Phapang pakeng tsa shoa lahla And tapa

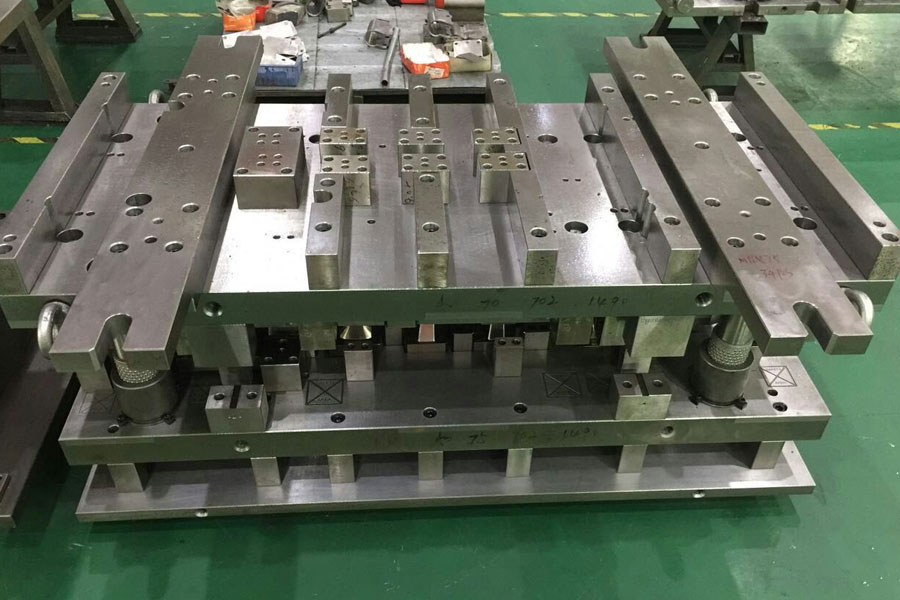

Ts'ebetso ea ho hatakela ke theknoloji ea ts'ebetso e etsang hore likarolo tse thunyang ka kotloloho li fumane matla le ho holofala ka hlobo ka thuso ea matla a lisebelisoa tse tloaelehileng kapa tse khethehileng tsa ho tapa ho fumana sebopeho se itseng. Hlobo e sebelisetsoang ho tapa e bitsoa stamping die, e leng lisebelisoa tse khethehileng bakeng sa ho sebetsa ha methapo ea thepa ea tšepe kapa thepa e sa sebeliseng tšepe, ho shapa likarolo ho bohlokoa haholo ts'ebetsong ea likarolo tsa ho tapa;

Ts'ebetso ea ho hatakela ke theknoloji ea ts'ebetso e etsang hore likarolo tse thunyang ka kotloloho li fumane matla le ho holofala ka hlobo ka thuso ea matla a lisebelisoa tse tloaelehileng kapa tse khethehileng tsa ho tapa ho fumana sebopeho se itseng. Hlobo e sebelisetsoang ho tapa e bitsoa stamping die, e leng lisebelisoa tse khethehileng bakeng sa ho sebetsa ha methapo ea thepa ea tšepe kapa thepa e sa sebeliseng tšepe, ho shapa likarolo ho bohlokoa haholo ts'ebetsong ea likarolo tsa ho tapa;

Ts'ebetso ea ho hatakela e na le menyetla e mengata e ikhethang ho latela theknoloji le moruo; Melemo ea mantlha ke ts'ebetso e phahameng ea tlhahiso, ts'ebetso e bonolo, le ts'ebetso e bonolo ea mochini o ikhethileng.

Ho lahla lefu ke mokhoa oa ho lahla die betloa ha. The shoa-foromeletsoeng shoela'ng betloa ha thulaganyou e ke thulaganyou e inehetseng etsoa ka shoa-lahla shoela'ng betloa ha mochini. Ke mokhoa oa ho tšela mokelikeli oa khauta oa fusion ka phapusing ea boralitaba ho tlatsa sekoti sa hlobo ea tšepe ka lebelo le phahameng. Mme o etse mokelikeli oa motsoako hore o tiee tlasa khatello ea ho etsa mokhoa oa ho betsa;

Ts'ebetso ea mantlha ea ho lahla tšepe ke hore tšepe e qhibilihisitsoeng e qala ho tlatsoa kahare ea hlobo ka lebelo le tlase kapa le phahameng. Hlobo e na le sekoti se ka tsamaisoang. E hatelloa ka thata ka mokhoa o pholileng oa tšepe e qhibilihisitsoeng, e felisang ho fokotseha ha letho. Liphoso tsa Shrinkage li boetse li etsa hore sebopeho sa kahare sa lithollo se fihle se robehile maemong a maiketsetso, mme thepa e phethahetseng ea se nang letho e ntlafalitsoe haholo. Ntle le moo, koluoa e hlahisoang ke ts'ebetso ena e na le bokaholimo ba 7 (Ra1.6), bo ts'oanang le bokaholimo bo hlahisoang ke extrusion e batang kapa machining, ka benya ba tšepe. Ka hona, re bitsa ts'ebetso ea "die-casting die forging" mohato oa "Ultimate Forming"

Phapang pakeng tsa shoa lahla Parts And tapa

Leha kaofela e le mekhoa ea ho sebetsana le tšepe, ho na le phapang e kholo lipakeng tsa tsona:

Ho hatakela tšepe ke mokhoa o sebelisang litebele le hlobo ho holofatsa kapa ho roba tšepe e sa hloekang, tšepe, aluminium, koporo le lipoleiti tse ling le lisebelisoa tse ling ho fihlela sebopeho le boholo bo itseng.

Shoa-foromeletsoeng ke mofuta oa likarolo khatello ea-lahla. E sebelisa mochini o laolang khatello ea mochini o nang le hlobo ea ho betla ho tšela mokelikeli o futhumetseng oa koporo, zinki, aluminium kapa aluminium alloy ka lesobeng la mochini o lahlang, ebe o o fetisa ka mochini o lahlang. Die lahla ke ho lahlela koporo, zinki, likarolo tsa aluminium kapa likarolo tsa aluminium tsa sebopeho le boholo bo thibetsoeng ke hlobo. Likarolo tse joalo hangata li bitsoa likarolo tse lahlang lefu.

Ho lahla le ho tapa ka bobeli ke mekhoa ea ho sebetsa le ho etsa likarolo tsa likarolo, empa shoa ho lahla sebelisa khatello ho tlatsa hlobo ka tšepe e metsi ho fumana likarolo tse tšoanang le hlobo; stamping e sebelisa ts'ebetso ea hlobo ho tlosa likarolo tse ling tsa tšepe e tiileng ho fumana likarolo tse hlokahalang.

Phapang pakeng tsa shoa lahla hlobo And tapa hlobo

Ho hatakela ho arotsoe ka ho tapa ho bata le ho chesa ho chesang. Ha e bapisoa le ho hatakela ho batang, ts'ebetso e chesang ea ho hatakela e ka nahanela litaba tsa polokeho e bobebe le ho thulana, le matla a phahameng likarolo tsa stamp selemo le ho shoa. Hot tapa e hlokomela ka ho etsa lona shoela'ng. Hore na moralo oa lefu o na le kahlolo e molemo kapa che ho tla ama ka kotloloho katleho ea litempe tse chesang.

Moralo le mekhoa ea ho etsa thepa ea li-stamping tse chesang haholo li arotsoe ka mefuta e mene: mofuta oa ho cheka, mofuta o khabisitsoeng, mofuta oa shaoara le mofuta oa ho lahla.

1. Mofuta oa ho cheka

Mofuta oa ho cheka o hlokomela tokisetso ea sistimi e kenang ea ho futhumatsa ka ho hlophisa liphaephe ka tsela e latelang ho isa bohōleng bo phahameng tlasa bokaholimo ba mofuta oa concve-concave. Melemo ke ho sebetsoa habonolo, phetoho e bonolo ea hlobo, le ho tenyetseha hantle;

Mathata ke: ho hloleha ho latela tšebetso ea sebopeho, le ho tšoana ho futhumetseng ha hlobo ho fokolang.

2. Lethathamo la liketsahalo

Mofuta o khabisitsoeng o entsoe le ho sebetsoa ka moralo o hlophisitsoeng le ho sebetsoa ha hlobo ea hlobo le likarolo tse ling tsa hlobo ka phala e pholileng joalo ka sehokelo. Melemo ke ho lumellana hantle, sebaka se seholo sa phapanyetsano ea mocheso le ho tiisa ho bonolo;

Bothata ke hore ho hlokahala lisebelisoa tse phahameng tsa ho sebetsa ka nepo, lipeipi tse futhumatsang li thata, mme ts'ebetso ea phetiso ea mocheso e futsanehile.

3. Mofuta oa shaoara

Mofuteng oa ho sesa, lethathamo la likoti tse nyane li buloa holim'a hlobo, 'me li-nozzle li hlophisitsoe ka masoba. Kamora hore hlobo e koaloe, nozzle e sebelisoa ho fafatsa setsidifatsi se nang le khatello e phahameng holim'a poleiti e chesang ea tšepe moholi ho fihlela o tima le ho pholisa. Molemo ke hore phello ea ho futhumatsa e ntle, the lisebelisoa tsa machining phetoho ea mokhahlelo e lekane, 'me likarolo tsa mochini oa likarolo li ntle haholo;

Bothata ke hore ho thata ho sebetsoa, 'me marotholi a masalla a metsi a hlobo a baka tšenyo e kholo holim'a hlobo mme a fokotsa bophelo ba hlobo.

4. Ho lahla mofuta

Mofuta oa ho qhibiliha o qhibilihisoa o kentsoe ka pele ho sebōpeho sa lehlabathe ka phala e tsitsitseng e pholileng, 'me hlobo e se nang letho e fumanoa ka ho lahla,' me hlobo e kopaneng e fumanoa kamora machining. Melemo ke tokisetso e feto-fetohang ea liphaephe tse pholileng, ho ikamahanya hantle, ho tiisa le ho ts'epahala ha phala, le ts'ebetso e bonolo;

Bothata ke hore matla a hlobo a futsanehile, ts'ebetso ea ho qhibiliha le ho lahla e rarahane, motsoako oa metallurgic pakeng tsa phala le substrate oa hlokahala, boemo ba ho nepahala bo phahame, 'me ho thata ho fihlela tokiso ea hlobo e sa fellang.

Har'a mefuta e mene e chesang ea stamping die die le mekhoa ea tlhahiso, mofuta oa ho cheka le mofuta o khabisitsoeng ke ona o sebelisoang haholo.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Phapang pakeng tsa shoa lahla And tapa

Khamphani ea Minghe Casting e nehetsoe ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo (likarolo tsa tšepe tsa die die li kenyelletsa haholo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off