Ts'ebetso ea Ntlafatso Bakeng sa Liphoso Tse Lahlehileng Tse Metsoalle le Mefokolo e Laoloang Haholo

Lerako la botenya ba sengoathoana se laolang le ho tiisa sekhechana sa likarolo tse phahameng tsa mocheso oa alloy li fetotsoe ho tloha ho 1.1mm ho isa ho 0.8mm, e lebisang ho tiisetsong e potlakileng ea li-castings. Ts'ebetso ea mantlha ea ho betsa e ke ke ea tlatsa ka nepo le ho fepa methapo ea likarolo, e leng ho fellang ka ho lahla ho lekaneng le ho lokoloha. sekoli. Ntlheng ena, motheong oa moralo oa tšebetso oa mantlha, mokhoa oa ho thatela asbestos sebakeng se mosesane oa marako o amoheloa ho fokotsa ho phola ha khetla ea hlobo le ho lelefatsa nako ea ho tiea ha sebaka se nang le mabota a masesaane, hore motsoako mokelikeli ka tsela e atlehang tlatsa hlobo le fepa bohale ba betsa ho felisa undercasting, Loose likoli.

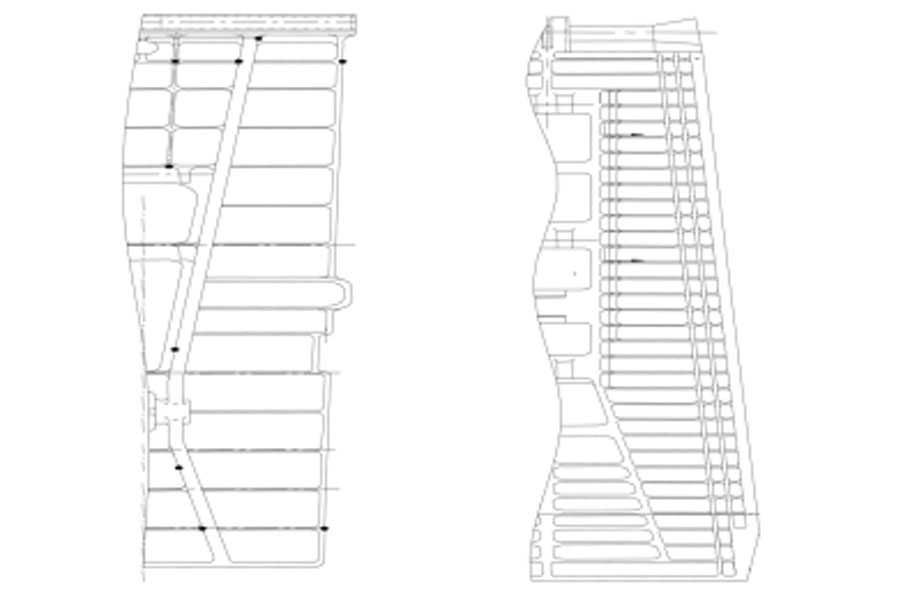

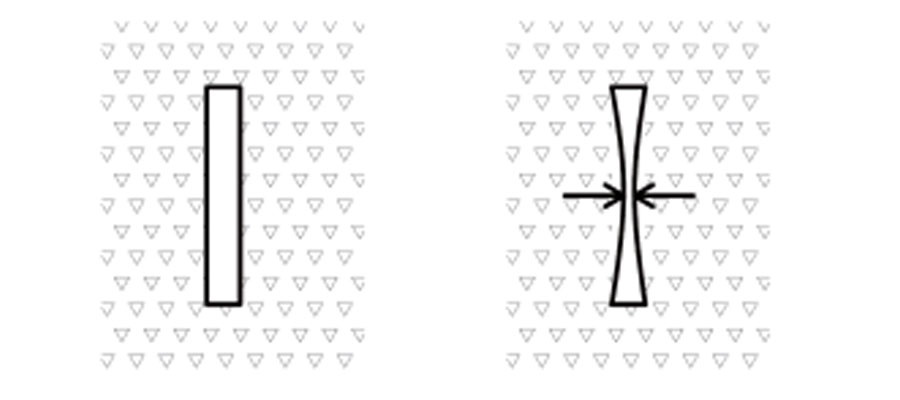

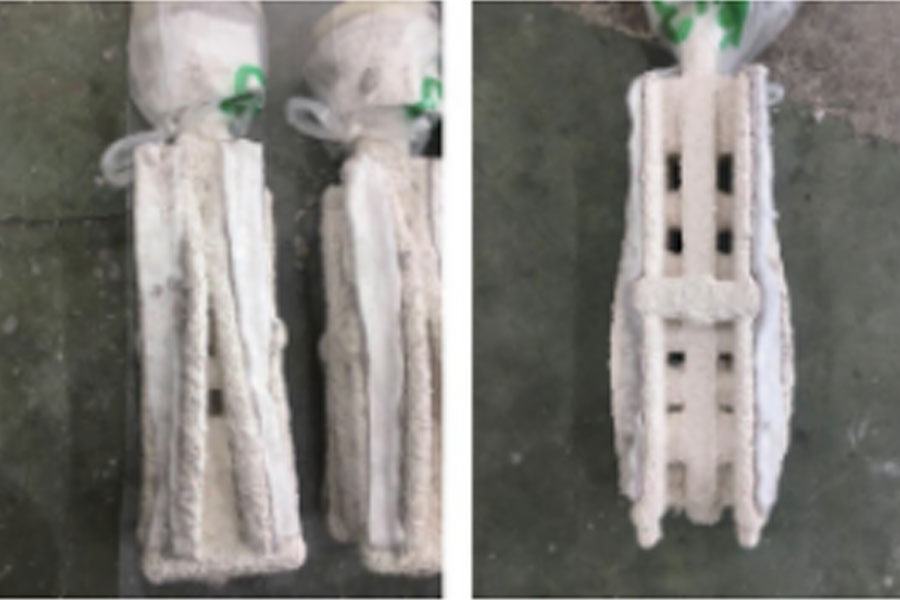

Ho laola sengoathoana le ho tiisa sengoathoana se nang le mocheso o phahameng oa mocheso (joalo ka ha ho bonts'itsoe setšoantšong se kaholimo), botenya ba lebota bo fetang 90% ea sebaka seo bo tlameha ho ba 0.8mm, mme botenya ba lebota la castings bo lahleloa ho latela holimo kheloha (+0.3), 'me e betsa e le hantle bōpa le boleng metallurgical ke molemo. Morero oa ts'ebetso o holile haholo, empa boima bo feta litlhoko tsa moralo; kamora hore botenya ba lerako bo fetohe 0.8mm, moralo oa tšebetso oa mantlha o ntse o hlahisoa. Hoo e ka bang 100% ea castings casted e hlephile, 'me mefokolo e hlephileng e tsepame mathopeng a mahlakore ka bobeli a mokato oa ho betla. Sebaka (joalo ka ha ho bonts'itsoe setšoantšong se ka tlase). Ntle le moo, ho feta 40% ea ba-cast ba ntse ba lahla, mme liphoso tsa kenyelletso ea slag le tsona li eketsehile haholo.

Tshekatsheko ya Bofokoli ba Taba

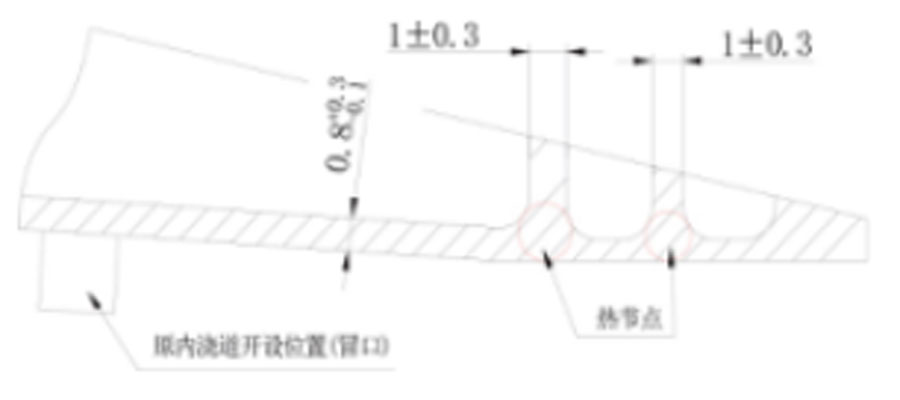

Ponahalo e fapaneng ea likarolo tsa mahlakore ka bobeli a poleiti e tlase e lahleloa setšoantšong se ka tlase. Ho na le likhopo tse matlafatsang metseng. Litlhoko tsa moralo oa botenya ba likhopo le poleiti e ka tlase li bonts'itsoe setšoantšong se ka tlase. Moralong oa pele oa hlobo, bokaholimo ba khopo le poleiti e tlase e tla ba 1.1mm, ke hore, botenya bo lekanang ba lebota. Kopanelo lipakeng tsa leqhoa le lebota la poleiti e tlase e theha node e chesang; modulus ea node e chesang ha e fapane haholo ha e bapisoa le poleiti e tlase. Ntle le moo, node e chesang e mocheng oa ho betsa, ho futhumatsa le ho tiisa kapele, mme mokelikeli oa motsoako o ka futhumatsa ka poleiti e tlase Li-node li fepuoa ntle le litšitiso tse hlephileng.

Kamora hore botenya ba lebota la poleiti e ka tlase bo fetoloe ho 0.8 mm, modulus ea poleiti e tlase e ile ea fokotsoa ka hoo e ka bang 1/3, mme lebelo le pholileng le ho tiisa la poleiti e tlase le ile la potlakisoa; ha botenya ba likhopo bo sa fetohe, modulus ea node e chesang e ile ea lula e sa fetohe, mme lebelo la ho futhumatsa le ho tiisa le ne le sa fetohe. Ka lebaka leo, mokelikeli oa motsoako o sitoa ho fepa li-node tse chesang ka poleiti e ka tlase, e hlahisang tokoloho.

Tlhahlobo ea Liphoso tsa Undercasting

Ho lahla ke sebopeho se kang poleiti ka kakaretso, se nang le lebota le lesesane botenya le sebaka se seholo. Ho etsa bonnete ba hore li-molding, khetla ea hlobo e hloka ho tlatsoa ka lehlabathe le ho futhumatsoa pele. Nakong ea ho futhumatsa pele, khetla ea hlobo e futhumatsoa le ho nolofatsoa mme matla a eona aa fokotseha. Joalokaha ho bonts'itsoe setšoantšong se ka tlase, mokoti o ka hare oa fokotseha, 'me botenya ba lebota bo fokotseha hanyane. Kamora botenya ba lebota le tlase bo fetotsoe ho 0.8 mm, botenya ba 'nete ba lebota bo tla ba nyane. Ntle le moo, lebelo la ho pholisa le ho tiisa le tla eketseha. Mokelikeli oa motsoako oa sebaka o tiile pele o ka phalla, o hlahisang likoli tse sa laoleheng.

Kamora hore botenya ba lebota le tlase bo fetotsoe ho 0.8 mm, lebelo le pholileng le ho tiisa lea potlakisoa, 'me li-slag inclusions tse mokelikeli oa alloy ha li na nako ea ho phaphamala kapa ho teba,' me mokelikeli oa motsoako o tiile mme o lutse ho lahla ho etsa slag likoli tse kenyeletsang.

Mehato ea Ntlafatso Bakeng sa Liphoso Tse Laoloang Le Tlas'a Lahleloa Ho Laola Sengoathoana Le Ho Senya Karolo ea Likarolo

Ha re ntse re etsa joalo, asbestos e phuthetsoe ka khetla ea hlobo (joalo ka ha ho bonts'itsoe setšoantšong se latelang), ke hore, asbestos e manehiloe poleiting e ka tlase (ho boloka node e chesang), ebe ho tšolloa ho tšeloa, ebe ho beoa node e chesang.

Ha ho porosity e fumanoeng, mme ha ho porosity e bonoeng poleiting e ka tlase, mme khaello ea liphoso tsa ho lahla le eona e eketsehile ka 80%.

Ts'ebetso ea Ntlafatso ea Ts'ebetso

Ha o qhibilihisa litšepe tse tšollelang, nakong ea ts'ebetso, o tla theoha mocheso oa khetla ea hlobo seboping se qhibilihang. Kamora hore poleiti e ka tlase e phuthetsoe ka asbestos, asbestos e tla futhumatsa khetla ea hlobo, e fokotsa lebelo le pholileng la poleiti e tlase mme e lelefatsa nako ea ho tiea ha poleiti e tlase, ka tsela eo e netefatse motsoako: Mokelikeli o fepa node tse chesang ka tlase tlase poleiti, hape e netefatsa hantle hore poleiti e tlatsoa ka tlase.

Asbestos ke sesebelisoa se bonolo. Kamora hore asbestos e phuthetsoe, asbestos e fokotsa lebelo la lehlabathe le khetleng la hlobo, e fokotsa ho fetoha ha khetla ea hlobo, ka tsela e sa tobang e eketsa botenya ba lebota la poleiti e tlase, mme e lelefatsa nako ea ho tlatsa poleiti e tlase.

Kamora hore asbestos e phuthetsoe, nako ea ho tiisoa ha poleiti e tlase e ea lelefatsa, e le hore li-inclusions tse mokelikeli oa motsoako li ka phaphamala ka botlalo kapa tsa teba, mme tloaelo ea ho lahla kenyelletso ea slag e batla e fokotsehile.

fihlela qeto e

Mokhoa oa ho sebelisa khetla ea hlobo ho thatela asbestos e ka sitisa ho ntšoa ha khetla ea hlobo ke lehlabathe, ho fokotsa sekhahla se pholileng sa khetla ea hlobo, le ho holisa nako ea ho tlatsa le ho tiisa ea poleiti e tlase, ka tsela eo ka nepo e fepa li-node tse chesang moeling oa ho betsa le ho ntlafatsa tloaelo ea porosity.

Minghe Khamphani ea Die Casting Na ke moetsi oa moetlo oa li-castings tse nepahetseng le tse sa sebetseng. Lihlahisoa li kenyelletsa aluminium & zinki shoa castings. Aluminium die li-castings li fumaneha ka lits'epe tse kopantsoeng ho kenyeletsoa 380 & 383. Litlhaloso li kenyelletsa mamello / - Zinki shoa likarolo lahla li fumaneha ka lits'epe tse kopantsoeng tse tloaelehileng joalo ka Zamak no. 3, Zamak no. 5 & Zamak no. 7 & alloys ea lebasetere joalo ka ZA-8 & ZA-27. Litlhaloso li kenyelletsa mamello / - 0.001 mamello le boima bo phahameng ba ho bōpa ba 4.5 lbs.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Ts'ebetso ea Ntlafatso Bakeng sa Liphoso Tse Lahlehileng Tse Metsoalle le Mefokolo e Laoloang Haholo

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off