Likarolo le Litlhokomelo tsa CNC Lathe Machining

Theknoloji ea machining ea li-lathes tsa CNC e ts'oana le ea li-lathes tse tloaelehileng, empa hobane li-lathes tsa CNC li ts'oara ka nako e le 'ngoe le ts'ebetso e tsoelang pele ea machining ho phethela lits'ebetso tsohle tsa ho fetoha, lintlha tse latelang li lokela ho tsotelloa.

1. Khetho e utloahalang ea ho khaola chelete

Bakeng sa ts'ebetso e phahameng ea ho itšeha ka tšepe, lisebelisoa tse lokelang ho sebetsoa, lisebelisoa tsa ho seha le maemo a ho itšeha ke likarolo tse tharo tse kholo. Tsena li supa nako ea machining, sesebelisoa sa bophelo le boleng ba machining. Mokhoa oa ho boloka chelete le o sebetsang o tlameha ho ba khetho e utloahalang ea maemo a ho itšeha.

Lintlha tse tharo tsa maemo a ho itšeha: lebelo la ho itšeha, sekhahla sa phepelo le botebo ba sehiloeng ka kotloloho li baka tšenyo ea sesebelisoa. Ka keketseho ea lebelo la ho itšeha, mocheso oa sesebelisoa o tla nyoloha, o tla baka ho tsofala ha mechini, lik'hemik'hale le mocheso. Lebelo la ho khaola le eketsehile ka 20%, sesebelisoa sa bophelo se tla fokotsoa ka 1/2.

Kamano lipakeng tsa boemo ba fepa le ho roala mokokotlong oa sesebelisoa e hlaha ka bongata bo nyane haholo. Leha ho le joalo, sekhahla sa phepelo se kholo, mocheso oa ho itšeha oa phahama, 'me mokokotlo oa morao o moholo. E na le tšusumetso e fokolang ho sesebelisoa ho feta lebelo la ho itšeha. Leha tšusumetso ea ho itšeha botebong ba sesebelisoa e se kholo joalo ka lebelo la ho itšeha le sekhahla sa phepelo, ha o seha botebong bo nyane ba sehiloeng, sesebelisoa se lokelang ho sehoa se tla hlahisa lera, se tla ama bophelo ba sesebelisoa.

Mosebedisi lokela ho khetha ho itšeha lebelo ho sebelisoa ho ea ka lintho tse sebetsitsoeng, thatafala, seha boemo, mofuta lintho tse bonahalang, sekhahla fepa ka, botebo ba sehiloeng, joalo-joalo

Khetho ea maemo a loketseng a machining e khethoa motheong oa lintlha tsena. Khafetsa, botsitso bo tsitsitseng le ho phela halelele ke maemo a loketseng.

Leha ho le joalo, ts'ebetsong ea 'nete, khetho ea sesebelisoa e amana le ho roala lisebelisoa, liphetoho tse tlil'o sebetsoa, boleng ba bokaholimo, lerata le sehang le mocheso oa machining. Ha ho khethoa maemo a machining, ho hlokahala hore ho etsoe lipatlisiso ho latela maemo a nnete. Bakeng sa lisebelisoa tse thata ho sebetsoa joalo ka tšepe e sa hloekang le lits'epe tse sa keneleng mocheso, ho ka sebelisoa li-coolants kapa li-blades tse thata.

2. Khetho e utloahalang ea lisebelisoa

- Ha o khena, khetha sesebelisoa se nang le matla a phahameng le ho tšoarella hantle ho fihlela litlhoko tsa phepelo e kholo ea morao le phepelo e kholo ha o khena.

- Ha o qeta ho fetoha, khetha lisebelisoa tse phahameng haholo le tse tšoarellang ho netefatsa litlhoko tsa ho nepahala ha machining.

- Bakeng sa ho fokotsa nako ea phetoho ea lisebelisoa le ho nolofalletsa ho beha lisebelisoa, lithipa tse kengoang ka mochini le li-blade tse kopaneng mochini li lokela ho sebelisoa ka hohle kamoo ho ka khonehang.

3. Khetho e utloahalang ea lihlopha

- Leka ho sebelisa lisebelisoa tse akaretsang ho ts'oara mosebetsi, qoba ho sebelisa lisebelisoa tse khethehileng;

- Karolo e behang datum e kopana ho fokotsa phoso ea boemo.

4. Fumana Tsela ea Machining

Tsela ea machining ke motsamao oa pina le tataiso ea sesebelisoa se amanang le karolo nakong ea ts'ebetso ea lesela le laoloang ke index.

- E lokela ho tseba ho netefatsa ho nepahala ha machining le litlhoko tsa ho ba thata holim'a metsi;

- Tsela ea machining e lokela ho khutsufatsoa ka hohle kamoo ho ka khonehang ho fokotsa sesebelisoa sa nako ea maeto e sa sebetseng.

5. Khokahano lipakeng tsa tsela ea Machining le kabelo ea machining

Hajoale, tlasa maemo a hore lathe ea CNC ha e so fihle ts'ebetsong e tsebahalang, lehlakore le fetelletseng ho letho, haholo-holo lekhalo le nang le letlalo le thata la letlalo, le lokelang ho hlophisoa ka lehare le tloaelehileng bakeng sa machining. Ha baetsi ba machining ba tlameha ho sebelisa li-lathes tsa CNC, ba hloka ho ela hloko tokisetso e feto-fetohang ea lenaneo.

6. Lintlha tsa mantlha tsa ho kenya ts'ebetso

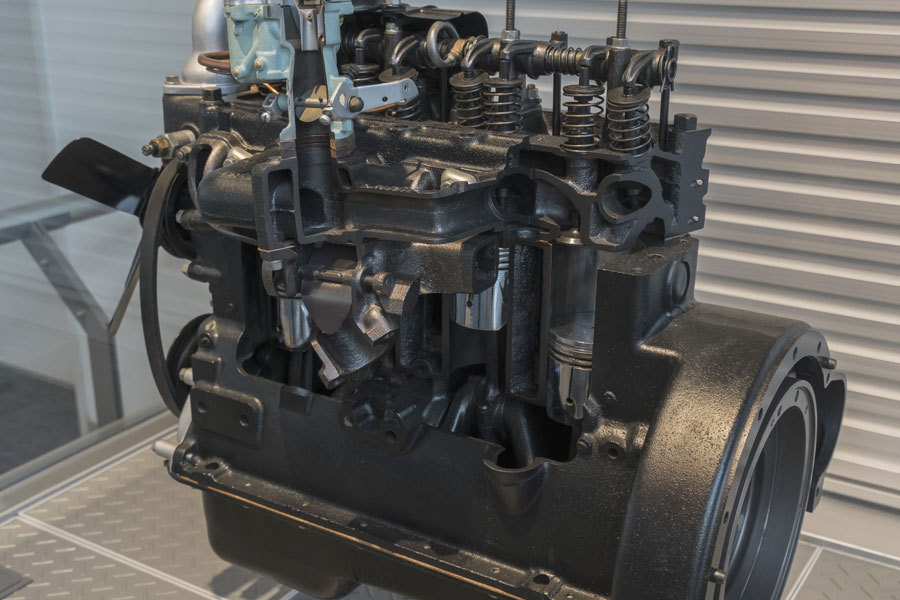

Hajoale, khokahano lipakeng tsa `` hydraulic chuck '' le `` hydraulic clamping cylinder '' e hlokomeloa ka molamu oa thae, joalo ka ha ho bonts'itsoe setšoantšong sa 1. silindara, tlosa tube, 'me u e ntše ka morao,' me u sebelise letsoho le tsamaeang ho tlosa sekontiri se khabisang ho tlosa mokotla.

Bohale ba wiper ho sesebelisoa bo bolela karolo e nyane ea lehare e ts'oanang le ntlha ea sesebelisoa e fatiloeng nqa ea sekhutlo se khelohileng sa bobeli kamora lehare la sesebelisoa. E sebelisoa haholo-holo bakeng sa ho itšeha ha bobeli kamora ho itšeha ha lehare. Ho ntlafatsa bohale bo holim 'a mosebetsi ho sebelisoa haholo thipa bakeng sa ho qeta.

Theknoloji ea machining ea li-lathes tsa CNC e ts'oana le ea li-lathes tse tloaelehileng, empa hobane li-lathes tsa CNC li ts'oara ka nako e le 'ngoe le ts'ebetso e tsoelang pele ea machining ho phethela lits'ebetso tsohle tsa ho fetoha, lintlha tse latelang li lokela ho tsotelloa.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Likarolo le Litlhokomelo tsa CNC Lathe Machining

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off