Stainless Steel Silica Sol le Ts'ebetso e nepahetseng ea ho lahla

- Ts'ebetso ea silica sol ke ea se bitsoang thoto ea matsete. Ke mokhoa oa ho lahla o tlase kapa o sehang. Ke mokhoa o tsoileng matsoho oa ts'ebetso ea mahlale indastering ea metheo ebile e na le likopo tse fapaneng. Ha e loketse feela ho lahla mefuta e fapaneng le lits'epe tse kopantsoeng, empa hape e hlahisa li-castings tse nang le ho nepahala ho phahameng ka ho fetesisa le boleng ba bokaholimo ho feta mekhoa e meng ea ho betsa, esita le ho rarahana, ho futhumatsa mocheso o phahameng, le ho thatafalloa ho sebetsa ho leng thata ho li lahla ka mekhoa e meng ea ho betsa. E ka lahleloa ka ho lahla matsete.

- Ts'ebetso ea matsete e hlahisoa motheong oa boka ba khale ba boka. Joaloka tsoelo-pele ea khale, China ke e 'ngoe ea linaha tsa pele ho sebelisa theknoloji ena. Ho tloha khale joalo ka makholo a lilemo a BC, batho ba khale ba sebetsang ba naha ea rona ba thehile theknoloji ena e lahlehileng ea boka ba linotsi, e neng e sebelisetsoa ho etsa mekhoa le libapali tse fapaneng tse ntle. Zhong Ding, lisebelisoa le lihlahisoa tse ling, joalo ka lebitla la Zeng Hou Yi nakong ea selemo le hoetla. Motheo oa lebitla la lebitla la Zenghou Yi le entsoe ka likhohlo tse 'maloa tse hokahantsoeng, tse hokahantsoeng qetellong ho isa qetellong le ho thekesela holimo le tlase ho theha paterone e koahetsoeng ka mekato e mengata. Meetso ena ho thata ho e hlahisa ka mekhoa e tloaelehileng ea ho betsa, empa e entsoe ka mokhoa o lahlehileng oa boka. Bokgoni bo ka nka monyetla ka ho hloka matla ha boka ba parafini le bonolo ba ho ngola. Lisebelisoa tse tloaelehileng li ka sebelisoa ho ngola mesebetsi ea matsoho e entsoeng ka boka ba parafine bo ts'oanang le lebitla la lebitla la Zenghou Yi, ebe o eketsa sistimi ea ho tšela, ho roala, ho theola metsi le ho tšela. U ka fumana poleiti e ntle ea lebitla la Zeng Hou Yi.

- Ts'ebeliso e sebetsang ea mekhoa ea sejoale-joale ea ho betsa matsete tlhahisong ea liindasteri e ne e le lilemong tsa bo-1940. Nts'etsopele ea lienjineri tsa sefofane ka nako eo e ne e hloka tlhahiso ea likarolo tse sa keneleng mocheso tse kang li-blade, li-impeller, li-nozzles, jj., Ka libopeho tse rarahaneng, litekanyo tse nepahetseng le bokaholimo bo boreleli. Hobane lisebelisoa tsa alloy tse sa keneleng mocheso li thata ho mochini mme likarolo li rarahane ka sebopeho, ho ke ke ha khoneha kapa ho ba thata ho etsoa ka mekhoa e meng. Ka hona, ho hlokahala hore ho fumanoe mokhoa o mocha oa ho etsa lintho ka nepo. Ntlafatso ea mekhoa ea sejoale-joale ea ho betsa matsete e fihletse nts'etsopele ea bohlokoa motheong oa botaki ba khale. Ka hona, nts'etsopele ea indasteri ea lifofane e khothalelitse ts'ebeliso ea ho betsa matsete, 'me ntlafatso e tsoelang pele le phetheho ea ho lahla matsete le hona ho thehile maemo a matle bakeng sa indasteri ea lifofane ho ntlafatsa ts'ebetso ea eona.

- Naha ea heso e ile ea qala ho etsa tšebetso ea ho tsetela ho tsetelo ho tlhahiso ea indasteri ho li-1950 le li 1960. Ho tloha ka nako eo, ts'ebetso ena e tsoetseng pele ea ho lahla e ntlafalitsoe haholo, 'me e sebelisitsoe haholo ho lifofane, likoloi, lisebelisoa tsa mochini, likepe, lienjine tse tukang tsa kahare, li-turbine tsa khase, lisebelisoa tsa likhokahanyo, libetsa, lisebelisoa tsa bongaka le lithipa le liindasteri tse ling tsa tlhahiso. Ho etsoa ha bonono bo botle.

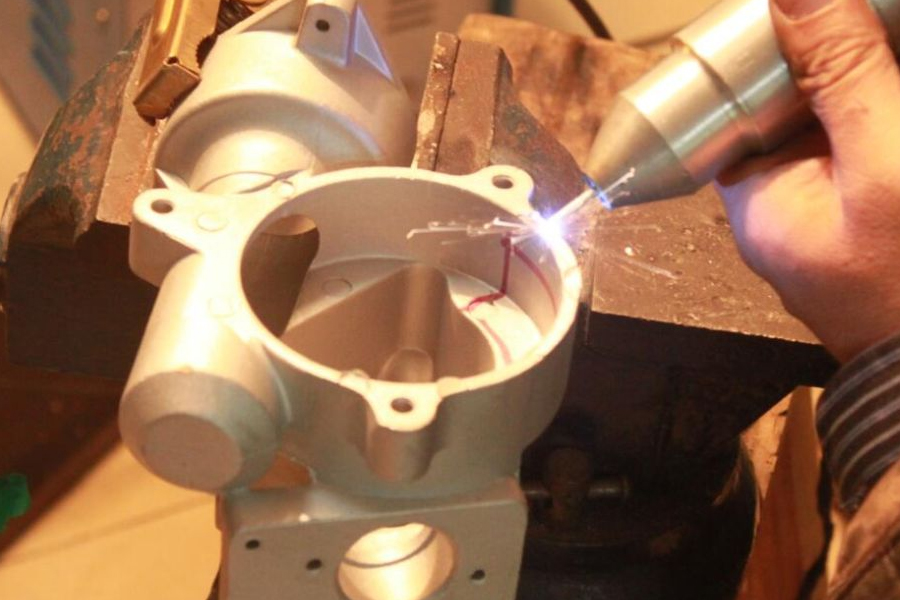

Ts'ebetso e bitsoang ts'ebetso ea ho lahla matsete ke ho sebelisa lisebelisoa tse ka fesible (joalo ka boka kapa polasetiki) ho etsa mofuta oa fusible (o bitsoang letsete kapa mmotlolo), ho kenya likarolo tse 'maloa tsa liaparo tse ikhethileng ho eona, ebe oa e omisa le ho e thatafatsa . Kamora ho etsa khetla ea bohlokoa, sebelisa mouoane kapa metsi a chesang ho qhibilihisa mohlala ho tsoa ho khetla, ebe o kenya khetla ka lebokoseng la lehlabathe, tlatsa hlobo ka lehlabathe le ommeng ho e potoloha, mme qetellong o kenye hlobo ka seboping sa ho chesa ka mocheso o phahameng oa ho chesa (haeba ho sebelisoa hlobo e matla haholo, khetla ea hlobo kamora ho senya e ka lelekoa ka kotloloho ntle le ho etsa mohlala). Ka mor'a hore hlobo kapa hlobo e chesoe, tšepe e entsoeng ka ho qhibilihisoa e tšeloa ka ho eona ho etsa hore e etsoe.

Ho nepahala ha tlhakore ea castings ea matsete ho batla ho phahame, ka kakaretso ho fihlela ho CT4-6 (CT10 ~ 13 bakeng sa ho betsa lehlabathe le CT5 ~ 7 bakeng sa ho betsa lefu). Ho joalo, ka lebaka la ts'ebetso e rarahaneng ea ho betsa matsete, ho na le lintlha tse ngata tse amang ho nepahala ha tlhakore ea castings, joalo ka hlobo. Ho fokotseha ha thepa, ho fetoha ha hlobo ea matsete, phetoho e lekanang ea khetla ts'ebetsong ea ho futhumatsa le ho futhumatsa, ho fokotseha ha motsoako le phetoho ea ho betsa nakong ea ts'ebetso ea ho tiisa, jj. Lits'oants'o tse tloaelehileng tsa matsete li phahame, empa tumellano ea eona e ntse e hloka ho ntlafatsoa (boholo ba tumellano ea castings e nang le boka ba mocheso o mahareng le o phahameng bo lokela ho ntlafatsoa haholo).

Ha o tobetsa hlobo ea matsete, mofuta oa khatello o nang le boreleli bo phahameng ba sekoti o sebelisoa, ka hona boreleli ba hlobo ea matsete le bona bo phahame. Ntle le moo, khetla e entsoe ka lesela le benyang le entsoeng ka sekhomaretsi se ikhethileng se nang le mocheso o phahameng, se koahetsoeng ka hlobo ea matsete, mme bokaholimo bo kahare ba mokoti bo kopaneng ka kotloloho le tšepe e qhibilihisitsoeng e na le boreleli bo phahameng. Ka lebaka leo, bokaholimo fihlela qetellong ea castings le dipeeletso tsa e phahameng ho feta ea castings kakaretso, ka kakaretso ho fihla Ra. 1.6 ~ 3.2μm.

Monyetla o moholo ka ho fetisisa oa ho lahla matsete ke hore hobane li-castings tsa matsete li na le ho nepahala ho holimo le ho qeta bokaholimo, mosebetsi oa machining o ka fokotsoa, empa ke karolo e nyane feela ea kabelo ea machining e ka salang likarolong tse nang le litlhokahalo tse phahameng, mme le ba bang ba nang le tumello ba na le Leave kabelo ea ho sila le ho bentsa, mme e ka sebelisoa ntle le ts'ebetso ea mochini. Ho ka bonoa hore ts'ebeliso ea mokhoa oa ho lahla lichelete e ka boloka lisebelisoa tse ngata tsa mochini le ho sebetsana le lihora tsa motho, mme ea boloka lisebelisoa tse tala tsa tšepe.

Molemo o mong oa mokhoa oa ho lahla matsete ke hore o ka lahla likarolo tse rarahaneng tsa lits'epe tse fapaneng, haholo-holo likarolo tse phahameng tsa mocheso o phahameng. Mohlala, lehare la jete ea jete, boemo ba eona bo hlakileng le sekoti se pholileng, li ka se thehwe ke mahlale a machining. Production le thulaganyou e lahla le dipeeletso tsa ka se feela fihlela tlhahiso ea boima, etsa bonnete ba tumellano ea castings, empa hape qoba khatello ea kelello mahloriso ea matšoao a barrel thipa mora machining

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Stainless Steel Silica Sol le Ts'ebetso e nepahetseng ea ho lahla

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off