Lost Foam foromeletsoeng Karolo ea Likarolo tse Kholo tsa 'Mapa o Metsoalle

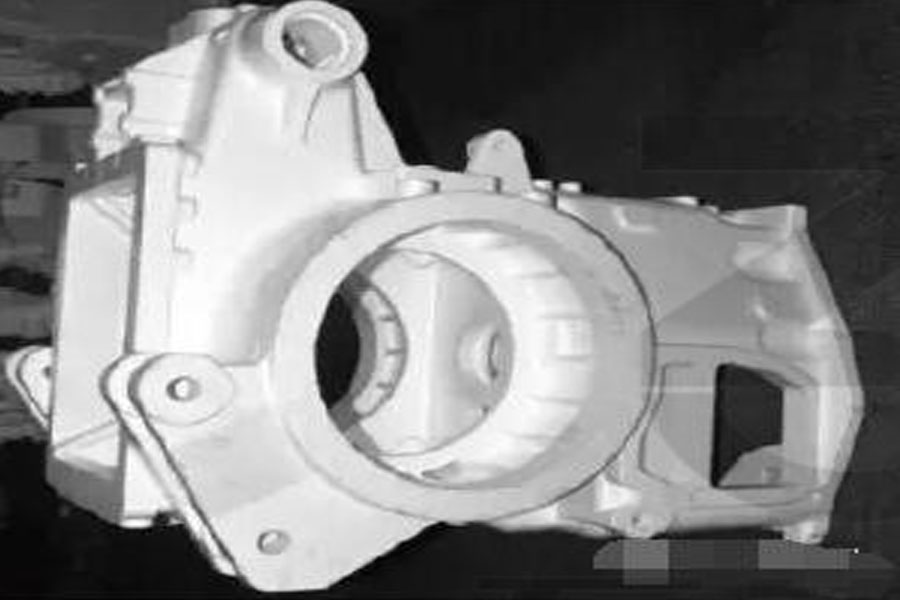

Terekere e mabili a matla e ikemetseng e ntlafalitsoeng ke China YTO Group Co., Ltd. e na le mokotlana o moholo oa phetisetso ea morao le sebopeho se rarahaneng haholo (bona Setšoantšo sa 1), se nang le boholo ba 1050mm × 925mm × 750mm, le bophahamo ba 'nete ba ho lahla hoo e ka bang 0.085m3. Boima ba thuto ke ba 615kg.

Tlhaisong ea liteko ea karolo ena ea khetla, ho ile ha sebelisoa theknoloji e lahlehileng ea foam. Karolo e nang le marako a tšesaane e nang le molumo o moholo joalo le boima le sebopeho se rarahaneng e hlahisitsoe ke mahlale ana, mme ho na le litlaleho tse fokolang likoranteng le limakasineng tse teng. Ka lihlahisoa tse ngata tsa liteko, ho fumanoe hore ho lahla kamora ho tšollela ho na le mathata a mararo a latelang: e 'ngoe ke phetoho ea ho betsa, e etsang hore ho be thata ho netefatsa ho nepahala ha tlolo; ea bobeli ke hore lehlabathe le apereng tšepe le thehoa habonolo kahare ea kahare, e leng ho eketsang bothata ba ho hloekisa; ea boraro ke bokaholimo ba ho betsa. Ho hlahisoa likoli tse ntšo tsa k'habone, ho etsa hore ho betloa ho hlakoloe nakong ea ts'ebetso.

Ho na le lintlha tse ngata tse bakang likoli tse hlahang kaholimo, empa seaparo se bapala karolo ea bohlokoa ts'ebetsong eohle e lahlehileng ea foam. Haeba seaparo ka botsona se sa etsoa hantle 'me tšebetso ea ho se roala e le mpe, e ke ke ea rarolla bothata ka nepo, empa e tla baka likoli.

- (1) Pente e na le bobebe bo bobebe. Pente e sebelisitsoeng tekong ea tlhahiso ke pente e thehiloeng metsing, 'me hlobo e tšoeu ea nyeoe e ka morao e entsoe ka foam ea polystyrene, e seng bonolo ho kolobisoa kapa ho kenella ka pente e thehiloeng metsing. Ho se boloke metsi hantle, ho roala hampe, le pente li ke ke tsa leketla holim'a hlobo e tšoeu kapa tsa khomarela hampe. Ka lehlakoreng le leng, e tla etsa hore mohlala o koahetsoe makhetlo a mangata, 'me tloaelo ea hlobo e tšoeu ea ho holofala nakong ea mekhahlelo e mengata ea ho roala le ho omisa e tla eketseha. ; Ka hlakoreng le leng, e tla etsa hore ho se lekane barbotage botenya, esita le barbotage discontinuous, 'me pepesehela ea moo ea hlobo tšoeu tla etsa hore lehlabathe khomarel likoli. Ka lebaka la boholo bo boholo ba hlobo e tšoeu ea nyeoe ea phetisetso e ka morao (bona Setšoantšo sa 2), boea bo hlahisoang nakong ea ho qoela bo tla etsa hore ponahalo e robehe. Ka hona, ts'ebeliso ea hlobo e tšoeu e sebelisa motswako oa ho fafatsa le ho roala lesira. Thepa ea ho roala e beha litlhoko tse phahameng pele.

- (2) Matla a ho roala a tlase. Hlobo e tšoeu ea nyeoe ea phetisetso e ka morao e na le molumo o moholo, lebota le lesesaane le letsoalo le tlase. Hlobo eohle e tšoeu ha e na ho tiea ka tlhaho. Matla a khomarelang a ho roala ka mocheso oa kamore ha a phahame, 'me ho bonolo ho etsa hore seaparo se senyehe ebe se senya nakong ea ho omisa le ho sebetsana le paterone. E ke ke ea netefatsoa hore paterone e na le khanyetso e lekaneng ho deformation nakong ea ts'ebetso ea lehlabathe le ts'ebetso ea ho kopanya, e hlahisang ho fetoha; matla a phahameng a mocheso oa ho roala ha a phahame, tlasa maemo a phahameng a mocheso, ho ke ke ha khoneha ho thibela tšenyo ea seaparo nakong ea ho betla le ho etsa ts'ebetso ea tšepe e qhibilihisitsoeng, e baka ho putlama, ho khomarela lehlabathe le liphoso tse ling, hore tlhakore tlhakore le boleng bo holimo ba ho betsa ho ke ke ha netefatsoa; matla a sallang a setseng a ho roala a tla baka Ha ho bonolo ho hloekisa seaparo ka holim'a samente kamora ho tšela.

- (3) The permeability moea oa barbotage e futsanehileng. Hobane lisebelisoa tsa sehlahisoa sa teko ke HT250, tekong ea tlhahiso, mocheso o tšollang o laoloa ho 1380 ~ 1430 ℃, ha thepa ea hlobo e tšoeu e le foam ea polystyrene, e maemong a mocheso oa 1350 ~ 1550 ℃. , E qala ho peperana ka potlako, e chese le ho fofonela, 'me lipolima tse nang le limolek'hule tse tlase li petsoha ka potlako,' me bongata ba haedrojene le khabone e sa lefelloeng boa senyeha. Haeba moea o kenella molemong oa ho roala o le bobebe, lihlahisoa tse ngata tsa pyrolysis li ke ke tsa romelloa hantle ka har'a seaparo, se tla baka masoba ha a betoa; haeba seaparo se sa khone ho monya masala a hlahisitsoeng nakong ea ho chesa foam ea polystyrene, ho lahla ho tloaetse ho ba le likoli tsa masale a kenyelletsang khabone.

Morero oa ho lahla liphoso tse bakiloeng ke ho roala ka morao botekgeniki, e shebile nts'etsopele ea libopeho tsa ho roala 'me ka nako e ts'oanang e hlahloba ts'ebetso ea ho kopanya liaparo.

Ntshetsopele ya formulations barbotage

1. Sebopeho le khetho ea thepa

- (1) Phofo e sa sebelisoeng e lahliloeng ke foam e na le litlhokahalo tse tharo tsa bohlokoa bakeng sa khetho ea phofo e qhekellang: Pele, boholo ba phatsa ea phofo e sa ts'oanelang e lokela ho ba mahoashe, empa haeba e le mahoashe haholo, khanyetso ea lehlabathe ea seaparo e tla ameha, mme lehlabathe le lwantshang thupa le tla elwa hloko. Le e phahameng permeability moea, khetha phatsa boholo ba 0.08 ~ 0.071mm (180/200 letlooeng); ea bobeli, ho potoloha sebopeho sa phofo e hanyetsang, ho betere, phofo e chitja e na le moea o kenang hantle; ea boraro ke hore phofo e hanyetsang e na le moea o kenang hantle; Lihlahisoa tsa pyrolysis tsa polasetiki ea foam li tlameha ho ba le matla a adsorption. E le hore ho ntlafatsa tshebetso ka kakaretso ea barbotage, phahameng ea alumina bauxite clinker phofo (phatsa boholo 0.08mm) le mica phofo (phatsa boholo 0.071mm) ba khethoa e le phofo refractory. Phofo e phahameng ea alumina bauxite e na le sebopeho se nang le lithollo tse lekaneng, se ka ntlafatsang moea o kenang oa seaparo le matla a adsorption a lihlahisoa tsa foam pyrolysis; phofo ea mica ke silicate e khabisitsoeng e tsoang mohahong, e sa keneleng mocheso ebile e sa keneng, ts'ebetso ea ho kenya lintho hantle, ho tenyetseha hantle le ho tenyetseha, ho eketsa karolo e itseng ea phofo ea mica ho bararo ho ka ntlafatsa tšireletso, ho kenella hoa moea o phahameng le ho sinterability ea ho roala.

- (2) Binder EPC barbotage binder ke karolo ea bohlokoa ea barbotage ea. Ha e fane feela ka matla le ho ata ha seaparo, empa e ama le ho kenella hoa moea le ho emisoa ha seaparo. Hangata, ho kopana ha binder e sa tloaelehang le binder ea manyolo ha ho netefatse feela matla a ho roala ka mocheso oa mohatsela le mocheso o phahameng, empa hape e ntlafatsa katleho ea moea oa seaparo. Ka lebaka la molumo o moholo le lebota le tšesaane la nyeoe ea phetisetso le nyeoe ea phetisetso, molemong oa ho netefatsa ho tiea, matla le moea o kenang molemong oa ho roala, mefuta e meraro ea likhomaretsi, latex e tšoeu, starch ea starch le phofo ea RSF e nang le phello ea metsi. khethiloe. Moemeli ea tlamang o tsoakane mme o sebelisoa ka bongata bo itseng. Haholo-holo khetho ea phofo ea RSF e ntlafatsa ka thata botsitso, matla le moea o lumellang moea hore o roale hantle.

- (3) Mosebetsi o ka sehloohong oa mokelikeli oa sesebelisoa ke ho hasanya phofo e hanelang ho eona. Ha ho lahleloa foam e lahlehileng ho nahanoa ka litlhoko tsa ts'ireletso ea tikoloho, ts'ebeliso, ho omisa, ho hlahisa khase le theko, ho bonolo ho sebelisa metsi joalo ka mokelikeli oa thepa. Etsa hore barbotage e fumane ho fanyeha hantle, borashe le thepa e sa phallang.

- (4) Ho fanyeha ha mochini o emisang moemeli ho ama ka kotloloho bokhoni ba ho roala le boleng ba ho roala, hape ho ama ts'ebetso ea tšebetso ea ho roala. Ka lebaka la boholo ba mahoashe a phofshoana le ponahalo e kholo ea seaparo, ha ho lokisoa liaparo, Lithium bentonite le attapulgite li sebelisoa e le mahlahana a emisang. Lithium bentonite le attapulgite li ka theha sebopeho sa marang-rang se nang le mahlakore a mararo ka metsing. Motsoako oa tse peli o ka ntlafatsa ho fanyeha ha seaparo le ho ntlafatsa rheology le ts'ebetso ea ts'ebetso ea ho roala.

Hona le mefuta e 3 e latelang ea litlatsetso tse thusang.

- EfDefoamer. E sebelisetsoa ho felisa bubble e thehiloeng ka ho hlohlelletsa nakong ea tlhahiso ea seaparo.

- E sebetsa hantle. Morero o ka sehloohong oa ho kenyelletsa palo e nyane ea motho ea sebetsang ho seaparo ke ho ntlafatsa khokahano ea seaparo ho paterone le ho tsamaisa ts'ebeliso.

- ③ Likokoana-hloko. Bakeng sa ho nolofatsa polokelo le ts'ebeliso ea nako e telele ea pente, ho eketsoa pente e itseng ea paballo, e ka thibelang pente ho hlobo, ho senyeha le tahlehelo ea viscosity sehleng ka mocheso o phahameng.

Lipatlisiso ka ts'ebetso ea ho roala

1. Mokhoa oa liteko oa ts'ebetso ea ho roala

- (1) Botenya ba pente bo lekanyetsoa ke 100mL e fumaneng lengolo la silindara le lekanyang mokhoa oa ho bona hore na pente e joang.

- (2) Teko ea ho emisa botsitso ea seaparo e amohela silinda sa 100mL se fumaneng lengolo la ho fumana mokhoa oa 6h oa sekhahla.

- (3) Meter ea Baume (e sebelisoang sebakeng sa tlhahiso) e sebelisetsoa ho leka mohopolo oa pente.

- (4) Teko ea botenya ba koae: Qoela sampole ea polasetiki e lokisitsoeng ea 100mm × 100mm × 12mm (ka ho khetheha ho tsoa hlobo e soeufalitsoeng), e qoelise ka pente e tsoakiloeng bakeng sa bo-10, e ntše, 'me ue kenye ka 50 ° C motlakase Kamora ho omisoa ka lihora tse 3 ka lebokoseng la ho omisa, ntša teko ea liteko ebe u metha botenya ba seaparo.

- (5) Ho kenella hoa mocheso o phahameng oa mocheso le matla a phahameng a mocheso oa ho roala ho amohela liteko tse sebetsang ka bongata tse entsoeng ke Huazhong University of Science le Technology.

2. Ts'ebetso ea koae e lahlehileng ea foam e ipapisitse le moralo o boletsoeng kaholimo

Mokhoa oa ho itokisa oa ho roala

Liteko tse ngata li fumane hore ts'ebetso ea ho roala ha e amane feela le sebopeho sa ho roala, empa hape e amana le ts'ebetso ea ho rala. Mokhoa o ts'oanang oa ho rala le ho etsa meralo e fapaneng li na le tšusumetso e kholo ts'ebetsong ea seaparo. Ho fumana sekoaelo ka ts'ebetso e ntle ea ts'ebetso, ts'ebetso ea ho itokisa e lokela ho netefatsa hore moemeli oa thixotropic, binder le solvent li qhalakane ka botlalo, 'me li na le adsorption e matla le phofo e hanyetsang, e le hore likarolo tsa seaparo li kopane ka botlalo, hore barbotage na thixotropy molemo le Coatability.

1. Lisebelisoa tsa ho penta pente

Mohlahlobi oa lebelo le phahameng haholo, moqapi oa lehlabathe oa mofuta o phahameng.

2. Mokhoa oa ho itokisa

- (1) Ho itokisa ha seaparo se metsi se metsi Metsotso e 5-10, e tla siloa 'me e kenngoe mekotla hore e tle e sebelisoe hamorao.

- (2) Ho itokisa ha pente ea slurry. Lekanya palo e itseng ea pente ea metsi a metsi, ho latela karolelano ea phofo le metsi ea 1: 0.6 ho isa ho 0.7, lekanya palo e itseng ea metsi ka nkhong ea ho kopanya pente, ebe o beha bakete ea pente tlasa sehatisi se hasang ka lebelo le phahameng. Bulela mochini o kopanyang oa lebelo le phahameng, ebe o eketsa pente ea phofo e metsi e lekiloeng. Hlohlelletsa ka lebelo le phahameng (800 ~ 900r / min) metsotso e ka bang 40, ebe o hlohlelletsa ka lebelo le tlase (< 600r / min) lihora tse 2. Kamora ho kopanya pente ea junifomo, e siee lihora tse 24, E holile ka botlalo, 'me mongobo o ka fetoloa ho latela litlhoko tsa Baume degree nakong ea ts'ebeliso.

fihlela qeto e

- (1) Phaella ka ho re ka palo e loketseng ea phofo mica ho phofo refractory ka ntlafatsa barbotage le ho fanyeha thepa ya barbotage ho. Ha paterone e sebelisoa, seaparo se motenya se ka fumanoa ka nako e le 'ngoe, ho fokotsa palo ea linako tsa ho penta paterone le ho nolofatsa Ts'ebetso ea tlhahiso e ntlafalitsoe; ho eketsa palo e nepahetseng ea phofo ea mica ho fumana botenya bo tšoanang ba ho roala, boima ba 'mele ka botlalo kamora ho roala bo fokotsoe, bo ka netefatsang ho tiea le matla a paterone; ho eketsa palo e loketseng ea mica phofo ho fokotsa bauxite phofo barbotage Sintering mocheso, barbotage ke ho le bonolo ho ebola theoha ho lahla ka mor'a hore a tšollele, 'me bokaholimo ba ho betsa e boreleli le e hloekileng.

- (2) Ka foromo ea ho roala, ho eketsa sekontiri se metsi sa RSF, khokahano ea seaparo ho mofuta oa foam e hlakile, mme matla a ho roala a ntlafalitsoe, a bohlokoa haholo ho netefatsa ho tiea le matla a paterone. .

- (3) Lithium bentonite le attapulgite li sebelisoa hammoho. Ho latela ts'ebetso ea ho kopanya e hlophiselitsoeng liaparo tse lahlehileng tsa foam, ho netefalitsoe hore ho fanyeha, thixotropy le thepa ea ho roala li ntlafalitsoe haholo. Boima ba lera ke junifomo, ho qoba litšitiso tsa lehlabathe tse bakoang ke ho pepeseha ha hlobo e tšoeu.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Lost Foam foromeletsoeng Karolo ea Likarolo tse Kholo tsa 'Mapa o Metsoalle

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off