le lisebelisoa, ts'ebetso e mpe ea ts'ebetso, jj. Bakeng sa ho ntlafatsa boleng ba likarolo tse laoloang ke likoloi, ho hlokahala hore ho eketsehe tekanyo ea tlhokomelo ho litšitiso tse boletsoeng kaholimo, le ho ntlafatsa tšebetso ea lihokela tsa moralo le litšitiso tsa masoba.

1 Ho hlahlojoa ka botlalo le taolo ea boleng ba likoloi tsa aluminium alloy die die

1.1 Tlhaloso ea liphoso tsa tlhahlobo

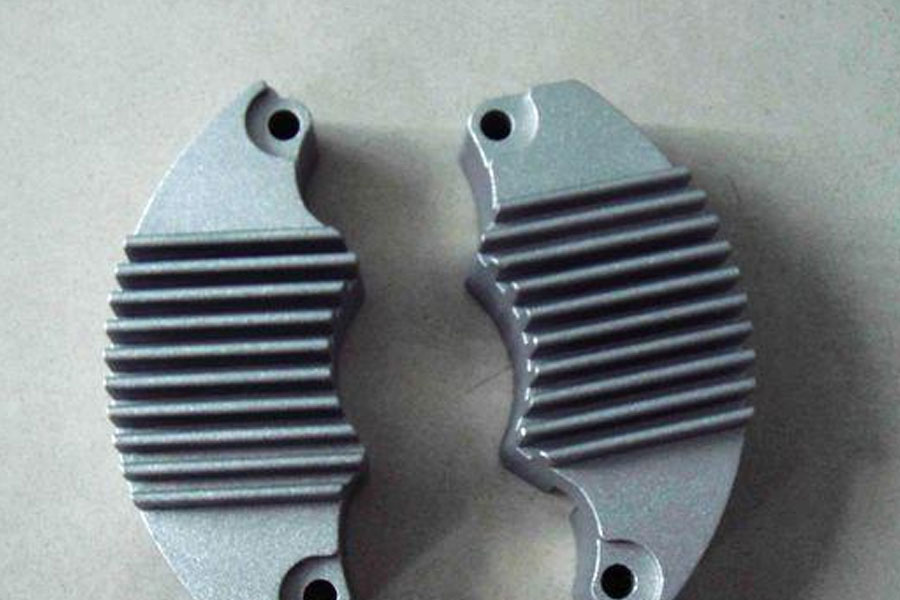

Bakeng sa likarolo tsa li-aluminium tsa koloi tse laoloang ka kakaretso, likhokahano tsa karolo ea koloi li batla li le kholo, haholo-holo boemo ba sekoahelo sa hlooho sa 'mele oa silindara bo na le sebaka se seholo mme sebopeho se thata. Likarolo tse ling tsa lihokelo tse sebetsitsoeng le bokaholimo ba silindara li ke ke tsa bakoa ke boteng ba masoba le masoba. Bakeng sa libaka tsa silindara tse lumellang masoba le masoba ho ba teng, kabo ea masoba le masoba e hasane ho feta, 'me ho na le litlatsetso le litlhoko tse thata bakeng sa boholo. Bakeng sa khokahano ea hlooho ea silindara, boemo ba camshaft bo tsamaisana le phumano e fosahetseng. Kamora ho sebetsoa, boholo ba sekoti bo tlameha ho fihlela litlhoko tsa ho lekola le ho fihlela maemo a tlase a ho lekola. Bakeng sa mofuta ona oa karolo, e tlisa bothata bo boholo ho moralo le mosebetsi oa tlhahiso, mme e ama ka mokhoa o tebileng ts'ebetso ea moralo le katleho ea tlhahiso. Theknoloji le ts'ebetso ea li-castings li ka se nahane ka botlalo lihokela tse fapaneng le maemo a li-castings kaofela, hape ha e lumellane haholo le lihokela tsa tlhahiso le lihokela tsa moralo oa ts'ebetso. Mabota a mang a liboko a tsamaea le likarolo tse boreleli, 'me botebo ba mabota a li-larvae bo boholo, bo tsamaisana le mathata a tšilafalo ea moea. Taba ea bobeli, ho boetse ho na le likotsi tse ling tse kang masoba a hokahanyang likheo tsa moea le likheo tsa shrinkage.

1.2 Tsamaisa tlhahlobo le tlhahlobo e felletseng le tlhahlobo ea papiso ea litšoantšo

Lisebelisoa le lisebelisoa tse rekiloeng kantle, lits'ebetso tse mpe, ts'ebetso ea moralo oa ts'ebetso, le ts'ebeliso ea lisebelisoa tsa mochini, jj. Kaofela li na le tšusumetso e kholo polokelong ea likoloi tse lahlang, tse lebisang phetohong ea boleng, 'me linyeoe tse matla li tla lebisa ho laoleng masalla. Lintlha tse boletsoeng kaholimo kaofela li na le litšobotsi tsa ho se tšoane, ka hona li na le tšusumetso e kholo boleng ba ho lahla. Phetoho efe kapa efe ho sehokela sefe kapa sefe e tla tlisa liphetoho ho boleng ba castings. Ha ho bonolo ho fumana mabaka a mantlha a liphetoho tsa boleng ba ho lahla tse tlisitsoeng ke likarolo le lisebelisoa tse rekiloeng kantle, lits'ebetso tse mpe, ts'ebetso ea moralo oa ts'ebetso, le ts'ebeliso e sebetsang ea lisebelisoa tsa mochini. Ha re tobane le boemo bona, ho a hlokahala ho eketsa ho latela le ho batlisisa ho tsoelang pele ha moralo le lihokela tsa ts'ebetso. Pele ho tsohle, re tlameha ho boloka le ho sekaseka matsatsi a tlhahiso ea lihlopha tse fapaneng, ho theha tlhophiso e behiloeng ea nako, ho theha boleng ba sebapali e le sepheo se tataisang, le ho lekola le ho tsoelapele ho boloka phokotso e latelang. Ho kenyelletsa tlhahlobo le tlhaiso-leseling e phethahetseng ea lisebelisoa tsa ho lahla, lisebelisoa tse thusang, litšepe tse qhibilihisang, boqapi le likarolo tsa tlhahiso ea ts'ebetso, ho beha boleng ba boleng le lihokela tse ling [21. Bakeng sa tlhahlobo ea papiso ea setšoantšo, liphoso tse ka sehloohong tsa castings li bonahala ka phapusing ea likere. Mabaka a ka sehloohong a susumetsang sekoli sena ke tšusumetso ea liphetoho tsa khase le ho honyela, e tlisang likoli tse kholo mekoting. Bakeng sa castings, khase e hlahisoang e fumanoa haholo-holo kahare ho qhibiliha le khase e fumanoang ho moemeli oa tokollo. Khase e sa lebelloang e tsoang ts'ebetsong ea ho betsa. Khase e hlahisitsoeng ka har'a tharollo e amana haufi-ufi le mofuta le thepa ea thepa ea ho betla, 'me e amana haufi-ufi le theknoloji ea ho qhibilihisa ea ho betsa.

2 Mehato ea ntlafatso le ntlafatso

2.1 Tsamaiso ea ketsiso ea setšoantšo le ntlafatso

Bakeng sa castings, khase e hlahisoang e fumanoa haholo-holo kahare ho qhibiliha le khase e fumanoang ho moemeli oa tokollo. Khase e sa lebelloang e tsoang ts'ebetsong ea ho betsa. Khase e hlahisitsoeng ka har'a tharollo e amana haufi-ufi le mofuta le thepa ea thepa ea ho betla, mme e amana haufi-ufi le theknoloji ea ho qhibilihisa ea ho betsa [41. Khase e hlahisoang ke moemeli oa tokollo e amana haufi-ufi le khetho ea khokahano ea mochini oa ho betsa le mofuta oa sehokelo se hatisang. Bakeng sa bofokoli bona ntlafatsong ea li-castings, ts'ebeliso ea liphetoho bakeng sa ho lahla theknoloji ea smelting le phetoho ea theknoloji ea fafatsa e ka sebelisoa ho ntlafatsa le ho ntlafatsa. Ho na le kamano e haufi lipakeng tsa likotsi tsa khase tse tlisitsoeng ke ho lahleloa nakong ea khatello le mofuta oa ts'ebetso oa tšepe ea mokelikeli. Litšitiso tsa katoloso le khutsufatso ea ho betsa li amana haufi le mocheso le ho tiisa ha ho betsa. Kamora ho hlakisa moralo oa moralo oa ho betsa, o ka holisa moralo le tlhophiso ea semathi, o seta mohala oa ho qeta le lisebelisoa tsa phallo, o beha mocheso oa hlobo ea ho lahla, 'me oa seta coefficient sa tobetsa. Ha ho raloa le ho hlophisa li-coefficients le likarolo tsa likarolo tsa khatello, sebopeho sa phallo ea tšepe ea mokelikeli 'meleng oa ho betla se lokela ho tsotelloa, ho tiea ha mokelikeli ho lokela ho tsotelloa, boleng ba mokokotlo oa shrinkage bo lokela ho fokotsoa, mme moeli o lokela ho nyenyefatsa. Ntle le moo, papiso ea litšoantšo e ka sebelisoa bakeng sa tlhahlobo sehokelong sena. Mokhoa oa papiso ea litšoantšo ke mokhoa o ka sehloohong oa ho sekaseka molao oa ho qhekella le ho utloisisa sebopeho sa ona sa ho tlatsa hajoale, le ho fana ka motheo oa mahlale ka lebaka la bofokoli ba li-castings. Fetola mofuta oa nako mme oe hlahise ka sebopeho se likhutlo li tharo, ebe o fana ka sistimi ea ketsiso ea mahlale a eona le ts'ebetso, 'me u khetholle sebopeho sa faele ea STL. Kamora ho khetholla, sebelisa software ea Msgmasoft ho qala karohano ea marang-rang. E fane ka li-node tsa marang-rang tse likete tse lekholo tse nang le li-castings le li-system tse tšollelang. Kamora ho etsa lipatlisiso tse tebileng le ho sekaseka software ea Msg-masoft, le ts'ebeliso ea eona e sebetsang, ho fumanoe hore ts'ebeliso ea software ea Msgmasoft e na le ts'ebeliso e sebetsang, e ka fetolang le ho nchafatsa hlobo ea ho lahla, le ho rala motheo oa thuto ea moralo oa ho betsa hlobo le lits'ebetso. .

2.2 Eketsa taolo ea likhase tse qhalaneng

Ha lisebelisoa tsa nako li le ts'ebetsong ea ho qhibilihisa, litefiso tse tsoang ka phapusing ea lisebelisoa li kenyelletsa 50% ea depositi ea aluminium le 39% ea sebōpi. Hobane mongobo le lintho tse ling li tla tsoelapele ho eketseha nakong ea ts'ebetso ea ho chesa sebopi, e tla eketsa khase, ebe lisebelisoa li lokela ho phekoloa le ho tsamaisoa ka nako ho fokotsa lintho tse qhibilihisitsoeng le ho li eketsa le ho li tlosa pele ho thepa o kenngoa ka sebōping. Bakeng sa khase le mokelikeli, ho lekola le ho shebella likateng tsa khase ho ekelitsoe. Ka nako e ts'oanang, ts'ebetso e lokela ho fetoloa le ho ntlafatsoa, theknoloji ea ente e lokela ho ntlafatsoa, 'me mohala oa ente o lokela ho fetoloa ho netefatsa ts'ebetso e sebetsang ea ho fokotsa litšila le ho ntlafatsa ts'ebetso ea ts'ebetso. Netefatsa hore likhahla tsa khase tsa ligrama tse lekholo tsa lisebelisoa tsa aluminium li haufi le 0.2ml.

2_3 Eketsa ho utloahala ha lipehelo tsa ts'ebetso le ho ntlafatsa maemo a ho lahla

Mabapi le boits'oaro ba mekhahlelo ea ts'ebetso, pele ho tsohle, ho latela sephetho sa ho lekola, mekhahlelo ea ts'ebetso le likamano tsa boleng tse ka amang castings li lokela ho hlahlojoa le ho ithutoa, 'me boleng ba castings bo ka eketsoa ntle le ho fetola maemo a ho lahla. Bakeng sa ho netefatsa maemo a ts'ebetso, ts'ebetso ea ente e ka sebelisoa ho eketsa ho ts'oarana ha castings, khatello ea khase e tlatsang ts'ebetsong, jj. Taba ea bobeli, ho hlokahala ho eketsa boemo ba tlhokomelo ho maemo a ho lahla, ho netefatsa ts'ebetso e utloahalang ea ts'ebetso, ho eketsa boemo ba tlhokomelo mekoting, ho lokisa boholo ba semathi, le ho eketsa phala ea mokelikeli mateanong a metsi. Mesebetsing ea 'nete ea tlhahiso le moralo oa li-castings, ho a hlokahala ho eketsa ho shebella likoti ho bona hore na ho na le liphoso le litšitiso, le ho bona boholo ba tsona le bophara ba tsona. Tlhokomelo ena ea li-castings ke haholo-holo ho lekola ts'ebetsong ea li-castings ho bona hore na li hloka ho hlakoloa le ho nchafatsoa. Qoba maqhama a senyehileng a li-castings ebe o pheta likarolo tse senyehileng ho netefatsa hore li fihlela litlhoko tsa castings e tloaelehileng le ho eketsa ts'ebeliso ea tsona e sebetsang. Bakeng sa li-castings tse felileng, ela hloko ho shebeloa ha lebota la lesoba ho bona hore na lebota la lesoba le thata. Bakeng sa lerako le mosesane la lesoba, e bonts'a semelo sa makala a lifate. Ha u sebelisa microscope bakeng sa ho shebisisa le ho e hlahloba, botlaaseng bo ka fumanoa Ts'ebetso e betere e tsamaisana le ho nyenyefala le ho khoehla hoa liboko.

3 mantsoe a phethelang

Ho sebetsana le litšitiso tsa boleng ba likoloi tsa aluminium alloy die, re tlameha ho qala ka ho eketsa taolo ea khase e qhibilihileng, ho fetola le ho ntlafatsa ts'ebetso, ho eketsa ho nepahala ha lipehelo tsa ts'ebetso, ho ntlafatsa maemo a ho lahla, ho lekola le ho boloka litšepe ho bona hore na li hloka ho ba Lephephe le ntlafatso. Pheta likarolo tse senyehileng ho etsa bonnete ba hore li fihlela litlhoko tsa likhetho tse tloaelehileng. Bakeng sa papiso ea setšoantšo le tlhahlobo ea litšitiso tsa mantlha tsa nako ea litšepe, o ka sebelisa phetoho ea mahlale a ho qhibilihisa le phetoho ea mahlale a ho fafatsa.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape:Tlhatlhobo e Felletseng le Taolo ea Boleng ba Likoloi tsa Aluminium Die Castings

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off