Mokhoa oa ho ntlafatsa methati ea ts'ebetso ea ho betsa ea sekhahla sa spheroidization

The spheroidization boemo ba malapeng tloaelehileng spheroidal graphite cast cast cast iron e hlokahala ho fihlela boemo ba 4 kapa kaholimo, (ke hore, sekhahla sa spheroidization ke 70%), sekhahla sa spheroidization se fihletsoeng ke setheo se akaretsang se ka bang 85%. Lilemong tsa morao tjena, ka nts'etsopele ea tlhahiso ea tšepe ea nodular, haholo liindastering tse nang le litlhoko tse phahameng bakeng sa tlhahiso ea matla a moea le boleng ba ho lahla, boemo ba spheroidization bo hlokahala ho fihlela boemo ba 2, ke hore, sekhahla sa spheroidization se fihla ho feta 90%. Khamphani ea mongoli e hlahlobile le ho ntlafatsa tšebetso ea spheroidization le inoculation e sebelisitsoeng ho QT400-15, hammoho le spheroidizing agent le inoculant, e le hore sekhahla sa spheroidization sa nodular cast iron se fihle ho feta 90%.

1. Ts'ebetso ea mantlha ea tlhahiso

Ts'ebetso ea mantlha ea tlhahiso:

- Lisebelisoa tsa ho qhibilihisa li amohela sebōpi sa maqhubu a 2.0T le lipakeng tsa 1.5T;

- Sebopeho sa mokelikeli oa tšepe e tala ea QT400-15 ke ω (C) = 3.75% ~ 3.95%, ω (Si) = 1.4% ~ 1.7%, ω (Mn) ≤0.40%, ω (P) ≤0.07%, ω ( S)) -0.035%;

- Moemeli oa spheroidizing o sebelisitsoeng kalafong ea spheroidizing ke 1.3% ho 1.5% RE3Mg8SiFe alloy;

- Ente e sebelisitsoeng kalafong ea ente ke 0.7% ~ 0.9% 75SiFe-C alloy. Kalafo ea spheroidizing e sebelisa mekhoa e 'meli ea ho phaphatha le ho hlatsoa:

Pele, 55% ~ 60% ea tšepe ea hlahisoa, ebe spheroidizing ea etsoa, ebe ho tšeloa ente, ebe metsi a mang a tšepe aa eketsoa.

Ka lebaka la mokhoa o tloaelehileng oa spheroidization le inoculation, sekhahla sa spheroidization se fumanoeng ke sekhahla se le seng sa "cast wedge test" se nang le botenya ba 25 mm hangata se ka bang 80%, ke hore, boemo ba spheroidization ke karolo ea boraro.

2. Moralo oa liteko ho ntlafatsa sekhahla sa spheroidization

Bakeng sa ho eketsa sekhahla sa spheroidization, ts'ebetso ea "spheroidization" ea mantlha le ts'ebetso ea ho enta e ntlafalitsoe. Mehato ea mantlha ke: ho eketsa palo ea moetsi oa spheroidizing le inoculant, ho hloekisa tšepe e qhibilihisitsoeng le kalafo ea desulfurizing. Sekhahla sa spheroidization se ntse se lekoa ka sekhahla se le seng sa "wedge test block" sa limilimithara tse 25. Morero o tobileng o tjena:

- (1) Sekaseka lebaka la sekhahla se tlase sa spheroidization sa ts'ebetso ea mantlha. Ho ne ho nahanoa hore palo ea moetsi oa spheroidizing e nyane, ka hona, palo ea moemeli oa spheroidizing e ekelitsoe e eketsehile ho tloha ho 1.3% ho ea ho 1.4% ho isa ho 1.7%, empa sekhahla sa spheroidizing ha se fihlelle litlhokahalo. . (2) Khopolo-taba e 'ngoe ke hore sekhahla se tlase sa spheroidization se kanna sa bakoa ke ho nyala kapa ho fokotseha ha kemolo. Ka hona, teko e ekelitse lethal dose ho tloha ho 0.7% ho ea ho 0.9% ho ea ho 1.1%, 'me sekhahla sa spheroidization ha sea ka sa fihlela litlhoko.

- (3) Tsoela pele ho sekaseka le ho lumela hore ho na le li-inclusions tse ngata tsa tšepe e qhibilihisitsoeng le likarolo tse phahameng tsa tšitiso ea spheroidization e kanna ea ba sesosa sa sekhahla se tlase sa spheroidization. Ka hona, ho etsoa tlhoekiso ea mocheso o phahameng oa tšepe e qhibilihisitsoeng. Mocheso o phahameng oa ho itlhoekisa o laoloa ka kakaretso ho 1500 ± 10 ° C, empa sekhahla sa ona sa spheroidization ha se feta 90%.

- (4) Palo e phahameng ea ω (S) e sebelisa tekanyetso ea spheroidizing mme e potlakisa ho fokotseha ha spheroidization. Ka hona, kalafo ea desulfurization e eketsoa ho fokotsa mokelikeli oa tšepe oa pele ω (S) ho tloha ho 0.035% ho ea tlase ho 0.020%, empa sekhahla sa spheroidization le sona se fihlile feela ho 86%. Liphetho tsa liteko tsa merero e mene e boletsoeng kaholimo li bonts'itsoe ho Tafole ea 1. Sebopeho le thepa ea mochini oa sebopeho sa teko e bopehileng joaloka chesele ha sea ka sa fihlela litlhoko.

3. Morero oa ntlafatso oa hoqetela o amohetsoe

3.1 Mehato e khethehileng ea ntlafatso

- Lisebelisoa tse tala ke tšepe ea kolobe, litšila tse se nang mafome kapa tse seng kae tse rusitseng le thepa e futhumatsang;

- Ho senngoa ha tšepe e qhibilihisitsoeng ka ho eketsa molora oa soda (Na2CO3) seboping;

- Sebelisa moemeli oa pele ho kalafo oa Foseco 390 ho etsa pele ho deoxidize ka mokotleng;

- Kalafo ea spheroidizing le Fozco Nodulizer;

- Sebelisa silicon carbide le ferrosilicon kopantswe inoculation.

Taolo ea pele ea tšepe e qhibilihisitsoeng ea ts'ebetso e ncha: ω (C) = (3.70% ~ 3.90%, ω (Si) = 0.80% ~ 1.20% [casting ω (Si final) = 2.60% ~ 3.00%], ω ( Mn) ≤ 0.30%, ω (P) ≤0.05%, ω (S) .0.02 %.Ha tšepe ea pele e qhibilihisitsoeng ω (S) e feta 0.02%, molora oa soda ea indasteri o sebelisetsoa desulfurization ka pele ho sebopi, hobane Ts'ebetso ea desulfurization ke karabelo ea ho qetela, mocheso oa desulfurization o hlokahala hore o laoloe ho pota 1500 ° C, mme palo ea soda molora e ekelitsoeng e laoloa ho 1.5% ~ 2.5% ho latela palo ea ω (S) nakong ea ho qhibiliha seboping .

Ka nako e ts'oanang, sephutheloana sa kalafo ea spheroidizing se amohela sephutheloana se tloaelehileng sa kalafo ea letamo. Taba ea mantlha, eketsa 1.7% ea moetsi oa mofuta oa Foseco NODALLOY7RE oa spheroidizing lehlakoreng la letamo botlaaseng ba sephutheloana, batalatsa le ho kopanya, 'me u sebelise 0.2% ea phofo ea silicon carbide le 0.3% e nyane Boholo ba 75SiFe bo koahetsoe ka lera ka tatellano. , 'me kamora ho hatakeloa, e koahetsoe ka tšepe ea khatello,' me 0.3% Foseke 390 inoculant e eketsoa ka lehlakoreng le leng la lere la tšepe. Ha o tlanya tšepe, 55% ~ 60% ea palo eohle ea tšepe e qhibilihisitsoeng e qala ho hlatsuoa. Kamora hore spheroidizing reaction e phethoe, 1.2% 75SiFe-C inoculant ea eketsoa mme tšepe e setseng e qhibilihisitsoeng ea tšeloa, ebe slag ea tšeloa.

3.2 Liphetho tsa liteko

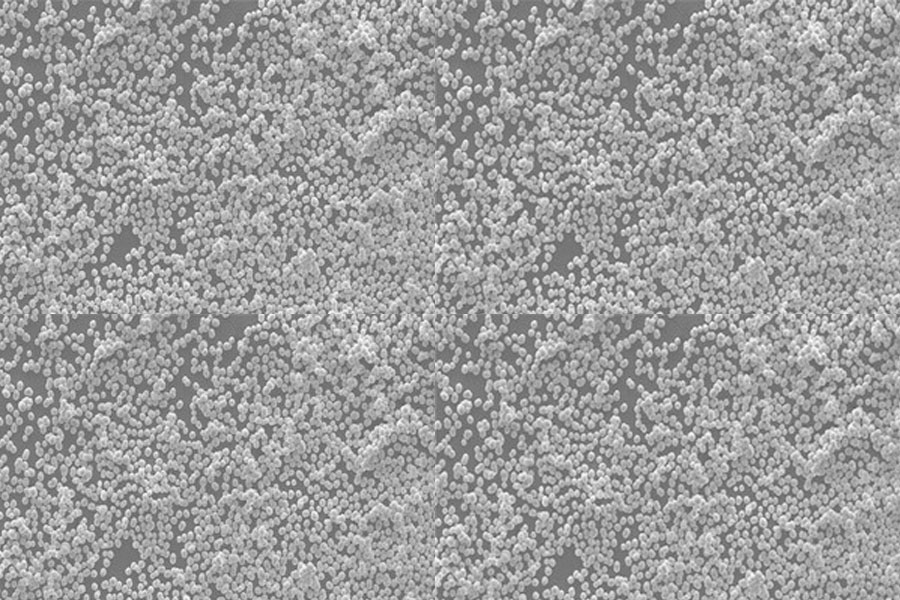

Sebopeho sa tšepe ea pele e qhibilihisitsoeng pele le kamora ho senyeha, thepa ea mochini le sebopeho sa tšepe sa 25mm e le 'ngoe e nang le sebopeho sa wedge, mme mokhoa oa ho lekola sekhahla sa spheroidization mohahong oa metallographic o fumanoa ka bo eona ke sistimi ea tlhahlobo ea litšoantšo ea metallographic .

4. Tlhahlobo ea sephetho

4.1 Tšusumetso ea likarolo tsa mantlha ho sekhahla sa spheroidization

- C, Si: C e ka khothaletsa graphitization le ho fokotsa tšekamelo ea molomo o mosoeu, empa palo e phahameng ea ω (C) e tla etsa hore CE e phahame haholo mme e bake habonolo hore graphite e phaphamala, hangata e laoloa ho 3.7% ~ 3.9%. Si e ka matlafatsa bokhoni ba graphitization le ho felisa cementite. Ha Si e kenyelletsoa e le ente, e ka fokotsa matla a supercooling haholo a tšepe e entsoeng ka ho qhibilihisoa. ho 1.3%, mme palo ea ω (Si ea ho qetela) e ne e laoloa ho 1.5% ho isa 0.8%.

- Mn: Nakong ea ts'ebetso ea li-crystallization, Mn o eketsa tloaelo ea tšepe ea tšepe ho feta le ho khothaletsa ho theoa ha carbides (FeMn) 3C. Ts'ebetsong ea phetoho ea eutectoid, Mn o fokotsa mocheso oa phetoho ea eutectoid, oa tsitsisa le ho ntlafatsa pearlite. Mn ha a na tšusumetso e kholo sekhahla sa spheroidization. Ka lebaka la tšusumetso ea lisebelisoa tse tala, ka kakaretso taolo ω (Mn) <0.30%.

- P: Ha ω (P) <0.05%, e qhibiliha ka thata ho Fe, mme ho thata ho theha phosphorus eutectic, e nang le phello e nyane ho sekhahla sa spheroidization sa tšepe ea ductile.

- S: S ke karolo e nyelisang. S e sebelisa Mg le RE ho spheroidizing agent nakong ea spheroidizing reaction, e sitisang graphitization le ho fokotsa sekhahla sa spheroidizing. Sulfide slag le eona e tla khutlela sebabole pele tšepe e qhibilihisitsoeng e tiisa, e boetse e sebelisa likarolo tsa spheroidizing, e potlakisang ho fokotseha ha spheroidization, hape e ama sekhahla sa spheroidizing. Bakeng sa ho fihlela sekhahla se phahameng sa spheroidization, palo ea ω (S) ka tšepe e tala e lokela ho fokotsoa ho ba tlase ho 0.02%.

Phekolo ea Desulfurization

Kamora hore qoso e qhibilihe, nka mehlala ebe u sekaseka lik'hemik'hale. Ha palo ea ω (S) e phahame ho feta 0.02%, desulfurization e ea hlokahala.

Molao-motheo oa soda molora desulfurization ke: kenya molora o itseng oa soda ka har'a ladle, sebelisa phallo ea tšepe e qhibilihisitsoeng ho hohola le ho hlohlelletsa, molora oa soda o bola ka mocheso o phahameng, mokhoa oa karabelo ke Na2CO3 = Na2O + CO2 ↑: Na2O e hlahisitsoeng ke ka tšepe e qhibilihisitsoeng hape Sebabalo le sebopeho sa Na2S, (Na2O) + [FeS] = (Na2S) + (FeO).

Na2CO3 e arola le ho rarolla CO2, e baka moferefere o mabifi oa tšepe e qhibilihisitsoeng, e khothalletsang ts'ebetso ea ho senya. Soda ash slag e bonolo ho phalla le ho phaphamala kapele, mme nako ea karabelo ea desulfurization e khuts'oane haholo. Kamora ho senyeha, slag e lokela ho tlosoa ka nako, ho seng joalo e tla khutlela sebabole. Kalafo ea pele ho deoxidation, kalafo ea spheroidization le kalafo ea ente eketsa sekhahla sa ho monyela ha Mg. Ntlafatsa haholo bokhoni ba ho hanela moruo le ho eketsa sekhahla sa spheroidization. Inchulant ea Fochke e na le ω (Si) = 4.3% ~ 390%, ω (Ca) = 60% ~ 70%, ω (Ba) = 0.4% ~ 2.0%, eo Ba e ka eketsang nako ea poloko e sebetsang. Sehlopha sa NODALLOY7RE sa Fozco Nodulizer se khethiloe, 'me ω (Si) = 11% ~ 7%, ω (Mg) = 40% ~ 50%, ω (RE) = 7.0% ~ 8.0%, ω (Ca) = 0.3 % ~ 1.0%, ω (Al) <1.5%. Kaha tšepe e entsoeng ka ho qhibilihisoa e etsoa kalafong ea kalafatso le kalafo ea pele ho ts'oaetso, likarolo tse jang li-nodulizer ka tšepe e qhibilihisitsoeng li fokotsehile haholo, ka hona ho khethoa nodulizer e nang le palo e tlase ea RE (RE) ho fokotsa ho senyeha ha spheroidal graphite morphology ke RE ; Karolo ea mantlha ea ts'ebetso ke Mg; Ca le Al ba ka bapala karolo ea ho matlafatsa poloko. Sebelisa silicon carbide le ferrosilicon kopantswe inoculation kalafo, qhibiliha tsa silicon carbide ke ka 2.5 ° C, le graphite kristale khubung e eketseha nakong ea solidification, le tekanyetso e kholo ea ferrosilicon e sebediswa bakeng sa inoculation, e leng ho ka thibela spheroidization tloha fokotseha.

Qeto ea 5

Ha ho etsoa tšepe ea ferritic nodular cast, ha sekhahla sa spheroidization se hlokahala ho fihlela 90%, ho ka sebelisoa mehato e latelang:

- (1) Khetha boleng bo phahameng qoso ho fokotsa likarolo de-spheroidization qoso.

- (2) Khetha moemeli oa spheroidizing ka palo e tlase ea ω (RE) ho fokotsa tšenyo e mpe ea RE ho morpholoji ea spheroidal graphite.

- (3) Likahare tsa ω (S) tsa tšepe ea pele e qhibilihisitsoeng e lokela ho ba tlase ho 0.020%, e ka fokotsang ts'ebeliso ea li-nodulizers, haholo-holo likarolo tsa nodulized tse sebelisoang ke sulfurization ea bobeli ea slag ea sulfide.

- (4) Pele ho deoxidize tšepe e entsoeng ka ho qhibilihisoa, eketsa palo ea likarolo tsa graphite sebakeng se seng le se seng, eketsa sekhahla sa spheroidization, e ntlafatsa haholo bokhoni ba ho hanela ho putlama ha moruo, le ho lelefatsa nako ea poloko e atlehang.

- (5) Fokotsa palo ea ω (Si) ka tšepe ea pele e qhibilihisitsoeng, eketsa palo ea moetsi oa spheroidizing, inoculant le mahlahana a fapaneng a kalafo ea pele, le ho matlafatsa kalafo ea ente.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Mokhoa oa ho ntlafatsa methati ea ts'ebetso ea ho betsa ea sekhahla sa spheroidization

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off