Microstructure Le Meaho ea Mechini ea Likarolo tsa Likoloi tsa Aluminium Chassis

Sebopeho sa li-castings le lintlha tsa bohlokoa tsa theknoloji ea nts'etsopele

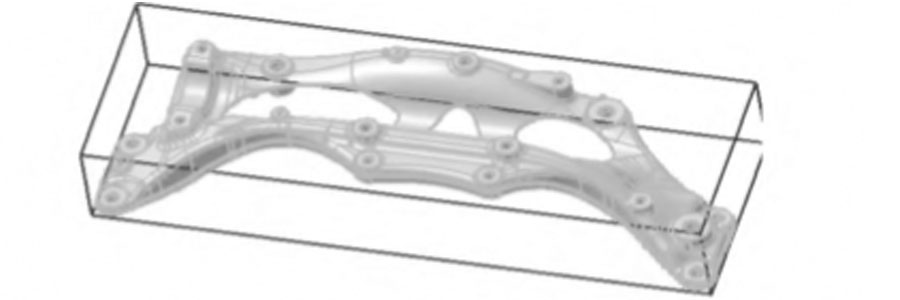

Sebopeho sa chassis ea makoloi se bonts'itsoe ho Setšoantšo sa 1. Boholo ba eona ba kemiso ke 677.79mm × 115.40mm × 232.42mm, boima ke 2.6kg, botenya bo boholo ba lebota ke 3.5mm, 'me bophahamo ba eona bo ka ba 9.88 × 105mm ^ 3. Sebaka se hlahisitsoeng sa ho betsa ke 86300mm ^ 2, 'me thepa ke Al-8Si-Mn-Mg alloy. Ho betloa ho na le manonyeletso a chesang a mangata a mangata, a bonolo ho etsa masoba a shrinkage. Litlhokahalo tsa boleng ba ponahalo ea li-castings: ha ho na matšoao a hlakileng a ho lahla phallo, ha ho na mapetso a totileng a sekolopata, 'me ha ho na bubble holim; litlhoko tsa boleng ba kahare tsa li-castings: masoba a boemo ba ho lahla ka kakaretso a ka tlase ho mm1mm, baokameli le likarolo tse teteaneng tsa nama li hloka masoba 2mm Tse latelang; litlhokahalo bakeng sa likahare tsa moea kahare ho karolo: 100% ea aluminium pheletsong e laetsoeng ea ho tlatsa e lokela ho ba tlase ho 15mL, mme karolo e khethiloeng ea heke e kahare e lokela ho ba tlase ho 10mL; thepa ea mochini oa ho lahla (kamora kalafo ea T5): matla a ho tenyetseha a 220MPa, chai Matla ke 150MPa, bolelele ke ≥5%, sekhahla sa ts'oaetso ke ≥6.0J / cm2, teko ea tensile teko ke M10-60kN, M12-85kN, thatafala (HRB) ke 30; litlhokahalo bakeng sa teko ea mokhathala ea li-castings: tlasa maemo a tloaelehileng, mamella matla a 6.1 ~ -4.8kN sebakeng se khethiloeng, maqhubu ke 2Hz, mme tšenyo ha e lumelloe kamora ho potoloha ha 20,000. Tlas'a maemo a liteko, palo ea lipotoloho ke makhetlo a 40,000. Ho latela litlhoko tse kaholimo, tlhahiso ea ho betsa ena e thata haholo.

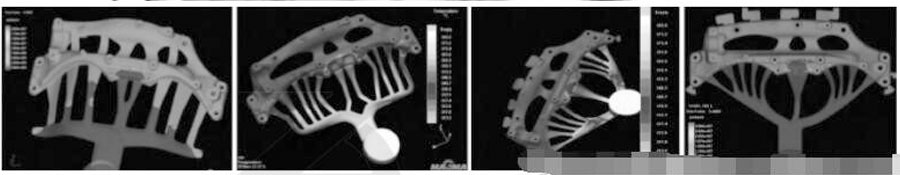

Ts'ebetsong ea ntlafatso ea ho betsa, ho khutsufatsa potoloho ea nts'etsopele, software ea lipalo e sebelisetsoang ho sekaseka, 'me ha ho buuoa ka mekhahlelo ea tlhahiso ea nnete, ho sebelisoa mekhoa e mene e fapaneng ea ho betsa (bona Setšoantšo sa 2). Moralo oa 1 le Moralo oa 2 sebelisa mokhoa oa ho tšela o bōpehileng joaloka khekhe, Moralo oa 3 le Moralo oa 4 o tla sebelisa mokhoa oa ho tšela o nang le sebopeho sa fan; Ha e bapisoa le Moralo oa 2, Moralo oa 1 o sebelisa mokhoa oa ho fepa o tsepamisitsoeng haholoanyane 'me Moralo oa 2 o sebelisa mokhoa oa ho fepa o qhalakaneng haholoanyane. ; Ha ho bapisoa le Khetho ea 4, Khetho ea 3 e na le semathi se seholo se khuts'oane mme Khetho ea 4 e na le semathi se selelele ho feta. Sebelisa software ea Magma ho etsisa le ho sekaseka merero e mene e kaholimo. Liphetho li bontša hore: Mokhethoa oa semathi oa 1 o otlolohile haholo, tahlehelo ea matla e kholo, mme ho tšoloha ha heke e ka hare ha ho lumellane, e leng ntho e makatsang; Khetho ea 2 e tletse ka khase ka mahlakore ka bobeli a limathi, 'me ho matlafatsa tlhahlobo ea ho tiisa ho na le masoba a shrinkage mahlakore ka bobeli a masoba a likhoele; 3 Semathi se sekhuts'oane haholo, se sa sebetseng ts'ebetsong ea ts'ebetso e phahameng ea lehare; Morero 4 Mocheso oa karolo e tšollang e tšollang bohareng o phahame haholo, 'me khoholeho ea hlobo e ka ba teng moo. Ha re nahana ka boemo ba mokelikeli oa ho tlatsa, ho tsitsisa ho tsitsisa, mocheso, jj. Khetho ea 4 e betere.

Teko ea optimization ea "Die casting process"

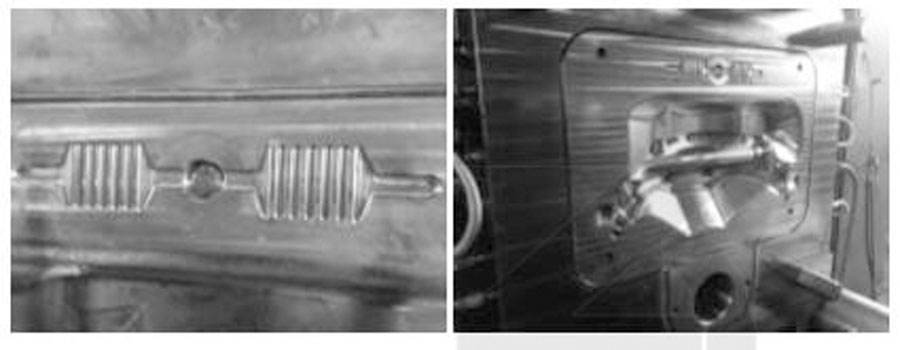

E hlahisoa ka mochini oa ho lahla o batang oa Idra's 16000kN kamoreng e batang, e nang le sistimi ea taolo ea ente ea nako ea nnete. Sephahla se koahelang metsi ke sephahla se emisang metsi se nang le matla a phahameng a kelello se nang le litokelo tsa thepa (bona setšoantšo sa 3), 'me se na le sistimi e laolang leruo le phahameng ho fihlella ho hloekisa ka lehare le ka kamoreng ea khatello; bokaholimo ba hlobo bo koetsoe ka mohala oa silicone o nang le bophara ba 10 mm (Bona Setšoantšo sa 4); hlobo e pholisoa ke seoli se nang le oli mme e kentsoe thermocouple ho laola mocheso oa hlobo ka nepo; pini ea mantlha e folisoa ke metsi a nang le khatello e phahameng tsidifatso; ho fafatsa ho itlhatsoa ka bohona ke roboto ea ABB.

Bakeng sa ho fumana motswako o nepahetseng ka ho fetesisa oa likarolo tsa mochini o laolang mochini le seterouku se phahameng, ho ile ha lekoa mefuta e 7 ea likarolo tsa parameter tlasa maemo a ho beha mocheso oa aluminium e 690 ℃ le mocheso oa hlobo ho 200 ℃.

Teko ea ho kenella ka 'mala e entsoe ho lahla,' me liphetho li bonts'a hore bokaholimo ba samente bo ne bo se na liphoso tse kang ho theha hampe, ho arohana ha serame, mapetso le machachetsi.

Boleng ba kahare ba castings bo ile ba hlahlojoa ke X-ray. Liphetho li bonts'itse hore ha ho na masoba a moea a fokotsang moea a fumanoeng sebakeng sa poleiti, mme ha ho na masoba a moea, masoba a shrinkage, kapa porcelain ea shrinkage e fumanoeng ho mookameli le libakeng tse teteaneng tsa lebota la ho betsa (bona Setšoantšo sa 6).

Ho ipapisitsoe le tlhahlobo e kaholimo, ho ka bonoa hore lebelo la ente le liehang ke 0.3m / s, boemo ba lephaka ke 480mm, lebelo la ho lahla ke 4.0-4.5m / s, khatello ea ho lahla e ka ba 76MPa, le ente e potlakileng hole ke 620mm ke motsoako o motle ka ho fetisisa oa litekanyo.

Teko le tlhahlobo ea ts'ebetso ea mochini

3.1 Tšusumetso ea lephaka mohahong le thepa ea mochini oa li-cast cast

Ho ka bonoa hore karolo e phahameng ea vacuum (degree ea vacuum ea 97 kPa) e na le letsoalo le phahameng ho feta, ho bolelang hore khase e kahare ea selahla e tlase. Ha ho bapisoa le lephaka tloaelehileng (65kPa lephaka) shoa castings, matla tensile, matla a ka lihlahisoa, elongation le thatafala ha castings phahameng lephaka shoela li eketseha ka 21%, 29%, 18%, le 10%, ka ho latellana, ho bontša hore phahameng lephaka shoa castings E na le phello e ntlafatsang ho ntlafatseng likarolo tsa mochini oa likarolo tsa sebopeho.

Hore na e ke phahameng-lephaka shoela'ng-foromeletsoeng kapa ba tloaelehileng lephaka shoela'ng-foromeletsoeng ho, le motsoako microstructure nakong phahameng-lephaka shoela'ng-foromeletsoeng le ba tloaelehileng lephaka shoela'ng-foromeletsoeng. Hore na e ke e phahameng-lephaka shoela'ng-foromeletsoeng kapa lephaka tloaelehileng shoa-foromeletsoeng, ho Al-8Si-Mn-Mg aluminium sebopeho sebopeho e entsoe ka batlang e le mahoashe α 1-Al le o motle potoloha α 2-Al, hammoho le e ntle dendritic eutectic Si, joalo-joalo. Leha Fe tse fumanehang ka har'a motsoako li le tlase, palo e nyane ea likarolo tsa granular Fe e ntse e ka bonoa. Hobane khatello ea khatello e tlas'a mocheso o phahameng le khatello e phahameng, tšepe e qhibilihisitsoeng e tlatsa mokoti ka nako e khuts'oane haholo mme e tiea hore e be teng. Sekhahla sena se seholo sa ho futhumatsa se ka etsa hore tšepe ea mokelikeli e fumane tekanyo e kholo ea phepelo ea metsi, ka hona e eketsa palo ea nucleation Sekhahla sa nucleation se ntlafalitsoe, eutectic Si e ntlafalitsoe, mme sebopeho sa karolo e kang nale ea AlSiFe ea hatelloa. Ka lebaka la lephaka le tlase, tlasa maemo a tloaelehileng a lephaka, ho ka bonoa liphoso tse nyane haholo tsa "pore" kahare.

3.2 Phello ea kalafo ea mocheso ts'ebetsong le sebopeho sa li-castings tse phahameng tsa lefu

3.2.1 Meaho ea mochini

Li-castings li hloka ho tsofala kalafo ea mocheso, 'me maemo a kalafo ea mocheso ke 200 ℃ × 2 h. Ka mor'a moo, ho etsoa teko ea tensile maemong a khethiloeng (maemo a 1, 2, 3) a likhopo tsa castings. Ho ka bonoa hore litšobotsi tsa mochini oa li-cast cast li fapana ka mokhoa oa ho lahla.

Ha ho bapisoa le ba tloaelehileng lephaka shoela'ng-foromeletsoeng, phahameng-lephaka shoela'ng-foromeletsoeng e haholo ntlafetse tensile matla, ka lihlahisoa matla, elongation le thatafala. Har'a bona, matla a tensile a eketsoa ka 21%, matla a chai a eketsoa ka 29%, mme sekhahla sa elongation se eketsoa ka 21%. E eketsehile ka hoo e ka bang 18% le thatafala ka bang 10%, ho ka bonoa hore phahameng lephaka shoela'ng foromeletsoeng haholo ntlafatsa matla le thatafala ha castings shoa.

3.2.2 Tšusumetso e matla

Teko ea tšusumetso maemong a khethiloeng a likhopo tse shoang (maemo a 1, 2, le 3, e leng lintlha tsa mehlala ea liteko tsa ts'ebetso ea mochini) e bonts'a hore ho ba thata ha tšusumetso ea batho ba nang le moea o phahameng ho fihlela litšebeletso ho fihlela litlhoko tsa botlalo ea ho lahla.

3.2.3 Ho taka khoele

M10 le M12 masoba a likhoele a li-castings a ile a fuoa liteko tsa ho taka. Khoele ea M10 ha ea ka ea fetoha tlasa tšebetso ea 66kN le khoele ea M12 tlasa ts'ebetso ea 85kN, e bontšang hore likhoele tsa li-castings tse phahameng tse shoeleng li fihlella ka botlalo litlhoko tsa matla.

3.2.4 Teko ea mokhathala

Kamora hore li-castings li fuoe liteko tse 410150 tsa ho tšoarella, ho bonoa ha fluorescence ho bonts'itse hore ho ne ho se na mapetso holim'a li-castings, mme liphetho li bontšitse hore ho hanyetsa mokhathala ha li-castings tse shoeleng haholo ho fihletse litlhokahalo tsa tekheniki.

3.2.5 Ho tseba litaba tsa khase

Teko ea khase e bonts'oa ho Tafole ea 2. Ho tsoa liphethong tsa liteko ho Tafole ea 6, ho ka bonoa hore khase ea 'mele oa' mele o kenang hekeng e ka hare e ka tlase ho 8.9ml ka 100g Al, le khase e teng ho eona 'mele tanka ea phallo ea mohatla oa metsi e ka tlase ho 12ml ka 100g Al, e fihlelang ka botlalo litlhokahalo tsa ho lahla.

Qeto ea 4

- (1) U sebelisa papiso ea linomoro, ts'ebetso ea ho lahla thepa le likarolo tse phahameng tsa ho lahla likarolo tsa likarolo tsa mochini oa chassis li ntlafalitsoe, mme likarolo tsa boleng bo holimo tse nang le boleng ba kantle le ba kahare bo kopana le litlhoko li entsoe.

- (2) Phahameng lephaka shoela'ng foromeletsoeng ka haholo ntlafatsa litšobotsi phetha molao feela tsa likarolo mehaho. Ha ho bapisoa le ho lahla batho ba tloaelehileng, letsoalo la castings nakong ea lehare le phahameng le ntse le eketseha, 'me matla a tensile, matla a kotulo, bophahamo le thatafalo ea castings li eketsehile ka 21%, 29%, 18%, le 10% ka ho latellana.

- (3) Liphetho tsa liteko tsa ho tšoarella, ho taka le khase ea li-castings kaofela li fihlella litlhokahalo tsa mahlale a sehlahisoa le ho fihlela maemo a tlhahiso ea bongata.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Microstructure Le Meaho ea Mechini ea Likarolo tsa Likoloi tsa Aluminium Chassis

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off