Lintlha tse susumetsang mokhathala bophelo ba li-rolling bearings

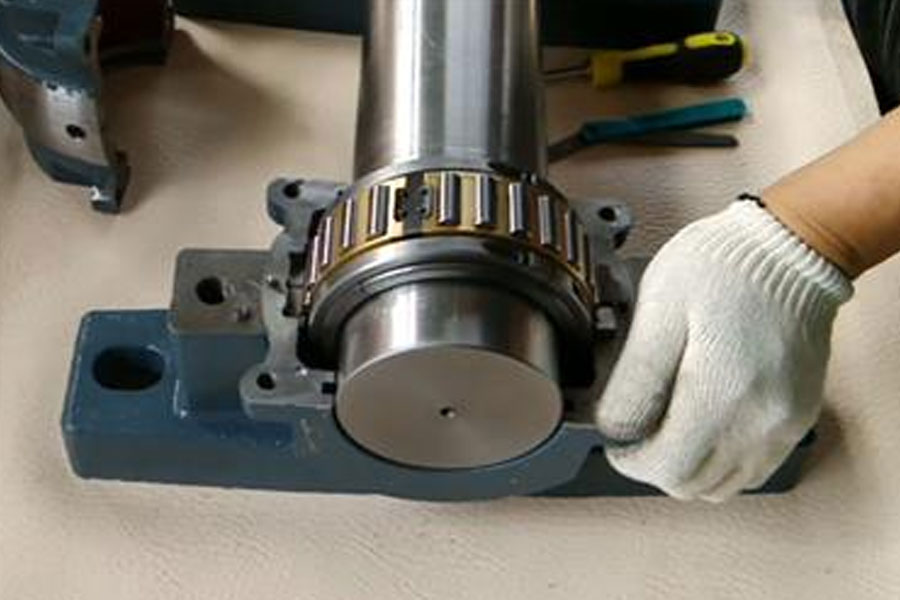

Lilemong tsa morao tjena, moralo oa tlhekefetso oa likarolo tsa mochini o akaretsang o amohetse tlhokomelo e pharalletseng. Li-rolling roll ke e 'ngoe ea likarolo tse sebelisoang haholo. Ka nts'etsopele ea mahlale le lipalo tsa lipalo, liteko tsa ketsiso le ketsiso li 'nile tsa sebelisoa haholo ho sehlohlolong sa libering. Lipatlisiso le moralo oa lihlahisoa. Moralo oa tlholeho oa libering tse tsamaisang o na le mehopolo e 'meli, pele le morao.

Ts'ebetso ea ho tsamaisa e na le tšusumetso e kholo ts'ebetsong ea sistimi ea mochini. Leha ho le joalo, ho na le lintlha tse ngata tse amang bophelo ba mokhathala ba lintho tse tsamaeang, joalo ka mocheso o sebetsang, mojaro oa tšusumetso, ts'epahalo, lisebelisoa, maemo a ts'ebeliso, lebelo la moeli, ho kobeha ha sefahleho, inclusions, intente, le boemo ba lubrication, tumello ea radial, deflection, mokhathala o bakoang ke khatello ea mokhathala, khohlano e matla, khatello ea maikutlo le khatello ea kelello, kalafo ea bokaholimo, jj.

Khopolo-taba ea khale ea LP ea bophelo ba mokhathala e ipapisitse le khopolo ea hore ho hloleha ha mokhathala ha motho ea ikopanyang ho tsoa botebong ba khatello ea 'mele e holimo ea orthogonal tlas'a sebaka seo motho a kopanang le sona. Leha ho le joalo, ka nts'etsopele ea mahlale a tlhahiso, mokhathala oa ho hloleha o tsoang holimo o hlaha khafetsa ho feta mekhahlelo ea mokhathala oa subsurface. Ho na le mekhoa e meraro ea ho qalisa ho qhekella: ho qhekella ho tloha holimo, ho qhekella ho tloha haufi le holimo, le ho qhekella ho matrix ea lintho tse bonahalang.

Pitting e hlahang kaholimo le bophelo bo sarolohang bo ka tlase ho bokaholimo ke mekhoa ea ho hloleha e qothisanang lehlokoa, e boletsoeng esale pele e le tšebetso ea karo-karolelano ea filimi, motso o bolela boleng ba sekwere sa letsoapo le phahameng, le ho lekana ha tšebetso molemong oa setlolo sa moeli ho kopana le tlhoro ea tlhoro.

Ka nts'etsopele ea literene tse lebelo le indasteri ea ho fofa, ho na le litlhoko tse eketsehileng bakeng sa ts'epahalo e phahameng ea libere. Ka nako e ts'oanang, mocheso oa tikoloho ea kopo o fetoha haholo. Hoa hlokahala hore u ithute ka botebo ka phello ea ho kopanya le ho tšepahala le mocheso. Lisebelisoa tsa Rolling bearing li ntse li le tlasa nts'etsopele. Hoa hlokahala ho lekola likamano lipakeng tsa bokaholimo ba likarolo le likoti tsa mokhathala o kaholimo, le ho senola tšusumetso ea karolo e 'ngoe ea bokhabane le litlamorao ho likoti tsa mokhathala ka tekanyo e nyane haholo. Ka lehlakoreng le leng, ho kopanya litšobotsi tsa mojaro le karabelo e matla ea lintho tse bonahalang ho ithuta ho hloleha, ho sekaseka karabelo e matla ea ho jara thepa ho mejaro e kantle, ho ithuta kamano ea ho kopanya pakeng tsa ts'ebetso ea mokhathala le thepa ea thepa, le ho fumana kamano lipakeng tsa karabelo e matla ea lintho le mokhathala o kaholimo. ho qhalana.

Bakeng sa lintlha tse ling tse amang bophelo ba mokhathala, joalo ka litlolo le li-additives, ho halefa ka holim'a metsi, khatello ea mohopolo le sethala sa li-interface, jj. Le khetho, ena ke e 'ngoe ea litsamaiso tsa nts'etsopele ea nako e tlang.

Ho sekaseka lintlha tse amang mokhathala o matlafatsang oa mokhathala ho tla thusa ho utloisisa hantle mochini oa ho hloleha ho khathala. Ka lehlakoreng le leng, e ka qoba lintlha tse fokotsang bophelo ba ho jara ka hohle kamoo ho ka khonehang le ho ntlafatsa bophelo ba mokhathala ba ho beha; ka lehlakoreng le leng, e ka fana ka tataiso e itseng bakeng sa nts'etsopele ea khopolo ea bophelo ba mokhathala, molemong oa ho ntlafatsa ho nepahala ha polelo ea bophelo ba mokhathala.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Lintlha tse susumetsang mokhathala bophelo ba li-rolling bearings

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off