Ts'ebetso ea khatello ea khatello e tlase-Mehato e lebisitsoeng ho lintlha tse tharo ho thibela litšila

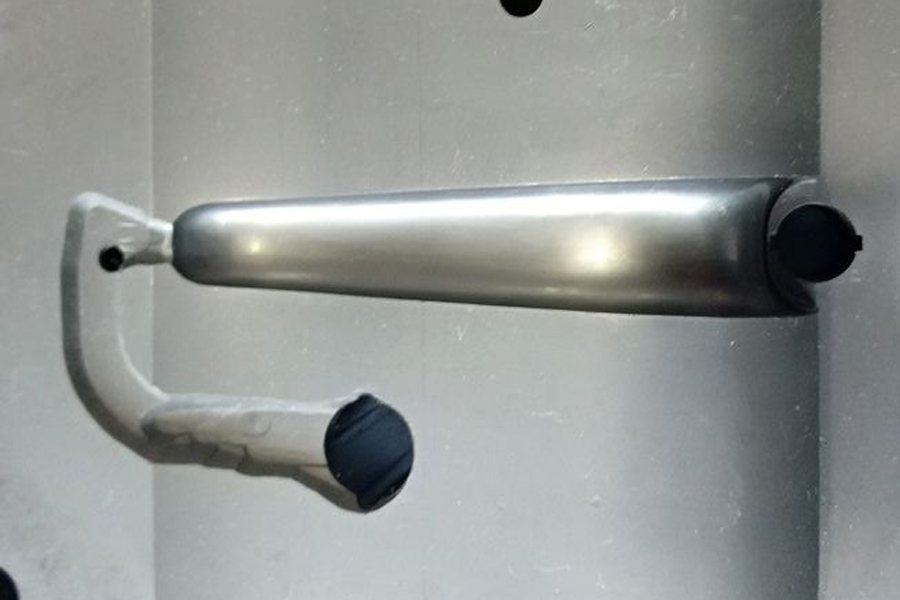

Ha ho lahleloa khatello e tlase, hlobo e beoa ka seboping se koetsoeng se koetsoeng, 'me lehare le tsebisoa ka tšepe ka seboping ka phala ea riser. Ha o sebetsa, eketsa moea o hatelletsoeng seboping, 'me tšepe e qhibilihisitsoeng e tla phallela kahare ho phala ea riser.

Kamora hore tšepe e qhibilihisitsoeng e tiee, moea o petelitsoeng seboping oa lokolloa, 'me tšepe e sa qhibilihisoang e khutlela seboping ho tsoa phala ea riser. Mabili a aluminium le li-blade tse khubung ea torque converter li na le menyetla e mene e meholo: ea pele, sebopeho sa ho betsa se teteaneng mme thepa ea mochini e hantle; ea bobeli, sekhahla sa tšebetso ea tlhahiso se phahame.

Hajoale, sekhahla sa ts'ebetso ea ho lahla ts'ebetso ea setsi sa k'hamphani ea rona se ka holimo ho 93%, sekhahla sa tlhahiso ea matla a khoheli a sehlahisoa se tšoanang ke 70% ho isa ho 80%; ea boraro, ts'ebetso ea tlhahiso e phahameng, ts'ebetso ea tlhahiso ea sehlahisoa se tšoanang sa ho lahla sehlahisoa ke makhetlo a mararo ho lahla matla a khoheli; ea bone, bokaholimo bo boreleli, bo ka fokotsang ts'ebetso ea margin.

Tlaase khatello ea foromeletsoeng ho hlahisoeng tlhahiso

- Tlhahlobo ea hlobo Pente e lokela ho hloekisoa pele hlobo e sebelisoa. Pente e hlotsoe kapa bokaholimo ha boa lekana kamora potoloho ea tlhahiso, 'me pente e hloka ho bentšoa ka lebili le silang. Ebe u hloekisa likhechana tsa aluminium tsa molamu oa ejector ebe u hloekisa polaka ea moea.

- Bake hlobo Mocheso o sebetsang hantle oa hlobo ke (360 ± 10) ℃, kahoo hlobo e lokela ho besoa mochesong o sebetsang pele o sebetsa.

- Ho roala: Ha hlobo e futhumetse ho 300 ℃, fafatsa seaparo. Ho roala ho tlameha ho lekana ebile ha hoa lokela ho ba le ho thekesela. Liaparo li bapala likarolo tse latelang: ea pele, thibela aluminium alloy ho senya sekoti le ho eketsa bophelo ba hlobo; Ntlha ea bobeli, thibela motsoako oa aluminium hore o se ke oa khomarela kahare kapa bokaholimo, e le hore tlhahiso e ka etsoa khafetsa le ka potlako; ea boraro, Ho roala ho etsa hore sekoti se be le mokato oa ts'ireletso ea ts'ireletso ea mocheso, e le hore tšepe e qhibilihisitsoeng e ka phalla habonolo kahare, e fokotsa ho hanyetsa ha aluminium e qhibilihisitsoeng, mme e eketsa ts'ebetso ea ho tlatsa tšepe e qhibilihisitsoeng.

- Motsoako o laetsoe.

- Ipehela thulaganyou e entsprechen The entsprechen thulaganyou e tlaase-khatello ea ho betsa ke haholo-holo mocheso oa aluminium entsoeng ka ho qhibilihisoa, sekhahla khatello ea thepa le bophirima khatello. Lintlha tsena tse tharo li tla ama boleng ba ho akheloa, ho baka likoli tse joalo ka ho khomarela lehlabathe, ho tšela le ho bipetsa. Ka hona, maemo a parameter a bohlokoa haholo bakeng sa castings.

- Ho tšela.

Liphoso tse tloaelehileng le mekhoa ea kalafo ea castings

- Ho bipetsoa ke mollo Setšoantšo sa 3 se bonts'a sekoli se bipetsang mollo qetellong ea sefahleho se seholo sa mabili a aluminium. Sesosa sa mollo o bipetsang: mocheso o tlase oa hlobo; ho felloa ke matla hampe; Tekanyo: eketsa mocheso oa hlobo ho 350 ℃ kapa kaholimo; matlafatsa sefuba, haholo-holo ka ho eketsa polaka ea moea, le ho fafatsa pente ka pente e ntle; ho eketsa nako ea ho tlatsa, e le hore khase eohle e ka fela.

- Lehlabathe le khomarelang Setšoantšo sa 4 se bonts'a sekoli se thellang sa lehlabathe la lehare. Mabaka a lehlabathe le khomarelang: mocheso o tšollang o phahame haholo; matla a lehlabathe a mantlha ha a lekana; Tharollo: Mocheso oa aluminium o qhibilihisitsoeng ha o phahame ho feta 670 ℃; fokotsa nako ea ho baka ea lehlabathe le ho boloka matla a mokokotlo oa lehlabathe; beha khatello e ts'oanang ea ho ts'oara.

- Mabaka a mantlha a ho ts'ela ho sa lekanang: mocheso o tlase oa aluminium e qhibilihisitsoeng le ho fokola ho fokolang; mekhahlelo e sa utloahaleng ea ho tlatsa, sekhahla se tlase sa phallo nakong ea ho tlatsa; ho felloa ke matla ha hlobo le khatello e phahameng ea kahare, e sitisang ho tlatsa.

- Shrinkage porosity e bua ka shrinkage porosity e bakoang ke lehare le lebili la aluminium ka tatellano. Mokhoa oa thibelo: ela hloko tšimo ea mocheso oa hlobo, theha maemo a latellanang a tiileng; eketsa khatello ea crystallization.

fihlela qeto e

Ha ho bapisoa le ho betsa ka mokhoa o tloahelehileng oa matla a khoheli, ho lahla khatello e tlase ho ka eketsa haholo sekhahla sa tlhahiso ea li-castings, mme ts'ebetso ea mosebetsi e phahameng. Hobane e koahetsoe tlasa khatello, sebopeho sa ho betsa se teteaneng, 'me matla a tensile a ka fihla ho feta 200MPa. Leha ho le joalo, ho lahla ka khatello e tlase ho na le litlhokahalo tse phahameng bakeng sa lisebelisoa, hlobo le lits'ebetso, mme ho se tsotelle hanyane ho ka baka litšila. Kamora kakaretso ea rona ea nako e telele, mabaka a mantlha a amang boleng ba khatello e tlase a ka hlahisoa ke lintlha tse tharo: e le 'ngoe ke mocheso (mocheso oa hlobo le mocheso oa aluminium o qhibilihisitsoeng); ea bobeli ke mokhathala; ea boraro ke ho tlatsa mekhahlelo. Ka ho nka mehato e lebisitsoeng ho lintlha tse tharo tse kaholimo, sekhahla sa ho lahla batho ba lahliloeng se ka fokotsoa khafetsa.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Ts'ebetso ea khatello ea khatello e tlase-Mehato e lebisitsoeng ho lintlha tse tharo ho thibela litšila

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off