Tlhatlhobo ea Aluminium Die Casting Mold Crack Failure

Ho hloleha ha crack ea alloy aluminium die-cast mode ho ke ke ha ama feela boleng ba tlhahiso ea hlobo le katleho ea tlhahiso, empa hape ho tla eketsa litšenyehelo tsa tlhahiso. Ha e le hantle, mabaka a ho petsoha le ho hloleha ha hlobo ea aluminium die-casting hlobo a fapane. Mohlala, tšepe ea mokelikeli e na le litlamorao khafetsa ho eona, maemo a tlhahiso a chesa haholo, thepa ea tlhahiso ea hlobo, le EDM le mabaka a mang. Leqepheng lena, ho etsoa tlhahlobo e ikhethileng ea ho hloleha ha aluminium alloy die-cast die. Ho tšeptjoa hore e ka bapala karolo ea ho hohela mehopolo e mecha, le ho tlisa boleng ba litšupiso ho basebetsi ba amehang.

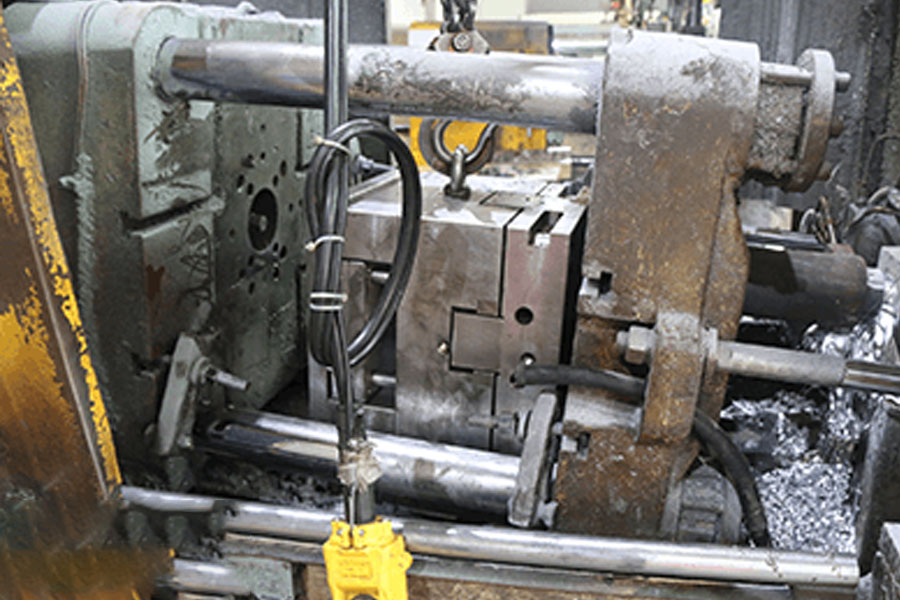

Maemo a sebetsang a hlobo ea aluminium die-casting a tsamaellana le mocheso o phahameng le khatello e phahameng. Ka nako e ts'oanang, hlobo ea aluminium e shoang e lahleloa ka mokhoa o sebetsang e hloka ho mamella tšusumetso e phetoang ea tšepe ea mokelikeli. Tlhahisong ea 'nete, ka lebaka la litheko tse phahameng tsa hlobo ea aluminium e laoloang ke aluminium, potoloho e telele ea tlhahiso, le ho hloleha pele ho nako, bophelo ba ts'ebeletso bo tla khutsufatsoa haholo. Hang ha bothata ba ho petsoha le ho hloleha ha hlobo ea aluminium ea ho lahla bo sa rarolloe ka nepo, e tla ama ka kotloloho melemo ea moruo ea khoebo ea tlhahiso. Ka lebaka lena, baetsi ba li-aluminium tsa morekisi ba ntseng ba eketseha ba ekelitse tlhahlobo ea bona ea ho hloleha. Litaba tse latelang li nka tšepe ea tšepe e chesang ea H13 e le mohlala, 'me e kopanya ts'ebetso ea' nete ea ho hlahisa lisosa tsa ho qhekella le ho hloleha ha hlobo ea aluminium die-casting e tsoang linthong tsa aluminium alloy hlobo, microstructure le machining e tsoang motlakase. Mehato e tsamaellanang e se e nkuoe.

1. Sesosa Analysis Of Aluminium motsoako shoa-lahla hlobo Cracking Ho hloleha

lik'hemik'hale Sebopeho

Ho tloha ponong ea lik'hemik'hale, mofuta oa tšepe oa H13 o chesang tšepe o koahela likarolo tsa C, SijMn, Mo, Cr, le V. Ho tloha ponong ea litšobotsi tsa lik'hemik'hale, mofuta oa tšepe oa H13 o chesang o sebetsa tšepe ho tlaase Si le phahameng Mo mosebetsi o chesang shoa tšepe ka ho ya ka lintho tse bonahalang. Ts'ebetsong ea tlhahiso, bahlahisi ba tla fokotsa boleng ba Si kapa ba eketse Mo litaba tsa tšepe ho latela litlhoko tsa 'nete. Ka ho fokotsa litaba tsa Si, leeme le ka fokotsoa ka nepo

Ketsahalo ea ketsahalo ea pula, le ho ntlafatsa lithollo tsa austenite, e ntlafatsa matla le ho tiea ha tšepe. Ho eketsa litaba tsa Mo ho ka ntlafatsa ho thatafala, ho hanyetsa mocheso le ho hanyetsa mocheso oa tšepe. Le ho thibela ka nepo pula ea li-carbides tsa lijo-thollo ka tšepe, hammoho le phetoho ea bainite. Tloaelo e bonts'itse hore tšepe e tlase ea Si le e phahameng ea Mo e tla fokotsa menyetla ea ho koaloa ka tlase nakong ea ts'ebetso ea ho tiisa, ka hona e thibela ka nepo ho hlaha ha li-dendrites, likristale tsa cellar tsa kholomo le khethollo ea dendrite. Motsoako oa likarolo tsa Mo le V o ka theha carbides ea alloy, joalo ka VC, MoC le Mo2C. Motsoako oa carbides o tla kenella maemong a qhalakaneng tlasa maemo a loketseng a mocheso o phahameng, o tla ntlafatsa haholo litšobotsi tsa thermosetting tsa thepa e phahameng ea mocheso. Le ha e le ka sebopeho sa lik'hemik'hale, mofuta oa tšepe oa H13 o chesang o chesang o na le ts'ireletso e matla ea ts'ireletso, ts'ebetsong ea 'nete, re fumane hore mofuta oa tšepe oa H13 o chesang o chesa tšepe o na le ho hloleha kapele. Bakeng sa ho sekaseka hantle lisosa tsa ho hloleha ha crack, ho bohlokoa ho kopanya ka mokhoa o hlophisitsoeng sebopeho sa tšepe sa tšepe sa H13 bakeng sa tlhahlobo e eketsehileng.

Microstructure

Bakeng sa ho ithuta ka botlalo sebopeho sa mochini oa aluminium alloy die-casting, karolo ena e sebelisa lisebelisoa tsa hlobo tse so sebelisoe kamora ho tima le ho chesa le ho sebelisa thepa ea hlobo joalo ka lintho tsa lipatlisiso ho sekaseka microstructure ea aluminium alloy die-casting hlobo, ebe u fumana Lisosa tsa ho hloleha ho petsoha.

Lisebelisoa tsa hlobo tse e-so sebelisoe kamora ho tima lephaka

Ka ho ikoetlisa, ho fumanoe hore ho na le lisele tse sa lekanang tse ajoang holim'a substrate ea ntho ea lipatlisiso kamora kalafo ea mocheso. Ka ho sheba ntho e batlisisitsoeng tlasa microscope e nang le matla a tlase, re fumane hore palo e kholo ea li-carbide tse nang le lehoakhoa tse hasitsoeng li ajoa ho matrix ebe li arotsoe. Ka mantsoe a mang, ha e bapisoa le carbides ea lisele tse tloaelehileng, karolo ena ea carbides E kholo ka boholo. Ka lebaka la pula e feteletseng ea carbides le carbides ea alloy, hlobo ea hlobo e lahleheloa ke likarolo tse ngata tse haufi tsa khabone le likarolo tse kopantsoeng. Maemong a tloaelehileng, li-carbide tse arotsoeng tsa hlobo li ke ke tsa qhibiliha habonolo ha hlobo e futhumatsoa ke ho tima. Leha ho le joalo, ka lebaka la khaello ea eona ea k'habone le likarolo tse kopantsoeng, ho bonolo ho fetohela ho martensite tlasa mocheso o phahameng oa mocheso, ka tsela eo ho fokotsa ho futhumatsa naleli ea boleng, mme ho fokotsa matla le ho thatafala ha tšepe, ho e nolofaletse ho robeha hona joale. Ka ho sebelisa microscope ea motlakase o tlase ho shebella tšepe e kentsoeng pele e tima, re fumane hore matrix ea tšepe le eona e na le khethollo. Ponahalo ea ketsahalo ena e bolela ho haelloa ke ts'ebetso ea lisebelisoa tse tala tsa tšepe. Mme hang ha ketsahalo ea khethollo e sa sebetsanoe ka katleho, e tla eketsa menyetla ea ho petsoha ha hlobo le ho hloleha, mme e ame bophelo ba ho qetela ba ts'ebeletso ea hlobo.

Hlobo Material Ka mor'a tšebeliso

Tlhahisong ea 'nete, mefuta e mengata ea tšepe e chesang ea tšepe ea H13 e tla hlaha ka mekhahlelo e fapaneng ea ho petsoha holim'a hlobo ka mor'a makhetlo a ka bang 30,000 a ts'ebeliso, joalo ka: likhechana tsa mekhahlelo le liphapano tsa mapetso a mangata kamora ho ebola, likoti le tse ling. li thehoa. Lebaka la ketsahalo ena ke haholo-holo ka lebaka la litšitiso tsa metallurgical ho lisebelisoa tse tala.

EDM

EDM ke e 'ngoe ea mekhoa e sebelisoang haholo ea ho sebetsana le hlobo ea aluminium alloy. Ha e bapisoa le mekhoa e meng ea ho e lokisa, mokhoa ona oa ho sebetsa o hlahisa melemo ea ho sebetsa ka nepo e phahameng, boemo bo phahameng ba boiketsetso le boiketlo ba ho sebetsana le likarolo tse sa sebetseng ka mokhoa o ikhethileng ts'ebetsong. Leha ho le joalo, litlhase tse lokollotsoeng nakong ea ts'ebetso li na le litšobotsi tsa mocheso o phahameng le khatello e phahameng, 'me mocheso oa mokelikeli o sebetsang o tla ba teng

Ho theoha ho matla ho entse hore bokaholimo ba tšepe bo aroloe ka libaka tse futhumatsang mocheso le libaka tse anngoeng ke mocheso. Sebaka seo ho thoeng ke thermoremelting se bolela hore tšepe ea bokaholimo e qhibilihisoa ke mocheso o phahameng o lokolloang nakong ea ho tsoa. Hobane qhibiliha ha e lahleloe ka ho felletseng, 'me ho qhibiliha ho bolokiloeng ho tiisa ha mokelikeli o sebetsang o ntse o phola. Sebaka se chesang se chesang se abuoa haholo karolong e kaholimo-limo ea bokaholimo ba tšepe. Ha ho bapisoa le lera le ammeng mocheso sebakeng se futhumatsang mocheso, thepa ea tšepe ea ameha

Kamora ho chesoa ke mocheso o phahameng, ha ho ts'ebetso e qhibilihang e etsahetseng, empa sebopeho sa metallographic sa thepa se fetohile hantle. Ka boikoetliso bo bongata, re fumane hore ts'ebetso e chesang ea hlobo e tla eketsa menyetla ea ho petsoha ha hlobo le ho hloleha sebakeng se chesang se chesang le sebaka se amehileng ka mocheso. Kamora hore aluminium alloy e lahleheloe ke tšepe kamora hore EDM e fete seboping sa khase, leha sebopeho sa metallographic sa hlobo se sa fetohe ka nepo, sea ntlafatsoa mochesong.

Leha ho le joalo, mapetso a fokolang a tla hlaha sebakeng seo, 'me ha mapetso a atoloha ho fihla sebakeng se anngoeng ke mocheso, sebaka sa micro-crack se tla eketseha hape, se tla eketsa tekanyo ea ho hloleha ha hlobo.

Mehato ea 2.Thibelo Khahlano le ho Qhekella ho Hloloa ha Aluminium Alloy Die-Casting Mold

- 2.1 Ho eketsa palo ea disampole bakeng sa liteko tsa metallographic tsa lisebelisoa tse tala bakeng sa hlobo ea aluminium alloy e etsoang nakong ea tlhahiso, baetsi ba bangata ha ba so etse liteko tsa metallographic ka botlalo tsa thepa e rekiloeng e le ho potlakisa lenane la tlhahiso. Bakeng sa ho fokotsa ho ba teng ha mapetso le ho hloleha ha hlobo ea aluminium alloy tlhahiso ea 'nete e hloka ho isa bohōleng bo boholo. Ha ho huloa mehlala ea thepa ea hlobo, mohlahisi o hloka ho khetha sebaka sa mehlala ka mahlale le ka mokhoa o utloahalang. Mohlala oa aluminium alloy hlobo e lahlang, ho netefatsa bonnete ba karolo ea mantlha ea mantlha le ho bona boleng bo nepahetseng ba thepa ea hlobo, bahlahisi ka kakaretso ba sebelisa heke joalo ka sebaka sa mehlala.

- 2.2 rarolla ka nepo libaka tse futhumatsang tse futhumetseng tse bakoang ke EDM: Sebaka se futhumatsang mocheso se bakiloeng ke ts'ebetso ea motlakase se na le thatafalo e phahameng le brittleness e kholo, mme li-microcracks li tloaetse ho hlaha nakong ea ts'ebetso ea machining. Haholo-holo ts'ebetsong ea ho chesa malakabe, monyetla oa likhahla tse nyane o kholo. Bakeng sa ho qoba mapetso le ho hloleha ha hlobo ea aluminium alloy e lahlang, ho hlokahala hore ka saense le ka mokhoa o utloahalang u qobe ponahalo ea libaka tse chesang tse ntlafatsang. Kamora EDM, libaka tse chesang tse lokisang metsi li hloka ho tlosoa ka nako, 'me hlobo e lokela ho halefa ka nako ho felisa khatello ea masalla ea lera le amehileng. .

- 2.3 Ka katleho qoba ts'ebetso ea ho hloleha ha pele ho nako: Ho hloleha ha mapolanka a aluminium alloy die-casting ho hlaha sethaleng sa pele, se bakoang haholo ke mocheso o phahameng haholo oa ho betla ho se nang letho. Ho hloleha ho petsoha ho bakiloeng ke lebaka lena ke phoso e ke keng ea qojoa. Ka hona, ts'ebetsong ea tlhahiso e se nang letho, mohlahisi o hloka ho laola ka thata mocheso o thellang. Mothating oa ho futhumatsa o tima, ho bohlokoa hape ho hlophisa nako ea ho futhumatsa ka mahlale le ka nepo ho laola mocheso o futhumatsang le ho thibela ketsahalo ea decarburization. Ka sethaleng le tima le tsidifatso, ho hlokahala hore ho ka tsela e atlehang ho laola nako tsidifatso, 'me ba leka ho tlatsa tshebetso tima le tsidifatso ka nako e khutsoanyane haholo le ka lebelo lebelo ka ho fetisisa. Bakeng sa kanale ea metsi a pholileng, moqapi o hloka ho boloka sebaka se lipakeng tsa eona le boemo le likhutlo tse kholo ho lekana ho netefatsa tsoelo-pele e hlakileng ea ts'ebetso ea ho futhumatsa.

- 2.4 Saense le kalafo e loketseng ea mocheso oa hlobo: Boleng ba thepa e tala bakeng sa hlobo e lahlang li ama bophelo ba ts'ebeletso ea hlobo ea aluminium die-casting ho isa tekanyong e kholo. Ka hona, basebetsi ba hloka ho khetha lisebelisoa tse loketseng tsa hlobo ea hlobo e laoloang ho latela litlhoko tsa 'nete. Kamora hore mosebeletsi a tsebe lisebelisoa tse sa sebetsoang tsa aluminium alloy hlobo e lahlang, ho hlokahala hore o phekole mocheso ka nako. Ka nako e ts'oanang, ho hlokahala hore ho etsoe mosebetsi o motle molemong oa ho imolla khatello ea maikutlo mohatong oa tlhahiso ho thibela khatello ea maikutlo, le ho laola lehlakore la R. Sistimi e sebetsa. -Ka kakaretso, ha hlobo ea aluminium e shoang e sebelisoa makhetlo a ka bang 10,000 XNUMX, e hloka ho halefa ka nako ho tlosa khatello ea maikutlo, e le ho thibela khatello ea maikutlo ho baka moferefere le ho hloleha. Bakeng sa ho eketsa nako ea ts'ebeliso ea hlobo ka botlalo, ho ka sebelisoa mekhoa e mengata ea ho phomola le khatello ea maikutlo.

- 2.5 Saense le taolo e utloahalang ea mocheso molemong oa tlhahiso ea aluminium alloy die-casting: Ts'ebetso ea tlhahiso ea hlobo ea aluminium die-cast e hlahisa mocheso o phahameng le khatello e phahameng. Ka hona, ho bohlokoa haholo-holo ho laola mocheso le ka mokhoa o utloahalang ts'ebetsong ea tlhahiso. Ts'ebetsong ea tlhahiso, mohlahisi a ka sebelisa thermometer e loketseng ho bala mocheso o phahameng haholo ts'ebetsong ea ho lahla le ho nka mehato e sebetsang ea taolo ho laola mocheso kahare ho likhato tse 650.

3. Qetello

Ka bokhutšoanyane, ka nts'etsopele e potlakileng ea moruo oa naha ea heso, baetsi ba hlobo ea aluminium alloy aluminium ba atolohile ka potlako ho latela palo le tlhahiso ea tlhahiso. Leha ho le joalo, ka lebaka la tsetelo e kholo ho theko ea tlhahiso ea aluminium alloy hlobo e lahlang, ha boleng ba tlhahiso bo ke ke ba netefatsoa ka nepo, bo tla ama ts'ebetso ea tlhahiso le tlholisano ea mmaraka ea moetsi. Ka tshebetso ya ho hlahisoeng, peperana hloleha ke e tloaelehileng boleng bothata ba hlobo hlobo aluminium shoela'ng-foromeletsoeng. Sena ha sea hohela tlhokomelo e pharalletseng feela ho tsoa ho baetsi, empa hape se sebelisitsoe haholo ho ama bareki. Ka lebaka lena, ho bohlokoa haholo ho eketsa lipatlisiso mabapi le ho hloleha ha mapheo a aluminium alloy die-cast. Litaba tse kaholimo li sekaseka lisosa tsa ho hloleha ha hlobo ea aluminium alloy Ho ts'epiloe hore e ka tlisa boleng bo itseng ba ts'upiso ho basebetsi ba amehang le ho ntšetsa pele nts'etsopele e ts'oarellang, e potlakileng hape e phetseng hantle ea indasteri ea hlobo ea aluminium ea alloy ea naha ea heso.

Lingoloa tsa Mofuta o Tšoanang: The Mabaka a Aluminium shoa lahla banana leaf Easy Cracking

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape:Tlhatlhobo ea Aluminium Die Casting Mold Crack Failure

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off