Nalane le Tloaelo ea Ts'ebetso ea Semi-Solid Metal Casting

Ho tloha ka 1971, DBSpencer le MCFlemings ba Setsi sa Theknoloji sa Massachusetts ho la United States ba qalile ts'ebetso e ncha ea ho hlohlelletsa (cast cast), ke hore, ho hlophisoa ha Srr15% pb rheological slurry ka ho potoloha habeli ea moqomo o hlohlelletsang mokhoa, semi-solid tšepe (SSM) Theknoloji ea Foundry e bile le lilemo tse fetang 20 tsa lipatlisiso le nts'etsopele.

Li-alloys tse lokiselitsoeng ke ho betsa ka mokhoa o hlohlelletsang hangata li bitsoa lits'epe tse seng tsa dendritic kapa li-alloys tse lahleloang ka mokhoa o itseng (Partially Solidified Casting Alloys). Hobane lihlahisoa tse sebelisang theknoloji ena li na le litšobotsi tsa boleng bo holimo, ts'ebetso e phahameng le lits'ebetso tse phahameng, li na le mafolofolo.

Ntle le ts'ebeliso ea lisebelisoa tsa sesole, e ile ea qala ho shebana le likarolo tsa bohlokoa tsa likoloi tse iketsang, mohlala, mabili a koloi, a ka ntlafatsang ts'ebetso, a fokotsa boima ba 'mele, le ho fokotsa sekhahla sa lisebelisoa. Ho tloha ka nako eo, butle-butle e sebelisitsoe masimong a mang, e hlahisa likarolo tse sebetsang hantle le tse haufinyane joalo ka letlooa. Ho etsa mechini bakeng sa mahlale a ho betla tšepe a tiileng le hona ho hlahisitsoe ka tatellano.

Hajoale, mochini o laoloang ka sekahare o tiileng o tsoang ho lithane tse 600 ho isa ho lithane tse 2000 o entsoe mme oa hlahisoa, 'me boima ba likarolo tse entsoeng bo ka fihla ho feta 7kg. Hajoale, theknoloji ena ea ts'ebetso e sebelisoa haholo United States le Europe. Ts'ebetso ea ho betla tšepe e sa fetoheng e nkuoa e le e 'ngoe ea mahlale a marang-rang a ts'episang le a macha a ho lokisa thepa lekholong le la bo21 la lilemo.

Tsamaiso ea tšebetso

Ts'ebetsong e tloaelehileng ea ho lahla, likristale tsa mantlha li hola ka sebopeho sa li-dendrites. Ha karo-karolelano ea karolo e tiileng e fihla ho 0.2, li-dendrites li theha masapo a marang-rang a tsoelang pele mme li lahleheloa ke fluidity ea tsona e kholo. Haeba tšepe ea mokelikeli e tsukutloa ka matla nakong ea ho futhumatsa ho tloha mohatong oa mokelikeli ho isa mohatong o tiileng, masapo a marang-rang a dendritic a bopehang habonolo nakong ea ho betloa ho tloaelehileng a tla rojoa ho boloka sebopeho se qhalakaneng sa granular le ho emisoa karolong e setseng ea mokelikeli. Microstructure ena ea granular non-dendritic e ntse e na le rheology e itseng ha sekhahla se tiileng sa karolo se fihla ho 0.5-0.6, e le hore lits'ebetso tse tloaelehileng tsa ho etsa joalo ka ho lahla, extrusion, die forging, jj li ka sebelisoa ho fihlela tšepe.

Ho itokisetsa motsoako

Ho na le mekhoa e mengata ea ho hlophisa lits'epe tse kopantsoeng tse sa tiiseng hantle. Ntle le mekhoa e susumetsang ea mochini, mekhoa ea motlakase e fehlang motlakase e se e ntlafalitsoe lilemong tsa morao tjena, mekhoa ea ho kenya motlakase ka motlakase, mekhoa e hlohlelletsang ea ho thothomela, ho qobella phallo e qobelloang ea mokelikeli oa alloy hammoho le metjha e kobehileng tlasa matla a kantle, le ts'ebetso ea khatello ea khatello. Method (SIMA), spray deposition method (Ospray), control alloy e tšollang mokhoa oa mocheso, jj. Har'a tsona, mokhoa o hlohlelletsang motlakase, motsoako o tšollang mokhoa oa taolo ea mocheso le mokhoa oa SIMA ke mekhoa e ts'episang ho feta bakeng sa lits'ebetso tsa indasteri.

1. Mokhoa o susumetsang oa mechini

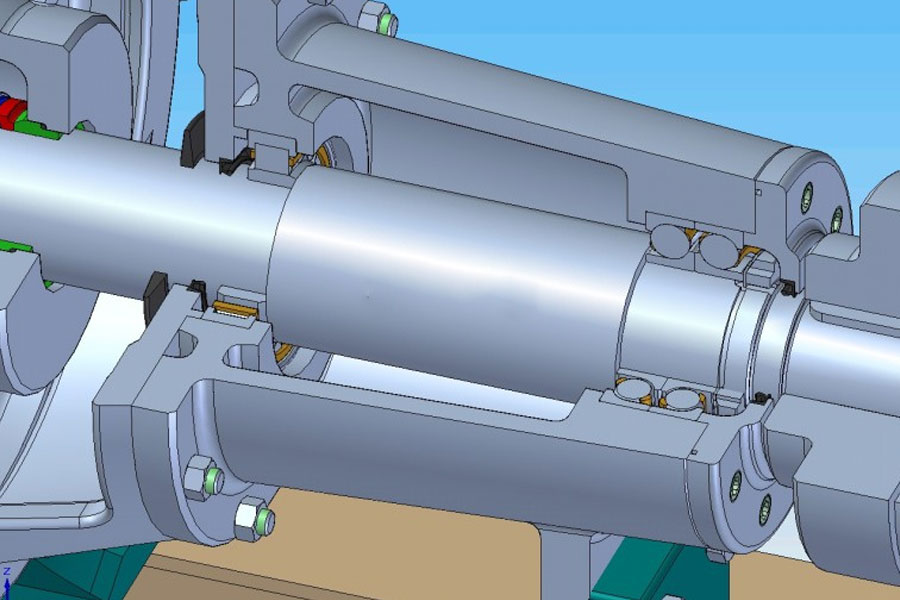

Mechini e hlohlelletsang ke mokhoa oa khale ka ho fetisisa o sebelisetsoang ho lokisa lits'epe tse kopaneng tse tiileng. Flemings et al. o hlophisitse ka katleho alloy-lead alloy semi-solid slurry a sebelisa seteishene sa lisebelisoa tse hlohlelletsang tse nang le silindara e ka hare le e kantle e nang le meno a mangata (silinda e kantle e ne e potoloha, 'me e ka hare e eme); H. Lehuy et al. o sebelisitse paddle e hlohlelletsang ho lokisa aluminium- Semi-solid slurry ea alloy ea koporo, zinc-aluminium alloy le aluminium-silicon alloy. Meloko e latelang e ntlafalitse agitator mme ea lokisa ZA-22 alloy semi-solid slurry ka ho sebelisa spit agitator. Ka ntlafatso, phello e sisinyehang ea slurry ea ntlafala, matla a phallo ka kakaretso ea tšepe e qhibilihisitsoeng ka hlobo ea matlafatsoa, 'me tšepe e qhibilihisitsoeng e baka khatello e tlase, e khothalletsang ho tšollela le ho ntlafatsa litšobotsi tsa ingot.

2. Mokhoa o hlohlelletsang motlakase

Ts'ebetso ea motlakase e susumetsang ke ts'ebeliso ea tšimo e potolohang ka motlakase ho hlahisa motlakase oa tšepe o qhibilihisitsoeng. Tshepe e qhibilihisitsoeng e tsamaea tlasa tšebetso ea matla a khoheli a Loren ho fihlela sepheo sa ho hlohlelletsa tšepe e qhibilihisitsoeng. Hajoale, ho na le mekhoa e 'meli ea ho hlahisa makenete a potolohang: e' ngoe ke mokhoa oa setso oa ho fetisa hajoale mochini oa coil oa induction; e 'ngoe ke mokhoa o potolohang oa makenete o sa feleng o hlahisitsoeng ke C. Vives oa Fora ka 1993, o nang le monyetla oa ho kenya motlakase ka motlakase Sesebelisoa sena se entsoe ka lisebelisoa tsa makenete tse sebetsang hantle tse nang le matla a phahameng a khoheli. Ka ho fetola tokisetso ea limakete tsa ka ho sa feleng, tšepe e qhibilihisitsoeng e ka hlahisa phallo e totobetseng ka mahlakore a mararo, e ntlafatsang tšusumetso e matlafatsang le ho fokotsa ho ts'oaroa ha khase nakong ea pherekano.

3. Mokhoa oa ts'ebetso ea ho qhibiliha o bakoang ke khatello (SIMA)

Mokhoa o qobelloang o qhibilihisang khatello (SIMA) ke ho koala li-ingots tse tloaelehileng, joalo ka extrusion, rolling le lisebelisoa tse ling tsa mocheso ho libare tse qetiloeng. Ka nako ena, microstructure e na le sebopeho se holofetseng ka matla, ebe se futhumetse Sebaka se tiileng se nang le mokelikeli se nang le mekhahlelo e 'meli se futhumetse ka nako e itseng,' me lithollo tsa kristale tse telele li fetoha likaroloana tse ntle, tse folisoang ka potlako ho fumana sebopeho se seng sa dendritic ingot.

Phello ea ts'ebetso ea SIMA e ipapisitse le mekhahlelo e 'meli ea mocheso o tlase oa ho sebetsa o chesang le ho lokisa, kapa ho eketsa mohato o batang oa ho sebetsa lipakeng tsa tsena tse peli, ts'ebetso e bonolo ho e laola. Theknoloji ea SIMA e loketse lits'epe tse fapaneng tse nang le lintlha tse holimo le tse tlase tse qhibilihisang, 'me e na le melemo e ikhethileng ho hlophiseng lits'epe tse senang dendritic tse nang le lintlha tse phahameng tse qhibilihang. E sebelisitsoe ka katleho ho tšepe e sa hloekang, sesebelisoa sa tšepe, motsoako oa koporo le letoto la aluminium alloy, 'me e fumane mochini o sa sebeliseng dendritic o nang le lithollo tse ka bang 20um. E ntse e fetoha mokhoa oa tlholisano bakeng sa ho lokisa thepa e tala e tiileng. Leha ho le joalo, bothata ba eona bo boholo ke hore boholo ba likheo tse lokisitsoeng bo nyane.

4. Mekhoa e mecha e ntlafalitsoeng lilemong tsa morao tjena

Lilemong tsa morao tjena, Univesithi ea Boroa-bochabela le Setsi sa Patlisiso sa Arety Japane ba fumane hore ka ho laola mocheso o lahlang motsoako, sebopeho sa mantlha sa dendritic se ka fetoloa sebopeho sa spherulitic. Tšobotsi ea mokhoa ona ke hore ha ho na tlhoko ea ho eketsa likarolo tsa alloying kapa ho hlohlelletsa. V. Dobatkin le al. O ile a etsa tlhahiso ea mokhoa oa ho eketsa mohloekisi oa tšepe le ho etsa kalafo ea mahlaseli ho fumana ingot e tiileng, e bitsoang kalafo ea mahlaseli.

Bōpa Method

Ho na le mekhoa e mengata ea ho etsa lits'epe tse tiileng tse tiileng haholo-holo:

1. Rheoforming (Rheocast) e hlohlelletsa tšepe e qhibilihisitsoeng ka matla ho tloha ho mokelikeli ho fihlela e tiea nakong ea ho futhumatsa, 'me ka kotloloho e lahla kapa e qhekella tšepe e fumanoeng e tiileng ka sekotoana se itseng.

Mohlala, R. Shibata et al. hang o ile a romela seka-solid alloy slurry e lokiselitsoeng ke mokhoa o hlohlelletsang motlakase ka kotloloho ka phapusing ea ente ea mochini o lahlang bakeng sa ho etsa. Lisebelisoa tsa mochini oa aluminium alloy castings tse hlahisoang ke mokhoa ona li phahame ho feta tsa li-castings tsa extrusion, 'me li lekana le tsa cast-semi-solid thixotropic. Bothata ke hore polokelo le lipalangoang tsa semi-solid metal slurry li thata, ka hona ha ho na likopo tse ngata tse sebetsang.

2.Lieketsi (Lieketseng, Liekeli)

Sebopeho se hlophisitsoeng se seng sa dendritic ingot se futhumatsoa ho ea mokelikeli o tiileng o nang le mekhahlelo e 'meli ho fihlela viscosity e loketseng, ebe o lahla kapa o etsa extrusion.

EOPCO, HPM Corp., Prince Machine, THT Presses in the United States, Buhler in Switzerland, IDRA USA, Italpresse of America in Italy, Producer USA in Canada, Toshib a Machine Corp.Lisebelisoa tse khethehileng bakeng sa thixoforming ea aluminium e tiileng ea alloy. Mokhoa ona o bonolo ho kenya mochini oa ho futhumatsa le ho fetisa o se nang letho, ka hona ke mokhoa o ka sehloohong oa ts'ebetso ea ho betsa seka-solid kajeno.

3. Ente bōpa

Tshepe e qhibilihisitsoeng e pholile ka kotloloho mochesong o loketseng ho fapana le slurry e tiileng kamora kalafo, mme e kenngoe ka mokokotlong ho theha ka maemo a itseng a ts'ebetso. Mohlala, Thixoforming Development Center e Wisconsin, USA, e sebelisitse mokhoa ona ho etsa li-alloys tsa magnesium ka thata. Moprofesa KK Wang oa Univesithi ea Cornell, United States le ba bang ba hlahisitse sesebelisoa se tšoanang sa magnesium alloy molding. The slurry seka-tiileng e eketsoa ho tloha tube, tse bonahalang le tshelwa ka cavity ka mor'a tsidifatso e loketseng.

4. Low mocheso lahla tsoelang pele

Seo ho thoeng ke mocheso o tlase o tsoelang pele ke mokhoa oa ho betsa oo sisteme e entsoeng ka tšepe e laoloang e ka bang 0 ° C mme ho qobelloa ho pholisa ho etsoa tlasa hlobo, joalo ka ha ho bonts'itsoe ho Setšoantšo sa 4. Khethollo e bohareng ke bothata bo boholo ho ho betsa ho tsoelang pele, 'me ho robeha ho ka etsahala nakong ea ho phalla ho tsoelang pele ha molamu oa terata. Ka hona, ts'ebetso ena e bohlokoa haholo.

5.Hlobola lesela le tsoelang pele

Flemings o sebelisitse Sn-15% pb low qhibiliha tšepe ho etsa liteko tse tsoelang pele tsa ho betsa liteko, le ho sekaseka phetiso ea mocheso, ho tiisa le ho fetoha. Ho lumeloa hore botenya ba hlobolisa bo amana le khatello ea moqolo, karolo e tiileng ea sekhahla, rheological shear lebelo le lebelo le tsoelang pele la ho betsa. Ha khatello e khethehileng tlasa extrusion e le kholo, khethollo e nyane ea khothaletsoa. Bakeng sa ho netefatsa bokaholimo le boleng ba kahare le ho nepahala ha tlhakore, ho hlokahala hore ho laoloe ka thata lipehelo tsa ts'ebetso ea tšepe e tiileng joalo ka sekhahla se tiileng sa sekhahla, boholo ba sebopeho sa kristale ea mantlha, le palo ea tšepe e lokollotsoeng.

Bakeng sa lisebelisoa tse phahameng tse qhibilihisang tse kang phosphor boronse Cu-Sn-P alloy (Cu-8% Sn-0.1% P), mocheso oa mokelikeli ke 10300 ℃, o leng thata ho o futhumatsa. E na le phello e hlakileng poleiting e tšesaane e entsoeng ka motsoako ona o tiileng. Hajoale, ho a khonahala ho hlophisa li-ingots tsa tšepe tse sa tiiseng le tse nang le lisebelisoa tse phahameng haholo tse nang le mokhatlo o tsoileng matsoho.

Melemo ea mahlale

Melemo ea seka-solid tshepe ea ho lahla e ka akaretsoa ka melemo ea ts'ebetso le melemo ea sehlahisoa.

1. Monyetla oa ts'ebetso

- 1) Sebopeho se setle sa lijo-thollo se ka fumanoa ntle le ho eketsa sesebelisoa sa lijo-thollo, ho felisa likristale tsa kholomo le li-dendrite tse mahoashe ha li lahleloa ka moetlo.

- 2) Mocheso o tlase oa ho etsa (joalo ka motsoako oa aluminium o ka theoleloa ho feta 1200 ℃), o ka bolokang matla.

- 3) Bophelo ba hlobo bo atolosoa. Khatello ea kelello ea shear ea semi-solid slurry ka mocheso o tlase o tlase ke litaelo tse tharo tsa boholo bo bonyenyane ho feta ba setso sa dendritic slurry, ka hona ho tlatsa ho tsitsitse, mojaro oa mocheso o monyane, mme matla a mokhathala a futhumetseng a fokotsehile.

- 4) Fokotsa tšilafalo le lintlha tse sa bolokehang. Lahla mocheso o phahameng oa tikoloho ea tšepe nakong ea ts'ebetso.

- 5) Khanyetso ea deformation e nyane, mme ts'ebetso e ts'oanang e ka phethahala ka matla a manyane, mme ho theoa ha lisebelisoa tse thata ho sebetsa ho bonolo.

- 6) Lebelo la ho tiisa le potlakile, tlhahiso e ntlafalitsoe, 'me potoloho ea ts'ebetso e khutsufatsoa.

- 7) E loketse moralo le thuso ea likhomphutha tse thusang k'homphieutha ho ntlafatsa.

2. Melemo ea lihlahisoa

- 1) Likarolo li boleng bo holimo. Ka lebaka la ntlafatso ea lithollo tsa kristale, kabo ea sebopeho sa junifomo, ho fokotseha ha mmele, le ho fokotsa tloaelo ea ho phatloha hoa mocheso, tloaelo ea ho fokotseha ha matrix e ea tlosoa, mme thepa ea mochini e ntlafalitsoe haholo.

- 2) The solidification shrinkage e nyane, kahoo 'mele o bōpiloeng o na le lintlha tse phahameng tse nepahetseng, kabelo e nyane ea machining le sebopeho se batlang se le letlooa.

- 3) Mefuta e fapaneng ea lits'epe tse kopantsoeng. Li-alloys tse se nang litšepe li kenyelletsa lits'epe tse kopantsoeng ka aluminium, magnesium, zinc, tin, koporo le nickel; lits'epe tse kopantsoeng ka tšepe li kenyelletsa tšepe e sa hloekang le tšepe e tlaase.

- 4) Ho etsa thepa ea tšepe ea popeho ea likarolo tse ngata. Ho sebelisa viscosity e phahameng ea tšepe e tiileng ho etsa lits'epe tse kopantsoeng ka phapang e kholo ea segokanyipalo le ho qhibiliha ho fokolang ho thata, e ka kopanya hantle lisebelisoa tse fapaneng ho etsa thepa e ncha e kopaneng.

Ka kopo boloka mohloli le aterese ea sengoloa sena hore se hatisoe hape: Nalane le Tloaelo ea Ts'ebetso ea Semi-Solid Metal Casting

Minghe Khamphani ea Die Casting li inehetse ho etsa le ho fana ka boleng bo phahameng le likarolo tse phahameng tsa ho lahla likarolo Thining-Wall Die Casting,Hot Chamber Die lahla,Cold Chamber shoa lahla), Tšebeletso e chitja (Die Casting Service,Cnc Machining,Ho Etsa Mofuta, Bokaholimo Phekolo) .Na tloaelo efe kapa efe ea Aluminium die die cast, magnesium kapa Zamak / zinc die casting le litlhoko tse ling tsa castings lia amoheleha ho ikopanya le rona

Tlas'a taolo ea ISO9001 le TS 16949, lits'ebetso tsohle li etsoa ka mechini e makholo ea li-die casting, mechini e 5-axis le lits'ebeletso tse ling, ho tloha ho li-blasters ho isa mechini ea ho hlatsoa ea Ultra Sonic. sehlopha sa baenjiniere ba nang le boiphihlelo, lisebelisoa le bahlahlobi ho etsa moralo oa moreki o phethahala.

Moetsi oa konteraka oa li-cast cast. Bokhoni bo kenyelletsa likarolo tse batang tsa aluminium die die likarolo tsa 0.15 lbs. ho isa ho li-6 lbs., Ho theha phetoho e potlakileng, le machining. Litšebeletso tse kenyellelitsoeng boleng li kenyelletsa ho bentsa, ho thothomela, ho qhekella, ho phatloha ha lithunya, ho penta, ho roala, ho roala, kopano le lisebelisoa. Lisebelisoa tse sebelisitsoeng le tsona li kenyelletsa lits'epe tse kopantsoeng tse kang 360, 380, 383 le 413.

Zinc e shoa ho lahla thuso ea moralo / lits'ebeletso tsa boenjineri tse tšoanang. Moetsi oa moetlo oa li-castings tsa zinc tse nepahetseng. Li-castings tse nyane, li-castings tse phahameng tsa khatello, li-cast cast tsa hlobo, li-castings tse tloaelehileng tsa hlobo, li-unit tsa die le li-cast cast tse ikemetseng le li-cast cast tse tiisitsoeng li ka etsoa. Li-castings li ka etsoa ka bolelele le bophara ho fihlela 24 ho. Ho +/- 0.0005 ho. Mamello.

ISO 9001: Moetsi ea netefalitsoeng oa 2015 oa magnesium ea die die, Bokhoni bo kenyelletsa khatello e phahameng ea khatello ea magnesium die cast to 200 ton room & 3000 kamoreng e batang, moralo oa lithulusi, polishing, molding, machining, powder & liquid paint, QA e felletseng e nang le bokhoni ba CMM , kopano, ho paka le ho tsamaisa.

ITAF16949 e netefalitsoe. Ts'ebeletso e 'ngoe ea ho lahla e kenyeletsa ho lahla lichelete,ho lahla lehlabathe,Matla a khoheli, Lahlehileng bubble lahla,Ho ts'oaroa ha Centrifugal,lephaka lahla,Sa Feleng hlobo lahlaBokhoni bo kenyelletsa EDI, thuso ea boenjiniere, ho etsa mohlala o tiileng le ho sebetsoa ka bobeli.

Lahla Liindasteri Liphuputso tsa likarolo tsa likarolo tsa: Likoloi, libaesekele, lifofane, liletsa tsa 'mino, sesepa sa metsi, lisebelisoa tsa Optical, li-sensor, mehlala, lisebelisoa tsa elektroniki, masaka, lioache, mechini, lienjine, thepa ea ka tlung, mabenyane, mabenyane, telecom, mabone, lisebelisoa tsa bongaka, lisebelisoa tsa litšoantšo, Liroboto, Litšoantšo tse betliloeng, Lisebelisoa tsa molumo, Lisebelisoa tsa lipapali, Lithulusi, Lipapali le tse ling.

Re ka u thusa ho etsa eng ka mor'a moo?

∇ Eya ho Homepage Bakeng sa Shoa lahla China

→Likarolo tsa ho lahla-Fumana seo re se entseng.

→ Malebela a Ralated ka Litšebeletso tsa Die Casting

By Moetsi oa Minghe Die Casting | Categories: Lingoloa tse thusang |lintho tse bonahalang Tags: Aluminium lahla, Ho lahla zinki, Ho lahla Magnesium, Lahleloa thaethaniamo, Ho lahla tšepe, Brass lahla,Ho lahleloa ka Bronze,Ho lahla Video,Histori ea Khamphani,Aluminium Die Casting | Litlhaloso Off