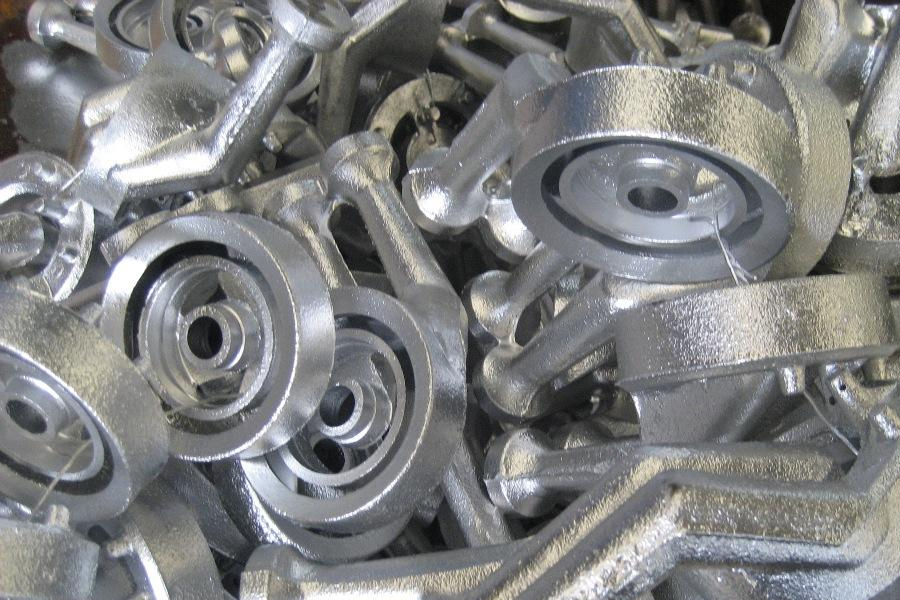

Bokaholimo le mekhoa ea tlhahlobo ea boleng bo kahare ea castings

Ho hlahlojoa ha castings ho kenyelletsa tlhahlobo ea boholo, tlhahlobo ea ponahalo le bokaholimo, tlhahlobo ea lik'hemik'hale le tlhahlobo ea ts'ebetso ea mochini. Bakeng sa li-castings tse hlokang litlhoko tsa bohlokoa haholo kapa tse nang le mathata ts'ebetsong ea ho betsa, ho hlokahala liteko tse sa senyeheng, tse ka sebelisoang bakeng sa li-cast iron tsa ductile. Mekhoa ea liteko tse sa senyeheng ea liteko tsa boleng e kenyelletsa tlhahlobo ea phepelo ea metsi, liteko tsa phatsa ea makenete, liteko tsa morao-rao tsa eddy, liteko tsa radiographic, liteko tsa ultrasonic le liteko tsa vibration.

Ho lemoha bokaholimo ba sefahleho le haufi le bokaholimo ba castings

1. Ho fumanoa ho kenella ka metsi

Ho lekoa ho kenella ka metsi ho sebelisetsoa ho lekola liphoso tse fapaneng tsa ho buloa holim'a li-castings, joalo ka mapetso a bokaholimo, li-pinholes tse holim'a metsi le liphoso tse ling tseo ho leng thata ho li fumana ka mahlo. Teko e sebelisoang khafetsa ea ho kenella ke tlhahlobo ea 'mala, e leng ho kolobisa kapa ho fafatsa mokelikeli o' mala (hangata o mofubelu) (o kenang kahare) o nang le bokhoni bo phahameng ba ho kenella ka holim'a samente. Motho ea kenang ka hare o kenella ka sekoli se bulehileng 'me o hlakola ka potlako motho ea kenang ka holim'a metsi. Ebe u fafatsa moemeli oa pontšo e ommeng habonolo (eo hape a bitsoang moqapi) holima samente. Kamora hore motho ea kenang ka sekoli a butsoe, moemeli oa ponts'o o dailoe, e leng se ka bonts'a sebopeho le sebopeho sa sekoli. Boholo le kabo. Ho hlokahala hore ho bontšoe hore ho nepahala ha tlhahlobo e kenang kahare ho fokotseha ka keketseho ea bohale ba thepa e hlahlobiloeng, ke hore, e bobebe holim'a metsi, e ntlafatsa phello ea tlhahlobo. Ho nepahala ha tlhahlobo ea mochini oa ho sila ke eona e phahameng ka ho fetesisa, esita le mapetso a intercrystalline a ka bonoa. Ntle le phumano ea 'mala, phumano e kenang ea fluorescent e kenang hape ke mokhoa o sebelisoang khafetsa oa phumano ea metsi. E hloka ho ba le leseli la mahlaseli a kotsi bakeng sa ho shebella mahlaseli a kotsi, 'me kutloisiso ea kutlo e phahame ho feta ea phumano ea' mala.

2. Eddy liteko tsa morao-rao

Teko ea hajoale ea Eddy e loketse ho lekola liphoso tseo hangata li sa feteng 6 ~ 7mm botebong ba lefatše. Teko ea hajoale ea Eddy e arotsoe ka mefuta e 'meli: mokhoa oa ho beha li-coil le oa coil. : Ha sengoathoana sa teko se behiloe haufi le kela e nang le phapanyetsano ea hona joale, matla a khoheli a fapakaneng a kenang sekhechaneng sa liteko a ka susumetsa motlakase oa morao-rao (eddy current) o phallang ka tsela ea eddy ea hona joale e lebisang ho matla a khoheli a khoheli sekotong sa liteko. Matla a khoheli a khahlano le tataiso ea matla a khoheli a khahlisang a tla hlahisoa, a tla fokotsa matla a khoheli a mantlha ka kela, e leng ho tla baka phetoho ea coil impedance. Haeba ho na le liphoso holima betsa, litšobotsi tsa motlakase tsa morao-rao li tla sotheha, ka hona li lemohe boteng ba sekoli. Bothata bo boholo ba liteko tsa morao-rao ke hore boholo le sebōpeho sa sekoli se fumanoeng se ke ke sa bonts'oa ka mokhoa o bonahalang, 'me ka kakaretso ke boemo ba botebo le botebo ba sekoli bo ka fumanoang. Ntle le moo, ha e hlonephe joaloka phumano ea ho kenella bakeng sa ho fumana liphoso tse nyane tse bulehang holim 'a mosebetsi.

3. Ho hlahloba likaroloana tsa matla a khoheli

Ho hlahloba likaroloana tsa matla a khoheli ho loketse ho bona liphoso le likoli tse kaholimo ho limilimithara tse 'maloa. E hloka lisebelisoa tsa matla a khoheli tsa DC (kapa AC) le phofo ea makenete (kapa ho emisoa ha makenete) ho etsa ts'ebetso ea tlhahlobo. Lisebelisoa tsa matla a khoheli li sebelisetsoa ho hlahisa matla a khoheli bokaholimo ba kahare le kantle ba samente, 'me phofo ea makenete kapa ho emisoa ha makenete e sebelisoa ho bonts'a liphoso. Ha matla a khoheli a hlahisoa ka har'a mofuta o itseng oa ho betsa, liphoso tse sebakeng sa makenete li tla hlahisa matla a khoheli a dutlang. Ha phofo ea makenete kapa ho emisoa ho fafatsoa, phofo ea khoheli e hoheloa, e le hore sekoli se ka bonts'oa. Liphoso tse bonts'itsoeng ka tsela ena ha e le hantle ke liphoso tse fetang meeling ea matla, 'me likoli tse nang le sebopeho se selelele tse tšoanang le matla a khoheli li ke ke tsa bonts'oa. Ka lebaka lena, tataiso ea matla a khoheli e hloka ho fetoha khafetsa nakong ea ts'ebetso ho netefatsa hore liphoso tse fapaneng libakeng tse sa tsejoeng li ka fumanoa. .

Ho lemoha liphoso tsa kahare ho castings

Bakeng sa liphoso tsa kahare, mekhoa e sebelisoang hangata e sa senyeheng ea liteko ke liteko tsa radiographic le liteko tsa ultrasonic. Har'a bona, tlhahlobo ea radiographic e na le phello e ntle. E ka fumana litšoantšo tse hlakileng tse bonts'ang mofuta, sebopeho, boholo le kabo ea liphoso tsa kahare. Leha ho le joalo, bakeng sa li-castings tse kholo tse nang le botenya bo boholo, tlhahlobo ea mahlaseli e sebetsa haholo, 'me sebaka sa liphoso tsa kahare se ka lekanngoa ka nepo. , Boholo bo lekanang le kabo.

1. Tlhahlobo ea Radiographic

Hangata liteko tsa radiographic li sebelisa X-ray kapa γ-ray e le mohloli oa ray. Ka hona, lisebelisoa le lisebelisoa tse ling tse tlatselletsang lia hlokahala ho hlahisa mahlaseli. Ha mosebetsi o pepesetsoa lebaleng la mahlaseli, matla a mahlaseli a mahlaseli a tla angoa ke liphoso tsa kahare tsa ho betsa. Matla a mahlaseli a hlahisoang ka ho lahla a fapana sebakeng sa heno ka boholo le sebopeho sa sekoli, ho theha setšoantšo sa radiographic ea sekoli, se bonts'itsoeng le ho tlaleoa ke filimi ea radiographic, kapa tlhahlobo ea nako ea 'nete le ho shebelloa ke skrine ea fluorescent, kapa ka khaontare ea radiation. Har'a bona, mokhoa oa ho nts'etsapele le ho rekota ka filimi ea radiographic ke mokhoa o sebelisoang haholo, o atisang ho bitsoa tlhahlobo ea radiographic. Setšoantšo se nang le sekoli se bonts'itsoeng ke radiography se na le tlhaiso-leseling, boholo, palo, boemo ba sefofane le phano ea likoli kaofela li ka bonts'oa, empa botebo ba sekoli bo ke ke ba bonahatsoa ka kakaretso, 'me ho hlokahala mehato e khethehileng le lipalo eona. Matsatsing ana, ts'ebeliso ea mekhoa ea li-computer tsa radiographic computer tomography ea hlaha. Hobane thepa e theko e tlase ebile litšenyehelo tsa ts'ebeliso li phahame, e ke ke ea tsebahala hajoale, empa theknoloji ena e ncha e emela tataiso ea nts'etsopele ea mahlale a morao-rao a tlhahlobo ea mahlaseli. Ntle le moo, ts'ebeliso ea sistimi ea X-ray e shebileng lintho tse nyane e batlang e le mohloli oa ntlha e kanna ea felisa methapo e mats'oafo e hlahisoang ke lisebelisoa tse kholo tsa ho tsepamisa maikutlo le ho hlakisa moeli oa setšoantšo. Ts'ebeliso ea sistimi ea litšoantšo tsa dijithale e ka ntlafatsa sekhahla sa lets'oao la lerata la setšoantšo mme ea ntlafatsa ntlafatso ea setšoantšo.

2. Tlhahlobo ea mahlaseli

Liteko tsa Ultrasonic li ka sebelisoa ho hlahloba liphoso tsa kahare. E sebelisa mahlaseli a molumo a nang le matla a phahameng a maqhubu a molumo ho jala kahare ho samente. Ha e kopana le bokaholimo ba kahare kapa litšitiso, e bonts'a mme e fumana liphoso. Boholo ba matla a molumo a bonts'itsoeng ke ts'ebetso ea ts'ebetso le sebopeho sa bokahare kapa sekoli se kahare le pherekano ea acoustic ea seipone sena. Ka hona, liphoso tse fapaneng kapa matla a molumo a bonts'itsoeng ke bokaholimo bo kahare a ka sebelisoa ho bona sebaka, botenya ba lerako kapa bokaholimo ba sekoli. Botebo ba sekoli se latelang. Ultrasonic liteko ke mokhoa o sebelisoang haholo o sa senyeheng oa liteko. Melemo ea eona ea mantlha ke: kutloisiso e phahameng ea phumano, e ka bonang mapatso a manyane; e na le bokhoni bo boholo ba ho kenella 'me e khona ho bona likarolo tse teteaneng. Mefokolo ea eona ea mantlha ke: ho thata ho hlalosa sebopeho sa leqhubu le sa bonahaleng la sekoli se khaotsoeng se nang le boholo ba kemiso le tatellano e mpe; bakeng sa likarolo tse sa rateheng tsa kahare, joalo ka boholo ba lijo-thollo, sebopeho, porosity, litaba tse kenyellelitsoeng kapa li-Precipitates tse ntle, jj. Ntle le moo, standard block test e lokela ho buuoa ka eona ha ho etsoa liteko.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape:Bokaholimo le mekhoa ea tlhahlobo ea boleng bo kahare ea castings

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off