Ntlafatso le Ts'ebeliso ea Morero oa Die Casting oa ETC Throttle Aluminium Shell Casting Ho ipapisitse le MAGMASOFT

Lilemong tsa morao tjena, ka nts'etsopele ea moruo oa lefatše, tlhoko ea likarolo tsa aluminium ea likoloi e na le tšusumetso e kholo ho litebello tse akaretsang tsa nts'etsopele ea indasteri ea batho ba shoang. Ha ho na le tlholisano ea indasteri e ntseng e mpefala le ho khutsufatsoa ha linako tsohle tsa nts'etsopele ea sehlahisoa, Phano ea lihlahisoa tse tšoanelehang tse fihlelang litlhokahalo tsa bareki ka nako e khuts'oane e tla ba tataiso e ncha bakeng sa nts'etsopele ea likhoebo tse lahlehang; sengoloa sena se sebelisa ts'ebetso ea DOE ea MAGMASOFT ho etsa tlhahlobo ea papiso le papiso ea merero e fapaneng ea ho betsa le mekhahlelo e fapaneng ea tšebetso qalong ea likhechana tsa ETC throttle aluminium. Le ntlafatso, ho khetha tharollo e molemohali, ka tsela eo ho fokotsa potoloho ea nts'etsopele, le ho netefatsa katleho ea teko ea nako e le 'ngoe ea sehlahisoa le tlhahiso le boima ba thepa bo bongata.

Ha re tobane le koluoa ea maemo a leholimo e ntseng e mpefala le mokhoa o ntseng o mpefala oa ho boloka matla, phokotso ea mochini le phokotso ea tšilafalo, indasteri ea makoloi le eona e tla tsoelapele ho nts'etsapele ntlheng ea ho boloka matla, phokotso ea mochini le bohlale; 'me sistimi ea motlakase ea elektroniki e hlahetse tikolohong ena (Elektroniki Throttle Control System bakeng sa ETC e khuts'oane) ke karolo ea bohlokoahali ebile e bohlokoa ea sistimi ea hajoale ea likoloi. E beha maemo a ts'ebetso ea enjene ka ho laola phallo ea moea oa enjene ho netefatsa matla le mafura a koloi. Moruo, molemong oa ho ntšetsa pele litlhoko tsa taolo. Hoa tsebahala hore mokhoping oa elektroniki, e le o mong oa mahlale a mantlha a taolo ea likoloi tse tsoetseng pele le lits'ireletso, o tla ba le menyetla e metle ea ts'ebeliso joalo ka mahlale a mang a tsoetseng pele a taolo ea makoloi.

E le e 'ngoe ea likarolo tsa bohlokoahali tsamaisong ea motlakase ea elektroniki, li-castings tsa likhetla tsa ETC li tla ama ho khoneha le botsitso ba sistimi; Ka hona, tlhahiso ea li-castings tsa alumina tsa ETC tse fihlelang litlhokahalo e tla ba ea bohlokoa haholo. Leqepheng lena, ka thuso ea DOE ts'ebetso ea MAGMASOFT, sethaleng sa pele sa ETC throttle aluminium casing castings, merero e fapaneng ea ho tšolla le lits'ebetso tse fapaneng tsa ts'ebetso ea papiso ea papiso le ntlafatso li etsoa ho khetha morero o motle, ka tsela eo ho fokotsa nts'etsopele potoloho le ho netefatsa sehlahisoa sena hang Katleho ea mofuta oa liteko le tlhahiso le boima ba eona bo bongata.

1 Tlhahlobo ea sebopeho sa sehlahisoa le litlhoko tsa tekheniki

Mokhahlelo oa ho lahla lintho tse bonahalang oa "ETC" throttle aluminium foromeletsoeng ho pampiri ena ke AlSi12Cu1Fe, 'me boholo ba eona ba kemiso ke 111mm * 109mm * 84mm. Boima ba karolelano ena ke 4mm, 'me botenya bo boholo ba lebota ke 13mm. Sebopeho sa sehlahisoa se rarahane haholo. , Ho na le likhopo tse ngata tse ka thoko tse ikhethileng, tse sa sebetseng ho tlatsoa ka tatellano ea aluminium e qhibilihisitsoeng; botenya ba lebota ba maemo a mang bo fapana haholo, 'me sebaka se nang le mabota a masesaane se tla qala ho tiea hore se be boemong bo tiileng, bo lekanang le ho arola motsoako o qhibilihisitsoeng ho ba bangata Sebaka se senyane se koetsoeng se theha sebaka se ikhethileng sa mokelikeli leboteng le teteaneng. Ha ts'ebetso ea tšepe e qhibilihisitsoeng le ts'ebetso ea shrinkage libakeng tsena tse ka thoko tsa mekhahlelo ea mokelikeli li ke ke tsa tlatsetsoa, bothata ba likhohlo tsa shrinkage le porosity li tla etsahala kahare.

Ka lebaka la tikoloho e rarahaneng ea ts'ebetso ea ETC throttle aluminium castings, ho thunngoa hoa hlokahala ho matlafatsa boleng ba li-castings le ho ntlafatsa ho hanyetsa ha tsona; boemo ba sehlahisoa bo lekanang ba ho kenya bo na le litlhokahalo tse phahameng tsa jiometri le tlhakore; Netefatsa hore bophahamo ba modumo oa khatello ea khatello ea 3bar e ka tlase ho kapa e lekana le 3cc / min, mme bophara ba sekoti sa shrinkage sebakeng sa lehae sa sehlahisoa ha se lumelloe ho feta 0.7mm, palo e felletseng ea ha e fete 5, sebaka se seng ka tlase ho 10mm, 'me ha se fete 10% ea sebaka sohle. ; Ka hona, bakeng sa sena lahla-shoa, haholo phahameng haholo foromeletsoeng ditlhoko thulaganyou e moralo hlokahala ho etsa bonnete ba hore boleng hare tsa foromeletsoeng ka kopana le ho amohela moreki maemo a;

2 Product shoa-lahla sekemeng le thulaganyou e moralo moralo

2.1 Product shoa-lahla sekemeng moralo

Sehokelo sa moralo oa heke se bohlokoa ka ho fetesisa sa mahlale a tlhahiso ea li-die-casting se khetholla boleng ba likarolo tse laoloang ke lefu, ts'ebetso ea tlhahiso ea lefu, bophelo ba hlobo, ho kuta le ho hloekisa likarolo tse lahlang, tse tlosang sekhahla sa lits'epe tse lahlang, le matla a bokgoni ba mechine shoa-lahla. E na le tšusumetso e kholo; ka hona, moralo oa boemo ba heke bo utloahalang, botenya ba heke le boholo, le bongata ba heke ke linotlolo tsa ho netefatsa boleng ba ho lahla bo tšoanelehang; ho tloha tlhahlobisong ea litšobotsi tsa sebopeho sa sehlahisoa le boiphihlelo ba moralo oa ts'ebetso, matlo a ETC throttle aluminium Ho na le libaka tse tharo bakeng sa li-castings tse loketseng moralo oa phepelo ea phepelo; ka hona, sengoloa sena se tla rala meralo e meraro e fapaneng ea ho tšolla batho. Ho tsoa tseleng ea ho tlatsa thuto le phallo ea phallo, meralo e fapaneng ea ho tšolla e tla hlahisa litlamorao tse fapaneng, ka hona li hloka ho ipapisa le liphetho tsa software ea ketsiso ea MAGMA le ho hlahlojoa bakeng sa netefatso;

2.1.1 Moralo oa ho tšela moralo o le mong

Joalo ka ha ho bonts'itsoe setšoantšong, palo ea liheke tsa morero oa pele oa ho tšela e entsoe joalo ka likhoele tse habeli, tse hlophisitsoeng ka tatellano sebakeng sa lebota le lehlakoreng la boemo ba ho kenya makoloi le boemo ba ho kenya poleiti ea valve. Punch ea ente e nang le bophara ba 60mm e khethiloe, 'me sekhahla sa lebelo la ente ke 1:14; Molemo oa morero ona oa ho tšela ke hore phallo ea tšepe e qhibilihisitsoeng e batla e le khuts'oane, e nang le phello e nyane ho boleng ba phokotso ea mocheso nakong ea ts'ebetso ea ho tlatsa; moralo oa liteishene tse tharo tsa phallo o loketse phetiso ea khatello le phepelo ea tšepe e qhibilihisitsoeng, e thusang ho fokotsa ts'ebetso ea tlhahiso ea morao-rao Kotsi ea likoli tsa shrinkage e na le phello e itseng e ntle; bothata ba eona ke hore ka lebaka la tlhophiso ea sehlahisoa le mabaka a sebopeho, semathi se tlameha ho qaptjoa ka mehato e itseng le libaka tse nang le mabota a masesaane. Maemo ana a tloaetse ho koahela khase nakong ea ts'ebetso ea ho tlatsa hamorao. Ntle le moo, boemo ba ho kenya enjene ea sehlahisoa sena ha bo sebetsane, 'me moralo oa heke o teng mona, o bonolo ho hlatsoa ka kotloloho mokokotlo oa lebota le kahare le mocheso boemong ba heke. E phahame, ho bonolo ho baka litšitiso tsa lefu le khoholeho ea mohala maemong a ho kenya makoloi; 'me boemo ba heke ha bo sebetsane, bo nang le tšusumetso e itseng e mpe ho khepheng le ho hloekiseng batšoaruoa ba morao-rao;

2.1.2 Moralo oa leano la bobeli la tšollo

Joalokaha ho bonts'itsoe setšoantšong, palo ea liheke tsa morero oa bobeli oa ho tšela e etselitsoe hore e be ngoe, 'me boemo bo entsoe ka lehlakoreng la lesoba le chitja la boemo ba ho kenya poleiti. Punch ea ente e nang le bophara ba 60mm e khethiloe, 'me sekhahla sa lebelo la ente ke 1:30; ho tšela hona Molemo oa tharollo ke hore semathi se ka etsoa ka phetoho e batlang e boreleli, e leng molemo ho tlatseng tšepe e qhibilihisitsoeng mme e fokotsa ts'ebetso ea khase e koahelang nakong ea ho tlatsa, mme e fokotsa likoli tse bakoang ke khase tlisoa ke semathi; heke e reretsoe ka boemo ba holim sebetsa. Fokotsa boima ba mosebetsi oa ho faola le ho hloekisa lisepa, le ho fokotsa litšenyehelo tsa tlhahiso; Heke e le 'ngoe ea likhoele e ka thibela likhoele tse ngata tsa tšepe e qhibilihisitsoeng hore e se ke ea kenella kahare ebe e baka vortex, entrainment le oxidation. Bothata ke hore e pheletsong ea heke. Phello ea phepo ea sebaka se chesang ha e hlile ha e eo, 'me merero e meng e thusang ea ho fepa e hloka ho tsotelloa; 'me phallo ea tšepe e qhibilihisitsoeng e batla e le telele, e nang le tšusumetso e itseng mochesong oa tšepe e qhibilihisitsoeng nakong ea ts'ebetso, mme liphoso tsa thepa e batang li ka hlaha libakeng tsa lehae. ;

2.1.3 Moralo oa leano la boraro la tšollo

Joalokaha ho bonts'itsoe setšoantšong, palo ea liheke tse tharo molemong oa ho tšela e etselitsoe hore e be ngoe, 'me boemo bo behiloe ka lehlakoreng la lesoba le chitja la boemo ba ho kenya poleiti ea valve. Punch ea ente e nang le bophara ba 60mm e khethiloe, 'me sekhahla sa lebelo la ente ke 1:30; Molemo oa heke ke hore heke e entsoe ka boemo ba bokaholimo ba ts'ebetso, bo ka fokotsang mosebetsi oa ho kuta le ho hloekisa mochini o lahlang, le ho fokotsa litšenyehelo tsa tlhahiso. Heke e entsoe ka setaele sa ho tlatsa, se ka fokotsang leqeba le tlatsitseng la aluminium e qhibilihisitsoeng le tahlehelo ea mocheso oa aluminium e qhibilihisitsoeng. Chelete e fokotsehile; sebaka se pakeng tsa litebele le heke se khuts'oane, se ka netefatsang phetiso e atlehang ea khatello ea litebele; Bothata ke hore maemo a ntlafatso ea tlhahiso ea morao-rao a futsanehile, 'me boleng ba sehlahisoa bo ke ke ba ntlafatsoa ka ho fetola mekhahlelo ea die casting.

Moralo oa paramethara ea ts'ebetso ea sehlahisoa sa Product

Ho latela tlhahlobo ea sebopeho le litlhoko tsa boleng tsa ETC throttle aluminium castings, sehlahisoa sena se sebelisa mochini o lahlang li-350T, hlobo e le 'ngoe le moralo oa sekoti,' me khatello ea ho lahlela e behiloe ho 100MPa ho netefatsa phepelo e lekaneng ea ho fepa le ho fokotsa ponahalo ea liphoso tsa shrinkage nakong e tlang. ; Mocheso o tšollang o etselitsoe ho ba 660-680 ℃, 'me li-cores tsa hlobo tse tsamaeang le tse tsitsitseng li futhumalitsoe ho 180-200 ℃; nakong ea ho tlatsa, lebelo le tlase le behiloe ho 0.25m / s, lebelo le phahameng le behiloe ho 3m / s, mme lintlha tse fetohang ka lebelo le phahameng li lekoa ho 340mm le 350mm ka ho latellana. Boemo bo sebelisetsoa ho fumana boemo ba botsitso ba tšepe bo qhibilihileng ka ho fetesisa le boemo bo bonyenyane haholo ba morao-rao le ba entrainment; ka nako e ts'oanang, sistimi ea taolo ea mocheso oa ho futhumatsa mohala le ho futhumatsa ha ntlha e sebelisetsoa ho netefatsa botsitso bo botle ba hlobo ea hlobo;

3. Ketsiso ea lipalo le tlhahlobo ea papiso ea tlanya e le 'ngoe e tlisoang

Tsamaiso ea ho tlatsa le ho tiisa ts'ebetso ea ho betsa e na le tšusumetso ea makhabane boleng ba samente, empa kaha lits'ebetso tsena tse peli li phethetsoe ka sekoting se koetsoeng le se sa bonahaleng nakong ea tlhahiso, ho ke ke ha khoneha ho boloka le ho sekaseka ka kotloloho kapa ka kotloloho, kahoo boleng ba pejana Ho etsisa ho bohlokoa haholo; ka ho sebelisa ts'ebetso ea MAG khoutu ea DoE, tlanya ha 'ngoe ho merero e meraro e kaholimo ea ente le maemo a mabeli a liteko tse potlakileng, palo ea nako e le' ngoe ea merero e mengata, ponelopele e potlakileng ea sebaka sa sekoli, mme o fumane Morero o motle oa ho o ntlafatsa boleng ba kahare ba lihlahisoa, ho fokotsa linako tsa nts'etsopele, le ho fokotsa litšenyehelo tsa tlhahiso.

3.1 Ketsiso le tlhahlobo ea ts'ebetso ea ho tlatsa

Joalokaha ho bontšitsoe ho Setšoantšo sa 3, sephetho sa ketsiso sa mola oa pele oa setšoantšo ke nako ea ho tlatsa. Boemo ba ho switjha ka lebelo le phahameng la merero e meraro ya pele ke 340mm, mme nako ya ho tlatsa e kgutshwane. Boemo ba ho chencha ka lebelo le phahameng ba merero e meraro ea ho qetela ke 350mm, 'me nako ea ho tlatsa e telele. Sebaka se khanyang sa 'mala ke boemo ba ho qetela ba ho tlatsa ba merero e meraro ea ente;

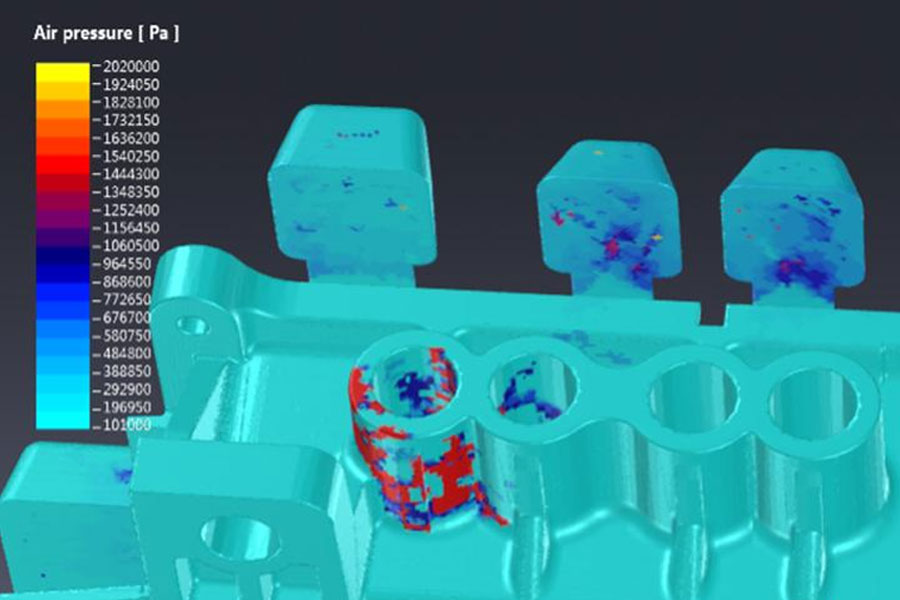

Sephetho sa mola oa bobeli oa setšoantšo ke sephetho se phahameng sa khatello ea moea. 'Mala o khanyang oa sephetho sa ketsiso ke boemo bo phahameng ba khatello ea moea, mme kotsi ea stomata e holimo. Ha ho bapisoa, ho fumanoe hore boleng ba khatello ea moea ea Morero 2 le Morero 5 bo tlase haholo, mme kotsi ea stoma e nyane haholo;

Sephetho sa mola oa boraro oa setšoantšo ke sephetho sa bophahamo ba modumo. Sephetho sa ketsiso se na le moea o phahameng o maemong a khanyang le kotsi e kholo ea ho dutla. Ha ho bapisoa, ho fumanoe hore boleng ba moqolo oa bobeli le oa bohlano oa morero o tlase haholo, mme kotsi ea ho dutla e batla e le nyane;

Tlhatlhobo e felletseng ea sephetho sa ketsiso ea ts'ebetso ea ho tlatsa e bonts'a khatello ea moea le ho kenella ha khetho ea bobeli le ea bohlano li tlase, mme boemo ba bobeli ba lebelo le phahameng bo ea pele, 'me nako ea ho tlatsa e khuts'oane, ka hona bophahamo ka kakaretso ke hantle.

3.2 Ketsiso le tlhahlobo ea ts'ebetso ea ho tiisa

Joalokaha ho bontšitsoe ho Setšoantšo sa 4, sephetho sa mola oa pele oa setšoantšo ke tšimo ea mocheso o batang. Liphetho tsa ketsiso li bontša hore nako ea ho tiea ha heke e kahare ea morero 3 le morero oa 6 ke e telele ka ho fetesisa, mme nako ea khatello ea phepelo ke e telele ho feta; morero oa 1 le morero oa 4 ke tsa bobeli, 'me nako ea ho fepa khatello ke bohareng; nako ea ho tiisa ea heke e ka hare ea morero 2 le morero oa 5 Nako e khuts'oane le e khuts'oane ho feta ea khatello;

Sephetho sa mola oa bobeli ke nako e atlehang ea ho fepa lenonyeletso le chesang, 'me' mala o khanyang oa sephetho sa ketsiso ke boemo ba lenonyeletso le chesang la sehlahisoa, e leng boemo boo sebopeho sa sehlahisoa se batlang se le motenya 'me qetellong se tiileng. Libaka tsa mananeo a 1, 2, 4 le 5 ha li ts'oane. Morero 3 le Morero 6 li na le liheke tse ka hare tse batlang li le tenya, kahoo haeba libaka tse peli tse chesang hekeng e kahare li hokahane, libaka tse chesang li tla eketseha;

Sephetho sa mola oa boraro ke sephetho sa shrinkage. Ka lebaka la khatello ea phepo, boemo ba shrinkage ba scheme 3 le scheme 6 ke bo bonyenyane haholo, mme ho fokotseha ha merero e meng e mene ho ts'oana. Ha ho bapisoa, scheme 2 le scheme 5 li batla li le nyane tse ling.

Ho ipapisitsoe le tlhahlobo ea liphetho tsa ketsiso ea ts'ebetso ea ho tiisa, sekoti sa shrinkage sa morero oa 3 le morero oa 6 ke o monyane ka ho fetesisa, empa lenonyeletso le chesang hekeng e kahare ke lona le leholo ka ho fetesisa, 'me kopane ea mocheso le sephetho sa morero. 2 mme morero oa 5 o batla o le betere.

4. Netefatso ea tlhahiso

Tlhatlhobo e akaretsang ea ketsiso, mokhoa oa bobeli oa ho betsa o sebelisoa bakeng sa tlhahiso. Setšoantšo sa 5 se bonts'a setšoantšo sa tlhahiso ea ETC throttle aluminium casing castings; ka tlhahlobo ea sehlahisoa le tlhahlobo ea X-ray, ho lahla ha hoa ka ha bontša li-pores le liphoso tsa shrinkage tse fetang litlhoko tsa boleng ba moreki; hape E fetisitse litlhoko tsa lehlakoreng la ho dutla, ha ho na ho dutla ho etsahetseng; bokaholimo ba ho betsa bo ne bo khanya, ho se na liphoso tse hlakileng tsa thepa e batang le ho tšolleloa ho sa lekanang ho hlahileng, phello e akaretsang e fihletse litlhoko tsa tlhahlobo ea boleng ba moreki, le tlhahiso e boreleli ea bongata.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape:Ntlafatso le Ts'ebeliso ea Morero oa Die Casting oa ETC Throttle Aluminium Shell Casting Ho ipapisitse le MAGMASOFT

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off