Tlhahlobo ea Boleng bo Hare ea Aluminium Alloy Castings

Lilemong tsa morao tjena, theknoloji ea ho lahla ea aluminium alloy castings e ntlafalitsoe haholo, 'me tlhahiso ea aluminium e ntse e eketseha selemo le selemo. Hona joale e se e sebelisoa haholo le ho feta masimong a libetsa, lifofane, sepakapaka, masela, jj, mme litlhoko tsa boleng ba castings le tsona lia eketseha. thata. Har'a litšobotsi tsohle tsa boleng ba ho betsa, boleng ba kahare ke ntlha ea bohlokoa e khethollang boleng bo akaretsang ba castings. Ka nako e ts'oanang, boleng ba kahare ba castings bo bonahatsa melemo le mathata a theknoloji ea ho lahla. Ka hona, taolo ea liphoso tsa boleng bo kahare ba castings ke sepheo seo litsebi tsa ho lahla li tlamehang ho li rarolla le ho li ntlafatsa kamehla.

1. Khopolo ea boleng ba kahare

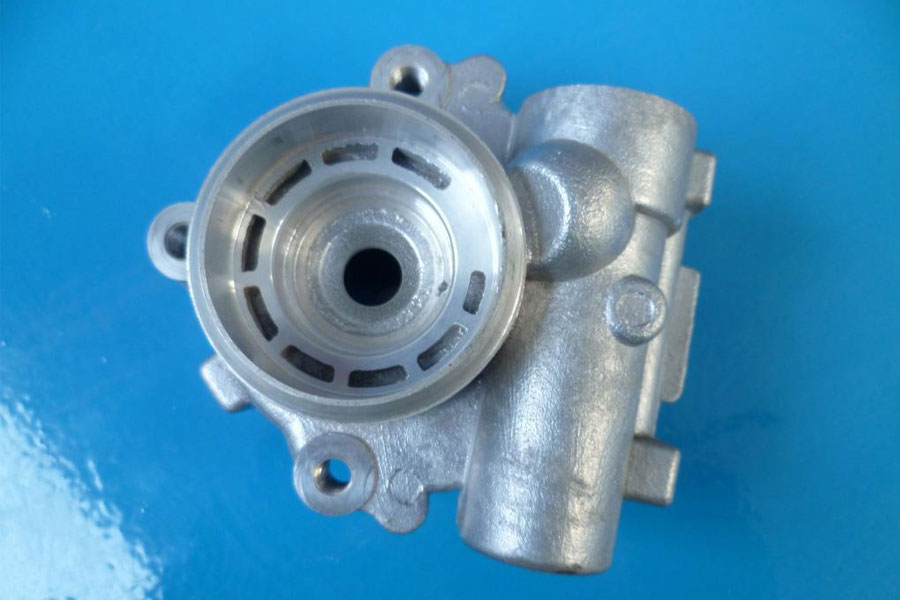

Boleng ba kahare ba likarolo tsa aluminium alloy ka kakaretso bo supa hore na liphoso tse kahare tsa ho betla li fihlela litlhoko tsa litekanyetso tse nepahetseng. Liphoso tsena ka kakaretso li kenyelletsa mapetso, li-pinholes, masoba, masoba a shrinkage, porosity, segregation le inclusions. Ka lebaka la boteng ba liphoso tsena, thepa ea 'mele, thepa ea mochini le sebopeho sa li-castlo hangata li tla fetoha, tse tla tlisa ts'ebeliso ea li-castings. Kotsi e tebileng e patiloeng. Ka hona, boleng ba kahare ke eona ntho e ka sehloohong e laolang tlhahiso le tlhahlobo.

2. Litšobotsi tsa litšitiso tsa boleng ba kahare

- (1) Liphoso tsa boleng ba kahare hangata li patiloe kahare ho castings, tse ke keng tsa hlahlojoa ke mekhoa e tloaelehileng ea pono, mme hangata li hloka mekhoa le lisebelisoa tse ikhethileng ho li phethela.

- (2) Bakeng sa kahlolo ea liphoso tsa boleng ba kahare, bahlahlobi ba hloka ho ba le koetliso ea tsebo ea botsebi le ho ba le boiphihlelo bo itseng bo sebetsang.

3. Litekanyetso tsa hajoale li kentsoe tšebetsong naheng ea heso

Hajoale, ho na le litekanyetso tse peli tsa tlhahlobo ea li-cast cast alloy naheng ea heso, e le 'ngoe ke GB / T9438--1999 (aluminium

Tekanyetso ea naha ea li-castings tsa alloy, e 'ngoe ke HB963-2005 (aluminium alloy castings) maemo a lifofane. Litlhoko tsa liphoso tsa kahare tsa maemo ana a mabeli lia tšoana ebile lia fapana, haholo-holo ka lebaka la liindasteri tse fapaneng le litlhoko tse fapaneng tsa ts'ebeliso, empa litlhoko tsa mantlha le mekhoa ea tlhahlobo li ts'oana, tse hlalositsoeng ka thoko ka tlase.

4. Kemiso ea castings

Litekanyetso tse peli li arola batho ba lahliloeng ka mekhahlelo e meraro ho latela bohlokoa ba bona ts'ebetsong ea ts'ebeliso.

Type Ⅰ castings: jara meroalo e boima, maemo a rarahaneng a ho sebetsa, a sebelisoang likarolong tsa bohlokoa, tšenyo ea castings e tla ba kotsi

Le ts'ebetso e bolokehileng ea mochini kaofela.

Li-castings tsa sehlopha: jara mojaro o mahareng, o sebelisitsoeng likarolong tsa bohlokoa, tšenyo ea castings e tla ama maemo a tloaelehileng a likarolo

Sebetsa mme o bake likotsi.

Class Ⅲ castings: castings e jereng mejaro e bobebe mme e sebelisetsoa likarolo tse akaretsang.

5. GB / T9438—1999 litlhokahalo

(1) Mofuta oa tlhahlobo ea ho lahla Tekanyetso ena e tiisa hore tlhahlobo ea boleng ba kahare e tlameha ho etsoa bakeng sa mofuta oa I castings; bakeng sa mofuta oa II oa mofuta le mofuta oa III, tlhahlobo ea boleng ba kahare e tla etsoa ha feela mosebelisi a hloka tlhahlobo.

(2) Ho boletsoe litekanyetso tse 'maloa tlhahlobo ea boleng ba kahare ea maemo ana

- ①GB / T11346-1989 Aluminium alloy castings X-ray ho nka lifoto tsa tlhahlobo ea pinhole (chitja). Tekanyetso e tiisa tlhophiso ea li-pinholes tse chitja ka likarolo tsa aluminium alloy, tse arotsoeng ka lihlopha tse peli A le B ho latela botenya ba transillumination. Mokhahlelo oa A o loketse li-castings tse nang le botenya bo fetotsoeng ba <13mm, 'me sehlopha sa B se loketse ho bonesoa. Bakeng sa li-castings tse nang le botenya ba 13-50mm, sehlopha ka seng se na le limaraka tse 8 tsa filimi ea litšupiso.

- ②HB6578-1992 standard radiograph ea tlhahlobo ea aluminium le magnesium alloy castings. Tekanyetso e na le tlhaiso-leseling e qaqileng ea liphoso tsa boleng ba kahare, haholoholo ho kenyeletsoa mekhahlelo e 6 ea li-pores, pinholes, shrinkage, porosity, inclusions le khethollo. Sehlopha ka seng se arotsoe ka limaraka tse 8 tsa filimi ea litšupiso.

- ③JB / T7946.3-1999 cast aluminium pinhole e kopantsoeng. Tekanyetso ena e totobatsa mokhoa oa ho hlophisa le mokhoa oa ho lekola bakeng sa tekanyo e tlase ea ho holisa pinhole ea motsoako oa aluminium. Tekanyetso e arola degree ea pinhole maemong a 5.

(3) Mekhoa ea ho hlahloba liteko tsa X-ray tse sa senyeheng; tlhahlobo ea tlhahlobo ea matla a tlase.

(4) Litlhoko tse ikhethileng tsa liteko

- ① Boleng ba ka hare ba ho betsa bo qala ho hlahlojoa ho latela litlhoko tsa tekheniki ea setoro se betliloeng.

- Ha ho na liphoso tsa ho petsoha tse lumelloang ka har'a samente.

- Haeba ho se na melaoana e hlakileng, bakeng sa liphoso tsa pinhole, li-castings tsa Class I, likarolo tsa hydraulic le likarolo tsa moea li lokela ho amoheloa ho latela boemo ba 2 ho standard GB / T11346-1989. Linokoane tse 4 tsa likoti li lumelloa, empa ka kakaretso ha lia lokela ho feta sebaka se hlahlobiloeng. 25% ea eona. Ha tlhahlobo ea ho tiisa moea e fihlela litlhoko tsa moralo, ho amoheloa ho latela boemo ba 3 hoa lumelloa. Li-castings tsa sehlopha li tla amoheloa ho latela li-pinholes tsa boemo ba 3.

- Matšoafo a kahare, masoba a shrinkage, ho holofala le ho kenyelletsoa ha liphoso tse fapaneng li tla kengoa tšebetsong joalo ka ha ho boletsoe ho Tafole 1.

6. Litlhoko tsa HB963-2005

Ho beiloe litekanyetso tse 'maloa tlhahlobo ea boleng ba kahare ea maemo ana:

- (1) GB / T11346-1989 aluminium alloy castings X-ray ho nka lifoto tlhahlobo pinhole (chitja) tlhophiso, tlhaloso tekanyetso ke tšoanang le ka holimo.

- (2) JB / T7946.3-1999 cast aluminium pinhole alloy, tlhaloso e tloaelehileng e ts'oana le e kaholimo.

- (3) HB5395—1988 Aluminium alloy X-ray ho nka lifoto tlhahlobo nako e telele pinhole classification standard. Tekanyetso e arotsoe ka lihlopha tse 3 ho latela botenya ba castings. Sehlopha sa pele se loketse li-castings tse nyane ho feta 13mm, sehlopha sa bobeli se loketse li-castings tse kholo ho feta 13-25mm, mme sehlopha sa boraro se loketse li-castings tse kholo ho feta 25-50mm. Sehlopha ka seng se na le 1, ho na le maemo a 5 ho 2, 3, 4 le 5.

- (4) HB5396-1988 aluminium motsoako X-ray radiography hlahloba spongy porosity tlhophiso tekanyetso; HB5397-1988 aluminium alloy X-ray radiography tlhahlobo e phatlalalitse maemo a khethollo ea porosity. Litekanyetso tsena tse peli li arotsoe ka lihlopha tse 2 ho latela botenya ba sebapali. Sehlopha sa pele se loketse li-castings tse nyane ho feta 13mm, mme sehlopha sa bobeli se loketse li-castings tse kholo ho feta 13-50mm. Sehlopha ka seng se na le 1, 2, 3, 4, le 5 ka kakaretso. Maemo ohle.

Ho tla kenngwa tšebetsong likarolo tse fapaneng tsa ka hare tsa porosity, shrinkage cavity, porosity le kenyeletso ea liphoso tse fapaneng joalo ka ha ho hlalositsoe ho Tafole ea 2.

7. JB / T7946.3-1999 (cast aluminium alloy pinhole) litlhoko

(1) Ha li-pinholes tsa kahare tsa li-castings li hlahlojoa ke mokhoa o tlase oa tlhahlobo ea matla, li-castings tsa Class I kapa likarolo tsa haeteroliki le tsa moea li tla amoheloa ho latela boemo ba bobeli ba maemo, mme boemo ba boraro ba li-pinholes boa lumelloa, empa ka kakaretso e ke ke ea feta sebaka se hlahlobiloeng. 250u. Ha tlhahlobo ea ho tiisa moea e fihlela litlhoko tsa moralo, ho amoheloa ho latela boemo ba 3 hoa lumelloa. Li-castings tsa sehlopha li tla amoheloa ho latela li-pinholes tsa boemo ba 3.

(2) itokisa mokhoa oa disampole tlaase magnification

- Mehlala ea tšepe e tla etsoa sampole ho latela litlhoko tsa metako. Ka kakaretso, likarolo tse teteaneng tsa castings li tla nkuoa.

- RoughSurface roughness Ra≤1.6μm kamora ts'ebetso ea sampole.

- Pele, hloekisa sampole ka peterole, joala kapa acetone, ebe o cheka sampole ka 10% -15% ea sodium hydroxide aqueous solution ho mongobo oa (25 ± 5) ° C, 'me nako ea mananose ke 7-10min.

- Kamora hore sampole e ts'oaroe, e hloekise ka metsi, ebe o tlosa filimi ea kutu holim'a sampole ka 20% ho isa ho 25% acid ea nitric, ebe oa e hloekisa ka metsi ebe oa e omisa.

- ⑤ Ahlola sampole khahlanong le boemo bo tloaelehileng.

8. Litlhokahalo tse ling tsa tlhahlobo ea boleng bo ka hare

- (1) Litaba le mekhoa e hlahang kaholimo ha e sebetse ho castings ea lefu.

- (2) Ha boleng ba ka hare bo hlahlojoa ke mokhoa o tlase oa motlakase, hobane sebaka seo sekoli se leng ho sona ho thata ho se tseba hantle, sebaka sa sampole ea sampole e lokiselitsoeng ha se hakaalo hore ke sebaka se tebileng ho feta sa phoso. Ka hona, ts'epahalo ea tlhahlobo ea mekhoa e tlase ea matla e mpe. Ka kakaretso, tlhahlobo ea X-ray e sa senyeheng ke khetho ea pele bakeng sa tlhahlobo ea boleng ba kahare, 'me tlhahlobo ea matla a tlase e sebelisoa e le tlatsetso.

- (3) Ho hlophisoa ha filimi ea radiographic ho lokela ho etsoa ho latela litlhoko tsa JB / T9217-1999 radiographic flaw method, mme botšo ba filimi e lokela ho ba 1.5-2.0.

- (4) Basebetsi ba etsang tlhahlobo ea radiographic ba tlameha ho tšoara setifikeiti sa boemo ba 2 kapa se phahameng se fanoeng ke ba boholong ba nang le boiphihlelo ba naha mme se loketse mosebetsi oa bona.

- (5) Ha sekoti sa pinhole (selikalikoe) se bonts'itsoeng filimi ea X-ray se le pakeng tsa maemo a mabeli a haufi, se tla hlahlojoa ho latela boemo ba matla.

9. Boiphihlelo ba mosebetsi

- (1) Bahlahlobi ba tlameha ho ithuta haholoanyane ka tsebo ea ho lahla ts'ebetso, ba utloisise ka botlalo lisosa le mefuta ea 'mele ea liphoso tse fapaneng, mme ba ntlafatse bokhoni ba bona ba ho ahlola e le ho etsa likahlolo tse nepahetseng liphosong tse fapaneng.

- (2) Litekanyetso tse boletsoeng ka holimo ke tokomane feela e tataisang, 'me li lokela ho sebelisoa habonolo ha ho etsoa kopo. Mosebetsi le khatello ea maikutlo tsa karolo ka 'ngoe ea karolo ka' ngoe li fapane, 'me mamello ea liphoso le eona e fapane. Bahlahlobi ba lokela ho tseba ts'ebeliso ea hantle ea karolo ka 'ngoe nakong ea ts'ebeliso, hore ba tle ba sebelise maemo hantle.

- (3) Leha likarolo tsa boleng bo holimo li na le ts'ebetso e ntle, ts'ebetso ea ho betsa e thata le ho feta, theko le eona e holimo, mme chai e tlase, e leng se tla baka tšenyo ea litšenyehelo. Ka hona, re tlameha ho theha mohopolo oa bonngoe ba liphapang lipakeng tsa boleng le theko mosebetsing oa rona. Ts'ebetso ea mantlha e tlameha ho netefatsoa, 'me litšenyehelo tsa ho lahla le tsona li lokela ho tsotelloa.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Tlhahlobo ea Boleng bo Hare ea Aluminium Alloy Castings

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off