Tšusumetso ea likarolo tse tharo tsa ho itšeha ka katleho ea mechini

Motho e mong le e mong oa tseba hore ha o ntlafatsa ts'ebetso ea machining, ho eketsa likarolo tse tharo tsa ho itšeha (lebelo la ho itšeha, botebo ba ho itšeha le sekhahla sa fepa) ke mokhoa o bonolo le o otlolohileng ka ho fetesisa. Leha ho le joalo, ntlafatso ea likarolo tse tharo tsa ho itšeha ka lisebelisoa hangata e lekantsoe ke maemo a teng a mochini oa moralo oa lisebelisoa. Kahoo tsela e theko e tlaase ka ho fetisisa ke ho khetha sesebelisoa se setle sa lisebelisoa.

Molao oa boikemisetso oa likarolo tse tharo tsa ho itšeha

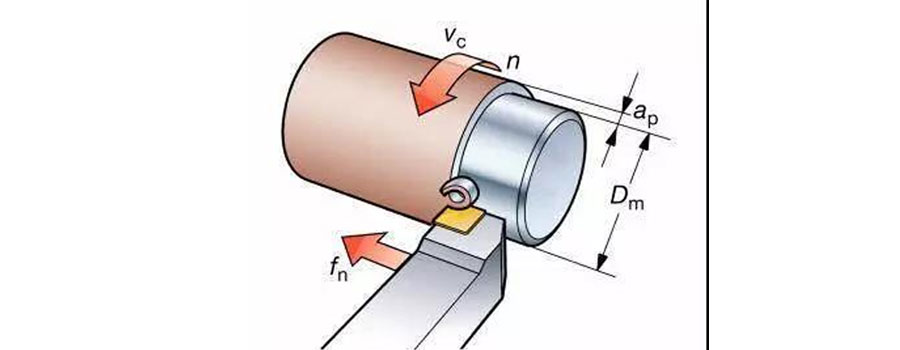

Fumana botebo ba thipa, palo ea fepa le lebelo le lekanang la ho itšeha.

Seha botebo: ka kakaretso ikemiselitse ho latela kabelo machining;

Sekhahla sa phepelo: Sekhahla sa phepelo se thata sa machining se khethoa ke matla a sesebelisoa sa mochini, 'me sekhahla sa phepelo ea ho fepa se khethoa ke ho ba thata ha holim'a metsi;

Lebelo la ho itšeha: Ikemisetsa ho latela lisebelisoa tsa sesebelisoa le lebelo la sekontiri sa sesebelisoa sa mochini.

Ho latela pono ea ntlafatso mochini oa cnc bokhoni, ho eketsa botebo ba sehiloeng mohlomong ke mokhoa o lokelang ho nahanoa. Le leng la mabaka a bohlokoa ke hore liteko li bonts'itse hore hang ha botebo ba ho seha bo lekana makhetlo a 10 ho fepa, ho eketsa botebo ba ho seha ho tla ba le phello e fokolang ho tšoarelleng ha lisebelisoa. Haeba lebelo la ho itšeha le eketseha, ho fetola lebelo la ho itšeha ho tla etsa hore sesebelisoa se tšoarellang se fetohe ka lebelo le habeli; haeba phepelo e fetotsoe, ho tšoarella ha sesebelisoa ho ka fetoloa ka mokhoa o ts'oanang. Ka hona, ha seo ho thoeng ke "boholo ba letlooa" se ke ke sa fihlelleha bakeng sa likheo tsa mokhoa oa rona oa tlhahiso ea bongata, ho eketsa botebo ba sehiloeng ke khetho e ka fihlellang potoloho ea tlhahiso e ntle ntle le ho baka keketseho e kholo ea litjeo tsa lisebelisoa.

Khetho ea lisebelisoa

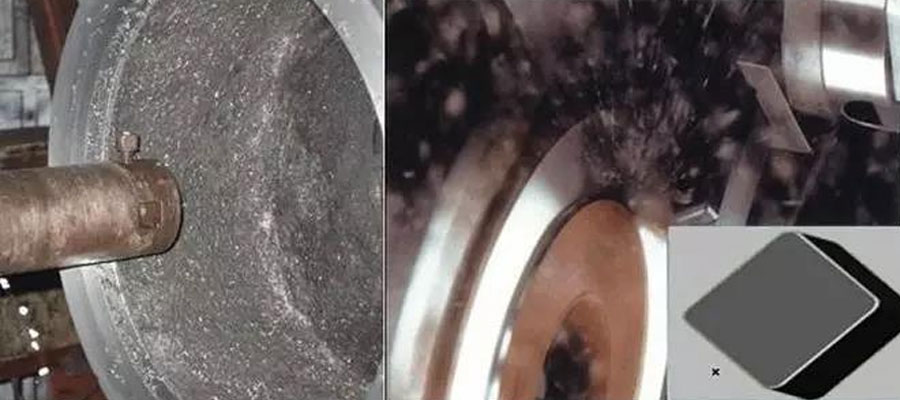

Lisebelisoa tse tiisitsoeng tsa carbide ke lisebelisoa tse ka sehloohong 'marakeng oa lisebelisoa tsa hajoale. Motho e mong le e mong o tloaelane le sesebelisoa sena. U ka fetola likarolo tse tharo tsa ho itšeha tsa lisebelisoa tse tiisitsoeng tsa carbide ho latela maemo a nnete a sebaka sa ts'ebetso, e le ho ntlafatsa bophelo ba sesebelisoa le ts'ebetso ea ts'ebetso. Leha ho le joalo, cubic nitrogen Nts'etsopele ea lisebelisoa tse thehiloeng boron ha ea nka nako e telele, mme batho ba bangata ha ba so ka ba ama lisebelisoa tse joalo. Leha ho le joalo, ka ho hlaha ha thepa e thata le thepa e thata ho sebelisoa mochini, lithulusi tsa "cubic boron nitride" li hlahile butle-butle tšimong ea motho e mong le e mong oa pono. Empa batho ba bangata ba lula ba nahana hore lithulusi tsa "cubic boron nitride" li na le moeli oa ts'ebetso ea ho seha le ho phethela ka lebelo le phahameng.

Ebile, ka R & D e tsoelang pele le boiphihlelo ba indasteri ea lisebelisoa tse phahameng ka ho fetesisa, lisebelisoa tsa cubic boron nitride li sebelisitsoe haholo lits'ebetsong tse thata tsa machining le maemong a ho itšeha a sa khaotseng. Khetho ea lisebelisoa tsa "cubic boron nitride" e ts'oana le ea lisebelisoa tse tiisitsoeng tsa carbide. Ho latela lisebelisoa tse fapaneng tsa mosebetsi, ho khethoa limaraka tse fapaneng tsa lisebelisoa le lisebelisoa tsa lisebelisoa.

Lehare le kopaneng la welding cubic boron nitride le sebelisoa haholo molemong oa ho phethela. E na le karolo e sehang feela ea "cubic boron nitride", mme matrix ke samente e tiisitsoeng ea carbide. Botebo ba thipa bo laoloa kahare ho 0.5mm, ka hona e ka sebelisoa feela bakeng sa ho phethela lits'ebetso, bakeng sa ba nang le maqhubu a maholo le libaka tse sa tloaelehang, khetha lehare la bohlokoa la cubic boron nitride. 'Mele oohle o entsoe ka "cubic boron nitride". Botebo ba ho itšeha ke 1-10mm, 'me bophelo ba sesebelisoa ka kakaretso ke lihora tse 3 / Ho itšeha.

Ka tsoelo-pele ea lipatlisiso ea li-cubic boron nitride lisebelisoa le litlhoko tsa 'nete ha ho sebetsoa, qete ea lebelo le phahameng e qalile ho ba lipakeng, ho ba thata le ho qeta, mme e ka sebelisoa le lisebelisoa tse tloaelehileng tsa mochini; litšenyehelo tsa tšebeliso li boetse li na le chelete e ngata.

Ho Bala ho Eketsehileng

Mefuta ea machining ea li-cubic boron nitride lisebelisoa le lisebelisoa tse tiisitsoeng tsa carbide lia kopana. Mohlala, li-iron cast tse nang le bohlooho, lisebelisoa tsa carbide tse samente le lithulusi tsa cubic boron nitride kaofela li ka sebetsoa. U ka khetha sesebelisoa sa sesebelisoa se bolokang chelete e ngata hape se bolokang litšenyehelo, se tiisitsoeng ka carbide ho latela litlhoko tsa khoebo. Ka lebaka la meeli ea ts'ebetso ea eona, lebelo le phahameng haholo la sesebelisoa le ka fihla ho 350m / min, ha sesebelisoa sa "cubic boron nitride" se ka fihla ho 1500m / min. Ka nako e ts'oanang, ho tšoarella ha sesebelisoa sa "boron nitride" ke makhetlo a 30-50 ho feta lisebelisoa tse tloaelehileng tse tiisitsoeng tsa carbide. Makhetlo a 5-15 bophelo ba sesebelisoa se khabisitsoeng sa carbide.

Leha ho le joalo, lik'hamphani ha li khethe ka leihlo la lithulusi li-cubic boron nitride ho sebetsana le tšepe ea bohlooho. Ntle le moo, theko ea lithulusi tsa "cubic boron nitride" e holimo ho feta ea lisebelisoa tse tiisitsoeng tsa carbide. Ka hona, ho khothaletsoa ho khetha tlhahiso ea bongata le litlhoko tse phahameng tsa ts'ebetso. Bakeng sa lisebelisoa tsa ho itšeha ka li-cubic boron nitride, haeba ts'ebetso ea ts'ebetso e sa phahama mme ho na le mesebetsi e fokolang, ho na le chelete e ngata ebile ho na le litšenyehelo ho khetha lisebelisoa tsa ho itšeha tsa carbide.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape:Tšusumetso ea likarolo tse tharo tsa ho itšeha ka katleho ea mechini

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off