Process litšobotsi tsa Low Khatello lahla

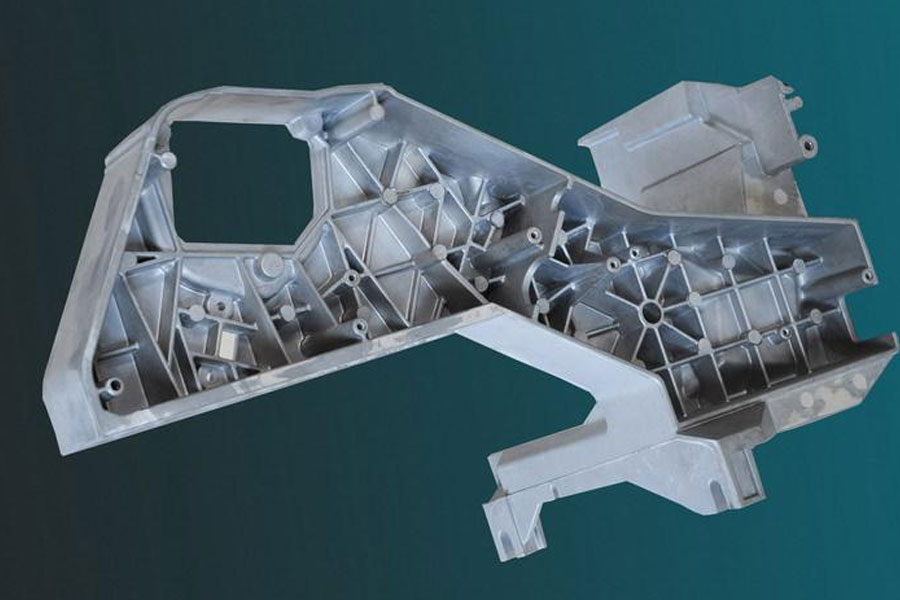

Ka thekenoloji foromeletsoeng ea castings aluminium motsoako, atileng ka ho fetisisa ke tlaase khatello ea foromeletsoeng. Ho lahla khatello e tlase ho fana ka tiiso ea boleng bo botle bakeng sa mabili a koloi le likarolo tse ling, 'me bophahamo ba eona bo ke keng ba khutlisoa bo amohetsoe ke boholo ba baetsi ba likoloi. Sengoloa sena se hlahisa nalane, molao-motheo, litšobotsi tsa ts'ebetso le maemo a hlokahalang a ho lahla khatello e tlase, ka sepheo sa ho fana ka litšupiso tse lekanang bakeng sa ba ka hare ho indasteri.

Mokhoa oa ho lahla o nang le khatello e tlase o sebelisitsoe lilemo tse mashome a 'maloa,' me o maemong a bohlokoa haholoholo ho castings ea aluminium alloy. Mokhoa o tlase oa khatello ea khatello ke mokhoa o tloaelehileng o nang le mesebetsi e matla, e ka eketsang matla a thepa le ho ntlafatsa ts'ebetso ea thepa. Ho lahla khatello e tlase ke mokhoa o sebetsang haholo oa ho betsa. Likarolo tseo li li lahlang li boleng bo holimo, 'me mokhoa ona o na le mokhoa o batlang o phahame haholo oa boiketsetso.

1. Nalane ea khatello e tlase ea khatello

Mokhoa oa ho lahla o nang le khatello e tlase o na le nalane ea lilemo tse fetang lekholo. Lilemong tsa bo-1920, linaha tse peli tse neng li sebelisa mokhoa o nang le khatello e tlase ho aluminium alloy e ne e le Fora le Jeremane, empa li ne li ntse li le mothating oa ho etsa liteko. Ka 1945, tlhahiso ea khatello e tlase e ile ea qala ho sebelisoa ka bongata, haholo tlhahiso ea lipeipi tsa metsi a pula le lijana tsa biri UK. Ka 1958, Maamerika a ile a sebelisa mokhoa oa khatello e tlase ha a ne a lahla likarolo tsa enjene ea likoloi. Ona e ne e le monyetla oa ho betsa ka khatello e tlase hore e sebelisoe haholo. Indasteri ea likoloi ea lefats'e e ile ea qala ho hlokomela mokhoa ona oa boloi oa boloi, mme mokhoa ona oa tsebisoa China ho elella lilemong tsa bo-1950.

Naheng ea heso, ts'ebeliso ea ho lahla ka khatello e tlase e qalile ka 1961. Ha tlhahiso ea lihlooho tsa silindara tse pholileng moea e ka lemohuoa ka mokhoa oa boloi oa khatello e tlase, mokhoa ona o ile oa qala ho ananeloa haholo. Ho tloha ka nako eo, theknoloji e laoloang ka khatello e tlase e 'nile ea sebelisoa khafetsa indastering ea likoloi,' me sekhahla sa ts'ebeliso ea eona se phahameng haholo, haholoholo ho castings ea aluminium alloy, e phahameng joalo ka halofo ea theknoloji ea khatello e tlase. Boleng ba likarolo tsa aluminium alloy tse hlahisitsoeng ke mahlale ana li ntle haholo, 'me mefuta ea lihlahisoa tse hlahisoang e lula e hola. Lilemong tsa bo-1970, theknoloji e laoloang ka khatello e tlase e ile ea qala ho sebelisoa ho hlahiseng mabili a likoloi. Mehleng ea kajeno, batho ba ile ba qala ho ela hloko kholo e bobebe ea likoloi. Theknoloji e laoloang ka khatello e tlase e qalile ho etsa likarolo tse nang le ts'ebetso e ntle, boleng bo holimo ba kahare le thepa e thata ea mochini.

2. Melao-motheo ea Motheo

Molao-motheo oa ho lahla khatello e tlase ke haholo-holo ho ntšetsa pele sopho e entsoeng ka ho qhibilihisoa ka hlobo ka ho sebelisa khatello, 'me sopho e entsoeng ka ho qhibilihisoa e tiisa butle butle ka ho tlatsa butle, mme ho tiisa karolo ea heke ke nako eo khatello e sebelisoang. Litlhaku tse tiisitsoeng ka tsela ena li tla ba tse phethahetseng. Tataiso ea ho tiisa e qala ho tloha ntlheng ea heke, ha e thulane le khatello, 'me e ke ke ea khathatsoa ke khatello, mme ts'ebetso ea ho tiisa le ho pholisa li phetheloa ka tlhaho le ka thello.

3. Litšobotsi tsa Ts'ebetso ea khatello ea khatello e tlase

Khatello le lebelo la foromeletsoeng tlaase khatello ea ka flexibly fetola nakong tšollela, e le hore ho betsa ka ho phethahatsoa ho latela dibopeho fapaneng fapaneng foromeletsoeng. Ho lahla khatello e tlase haholo-holo ho amohela mofuta oa tlatsetso oa tlase, o ka netefatsang ho tlatsoa ho tsitsitseng ha tšepe e qhibilihisitsoeng, hape ho ka khona ho qoba tšitiso ea sebaka ho tšepe e qhibilihisitsoeng, le ho qoba sebopeho sa liphoso tsa boleng kamora ho betloa. Tlas'a khatello ea khatello, li-castings tse bopehileng li na le boleng bo holimo, bokaholimo bo boreleli le ts'ebetso e phahameng. Ka nako e ts'oanang, ho lahla khatello e tlase ho fokotsa matla a mosebetsi, tikoloho e betere, mme lisebelisoa li bonolo ebile lia sebetsa. Bapisoa le mekhoa e meng foromeletsoeng, tlaase khatello ea foromeletsoeng na peculiarities itseng le boetse o na le litšobotsi tse ikhethang haholo thulaganyou e.

Litšobotsi tsa 3.1 ha li bapisoa le ho lahla ka mokhoa o tloaelehileng li ka sebelisa hlobo ea tšepe, hlobo ea lehlabathe, hlobo ea lejoe la majoe, jj. Ho lahla khatello e tlase ho loketse tšepe e se nang litšepe le tšepe e litšepe, e sa fihlelloeng ke mekhoa e mengata e tloaelehileng ea ho betsa. Ho tlatsoa ha khatello e tlase ho tsitsitse haholo, hobane e amohela mofuta o tlase oa kaho, kahoo khatello le lebelo li ka fetoha habonolo. Tlas'a tšebetso ea khatello, ho tiea ha tšepe e qhibilihisitsoeng ho lekane haholo, sekhahla sa ts'ebeliso se phahameng, 'me fluidity e betere, mme boleng ba ho betla bo ntlafalitsoe. Ha ho betsa ho rarahane, e ka bonts'a melemo ea eona haholoanyane.

Likarolo tsa 3.2 ha li bapisoa le ho betsa die

Ho lahla khatello e tlase ho ka sebelisoa ho etsa mefuta e mengata ea litšepe, 'me kalafo ea mocheso e ka etsoa habonolo ho latela boemo ba nnete. E ka sebelisoa ho etsa li-castings tse nang le mabota a masesaane hammoho le li-castings tse teteaneng, 'me e ka qoba ka botlalo tšitiso ea moea nakong ea ts'ebetso. , Fumana li-castings tsa boleng bo holimo, bokaholimo bo boreleli, sebopeho se setle le bubble e nyane. Ho feta moo, thepa ea mochini oa castings e hlahelletse haholo, ka mefuta e mengata, e bobebe ebile e theko e tlase.

3.3 Mathata a angoa ke sebaka le boholo ba liheke, hammoho le botenya ba lebota le kahare, sehlahisoa se tla ba le lithibelo tse itseng. Bakeng sa ho bonahatsa botlalo ba tšepe e qhibilihisitsoeng ka botlalo le ho netefatsa hore ho tiea ho qala hekeng, potoloho ea ho betla e tla eketsoa mme sekhahla sa ho tiisa se tla boela se fokotsehe. Ha tšepe e qhibilihisitsoeng e tlatsa mokoti, litšobotsi tsa mochini o entsoeng ka tšepe e qhibilihisitsoeng li tla fokotsoa.

4. Maemo a Hlokahala Bakeng sa ho Lahla Khatello e Tlaase

Mocheso oa 4.1

Mocheso oa sopho e entsoeng ka ho qhibilihisoa o tla angoa ke mofuta le sebopeho, empa phapang e akaretsang e ke ke ea ba kholo haholo. Hore na thempereichara ea eona e loketse kapa che e tla ama ka kotloloho boleng le botle ba sehlahisoa, ka hona mocheso o lokela ho laoloa ka bongata bo lekaneng. Re lokela ho hlokomela hore mocheso oa hlobo le oona o ke ke oa hlokomolohuoa.

Ho ea ka pono ea ho qhibilihisoa ha tšepe e qhibilihisitsoeng, kabo ea mocheso oa hlobo ke haholo-holo ho tloha hekeng ho ea holimo ho ea butle butle, empa hobane sena se tla lelefatsa potoloho mme se ame sekhahla sa ho tiea, ka hona, ho futhumatsa ho holimo le ho tshekaletseng ho tlameha ho etsoa . Potoloho ea tlhahiso, mocheso oa tšepe e qhibilihisitsoeng le likarolo tse ling li hloka ho tsotelloa le ho fetoloa, tse tla ama haholo boleng ba kahare le kantle ba samente, ka hona phapang ea mocheso oa heke e ka eketsoa ho latela boemo ba 'nete, hore maemo a teng a ka fetoloa.

4.2 Nako ea khatello

Nako ea khatello e bua haholo ka nako e nkuoeng ke tšepe e qhibilihisitsoeng ho tloha ho tlatseng ho fihlela e tiea hekeng. Nako ea khatello e ka angoa ke lintlha tse fapaneng, tse hlokang ho tsotelloa ka nako ea hlooho ea silindara. Katoloso e lokela ho ba bolelele kamoo ho ka khonehang, mme motheo oa katoloso o its'etleha haholo hodima boima. Nako ea khatello e angoa habonolo ke maemo a mocheso. Haeba mocheso o tsitsitse, nako ea khatello e tla ba e tsitsitseng haholo.

Nako ea ho tiea ha tšepe e qhibilihisitsoeng e kanna ea se tsitse ka lebaka la liphetoho mochesong le ho fokotseheng ha mocheso. Hobane palo ea li-castings e tla tsoelapele ho eketseha, mocheso o tla ba o sa tsitsang haholo, 'me ka nako e ts'oanang, sebaka se nang le likarolo tse fapaneng tsa heke se tla fokotseha, se tla etsa hore nako ea ho tiisa e fetohe, e hlahisang liphoso tsa kahare ho boleng ba li-castings. Ka hona, re lokela ho ela hloko haholo tšusumetso ea lintlha tse kang mocheso, heke le phala ea phepo ho sopho ea sopho.

Nako ea ho Ipehela ea 4.3

Nako ea ho tiisa e bua ka nako ho tloha phethisong ea khatello ho isa ts'ebetsong ea sehlahisoa. Kamora ho betloa ha thepa fatše ho hlile ha ho phetheloe, empa ke ho netefatsa hore ho betloa ha ho holofale mme boleng ba ho betsa bo netefalitsoe. Nako e hlokahalang bakeng sa karolo ena e tlameha ho eketsoa nakong e hlokahalang bakeng sa ho tiisa. Nako ea ho tiisa e ke ke ea nka nako e telele, e amana le mocheso, 'me lebelo la ho tiisa le tla potlaka ho feta nako ea khatello. Bakeng sa ho khutsufatsa nako ea ho tiisa, sekhahla sa pholileng se ka eketsoa.

Maemo a Hatelletsoeng

Bakeng sa ho netefatsa ts'ebetso ea ho tlatsa, ela hloko ho lokisa lebelo le hatellang, kapele haholo kapa butle haholo le tla ama phello ea ho tlatsa le boleng ba ho betsa. Ka ho khetheha, haeba lebelo le lieha, le tla baka bothata ba mokelikeli o fokolang oa sopho e entsoeng ka ho qhibilihisoa; haeba lebelo le le lebelo haholo, sehlahisoa se tla khathatsoa ke khase ebe se baka litšitiso tsa boleng. Ka hona, ho bohlokoa ho fetola lebelo la khatello. Kaha sekhahla sa phallo se tla angoa ke phapang ea sebopeho sa tsela ea phallo, ho a hlokahala ho laola lebelo ho latela maemo a nnete.

5. Qetello

Ka kakaretso, theknoloji e tlaase lahla theknoloji e na le menyetla e meholo 'me ke theknoloji e ka sehloohong ea ho betsa bakeng sa likarolo tsa aluminium alloy. Ha e bapisoa le mekhoa e meng ea ho betsa, mahlale ana a na le lits'ebetso tse fapaneng, tse nang le boleng bo phahameng ba ho lahla, ts'ebetso e phahameng, ts'ebetso e ntle le boits'oaro bo phahameng. Low khatello ea thekenoloji foromeletsoeng na le histori ea lilemo tse lekholo ho tloha ka theho ea eona, 'me e susumetsa motsoako indasteri foromeletsoeng le tšekamelo e molemo ntshetsopeleng.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape:Process litšobotsi tsa Low Khatello lahla

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off